Professional Documents

Culture Documents

IQB 05 Fire Wall 20130220

Uploaded by

Uday SharmaCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

IQB 05 Fire Wall 20130220

Uploaded by

Uday SharmaCopyright:

Available Formats

20130220

IQB 05 – Quality Fire Wall

Purpose:

Quality Fire Wall is a control applied to 100% of the parts before delivery, in order to protect our

customer from not capable processes.

Process Users

Actors

Firewall Supervisor - will manage and schedule people resources, materials and handling,

Quality Firewall leader – will determine the parts to pass through the quality firewall, will

update QPS/Quality Alert regarding any customer issues, will prepare boundary parts, will

train Firewall operators,

Firewall operators, will check the parts,

Process Owners

Plant Manager will sponsor the activity providing resources, people, surfaces, handling

equipment,

Quality Manager will supervise efficacy and efficiency of Firewall.

Initiating Inputs:

Customer PPM and written concerns are out of targets,

Safe Launch activity during Ramp up process must implement a Fire wall for all new parts and

components,

New processes, launches or transfers when capabilities and readiness have never been

demonstrated,

Suppliers for cross dock parts not achieving PPM targets,

Suppliers in a risk situation, important headcounts reductions, economics difficulties, or

savage process transfers to other supplier facilities or countries

Outputs:

Firewall layout/workstations/stock area,

Firewall QPS/ Quality Instructions,

Firewall daily TPPA / Customer PPM weekly TPPA,

Firewall audit (see attachment 1)

Definitions

8D process - is a collection of 9 disciplines that go to make a systematic problem solving

process known as 8D Methodology. The process is used globally within Visteon and mirrors

similar processes from other OEM’s.

(ERA) Emergency Response Actions - actions in place to protect/isolate your customer from

the symptom whilst you investigate the causes of these symptoms, until Interim Containment

Actions are implemented and validated

(ICA) Interim Containment Actions – actions in place to isolate the effects of the problem from

the customer until Permanent Corrective Actions PCA) are implemented and validated

TPPA - A TPPA, also know as a ‘Four Panel’ chart, is a one page chart that will show the

trend of something that is measurable, with detail behind the trend and actions to correct

issues, TPPA is an Acronym for Trend Paynter Pareto Action.

Quality firewall list of parts – is the list of part# that systematically must pass through the

firewall, the list is daily updated by quality

Hard Copies of This Document are Uncontrolled Page 1 de 6

20130220

IQB 05 – Quality Fire Wall

General rules:

Initiation conditions, (see initiating inputs paragraph),

A Fire wall can be considered as an ERA or ICA not solving the source of the problems,

unless is accompanied by a strong action plan based on TPPA and a full 8D package,

Don’t apply a firewall approach whenever defects are a few, very specific, and escape points

well identified, in these cases reinforcing final control of escaping workstations is a better and

cheaper solution.

Don’t include or mix, rework or mock-up operations into the firewall workstations,

Firewall must be placed out of the sight of the assembly line operators, to prevent loose of

their quality awareness, trusting that someone else is checking their work after them.

Quality Function will define and update a “Quality Firewall List of Parts” to pass through the

firewall, this list will be in line with initiating conditions,

Quality Firewall List of Parts will be distributed to logistics and production,

Firewall control instructions will be aligned with “IQB 04 Self-Inspection and Final Control”,

Remove conditions, parts will be remove from the Firewall whenever the next 2 conditions

happen:

1. 5000 consecutive checked parts are good, or 1 week production without defects,

2. 8D report is completed or strong containment (Poka-Yoke) has been implemented and

validated.

Firewall operators will use pace-boards to record rejections; they will react upon certain

rejection threshold defined in the plant,

Firewall failures will be feedback immediately to upstream process by the quality leader or the

firewall supervisor,

Firewall supervisor will prepare a daily TPPA summary of rejections by part#

Firewall supervisor will discuss with upstream assembly process Leaders, Quality &Process

Engineers main issues and actions, the team will agree:

New parts to include in the “Quality Firewall List of Parts”,

New actions to reinforce TPPA,

Parts to remove from the “Quality Firewall List of parts”,

Quality firewall leader will be informed on time by Customer Engineers of any customer

rejection, or written concerns, the Firewall Quality leader will prepare Quality Alerts, updated

QPS, and weekly TPPA with customer PPM,

Mislabelling Issues are critical in firewalls, rules to relabeling, remove labels, print, mark etc.

have to be defined and applied, according Mislabelling best-practices in the region,

Don’t check two different part numbers at the same time in the same workstation; this is a risk

for mislabelling.

Put specific marks for OK checked parts leaving the firewall, recommended to stick the

operator number and date, use a small sticker applied in each single part,

Use boundary parts approved by customers and quality alerts, to train and provide clear

criteria decision to operators about what is good, and what is no good,

Use Versatility Matrix process to manage people skills and training,

Operators must be trained daily about last customer alerts and problems,

LPA must be applied in firewalls areas to confirm people follows operation standards,

Once implemented the FW, it must be validate by auditing following IQB 04 A Attachment 1,

Firewall Audit, apply corrective actions to solve any non-conformity,

Hard Copies of This Document are Uncontrolled Page 2 de 6

20130220

IQB 05 – Quality Fire Wall

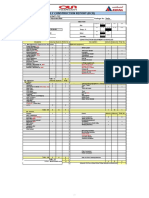

Procedure:

Responsibility Flowchart Notes/Deliverables

Inputs:

Quality Manager

see initiating inputs list

Plant manager 1. Firewall decision

Outputs

Quality Firewall List of Parts,

Resources allocation (people,

surface, workstations, lighting, etc.)

Documents/People training

Firewall Supervisor 2. FW implementation Inputs:

Quality Leader

Quality Firewall List of Parts,

Process Engineers

Outputs

Firewall Layout implemented

FW CCAR QPS Final Control instructions

Improvement

Plan

Boundary parts & Pictures

Pace boards record forms

Firewall TPPA

Firewall Customer TPPA

Audit Versatility matrix / training records

RED

To validate implementation a

Firewall audit following Attachment

GREEN

1 must to be done with green

assessment.

Rejections feedback on Upstream

Operator

3. Firewall working process (reaction threshold)

Inputs:

Yes Quality Firewall List of Parts,

Rejects? QPS Final Control instructions

Boundary parts & Pictures

Pace boards record forms

3.1 Feedback

Upstream Outputs

Process Pace boards records

Firewall: Feedback to Upstream process

Supervisor leaders,

4. Team board daily meeting Decision to remove or include new

Quality Leader

parts in the FW see “initiation” or

Upstream Process: “removal” conditions

Supervisor Inputs:

4.1 Customer

Quality Leader Daily TPPA on rejections

Risk? Customer TPPA weekly

Yes

8D

No

Outputs

Quality FW List of Parts, Update

END TPPA update

8D update

Hard Copies of This Document are Uncontrolled Page 3 de 6

20130220

IQB 05 – Quality Fire Wall

Support Documents in the Fire Wall Workstation

Pictures with the

control path (Eye

path sequence)

QPS (Quality

Process Sheet)

Detailing each one

of the 16 control

points

Pace-board hourly

rejections record,

Daily TPPA

Versatility Matrix

Weekly OEM TPPA

Hard Copies of This Document are Uncontrolled Page 4 de 6

20130220

IQB 05 – Quality Fire Wall

Firewall pictures/Examples

Berlin FW for Door

Panels,

With RED light &

Siren

Firewall Layout

example

Hard Copies of This Document are Uncontrolled Page 5 de 6

20130220

IQB 05 – Quality Fire Wall

List of Records

Pace board records

Daily FW TPPA results

FW Versatility matrix / training records

FW LPA Audit results

Attachments

IQB 05 A - Attachment 1, Firewall Audit

References

IQB 04 Self inspection and Final Control

Originator

Jordi Lopez

Record of Revision:

Date Description of Change

1/6/2011 New Instruction

6/8/2011 Added Initiating Inputs, Safe Launch activity

must apply a Fire Wall for all new parts

20/2/2013 Included Firewall audit assessment IQB 05 A,

in step 2, and attachment 1 audit document

(translated and adapted document from

Renault Firewall audit)

Hard Copies of This Document are Uncontrolled Page 6 de 6

You might also like

- Practical, Made Easy Guide To Building, Office And Home Automation Systems - Part OneFrom EverandPractical, Made Easy Guide To Building, Office And Home Automation Systems - Part OneNo ratings yet

- Risk Solutions Value-Added ServicesDocument14 pagesRisk Solutions Value-Added ServicesGaurav KumarNo ratings yet

- DuPont's Approach to Safety Instrumented Functions and BypassingDocument34 pagesDuPont's Approach to Safety Instrumented Functions and BypassingDave C100% (2)

- Amf-P-22 Procedure For Error ProofingDocument3 pagesAmf-P-22 Procedure For Error Proofinggangadhar.patilNo ratings yet

- LPA Line Walk Audit MethodologyDocument4 pagesLPA Line Walk Audit Methodologymougib soltaniNo ratings yet

- Opertaing Window LimitsDocument6 pagesOpertaing Window LimitshejaNo ratings yet

- RA For Installation of Fuel SystemDocument7 pagesRA For Installation of Fuel SystemAdel MorsyNo ratings yet

- Magna Global Quality Standard: MQS 10 - Error Proofing and Detection Device VerificationDocument4 pagesMagna Global Quality Standard: MQS 10 - Error Proofing and Detection Device VerificationGonzalo MazaNo ratings yet

- Infrared Thermography Testing-Procedure PDFDocument7 pagesInfrared Thermography Testing-Procedure PDFHoang Diep PhanNo ratings yet

- How To Implement and Maintain Pci Compliant FirewallsDocument21 pagesHow To Implement and Maintain Pci Compliant FirewallsNajaf AliNo ratings yet

- SMP For PLCDocument4 pagesSMP For PLCRupesh Kumar SINGHNo ratings yet

- 1..firewall Inspection ProcedureDocument3 pages1..firewall Inspection ProcedureRS MANIKANDANNo ratings yet

- AIAG and VDA FMEA Handbook Apr 4 2019-1Document16 pagesAIAG and VDA FMEA Handbook Apr 4 2019-1Rudiney Trombetta88% (16)

- CD-00519-002 Anh N en 2018-07-06Document2 pagesCD-00519-002 Anh N en 2018-07-06Nicole de Castro RoveriNo ratings yet

- WP QCA PRO 001 Problem Solving ProcedureDocument8 pagesWP QCA PRO 001 Problem Solving ProceduredhuntNo ratings yet

- Supplier Audit Check SheetDocument5 pagesSupplier Audit Check SheetMotive Post100% (2)

- I&C Chapter 8 - LANL Engineering Standards Manual Attachment E Provides Guidance on Alarm ManagementDocument11 pagesI&C Chapter 8 - LANL Engineering Standards Manual Attachment E Provides Guidance on Alarm ManagementCarlos SalazarNo ratings yet

- SCP-M-022 - Pipette CalibrationDocument3 pagesSCP-M-022 - Pipette CalibrationChristian LefroitNo ratings yet

- Surveillance Aircraft QMPDocument17 pagesSurveillance Aircraft QMPZohaib hassanNo ratings yet

- ElectricidadDocument9 pagesElectricidadDomingo esteban perez ceballoNo ratings yet

- An Approach To Grid Control Engineer Training Using National Occupational StandardsDocument6 pagesAn Approach To Grid Control Engineer Training Using National Occupational StandardsHamlyn HolderNo ratings yet

- Workshops and TrainingDocument2 pagesWorkshops and TrainingAniruddhaNo ratings yet

- Testing & Commissioning of Fire Alarm SystemDocument3 pagesTesting & Commissioning of Fire Alarm Systemhaytham65No ratings yet

- 0-12-VR-191 - 20nov2023 - PM ReporteDocument9 pages0-12-VR-191 - 20nov2023 - PM ReportejeisonNo ratings yet

- Electrical Commissioning Procedure: Document Number Version Number AuthorDocument16 pagesElectrical Commissioning Procedure: Document Number Version Number Authorizzy umandalNo ratings yet

- ANPQP Category 8 Non Conforming Product ManagementDocument8 pagesANPQP Category 8 Non Conforming Product Managementjefry sitorusNo ratings yet

- SOP in Use QualificationDocument4 pagesSOP in Use QualificationDharmesh PatelNo ratings yet

- 7 - 01 - H - MANAGEMENT OF QUALITY OF INFORMATION MEANSDocument32 pages7 - 01 - H - MANAGEMENT OF QUALITY OF INFORMATION MEANSAsep SomantriNo ratings yet

- TripleeeeDocument12 pagesTripleeeeDomingo esteban perez ceballoNo ratings yet

- Product Safety Procedure SummaryDocument2 pagesProduct Safety Procedure SummaryGANESH BORUDE100% (2)

- ICSSDocument4 pagesICSSabha singhNo ratings yet

- Operator Effectiveness - Alarm Management - Oct-15Document13 pagesOperator Effectiveness - Alarm Management - Oct-15syed muffassirNo ratings yet

- Training Copy Not For Execution: Sop No. Supersedes Effective Date Next Review DateDocument12 pagesTraining Copy Not For Execution: Sop No. Supersedes Effective Date Next Review Datemanohar kumarNo ratings yet

- C CMM PiptcpDocument34 pagesC CMM Piptcpnegma6099No ratings yet

- Eddy LaRocqueDocument25 pagesEddy LaRocqueRaviNo ratings yet

- Lead I&C Engineer resume summaryDocument3 pagesLead I&C Engineer resume summaryFaizan AadilNo ratings yet

- Testing and Commissioning of Electrical Equipment ProceduresDocument45 pagesTesting and Commissioning of Electrical Equipment ProceduresJonathan Feruelo100% (1)

- Risk QualificationDocument50 pagesRisk QualificationABEER0% (1)

- Alarm ManagementDocument7 pagesAlarm ManagementWAGUDELONo ratings yet

- Aea 1305 WC El MS 0028Document5 pagesAea 1305 WC El MS 0028Adil HasanovNo ratings yet

- Haccp PlanDocument1 pageHaccp Planjlordmercader100% (1)

- SPTR audit CSDocument3 pagesSPTR audit CSRakesh SNo ratings yet

- Pressure Relieving and Venting Devices BC032025 - FlashbackDocument4 pagesPressure Relieving and Venting Devices BC032025 - FlashbackMEGAN ASBROCKNo ratings yet

- SPD0054ERN - 2 HEMP Procedure Att.6.6Document4 pagesSPD0054ERN - 2 HEMP Procedure Att.6.6chuntao fengNo ratings yet

- QAD Procedure - Lab Management P2Document1 pageQAD Procedure - Lab Management P2sumanNo ratings yet

- Installation QualificationDocument14 pagesInstallation QualificationTuan Nguyen100% (1)

- Petroleum Development Oman LLC: 3.8.3 Factory Acceptance TestsDocument2 pagesPetroleum Development Oman LLC: 3.8.3 Factory Acceptance Testskami safaviNo ratings yet

- Citp Final - For ExcavationDocument39 pagesCitp Final - For ExcavationGAhr CeredonNo ratings yet

- Day5 FDP IoT Part2Document51 pagesDay5 FDP IoT Part2ksisodiaNo ratings yet

- Renewed Performance Qualification After Replacing Device ComponentsDocument8 pagesRenewed Performance Qualification After Replacing Device ComponentsМаксим ШульгаNo ratings yet

- 4 Project Execution Best PracticesDocument38 pages4 Project Execution Best PracticesdanderjNo ratings yet

- Testing and Commissioning of Fire Alarm System InstallationDocument34 pagesTesting and Commissioning of Fire Alarm System InstallationAbdul JabbarNo ratings yet

- Micom P439: Distance Protection and Control UnitDocument834 pagesMicom P439: Distance Protection and Control UnitRazvan Stoica TartaNo ratings yet

- Instrument HH BDDocument4 pagesInstrument HH BDZain RehmanNo ratings yet

- Quick Response Quality ProcessDocument8 pagesQuick Response Quality ProcessUday SharmaNo ratings yet

- Method of Statement For Transformer Diff Protection: Owner/Client Consultant ContractorDocument6 pagesMethod of Statement For Transformer Diff Protection: Owner/Client Consultant ContractorPandrayar Maruthu100% (1)

- Linux Display Workflow Overview: Confidential and Proprietary - Qualcomm Technologies, IncDocument20 pagesLinux Display Workflow Overview: Confidential and Proprietary - Qualcomm Technologies, Incburdun777No ratings yet

- Safety MomentDocument5 pagesSafety Momenttarek_bouzayaniNo ratings yet

- Lessons Learned HTv4 - Rev2Document7 pagesLessons Learned HTv4 - Rev2manuelNo ratings yet

- Telephone EtiquetteDocument15 pagesTelephone EtiquetteUday SharmaNo ratings yet

- Mini-Tutorial Quality Functional Deploment: Prepared For: Opermgt 345 Boise State UniversityDocument6 pagesMini-Tutorial Quality Functional Deploment: Prepared For: Opermgt 345 Boise State UniversityUday SharmaNo ratings yet

- IQB 01 OK To Run 20110214Document7 pagesIQB 01 OK To Run 20110214Uday SharmaNo ratings yet

- Quick Response Quality ProcessDocument8 pagesQuick Response Quality ProcessUday SharmaNo ratings yet

- Train The TrainerDocument14 pagesTrain The TrainerUday SharmaNo ratings yet

- Team BuildingDocument13 pagesTeam BuildingUday SharmaNo ratings yet

- National Guard Black Belt Training: Intro To MinitabDocument90 pagesNational Guard Black Belt Training: Intro To MinitabUday SharmaNo ratings yet

- Control Chart: "Avoid Prints - Save Paper"Document1 pageControl Chart: "Avoid Prints - Save Paper"Uday SharmaNo ratings yet

- Winning PersonalityDocument8 pagesWinning PersonalityUday SharmaNo ratings yet

- MotivationDocument7 pagesMotivationUday SharmaNo ratings yet

- Effective Writing Skills: Ways To Write Dynamic MessagesDocument11 pagesEffective Writing Skills: Ways To Write Dynamic MessagesUday SharmaNo ratings yet

- Stress ManagementDocument13 pagesStress ManagementUday SharmaNo ratings yet

- MGMI Supplier Quality RequirementsDocument8 pagesMGMI Supplier Quality RequirementsUday SharmaNo ratings yet

- E-Mail Etiquette: Writing Powerful MessagesDocument8 pagesE-Mail Etiquette: Writing Powerful MessagesUday SharmaNo ratings yet

- Evaluation of Field Data: Quality Management in The Bosch Group - Technical StatisticsDocument42 pagesEvaluation of Field Data: Quality Management in The Bosch Group - Technical StatisticsUday SharmaNo ratings yet

- 7 Myths of Leadership in BusinessDocument15 pages7 Myths of Leadership in BusinessUday SharmaNo ratings yet

- Data Quality and DataDocument5 pagesData Quality and DatahametNo ratings yet

- Creating A Lasting ImpressionDocument8 pagesCreating A Lasting ImpressionUday SharmaNo ratings yet

- APQP Complete Presentation 1642700707Document69 pagesAPQP Complete Presentation 1642700707Uday SharmaNo ratings yet

- Process Capability QP 2020Document8 pagesProcess Capability QP 2020Uday SharmaNo ratings yet

- TQM HerasDocument20 pagesTQM HerasUday SharmaNo ratings yet

- Expert Perspectives On The Future of The Quality Profession and Its PractitionersDocument9 pagesExpert Perspectives On The Future of The Quality Profession and Its PractitionersUday SharmaNo ratings yet

- Statistics 1060 - Winter 2012 - Tutorial 1Document6 pagesStatistics 1060 - Winter 2012 - Tutorial 1Uday SharmaNo ratings yet

- Data Quality ManagementDocument10 pagesData Quality ManagementhametNo ratings yet

- VR Quality Trends PDFDocument4 pagesVR Quality Trends PDFAMitNo ratings yet

- Applied Data Analysis For Process Improvement SamplerDocument149 pagesApplied Data Analysis For Process Improvement SamplerUday SharmaNo ratings yet

- Injection Molding EngDocument28 pagesInjection Molding Engthejaka100% (1)

- 2020 QP Salary SurveyDocument8 pages2020 QP Salary SurveyUday SharmaNo ratings yet

- Champions Trophy: Industry 4.0Document13 pagesChampions Trophy: Industry 4.0Uday SharmaNo ratings yet

- Foxboro IA Series Product ManualDocument7 pagesFoxboro IA Series Product Manualkumar1123100% (1)

- Organization Structure of Hul: Presented By:-Lavesh SethiaDocument11 pagesOrganization Structure of Hul: Presented By:-Lavesh SethiaLavesh SethiaNo ratings yet

- Daily Construction Report (DCR) : Project ManagerDocument5 pagesDaily Construction Report (DCR) : Project ManagerMoath AlhajiriNo ratings yet

- Prelims Reviewer Corpo Momo Eats Et - Al 1 1Document73 pagesPrelims Reviewer Corpo Momo Eats Et - Al 1 1Francois Amos PalomoNo ratings yet

- Case - INOXDocument2 pagesCase - INOXRam PowruNo ratings yet

- Group 1 Kim Jubilee Casencia Flordeliza Nanoy Irish Cayao Erman Dave Sabuya Edrian Carejon Jelyn Paredes Jessica GajetoDocument18 pagesGroup 1 Kim Jubilee Casencia Flordeliza Nanoy Irish Cayao Erman Dave Sabuya Edrian Carejon Jelyn Paredes Jessica GajetoPrincess Di BaykingNo ratings yet

- Faqir Chand Gulati v. Uppal Agencies Pvt. Ltd. principles housing constructionDocument5 pagesFaqir Chand Gulati v. Uppal Agencies Pvt. Ltd. principles housing constructionArnav LekharaNo ratings yet

- Artificial Intelligence Chatbot Adoption FrameworkDocument18 pagesArtificial Intelligence Chatbot Adoption FrameworksaraNo ratings yet

- Custom Authentication in Oracle APEXDocument19 pagesCustom Authentication in Oracle APEXBala SubramanyamNo ratings yet

- Case 1.1 Ba-Zynga! Zynga Faces Trouble in Farmville FINAL 1-19-20Document3 pagesCase 1.1 Ba-Zynga! Zynga Faces Trouble in Farmville FINAL 1-19-20eamccuneNo ratings yet

- AirAsia's Social Responsibility and CSR ProgramsDocument4 pagesAirAsia's Social Responsibility and CSR ProgramsPrivate TitaniumNo ratings yet

- Abbott Diagnostics Cell Dyn Emerald Operating Manual PDFDocument298 pagesAbbott Diagnostics Cell Dyn Emerald Operating Manual PDFAhmedMoussa0% (1)

- Pivot Table Practice - SolvedDocument11 pagesPivot Table Practice - SolvedanzarNo ratings yet

- The Electronic Commerce Act RA 8792Document18 pagesThe Electronic Commerce Act RA 8792GF Sotto100% (2)

- Podcasts For Real Estate Professionals Check Out Advantages and ExamplesDocument3 pagesPodcasts For Real Estate Professionals Check Out Advantages and Exampleskomal khanNo ratings yet

- Mragr00028620000020847 2023Document2 pagesMragr00028620000020847 202394116521No ratings yet

- Audit of Liabilities - Guidance Note PDFDocument22 pagesAudit of Liabilities - Guidance Note PDFRicalyn E. SumpayNo ratings yet

- Date Narration Chq./Ref - No. Value DT Withdrawal Amt. Deposit Amt. Closing BalanceDocument8 pagesDate Narration Chq./Ref - No. Value DT Withdrawal Amt. Deposit Amt. Closing BalanceProficient CyberNo ratings yet

- Flattening of Copper and Copper-Alloy Pipe and Tube: Standard Test Method ForDocument3 pagesFlattening of Copper and Copper-Alloy Pipe and Tube: Standard Test Method ForErick VargasNo ratings yet

- Godrej Appliances - Case PDFDocument22 pagesGodrej Appliances - Case PDFAbhijit Kumar100% (1)

- Up and Running With Power BI ServiceDocument117 pagesUp and Running With Power BI ServiceSaha2No ratings yet

- Short Selling Comes Under Fire - AgainDocument1 pageShort Selling Comes Under Fire - AgainSUNLINo ratings yet

- Government and Corporate Social Responsibility (GCSR) Chapter 1: Strategic Public Policy Vision for CSRDocument4 pagesGovernment and Corporate Social Responsibility (GCSR) Chapter 1: Strategic Public Policy Vision for CSRLouelie Jean AlfornonNo ratings yet

- Multimodal TransportDocument58 pagesMultimodal TransportAbdurahmanNo ratings yet

- UAS Report Laundry - inDocument13 pagesUAS Report Laundry - inJody RanklyNo ratings yet

- Design and Fabrication of Compound DieDocument7 pagesDesign and Fabrication of Compound DieRaj PremrajNo ratings yet

- Alyssa Li ResumeDocument1 pageAlyssa Li ResumeMING JUNo ratings yet

- IGEM 2016 Key in Enquiry 10 Oct 2016Document38 pagesIGEM 2016 Key in Enquiry 10 Oct 2016rexNo ratings yet

- Arens14e ch25 PPTDocument37 pagesArens14e ch25 PPTLouis ValentinoNo ratings yet

- King County Metro Budget 2021-2022 BriefDocument3 pagesKing County Metro Budget 2021-2022 BriefThe UrbanistNo ratings yet