Professional Documents

Culture Documents

C A 2018 DIAB Designinfo

Uploaded by

aandueza_1Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

C A 2018 DIAB Designinfo

Uploaded by

aandueza_1Copyright:

Available Formats

Simpson Strong-Tie® Anchoring, Fastening and Restoration Systems for Concrete and Masonry

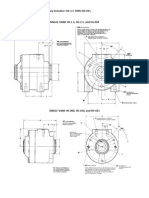

Drop-In (DIAB) Design Information — Concrete

DIAB Allowable Tension and Shear Loads IBC *

in Normal-Weight Concrete

f'c ≥ 2,500 psi (17.2 MPa) f'c ≥ 4,000 psi (27.6 MPa)

Rod Embed Critical Critical

Drill Bit

Model Size Depth Edge Dist. Spacing Tension Load Shear Load Tension Load Shear Load

Dia.

No. in. In. In. In.

In. Ultimate Allowable Ultimate Allowable Ultimate Allowable Ultimate Allowable

(mm) (mm) (mm) (mm)

lb. (kN) lb. (kN) lb. (kN) lb. (kN) lb. (kN) lb. (kN) lb. (kN) lb. (kN)

DIAB25 1/4 1 3 4 1,565 390 1,840 460 1,965 490 1,840 460

3/8 (25) (76) (102) (7.0) (1.7) (8.2) (2.0) (8.7) (2.2) (8.2) (2.0)

DIABL25 (6.4)

DIAB37 3/8 1 9/16 4 1/2 6 2,950 740 4,775 1,195 3,910 980 4,775 1,195

1/2 (152) (13.1) (3.3) (21.2) (5.3) (17.4) (4.4) (21.2) (5.3)

DIABL37 (9.5) (40) (114)

DIAB50

DIABL50 1/2 2 6 8 5,190 1,300 6,760 1,690 6,515 1,630 6,760 1,690

5/8

Mechanical Anchors

(12.7) (51) (152) (203) (23.1) (5.8) (30.1) (7.5) (29.0) (7.3) (30.1) (7.5)

DIAB50C

5/8 2 1/2 7 1/2 10 7,010 1,755 12,190 3,050 9,060 2,265 12,190 3,050

DIAB62 7/8 (254) (31.2) (7.8) (54.2) (13.6) (40.3) (10.1) (54.2) (13.6)

(15.9) (64) (191)

DIAB75 3/4 3 1/8 9 12 1/2 9,485 2,370 15,960 3,990 11,660 2,915 15,960 3,990

1 (229) (42.2) (10.5) (71.0) (17.7) (51.9) (13.0) (71.0) (17.7)

DIAB75C (19.1) (79) (318)

1. The allowable loads listed are based on a safety factor of 4.0.

2. Refer to allowable load-adjustment factors for edge distance and spacing on p. 186.

3. Allowable loads may be linearly interpolated between concrete strength listed.

4. The minimum concrete thickness is 1 1/2 times the embedment depth.

5. Allowable loads may not be increased for short-term loading due to wind or seismic forces.

DIAB Allowable Tension and Shear Loads IBC *

in Soffit of Sand-Lightweight Concrete over Metal Deck

f'c ≥ 3,000. psi (20.7 MPa)

Embed Critical Critical

Rod Size Drill Bit

Model Depth End Dist.6 Spacing Tension Load Shear Load

in. Dia.

No. In. In. In.

(mm) In. Ultimate Allowable Ultimate Allowable

(mm) (mm) (mm)

lb. (kN) lb. (kN) lb. (kN) lb. (kN)

DIAB37 3/8 1 9/16 4 1/2 6 2,895 725 3,530 885

1/2 (152) (12.9) (3.2) (15.7) (3.9)

DIABL37 (9.5) (40) (114)

DIAB50

1/2 2 6 8 4,100 1,025 4,685 1,170

DIABL50 (12.7)

5/8 (51) (152) (203) (18.2) (4.6) (20.8) (5.2)

DIAB50C

C-A-2018 © 2018 SIMPSON STRONG-TIE COMPANY INC.

1. The allowable loads listed are based on a safety factor of 4.0.

2. Allowable loads may not be increased for short-term loading due to wind or seismic forces.

3. Refer to allowable load-adjustment factors for edge distance and spacing on p. 186.

4. Anchors were installed in the center of the bottom flute of the steel deck.

5. Metal deck must be minimum 20-gauge thick with minimum yield strength of 33 ksi.

6. Critical end distance is defined as the distance from end of the slab in the direction of the flute.

61⁄4"

3" Min. Upper

20-gauge flute

steel deck

Min. 41⁄2"

Drop-In

anchor

41⁄2" 71⁄2"

Lightweight Concrete over Metal Deck

* See p. 13 for an explanation of the load table icons.

185

Simpson Strong-Tie® Anchoring, Fastening and Restoration Systems for Concrete and Masonry

Drop-In (DIAB) Design Information — Concrete

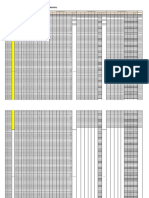

Allowable Load-Adjustment Factors for Drop-In Anchor (DIAB) in Normal-Weight Concrete and Sand-Lightweight

Concrete over Metal Deck: Edge Distance and Spacing, Tension and Shear Loads

How to use these charts:

1. The following tables are for reduced edge distance and spacing. 4. The load adjustment factor (fc or fs) is the intersection of the row and column.

2. Locate the anchor size to be used for either a tension and/or a shear 5. Multiply the allowable load by the applicable load adjustment factor.

load application. 6. Reduction factors for multiple edges or spacing are multiplied together.

3. Locate the edge distance (cact) or spacing (sact) at which the anchor is

to be installed.

Edge Distance Tension (fc ) Edge Distance Shear (fc )

IBC * IBC *

Edge Size 1/4 3/8 1/2 5/8 3/4 Edge Size 1/4 3/8 1/2 5/8 3/4

Dist. ccr 3 4 1/2 6 7 1/2 9 Dist. ccr 3 4 1/2 6 7 1/2 9

cact cmin 1 3/4 2 5/8 3 1/2 4 3/8 5 1/4 cact cmin 1 3/4 2 5/8 3 1/2 4 3/8 5 1/4

(in.) fcmin 0.77 0.77 0.77 0.77 0.77 (in.) fcmin 0.54 0.54 0.64 0.64 0.64

1 3/4 0.77 1 3/4 0.54

2 0.82 2 0.63

Mechanical Anchors

2 1/2 0.91 2 1/2 0.82

2 5/8 0.93 0.77 2 5/8 0.86 0.54

3 1.00 0.82 3 1.00 0.63

3 1/2 0.88 0.77 3 1/2 0.75 0.64

4 0.94 0.82 4 0.88 0.71

4 3/8 0.98 0.85 0.77 4 3/8 0.97 0.77 0.64

4 1/2 1.00 0.86 0.78 4 1/2 1.00 0.78 0.65

5 0.91 0.82 5 0.86 0.71

5 1/4 0.93 0.83 0.77 5 1/4 0.89 0.74 0.64

5 1/2 0.95 0.85 0.79 5 1/2 0.93 0.77 0.66

6 1.00 0.89 0.82 6 1.00 0.83 0.71

6 1/2 0.93 0.85 6 1/2 0.88 0.76

7 0.96 0.88 7 0.94 0.81

7 1/2 1.00 0.91 7 1/2 1.00 0.86

8 0.94 8 0.90

8 1/2 0.97 8 1/2 0.95

9 1.00 9 1.00

1. cact = actual edge distance at which anchor is installed (inches). 1. cact = actual edge distance at which anchor is installed (inches).

2. ccr = critical edge distance for 100% load (inches). 2. ccr = critical edge distance for 100% load (inches).

3. cmin = minimum edge distance for reduced load (inches). 3. cmin = minimum edge distance for reduced load (inches).

4. fc = adjustment factor for allowable load at actual edge distance. 4. fc = adjustment factor for allowable load at actual edge distance.

5. fccr = adjustment factor for allowable load at critical edge distance. 5. fccr = adjustment factor for allowable load at critical edge distance.

fccr is always = 1.00. fccr is always = 1.00.

6. fcmin = adjustment factor for allowable load at minimum edge distance. 6. fcmin = adjustment factor for allowable load at minimum edge distance.

7. fc = fcmin + [(1 – fcmin) (cact – cmin) / (ccr – cmin)]. 7. fc = fcmin + [(1 – fcmin) (cact – cmin) / (ccr – cmin)].

Spacing Tension (fs) Spacing Shear (fs)

Spacing Size

scr

1/4

4

3/8

6

1/2

8

5/8

10

3/4

12 1/2 IBC * Spacing Size

scr

1/4

4

3/8

6

1/2

8

5/8

10

3/4

12 1/2 IBC *

sact smin 3 sact smin 3

(in.) 1 1/2 2 1/4 3 3/4 4 3/4 (in.) 1 1/2 2 1/4 3 3/4 4 3/4

fsmin 0.72 0.72 0.80 0.80 0.80 fsmin 1.00 1.00 1.00 1.00 1.00

C-A-2018 © 2018 SIMPSON STRONG-TIE COMPANY INC.

1 1/2 0.72 1 1/2 1.00

2 0.78 2 1.00

2 1/4 0.80 0.72 2 1/4 1.00 1.00

2 1/2 0.83 0.74 2 1/2 1.00 1.00

3 0.89 0.78 0.80 3 1.00 1.00 1.00

3 1/2 0.94 0.81 0.82 3 1/2 1.00 1.00 1.00

3 3/4 0.97 0.83 0.83 0.80 3 3/4 1.00 1.00 1.00 1.00

4 1.00 0.85 0.84 0.81 4 1.00 1.00 1.00 1.00

4 1/2 0.89 0.86 0.82 4 1/2 1.00 1.00 1.00

4 3/4 0.91 0.87 0.83 0.80 4 3/4 1.00 1.00 1.00 1.00

5 0.93 0.88 0.84 0.81 5 1.00 1.00 1.00 1.00

5 1/2 0.96 0.90 0.86 0.82 5 1/2 1.00 1.00 1.00 1.00

6 1.00 0.92 0.87 0.83 6 1.00 1.00 1.00 1.00

6 1/2 0.94 0.89 0.85 6 1/2 1.00 1.00 1.00

7 0.96 0.90 0.86 7 1.00 1.00 1.00

7 1/2 0.98 0.92 0.87 7 1/2 1.00 1.00 1.00

8 1.00 0.94 0.88 8 1.00 1.00 1.00

8 1/2 0.95 0.90 8 1/2 1.00 1.00

9 0.97 0.91 9 1.00 1.00

9 1/2 0.98 0.92 9 1/2 1.00 1.00

10 1.00 0.94 10 1.00 1.00

10 1/2 0.95 10 1/2 1.00

11 0.96 11 1.00

11 1/2 0.97 11 1/2 1.00

12 0.99 12 1.00

12 1/2 1.00 12 1/2 1.00

1. sact = actual spacing distance at which anchor is installed (inches). 1. sact = actual spacing distance at which anchor is installed (inches).

2. scr = critical spacing distance for 100% load (inches). 2. scr = critical spacing distance for 100% load (inches).

3. smin = minimum spacing distance for reduced load (inches). 3. smin = minimum spacing distance for reduced load (inches).

4. fs = adjustment factor for allowable load at actual spacing distance. 4. fs = adjustment factor for allowable load at actual spacing distance.

5. fscr = adjustment factor for allowable load at critical spacing distance. 5. fscr = adjustment factor for allowable load at critical spacing distance.

fscr is always = 1.00. fscr is always = 1.00.

6. fsmin = adjustment factor for allowable load at minimum spacing distance. 6. fsmin = adjustment factor for allowable load at minimum spacing distance.

7. fs = fsmin + [(1 – fsmin) (sact – smin) / (scr – smin)]. 7. fs = fsmin + [(1 – fsmin) (sact – smin) / (scr – smin)].

186 * See p. xx for an explanation of the load table icons.

You might also like

- Drilling Fluids Processing HandbookFrom EverandDrilling Fluids Processing HandbookRating: 4.5 out of 5 stars4.5/5 (4)

- Wedge Anchor Simpson 2016Document10 pagesWedge Anchor Simpson 2016mikeroack_11No ratings yet

- CCTV Surveillance: Video Practices and TechnologyFrom EverandCCTV Surveillance: Video Practices and TechnologyRating: 4 out of 5 stars4/5 (1)

- Sleeve-All Design Information - Concrete and MasonryDocument3 pagesSleeve-All Design Information - Concrete and MasonryEmad Ahmed KhanNo ratings yet

- Hoja Tecnica - G5+Document3 pagesHoja Tecnica - G5+fabians77No ratings yet

- Technical Bulletin For Kwik BoltDocument3 pagesTechnical Bulletin For Kwik BoltAbu Hena Mostofa KamalNo ratings yet

- Technical Bulletin For Kwik BoltDocument3 pagesTechnical Bulletin For Kwik BoltAbu Hena Mostofa KamalNo ratings yet

- Handbook - Cored Wire Products PDFDocument1 pageHandbook - Cored Wire Products PDFtuna61No ratings yet

- Technical-Information-HILTI HITI HY 270Document13 pagesTechnical-Information-HILTI HITI HY 270michael martinNo ratings yet

- Kobelco RK450 PenterDocument14 pagesKobelco RK450 PenterSB GLOBAL GROUP BINTULU BRANCHNo ratings yet

- Dynabolt® Sleeve Anchors: Technical DataDocument1 pageDynabolt® Sleeve Anchors: Technical DataCoco Aryan TundyNo ratings yet

- HS CatalogDocument8 pagesHS CatalogvijaykumarnNo ratings yet

- HS CatalogDocument8 pagesHS CatalogMahesh NanayakkaraNo ratings yet

- HS 1.5 Thru 015 SpecsDocument8 pagesHS 1.5 Thru 015 SpecsvijaykumarnNo ratings yet

- Lincore 65-O: Typical Applications Key FeaturesDocument2 pagesLincore 65-O: Typical Applications Key FeaturesDaniel Lvqve GarciaNo ratings yet

- Teslin TableDocument1 pageTeslin TableEzequiel FernandezNo ratings yet

- BBB5 Features and OptionsDocument4 pagesBBB5 Features and OptionsCoordinador InterjuiceNo ratings yet

- IN33001Document2 pagesIN33001Khalid ZaeemNo ratings yet

- Compare Pc45mr3-Cat304-305Document14 pagesCompare Pc45mr3-Cat304-305Gaming BebasNo ratings yet

- Valvula de Balanceo Automatica Conexion BridadaDocument5 pagesValvula de Balanceo Automatica Conexion Bridadajackpillaca4No ratings yet

- Tapcon Technical DataDocument5 pagesTapcon Technical DataAndreaParraNo ratings yet

- Outdoor unit specifications tableDocument2 pagesOutdoor unit specifications tableAhmed NajjarNo ratings yet

- Technical Specifications: JS Sand FiltersDocument2 pagesTechnical Specifications: JS Sand FiltersEmanuel MurilloNo ratings yet

- Arbol de Levas EspecificacionesDocument73 pagesArbol de Levas Especificacionesariel avalosNo ratings yet

- Lampiran - 1 Contoh Perhitungan Tebal Perkerasan Kaku Metode AASHTO 1993Document17 pagesLampiran - 1 Contoh Perhitungan Tebal Perkerasan Kaku Metode AASHTO 1993Cileungsi NarogongNo ratings yet

- Valvulas MultipropositoDocument4 pagesValvulas MultipropositoSaulo ArturoNo ratings yet

- Test Sieve Comparison TableDocument3 pagesTest Sieve Comparison TableVasant HiremathNo ratings yet

- 42 - 0718 - 24 - A5 - en - FR - Es - BS LT NAFTA NLO CPDocument24 pages42 - 0718 - 24 - A5 - en - FR - Es - BS LT NAFTA NLO CPBAYARDNo ratings yet

- Mve SC Series Spec SheetDocument2 pagesMve SC Series Spec SheetБранко ЛуковићNo ratings yet

- Grinnell Mechanical Products Figure 909 Plain End Coupling For Steel Pipe - Patented & Patents Pending General Description Technical DataDocument4 pagesGrinnell Mechanical Products Figure 909 Plain End Coupling For Steel Pipe - Patented & Patents Pending General Description Technical DataСергей КолесниковNo ratings yet

- Screenshot 2022-07-14 at 12.30.24Document44 pagesScreenshot 2022-07-14 at 12.30.24zakkNo ratings yet

- FP 1.0 Fire Pump Systems Engineering DataDocument1 pageFP 1.0 Fire Pump Systems Engineering DataAlexis PradoNo ratings yet

- FPS 100 Informacion ExtraDocument1 pageFPS 100 Informacion ExtraLuis Daniel Aguirre RuizNo ratings yet

- Ds Barracuda 7200 10Document2 pagesDs Barracuda 7200 10zhabkoffNo ratings yet

- STAAD.Pro Report BM 01Document9 pagesSTAAD.Pro Report BM 01isaacjoe77No ratings yet

- Pipe Support TableDocument1 pagePipe Support Tablehtoomyat.chrisNo ratings yet

- R.1.05.01 Insert Type HoldersDocument2 pagesR.1.05.01 Insert Type HoldersbondsivamaniNo ratings yet

- Torques Con Lubricante y UpgradeDocument17 pagesTorques Con Lubricante y UpgradeJed MayNo ratings yet

- Canada Culvert Non Woven Geotextile Spec Sheet 1Document1 pageCanada Culvert Non Woven Geotextile Spec Sheet 1VindireNo ratings yet

- Insulators Insulator Catalog: For 15-69kV Applications Distribution & TransmissionDocument132 pagesInsulators Insulator Catalog: For 15-69kV Applications Distribution & TransmissionAndresNo ratings yet

- Former Models CPH v1.1 03.13.14Document105 pagesFormer Models CPH v1.1 03.13.14sinho27100% (1)

- 1200 Series DatasheetDocument12 pages1200 Series DatasheetbandaemetNo ratings yet

- Across The Civilizations: Transporting WaterDocument20 pagesAcross The Civilizations: Transporting WaterKoduru SiddharthNo ratings yet

- 09.15Document7 pages09.15Juan AliagaNo ratings yet

- Ansi B16 Valve Face To Face Dimensions: Ball ValvesDocument3 pagesAnsi B16 Valve Face To Face Dimensions: Ball ValvesAslam ShaikhNo ratings yet

- Trip BHA#12.25in TPN - DZ 20.6 (TPN-223)Document2 pagesTrip BHA#12.25in TPN - DZ 20.6 (TPN-223)Setya AminNo ratings yet

- 下载Document4 pages下载Mars JackNo ratings yet

- B16 10ASMEValveFacetoFaceDimensionsDocument22 pagesB16 10ASMEValveFacetoFaceDimensions오부열No ratings yet

- Alternator: SpecificationsDocument4 pagesAlternator: SpecificationsjogremaurNo ratings yet

- Catalogue DARCO Flottant ENDocument20 pagesCatalogue DARCO Flottant ENScipp ZengNo ratings yet

- 27th RA Sump WellDocument5 pages27th RA Sump WellKishan Bisalpure RathoreNo ratings yet

- McKissick Overhaul BallsDocument1 pageMcKissick Overhaul BallsYADAGIRI REDDYNo ratings yet

- Sec19 Sebd0350Document92 pagesSec19 Sebd0350pmcisissengueNo ratings yet

- Monitoring Pabrikasi PT AbgDocument58 pagesMonitoring Pabrikasi PT AbgabdiNo ratings yet

- TRAC Stabiliser Install & Operators Manual - Golden Arrow MarineDocument127 pagesTRAC Stabiliser Install & Operators Manual - Golden Arrow MarineRafael ValenteNo ratings yet

- AD 1+Tension+PackerDocument2 pagesAD 1+Tension+PackerHamid Reza BabaeiNo ratings yet

- Grooved Fire Protection Installation HandbookDocument67 pagesGrooved Fire Protection Installation HandbookPavel RamirezNo ratings yet

- Dyna Bolt Technical DataDocument1 pageDyna Bolt Technical DataSulthan AriNo ratings yet

- Embragues OkDocument1 pageEmbragues Okmiltonpaul95No ratings yet

- Pages From Hilti BrochureDocument1 pagePages From Hilti BrochureCarlos Andres Santin OrtizNo ratings yet

- Product Manual enDocument122 pagesProduct Manual enadacostNo ratings yet

- TLE2015 05TekmarineCatalogueR001cDocument18 pagesTLE2015 05TekmarineCatalogueR001caandueza_1No ratings yet

- Fender Systems Ver3 - 9Document5 pagesFender Systems Ver3 - 9aandueza_1No ratings yet

- Fender Systems Ver3 - 9Document5 pagesFender Systems Ver3 - 9aandueza_1No ratings yet

- TLE2015 05TekmarineCatalogueR001cDocument18 pagesTLE2015 05TekmarineCatalogueR001caandueza_1No ratings yet

- XLF60 Service Manual 1Document18 pagesXLF60 Service Manual 1aandueza_1No ratings yet

- Matias Bedroom: Designed by Maiya Rojas - Dec 1, 2021 Made For AndresDocument4 pagesMatias Bedroom: Designed by Maiya Rojas - Dec 1, 2021 Made For Andresaandueza_1No ratings yet

- Drafts - Concrete - Nov 24, 2021Document8 pagesDrafts - Concrete - Nov 24, 2021aandueza_1No ratings yet

- AG 18420 Penguard Pro GF Euk GBDocument12 pagesAG 18420 Penguard Pro GF Euk GBaandueza_1No ratings yet

- 5 1Document12 pages5 1mahakNo ratings yet

- Ku 6 y NPXDocument1 pageKu 6 y NPXaandueza_1No ratings yet

- XLF60 Owners Manual 1Document78 pagesXLF60 Owners Manual 1aandueza_1No ratings yet

- USNS Bob Hope Class in BremertonDocument1 pageUSNS Bob Hope Class in Bremertonaandueza_1No ratings yet

- 68 PNCQ ODocument1 page68 PNCQ Oaandueza_1No ratings yet

- 190924-N-BI924-9813 USNS GillilandDocument1 page190924-N-BI924-9813 USNS Gillilandaandueza_1No ratings yet

- ABS RECORD, The Online Database For ABS Vessel Records, Lists All Vessels and Offshore Installations in Class With ABS, Including Class NotationsDocument3 pagesABS RECORD, The Online Database For ABS Vessel Records, Lists All Vessels and Offshore Installations in Class With ABS, Including Class Notationsaandueza_1No ratings yet

- HILTI PROFIS Anchor Design GuideDocument362 pagesHILTI PROFIS Anchor Design Guidearun_angshu100% (2)

- QVF by 9 JDocument1 pageQVF by 9 Jaandueza_1No ratings yet

- GD-APS FutureWaves Oceans2016Document9 pagesGD-APS FutureWaves Oceans2016aandueza_1No ratings yet

- TAKR-300 USNS Bob HopeDocument2 pagesTAKR-300 USNS Bob Hopeaandueza_1No ratings yet

- SAP2000 Pipe Rack Modeling GuideDocument92 pagesSAP2000 Pipe Rack Modeling Guideagvelazquez100% (9)

- Pandas PDFDocument3,071 pagesPandas PDFJoemon JoseNo ratings yet

- NWSA Slide Deck For USNS Bob HopeDocument5 pagesNWSA Slide Deck For USNS Bob HopeWestSeattleBlogNo ratings yet

- Evaluate The Cylindrical Rubber Fender Response Under Dynamic LoadDocument5 pagesEvaluate The Cylindrical Rubber Fender Response Under Dynamic Loadaandueza_1No ratings yet

- Pandas PDFDocument3,071 pagesPandas PDFJoemon JoseNo ratings yet

- Wheel Loader: Engine (Tier 4) Engine (Tier 2)Document28 pagesWheel Loader: Engine (Tier 4) Engine (Tier 2)Chenna VijayNo ratings yet

- Newapps HughesDocument16 pagesNewapps Hughesaandueza_1No ratings yet

- Beginners Python Cheat Sheet PCC All PDFDocument26 pagesBeginners Python Cheat Sheet PCC All PDFName100% (1)

- Fender Design Test GuidelineDocument135 pagesFender Design Test GuidelineAleksa CavicNo ratings yet

- Beginners Python Cheat Sheet PCC All PDFDocument26 pagesBeginners Python Cheat Sheet PCC All PDFName100% (1)

- Electrical Application and Installation Guide For Petroleum TransmissionsDocument131 pagesElectrical Application and Installation Guide For Petroleum Transmissionsharikrishnanpd3327100% (2)

- TENSION PNEUMOTHORAX (Malav Shah)Document66 pagesTENSION PNEUMOTHORAX (Malav Shah)Sharath PsNo ratings yet

- Q 0092r1 - Mastersizer 3000 MAZ6222 2022 Kimia FarmaDocument4 pagesQ 0092r1 - Mastersizer 3000 MAZ6222 2022 Kimia FarmaCapital ExpenditureNo ratings yet

- Island Arc: LocationDocument7 pagesIsland Arc: LocationBlessing NgonidzasheNo ratings yet

- Bamuoingaythienquan NguyenduynhienDocument9 pagesBamuoingaythienquan NguyenduynhienFLed NguyenNo ratings yet

- Lubricated Coupling TrainingDocument47 pagesLubricated Coupling TrainingTheerayootNo ratings yet

- Principle Principle PrincipleDocument12 pagesPrinciple Principle PrincipleDarshana JuvekarNo ratings yet

- Salary Income Tax Calculation in EthiopiaDocument4 pagesSalary Income Tax Calculation in EthiopiaMulatu Teshome95% (37)

- Spread footing design calculationDocument6 pagesSpread footing design calculationFrancklinMeunierM'ondoNo ratings yet

- Ingredient Branding: P. Kotler, Northwestern University, Evanston, USA W. Pfoertsch, China EuropeDocument1 pageIngredient Branding: P. Kotler, Northwestern University, Evanston, USA W. Pfoertsch, China EuropeCristea GianiNo ratings yet

- Cost and Cost ClassificationDocument35 pagesCost and Cost ClassificationSusmita AcharyaNo ratings yet

- CA ruling on fertilizer disputeDocument16 pagesCA ruling on fertilizer disputeRuby Anna TorresNo ratings yet

- THE END - MagDocument164 pagesTHE END - MagRozze AngelNo ratings yet

- Getting Started With PhotoshopDocument15 pagesGetting Started With PhotoshopJEANIFER BUGARINNo ratings yet

- Quality Control and Assurance Processes for Coffee ProductionDocument5 pagesQuality Control and Assurance Processes for Coffee ProductionSharifah NuruljannahNo ratings yet

- Easy Eight's Battleground World War II Normandy NightmareDocument97 pagesEasy Eight's Battleground World War II Normandy NightmareAdolfo JoseNo ratings yet

- Data CollectionDocument4 pagesData CollectionjochukoNo ratings yet

- Gas Turbine Flow MeterDocument33 pagesGas Turbine Flow MeterKhabbab Hussain K-hNo ratings yet

- Domain Logic and SQLDocument23 pagesDomain Logic and SQLatifchaudhryNo ratings yet

- Studies on the vertically barred Haplochromis electra from Lake MalawiDocument5 pagesStudies on the vertically barred Haplochromis electra from Lake MalawiCenk Sururi KarabulutNo ratings yet

- Percent CompositionDocument4 pagesPercent CompositionTshiamo MotaungNo ratings yet

- Ruminations by Other PeopleDocument31 pagesRuminations by Other PeopledhultstromNo ratings yet

- Master of Arts (Education) /post Graduate Diploma in Educational Management and Administration (Maedu/Pgdema) Term-End Examination June, 2020Document7 pagesMaster of Arts (Education) /post Graduate Diploma in Educational Management and Administration (Maedu/Pgdema) Term-End Examination June, 2020Shreyashi Santra MitraNo ratings yet

- The Teacher and Student Relationship of Haydn and BeethovenDocument10 pagesThe Teacher and Student Relationship of Haydn and BeethovenVinny MuscarellaNo ratings yet

- Biology of Tooth MovementDocument22 pagesBiology of Tooth MovementsakshiNo ratings yet

- MCMC Methods For Multi-Response Generalized LinearDocument22 pagesMCMC Methods For Multi-Response Generalized LinearkyotopinheiroNo ratings yet

- Contractor base list in UsaDocument8 pagesContractor base list in Usamytech206No ratings yet

- Mhdp-08-Rsdll Report Issue 6.0Document159 pagesMhdp-08-Rsdll Report Issue 6.0billNo ratings yet

- Detector Balance Induccion.Document11 pagesDetector Balance Induccion.Jesus OrtizNo ratings yet

- BEETLE /M-II Plus: POS System For The Highest Standards of PerformanceDocument2 pagesBEETLE /M-II Plus: POS System For The Highest Standards of PerformanceHeather JensenNo ratings yet