Professional Documents

Culture Documents

Protective Device DR3-10

Uploaded by

fatchur rochmanOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Protective Device DR3-10

Uploaded by

fatchur rochmanCopyright:

Available Formats

Fitting instructions MGS/ZMS overload

protective devices for DR 3 – 10 hoists

2/1 reeving 4/1, 6/1 reeving

42382944.eps 42382844.eps

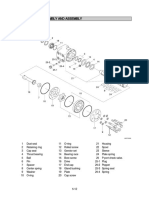

Arrangement of pins, washers, rings for MGS/ZMS

Le. Ri.

1.3

Setbolt top (1)

1.2

1.1

MGS or ZMS

2.4

Setbolt bottom (2)

2.3

2.1

2.2

42728544.eps

Item Designation Arrangement DR 3 DR 5 DR 10

Dimensions (quantity cpl.)

(1) Setbolt top

1 Setbolt 16H 9x 46 20H 9x 45 20H 9x 71

1.1 Ring Inside Ri./Le. 18 x 22 x 8 (2 off) 22 x 25 x 8 (2 off) 22 x 25 x 10 (2 off)

1.2 Ring On retaining ring 18 x 22 x 8 (1 off) 22 x 25 x 8 (1 off) 22 x 25 x 6 (1 off)

1.3 Retaining ring 16x 1,5 20x 1,75 20x 1,75

(2) Setbolt bottom

2 Setbolt 16H 9x 53 20H 9x 53 20H 9x 71

2.1 Ring Inside Ri./Le. 18 x 22 x 8 (2 off) 22 x 25 x 8 (2 off) 22 x 25 x 10 (2 off)

2.2 Ring Inside Ri./Le. 18 x 22 x 5 (2 off) 22 x 25 x 8 (2 off) 22 x 25 x 6 (2 off)

2.3 Supporting washer On retaining ring 16 x 22 x 1,5 (1 off) - -

2.3 Shim On retaining ring - 20 x 28 x 1 (1 off) 20 x 28 x 1 (1 off)

2.4 Retaining ring 16x 1,5 20x 1,75 20x 1,75

201106 EN / PDF 214 025 44 720 IS 813

Fitting instructions MGS/ZMS overload

protective devices for DR 20 hoists

MGS ZMS

1 8 1 8

3 8 9 3 8 9

4 4

7

6

5 5

42710744.eps

1. Fit retaining plate (1).

2. Insert rope end with rope wedge in rope socket (5) and first suspend without MGS or ZMS in the crossbar with setbolt (4),

briefly load bottom block so that the rope with rope wedge is drawn into rope socket (5). Then unload again and pull

setbolt (4) out of the crossbar.

3. Grease the contact points between MGS or ZMS and setbolt with a suitable grease (e.g. Molykote Longtherm).

4. Insert setbolt (3) in the upper bore hole in the side plate and proceed as follows:

Only for ZMS: Slide spacer ring (6) inside the crossbar over setbolt (3),

Slide MGS or ZMS (8) over setbolt (3),

Only for ZMS: Insert spacer ring (7) from above and push through setbolt (3) completely at the same time.

5. Insert rope socket (5) from below between the retaining plate and the strain gauge carrier link and slide through setbolt (4).

6. Make sure that the lower setbolt (4) with suspended rope socket and strain gauge carrier link can move freely in the

crossbar bore hole (bottom bore hole > dia. setbolt).

7. Secure setbolts (3/4) with shims (8) and double spring clips (9).

Printed in Germany PDF 201106

Demag Cranes & Components GmbH

P.O. Box 67, D-58286 Wetter

Telephone +49 (0) 2335 92-0 · Telefax +49 (0) 2335 927676

www.demagcranes.com

Reproduction in whole or in part only with prior consent of Demag Cranes & Components GmbH, D-58286 Wetter Subject to change. Not liable for errors or omissions.

You might also like

- Midsection: Section 5 - Clamp and Swivel BracketDocument8 pagesMidsection: Section 5 - Clamp and Swivel BracketpedroNo ratings yet

- Group 4 Disassembly and AssemblyDocument30 pagesGroup 4 Disassembly and Assemblymãi bên emNo ratings yet

- 5-4 Disassembly and AssemblyDocument31 pages5-4 Disassembly and AssemblyGustavo Alonso Cappa SalasNo ratings yet

- Mitsubishi FD70N Part 3 Mast & ForksDocument66 pagesMitsubishi FD70N Part 3 Mast & Forksben.williamsNo ratings yet

- CALFEM Mesh Module ManualDocument28 pagesCALFEM Mesh Module ManualJohan Lorentzon100% (1)

- Hydac Safety and Shut Off Valve Page 9Document1 pageHydac Safety and Shut Off Valve Page 9varaNo ratings yet

- Group 3 Disassembly and Assembly: 1. Steering UnitDocument25 pagesGroup 3 Disassembly and Assembly: 1. Steering UnitAndré TarginoNo ratings yet

- Group 6 and 7 ComputationDocument22 pagesGroup 6 and 7 ComputationPajarillaga Franz Erick QuintoNo ratings yet

- Divisor Flujo RV 1d 32x3 VivoloDocument2 pagesDivisor Flujo RV 1d 32x3 VivoloIecsa IngenieriaNo ratings yet

- Hce80 2fhcc80 Installation GuideDocument62 pagesHce80 2fhcc80 Installation GuideSelvan govenderNo ratings yet

- Group 5 Power Train SystemDocument2 pagesGroup 5 Power Train SystemSaidi JalelNo ratings yet

- 5-3 Group 3 Disassembly and AssemblyDocument25 pages5-3 Group 3 Disassembly and Assemblystefan corjucNo ratings yet

- Group 3 Disassembly and Assembly: 1. Steering UnitDocument29 pagesGroup 3 Disassembly and Assembly: 1. Steering UnitBaciu NicolaeNo ratings yet

- VT098 - VT099DAM-83RCV2 Remote Control Valves Bosun StoreDocument11 pagesVT098 - VT099DAM-83RCV2 Remote Control Valves Bosun StorelequangNo ratings yet

- Group 7 RCV LeverDocument14 pagesGroup 7 RCV LeverDeyvi Cconocuyca HuallparimachiNo ratings yet

- MSX125 - 2 - Body Panels - Exhaust System - 4Document10 pagesMSX125 - 2 - Body Panels - Exhaust System - 4camu233No ratings yet

- 04 - 05-3657707e - Bottom Roller.Document6 pages04 - 05-3657707e - Bottom Roller.Enso RosalesNo ratings yet

- Exploded-ML3051ND SEEDocument24 pagesExploded-ML3051ND SEEBrankoNo ratings yet

- Cable Harnes TramioDocument2 pagesCable Harnes TramioAlf NeroNo ratings yet

- 2volvo BL 61 71 YmDocument11 pages2volvo BL 61 71 YmIsa YılmazNo ratings yet

- C A 2018 DIAB DesigninfoDocument2 pagesC A 2018 DIAB Designinfoaandueza_1No ratings yet

- 2PM Contact ArrangementsDocument2 pages2PM Contact ArrangementsmostafaNo ratings yet

- WDT0500 102R0Document14 pagesWDT0500 102R0Rytis SiaulysNo ratings yet

- Sis 2.0Document2 pagesSis 2.0SERGIONo ratings yet

- B2-01 Booster Gun: Instruction ManualDocument2 pagesB2-01 Booster Gun: Instruction ManualJod RichNo ratings yet

- 12g Cilinder Motor1n3576Document3 pages12g Cilinder Motor1n3576Maria De Jesus Padua DominguezNo ratings yet

- 42 - 0718 - 24 - A5 - en - FR - Es - BS LT NAFTA NLO CPDocument24 pages42 - 0718 - 24 - A5 - en - FR - Es - BS LT NAFTA NLO CPBAYARDNo ratings yet

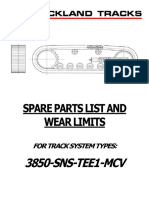

- 3850-SNS-TEE1-MCV Parts ManualDocument23 pages3850-SNS-TEE1-MCV Parts ManualJavier Pilquiman GaticaNo ratings yet

- Mando Final Sellos 725Document2 pagesMando Final Sellos 725ericNo ratings yet

- Controls: Section 7B - Tiller HandleDocument11 pagesControls: Section 7B - Tiller HandlepedroNo ratings yet

- CamshaftDocument2 pagesCamshaftGendon ArkanaNo ratings yet

- H100 Kit-SealDocument2 pagesH100 Kit-Sealb2mgarantieNo ratings yet

- Spare Part Designation S40.1 S50.1 S63.1 S80.1: N/a N/aDocument3 pagesSpare Part Designation S40.1 S50.1 S63.1 S80.1: N/a N/aeli saNo ratings yet

- Lab - 0 - Tensile Strength of Mild SteelDocument7 pagesLab - 0 - Tensile Strength of Mild Steelrajeshguptarg7246No ratings yet

- Attachments/Control Linkage: Section 7A - Throttle/Shift LinkageDocument10 pagesAttachments/Control Linkage: Section 7A - Throttle/Shift LinkagepedroNo ratings yet

- Null 2Document10 pagesNull 2Brayan NohNo ratings yet

- Neutron Assembly DrawingDocument1 pageNeutron Assembly Drawingpablocoelho22No ratings yet

- Esr 5200 Parts - Maq BetâniaDocument644 pagesEsr 5200 Parts - Maq Betâniaedipo carlosNo ratings yet

- New Microsoft Office Excel WorksheetDocument4 pagesNew Microsoft Office Excel WorksheetDiskJockey JaguaroNo ratings yet

- Exploded Views and Parts ListDocument16 pagesExploded Views and Parts Listjroyal69No ratings yet

- 5030 125460 Assale 707 164 E8cb83 125458Document8 pages5030 125460 Assale 707 164 E8cb83 125458Mepita MecânicaNo ratings yet

- Parts Information: Char-LynnDocument5 pagesParts Information: Char-LynnRidha AbbassiNo ratings yet

- HAMMER STRENGTH EQUIPMENT ILSP Iso Lateral Shoulder ...Document8 pagesHAMMER STRENGTH EQUIPMENT ILSP Iso Lateral Shoulder ...Rida DahmounNo ratings yet

- KC25 2Document2 pagesKC25 2Cesar Ivan Reyes TrejoNo ratings yet

- Dribble Drive Motion PlaybookDocument32 pagesDribble Drive Motion PlaybookJanka DebackerNo ratings yet

- Design Scaffolding TKBT 2 NewDocument2 pagesDesign Scaffolding TKBT 2 NewAnnisa TassiaNo ratings yet

- MIL-STD-147E Palletized Unit LoadsDocument117 pagesMIL-STD-147E Palletized Unit Loadsfake77No ratings yet

- Group 7 RCV LeverDocument14 pagesGroup 7 RCV Leverdeniden2013No ratings yet

- Inverseur TTMC35 A & PDocument12 pagesInverseur TTMC35 A & PDavid dounaiNo ratings yet

- Group 3 Disassembly and Assembly: 1. Steering UnitDocument25 pagesGroup 3 Disassembly and Assembly: 1. Steering UnitAndré TarginoNo ratings yet

- 40 50 Manual Tilt AssistDocument8 pages40 50 Manual Tilt AssistRyan ActonNo ratings yet

- Hammer Select: Parts ManualDocument15 pagesHammer Select: Parts Manualhegang liuNo ratings yet

- 2752 HGB ServiceDocument4 pages2752 HGB ServiceJorge CabreraNo ratings yet

- Gaus GableDocument20 pagesGaus GableWayan SuwestraNo ratings yet

- AcopleDocument5 pagesAcoplecesarNo ratings yet

- 7. اذرعت التحكم (العصيان)Document14 pages7. اذرعت التحكم (العصيان)المهندسوليدالطويلNo ratings yet

- Çukurova 828b ArkaDocument8 pagesÇukurova 828b Arkakaleismakinalari01No ratings yet

- 4 SF Travel Drive: Cable GlandDocument3 pages4 SF Travel Drive: Cable Glandjihad Technical MaintenanceNo ratings yet

- Engineering Drawing from the Beginning: The Commonwealth and International Library: Mechanical Engineering DivisionFrom EverandEngineering Drawing from the Beginning: The Commonwealth and International Library: Mechanical Engineering DivisionRating: 4.5 out of 5 stars4.5/5 (3)

- ZMS Data DimensionDocument2 pagesZMS Data Dimensionfatchur rochmanNo ratings yet

- ZMS For DR HoistDocument12 pagesZMS For DR Hoistfatchur rochmanNo ratings yet

- DH 500 Part Set - ENDocument68 pagesDH 500 Part Set - ENfatchur rochman100% (3)

- Operating Inst DR 10 - Versi Holding BrakeDocument20 pagesOperating Inst DR 10 - Versi Holding Brakefatchur rochmanNo ratings yet

- Parts DH 1000 New PDFDocument64 pagesParts DH 1000 New PDFfatchur rochman100% (2)

- DH300 Part SetDocument68 pagesDH300 Part Setfatchur rochman67% (3)

- OHC Man Basket SOPDocument7 pagesOHC Man Basket SOPfatchur rochmanNo ratings yet

- Must Read List For MGMT ConsultantsDocument8 pagesMust Read List For MGMT Consultantsakhilyerawar7013100% (2)

- Teves Mk60 - Abs - Eds - Asr & Esp: Brake TechnologyDocument2 pagesTeves Mk60 - Abs - Eds - Asr & Esp: Brake TechnologyLpr ElectronicasNo ratings yet

- History of ERPDocument8 pagesHistory of ERPK aeriNo ratings yet

- Jawaharlal NehruDocument1 pageJawaharlal Nehruprem247No ratings yet

- (HSE-ForM-A.05) Form Inspection Rough Terrain CraneDocument6 pages(HSE-ForM-A.05) Form Inspection Rough Terrain CraneIvansyah SastrowardoyoNo ratings yet

- Rr210106 Fluid MechanicsDocument8 pagesRr210106 Fluid MechanicsSrinivasa Rao GNo ratings yet

- Monarch TT 30Document4 pagesMonarch TT 30Migue ToasaNo ratings yet

- Roxxane Quimby CaseDocument2 pagesRoxxane Quimby CaseAbdur Rehman Bin Zaheer0% (1)

- 13 Reservoir & Detail PondasiDocument8 pages13 Reservoir & Detail PondasiChua MilanoNo ratings yet

- Dwnload Full Genetics Analysis and Principles 4th Edition Brooker Test Bank PDFDocument35 pagesDwnload Full Genetics Analysis and Principles 4th Edition Brooker Test Bank PDFzaridyaneb100% (9)

- Triaxial Test IntroductionDocument4 pagesTriaxial Test IntroductionAshadi Hamdan100% (3)

- Bruce Copen - Agricultural Radionics (OCR)Document43 pagesBruce Copen - Agricultural Radionics (OCR)evandrojsilva75% (8)

- The Saho of EritreaDocument28 pagesThe Saho of EritreaahahaNo ratings yet

- Schneider Price List (Packard Engineering)Document14 pagesSchneider Price List (Packard Engineering)Mamun Al-Reja100% (2)

- Contemporary Art Elements and PrinciplesDocument30 pagesContemporary Art Elements and PrinciplesLorraine Joy Zaragoza BalesNo ratings yet

- Temporary Works & The Structural EngineerDocument5 pagesTemporary Works & The Structural EngineerLim Yew KwangNo ratings yet

- Eng-4112-2 RubricDocument8 pagesEng-4112-2 Rubricapi-409215063No ratings yet

- MQB 05 WS 1Document6 pagesMQB 05 WS 1Vincents Genesius EvansNo ratings yet

- MaxMarking LaserDocument66 pagesMaxMarking Laserodhiles10% (1)

- 3 Ps in Practice 8th Ed. Chapter 12 Page 456Document3 pages3 Ps in Practice 8th Ed. Chapter 12 Page 456Chitvan BhargavaNo ratings yet

- Artigo 1 Clinical Nursing AdrielleDocument10 pagesArtigo 1 Clinical Nursing AdrielleJuliana MaiaNo ratings yet

- F 360BXP.24: Fassi CraneDocument10 pagesF 360BXP.24: Fassi Craneניקולאי איןNo ratings yet

- Sumatera-Jawa Transmission ProjectDocument7 pagesSumatera-Jawa Transmission ProjectSingal SihombingNo ratings yet

- Some Physiologic Consideration of Centric and Other Jaw RelationsDocument12 pagesSome Physiologic Consideration of Centric and Other Jaw RelationsMartha Lia Castaño EcheverryNo ratings yet

- Week 2Document15 pagesWeek 2Rainman InsanityNo ratings yet

- What Are Electromagnetic Transients?: Intro To Atp and AtpdrawDocument7 pagesWhat Are Electromagnetic Transients?: Intro To Atp and AtpdrawJosNo ratings yet

- Revision Tasks Sec. Pre Advanced (Advanced Speak Out) Progress Test 1Document5 pagesRevision Tasks Sec. Pre Advanced (Advanced Speak Out) Progress Test 1Александра АлександраNo ratings yet

- 04 Unit 03 Procedure-KCDocument19 pages04 Unit 03 Procedure-KCfitriNo ratings yet

- ASCP BOC US Procedures BookDocument32 pagesASCP BOC US Procedures BookcarlosrubenecNo ratings yet

- Atomic FE TutorialDocument46 pagesAtomic FE TutorialVegaNo ratings yet