Professional Documents

Culture Documents

Optimal Approach Autopilot Topologies

Uploaded by

JohnOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Optimal Approach Autopilot Topologies

Uploaded by

JohnCopyright:

Available Formats

See discussions, stats, and author profiles for this publication at: https://www.researchgate.

net/publication/303256153

Missile Longitudinal Autopilots: Connections Between Optimal Control and

Classical Topologies

Conference Paper · August 2005

CITATIONS READS

28 3,280

2 authors:

Curtis Mracek D. Ridgely

Non-affiliated Raytheon Technologies

24 PUBLICATIONS 1,275 CITATIONS 60 PUBLICATIONS 872 CITATIONS

SEE PROFILE SEE PROFILE

Some of the authors of this publication are also working on these related projects:

Missile Autopilots View project

Optimal Delivery Drone Collision Avoidance View project

All content following this page was uploaded by Curtis Mracek on 16 May 2016.

The user has requested enhancement of the downloaded file.

Missile Longitudinal Autopilots: Connections Between

Optimal Control and Classical Topologies

Curtis P. Mracek ∗ and D. Brett Ridgely †

Raytheon Missile Systems, Tucson, AZ 85734, USA

For several decades classical three loop autopilot topologies have been successfully employed as

missile longitudinal autopilots. This paper deals with the autopilot design process from an optimal

control perspective. The optimal control solution of the weighted sum of acceleration error and

control usage results in a two loop topology. The weighted sum of acceleration error and control

rate results in a three loop topology. A state transformation that leads to the “classic” autopilot 1

is presented. This paper then introduces what is termed a “neoclassic” topology. This topology

adds a fourth loop so that “all” rate and acceleration gains are used. The four loop topology

uses the same plant model as the three loop autopilots except that an added first order lag (which

can represent additional dynamics, such as a Control Actuation System (CAS)) is explicitly taken

into account using the additional gain. The four loop design reduces to the “classic” three loop

topology as the lag bandwidth becomes infinite. Two five loop topology are also introduced which

may be useful but one does not reduce to the superior robustness case as the CAS bandwidth is

increased.

I. Introduction

Longitudinal autopilots for tactical missiles have been successfully employed for over fifty years. In the

past several years, at Raytheon, the “classic” three loop autopilot (often dubbed the “Raytheon autopilot”1 )

has been the design topology of choice. The design goal of any autopilot is to use sensed quantities to

produce a stable response that robustly follows commanded inputs. The classic three loop autopilot has

the desired longitudinal acceleration as the command and the sensed acceleration and sensed angular rate

as the measured quantities. This paper deals with approaching the autopilot design process by looking

at the optimal control problem. It is found that solving the optimal control problem where the cost is a

weighted sum of the acceleration error and the fin deflection leads to a two loop controller. The optimal

control problem where the cost is the weighted sum of the acceleration error and the fin rates leads to a

three loop topology. Next, a “neoclassic” four loop autopilot is presented that has the same commanded

and sensed quantities as the three loop designs, but uses four gains instead of three. The adaptation for

a Linear Quadratic (LQ) design technique is developed which allows for the direct augmentation of a first

order dynamics model (to represent the CAS, IMU, delays, etc.) to the plant. Two five loop topologies are

also introduced which allows augmentation of a second order dynamics model to the system. The five loop

design requires either more than a single integration of the commanded acceleration or a first order lead. All

higher order designs result in either double integration of the acceleration command or the four loop design

with more and more complex lead systems. A longitudinal missile example is used throughout the paper to

clarify the discussion.

II. Missile Longitudinal Dynamics

A missile’s longitudinal dynamics can be described using the short period approximation of the longitu-

dinal equations of motion. Written in state space notation the basic missile longitudinal plant is

ẋ = Ax + Bu (1)

y = Cx + Du

∗ Engineering Fellow, Raytheon Missile Systems, Senior Member AIAA

† Senior Department Manager, Raytheon Missile Systems, Senior Member AIAA

1 of 29

American Institute of Aeronautics and Astronautics

where " # " #

α Azm

x= u = δp y=

q qm

To be more specific, the short period dynamics are

⎡ h i ⎤ ⎡ Q̄SCzδp ⎤

1 Q̄SCzα0

Vm0 m − AX0 1 mVm0

0

⎢ ⎥ ⎢ ⎥

A=⎢

⎣

⎥

⎦ B=⎢

⎣

⎥

⎦

Q̄SdCmα0 Q̄SdCmδp

IY Y 0 0

IY Y

⎡ Q̄SCzα0 Q̄SdCmα0 x̄

⎤ ⎡ Q̄SCzδp Q̄SdCmδp x̄ ⎤

mg − gIY Y 0 mg

0

− gIY Y

0

⎢ ⎥ ⎢ ⎥

C=⎣ ⎦ D=⎣ ⎦

0 1 0

The following numerical values will be used in the examples throughout this paper. Note that when Cmα0

is positive, the system is statically unstable, and stable when Cmα0 is negative.

Variable Value Units Description

Vm0 3350 ft/sec Total Missile Velocity

m 11.1 slug Total Missile Mass

IY Y 137.8 slug-ft2 Pitch Moment of Inertia

x̄ 1.2 ft Distance from CG to IMU Positive Forward

AX0 -60 ft/sec2 Axial Acceleration Positive Forward

Czα0 -5.5313 - Pitch Force Coefficient due to Angle of Attack

Cmα0 ±6.6013 - Pitch Moment Coefficient due to Angle of Attack

Czδp0 -1.2713 - Pitch Force Coefficient due to Fin Deflection

Cmδp0 -7.5368 - Pitch Moment Coefficient due to Fin Deflection

2

Q̄ 13332 lb/ft Dynamic Pressure

S 0.5454 ft2 Reference Area

d 0.8333 ft Reference Length

g 32.174 ft/sec2 Gravity Constant

For the unstable system this yields

⎡ ⎤ ⎡ ⎤

−1.064 1 −0.25

⎢ ⎥ ⎢ ⎥

A=⎣ ⎦ B=⎣ ⎦

290.26 0 −331.40

⎡ ⎤ ⎡ ⎤

−123.34 0 −13.51

⎢ ⎥ ⎢ ⎥

C=⎣ ⎦ D=⎣ ⎦

0 1 0

and the open loop transfer functions are

Azm −13.51s2 + 16.29s + 44800 −13.51(s + 56.98)(s − 58.18)

= =

δp s2 + 1.064s − 290.26 (s + 17.58)(s − 16.51)

and

qm −331.4s − 424.7 −331.4(s + 1.281)

= 2 =

δp s + 1.06s − 290.28 (s + 17.58)(s − 16.51)

This plant is a relatively fast unstable missile.

2 of 29

American Institute of Aeronautics and Astronautics

For the stable system the state space description is given by

⎡ ⎤ ⎡ ⎤

−1.064 1 −0.25

⎢ ⎥ ⎢ ⎥

A=⎣ ⎦ B=⎣ ⎦

−290.26 0 −331.39

⎡ ⎤ ⎡ ⎤

−101.71 0 −13.51

⎢ ⎥ ⎢ ⎥

C=⎣ ⎦ D=⎣ ⎦

0 1 0

and the open loop transfer functions are

Azm −13.51s2 + 10.91s + 29780 −13.51(s + 46.55)(s − 47.35)

= =

δp s2 + 1.064s + 290.26 (s + 0.53 ± 17.03j)

and

qm −331.4s − 280.3 −331.4(s + 0.846)

= 2 =

δp s + 1.064s + 290.26 (s + 0.53 ± 17.03j)

This plant is a relatively fast lightly damped stable missile. Both of these models conform to the sign

convention that a positive pitch fin deflection produces a negative moment.

III. Autopilot Development as an Optimal Control Problem

In this section, the design of the pitch autopilot will be set up as an LQR optimal control problem.

Several extensions to the “standard” LQR problem are required here, including feedforward terms in the

objective, output feedback, and tracking a step command. These will all be dealt with in the following

subsections. As a quick refresher and to establish notation, the “standard” LQR problem is4

Z ∞

¡ T ¢

min J = z Qz + uT Ru dt

u 0

subject to the dynamics

ẋ = Ax + Bu

z = Hx

with (A, B) stabilizable, (H, A) detectable, Q ≥ 0 and R > 0. The optimal state feedback is given by

u = Kx

where

K = −R−1 B T P

and P is the positive semidefinite stabilizing solution to the algebraic Riccati equation

0 = AT P + P A − P BR−1 B T P + H T QH

A. LQ State Feedback with Feedthrough Term in Objective

The solution of the linear quadratic optimal control problem with a feedthrough term in the optimization

objective is derived in this section. The optimization objective is given as

Z ∞³ ´

min J = z T Q̃z + uT R̃u dt

u 0

s.t. ẋ = Ax + Bu

z = Hx + Lu

3 of 29

American Institute of Aeronautics and Astronautics

Substituting z into the performance index yields

Z ∞h i

min J = (Hx + Lu)T Q̃ (Hx + Lu) + uT R̃u dt

u 0

Let

Q = H T Q̃H

S = H T Q̃L

R = R̃ + LT Q̃L

then the performance index becomes

Z ∞ ¡ T ¢

min J = x Qx + xT Su + uT S T x + uT Ru dt

u 0

This optimal control problem can be solved by forming the Hamiltonian

µ ∗ ¶T

T T T T T ∂J

H = x Qx + x Su + u S x + u Ru + [Ax + Bu]

∂x

Taking the partial of the Hamiltonian with respect to the control and setting this to zero. This results in

µ ∗¶

∂H T T ∂J

= 2S x + 2Ru + B =0

∂u ∂x

so that

∙ µ ¶ ¸

∗ −1 1 T ∂J ∗ T

u = −R B +S x

2 ∂x

The Hamilton-Jacobi equation then becomes

µ ¶T

∂J ∗ ∗ T

¡ −1 T

¢ ∂J ∗

− = H =x Q − SR S x+ Ax

∂t ∂x

µ ¶T µ ¶ µ ¶

1 ∂J ∗ −1 T ∂J ∗ T −1 T ∂J ∗

− BR B − x SR B

4 ∂x ∂x ∂x

Assume the optimal performance index has the form

J ∗ = xT P x

so that

∂J ∗ ∂J ∗

= xT Ṗ x = 2P x

∂t ∂x

Substituting these in the Hamilton-Jacobi equation and rearranging terms we get

£ ¡ ¢¤

−xT Ṗ x = xT (A − BR−1 S T )T P + P (A − BR−1 S T ) − P BR−1 B T P + Q − SR−1 S T x

Since this is an infinite horizon problem, it is easy to show that Ṗ −→ 0, so that we have the algebraic

Riccati equation

¡ ¢

(A − BR−1 S T )T P + P (A − BR−1 S T ) − P BR−1 B T P + Q − SR−1 S T = 0 (2)

where we also require that

Q − SR−1 S T ≥ 0

and the optimal control is given by

¡ ¢

u∗ = Kx = −R−1 B T P + S T x

where P is the stabilizing solution of Equation 2.

4 of 29

American Institute of Aeronautics and Astronautics

B. Optimal Solution with Full State Observability

Next we will deal with the problem that the full state is not available for feedback in a missile control

£ ¤−1

problem. Define “full state observability” as requiring that C −1 and I + KC −1 D exist. Then any state

feedback optimal solution can be transformed to output feedback given the system is full state observable.

That is, given the state feedback solution

u = Kx

and the output relation

y = Cx + Du

−1

with C existing, it is easy to see that

x = C −1 (y − Du)

The optimal control is then

u = KC −1 (y − Du)

£ ¤−1

Solving for the control using the assumption that I + KC −1 D exists results in

£ ¤−1

u = I + KC −1 D KC −1 y

which is now an output feedback law. Clearly, if D = 0, the requirement to transform a state feedback

solution to output feedback reduces to requiring C −1 to exist, as this becomes a state transformation.

C. Regulator Problem

The autopilot, at its most basic, is trying to control the airframe while regulating/tracking an acceleration.

So let’s try to set up an optimization problem to find the “best” control. We will begin with the regulation

problem. The obvious optimization objective would be to use a weighted sum of the measured acceleration

and the control usage. If there is no penalty on control usage the optimal controller would be bang-bang or

singular control. A reasonable cost would thus be something like

Z ∞ Z ∞

¡ T ¢ ¡ ¢

min J = z Qz + uT Ru dt = Q11 A2zm + R11 δ 2p dt (3)

δp 0 0

where

z = Azm = Hx + Lu = C11 α + D11 δ p

Using the results of the previous subsections, this optimal control problem can be written as

Z ∞

¡ T ¢

min J = x Qx + 2xT Su + uT Ru dt

δp 0

where " # " #

2

Q11 C11 0 Q11 C11 D11 ¡ 2

¢

Q= S= R = Q11 D11 + R11

0 0 0

As previously shown, the optimal solution is

uopt = (I + Kopt C −1 D)−1 Kopt C −1 y (4)

¡ ¢

where Kopt = −R−1 B T P + S T and P is the stabilizing solution to

¡ ¢

(A − BR−1 S T )T P + P (A − BR−1 S T ) − P BR−1 B T P + Q − SR−1 S T = 0

5 of 29

American Institute of Aeronautics and Astronautics

D. Tracking Solution

Now let’s turn our attention to the tracking problem. Here, we will define tracking as following a step

command input, so that this is a set point regulator. The obvious optimization objective would be to use

a weighted sum of the square of the error between the measured acceleration and the command, along with

the control usage. In the tracking problem we will minimize the cost function

Z ∞h i

min J = Q11 (Azm − Kss Azc )2 + R11 δ 2p dt

δp 0

s.t. ẋ = Ax + Bu

y = Cx + Du − K̃ss r

" #

Kss

K̃ss =

0

Note that a Kss term is included on the command to ensure a zero steady-state error to a step. The general

statement of the problem is

Z ∞h i

T

min J = (z − Kss r) Q (z − Kss r) + uT Ru dt

u 0

Let

z̃ = z − zss = z − Kss r

Given this, the problem is equivalent to the regulator problem

Z ∞ ¡ T ¢

min J = z̃ Qz̃ + uT Ru dt

u 0

s.t. ẋ = Ax + Bu

y = Cx + Du − K̃ss r

z̃ = Hx + Lu − Kss r

Let’s turn to the determination of the steady state gain such that the command is followed. The optimal

control can be written as

" #

Azm − Kss Azc

u = Kopt

qm

" #

Hx + Lu − Kss Azc

= Kopt

qm

" #

Kss Azc

= Kopt [Cx + Du] − Kopt

0

Thus the control is " " ##

−1 Kss Azc

u = [I − Kopt D] Kopt Cx −

0

The closed loop system can be written as

ẋc = Ac xc + Bc Azc

Az = Cc xc + Dc Azc

6 of 29

American Institute of Aeronautics and Astronautics

5

Control (deg)

2

−1

0 0.1 0.2 0.3 0.4 0.5

Time (sec)

Figure 1. Optimal Control for the Tracking Problem

where

Ac = A + B [I − Kopt D]−1 Kopt C

" #

−1 Kss

Bc = −B [I − Kopt D] Kopt = −Bc0 Kss

0

−1

Cc = H + L [I − Kopt D]Kopt C

" #

−1 Kss

Dc = −L [I − Kopt D] Kopt = −Dc0 Kss

0

and

" #

−1 1

Bc0 = B [I − Kopt D] Kopt

0

" #

−1 1

Dc0 = L [I − Kopt D] Kopt

0

In order to insure zero steady state error

Az

lim = 1

s→0 Azc

= −Cc A−1

c Bc + Dc

£ ¤

= Cc Ac Bc − Dc0 Kss

−1 0

Therefore £ ¤

0 −1

Kss = Cc A−1 0

c Bc − Dc

The unstable plant example with the initial conditions equal to zero and a command of 1g applied at

t = 0.1 sec is used, with the weights chosen as Q11 = 2.0 and R11 = 1.0. The optimal gains are the same as

for the regulator problem. The closed loop optimal solution is shown in Figures 1 and 2.

The closed loop optimal control law is

" #

h i A −K A

zm ss zc

uopt = −0.0395 0.1568

qm

7 of 29

American Institute of Aeronautics and Astronautics

1

0.8

0.6

0.4

Acceleration (g)

0.2

−0.2

−0.4

−0.6

−0.8

−1

0 0.1 0.2 0.3 0.4 0.5

Time (sec)

Figure 2. Optimal Step Response for the Tracking Problem

Azc + ²¯ + ²¯ δ p

±° ±°

- Kss -@¡ - KAz -@¡ -

¡

@ ¡

@

− 6 + 6

Azm

Kq

6

qm

Figure 3. Two Loop Autopilot Topology

For this example, Kss = 0.8735. The two loop topology is shown in Figure 3.

The sign convention needs to be addressed. The sign convention used is such that the feedback gains

are usually positive. In all cases the controller is defined, including the sign of the feedback term, before

the gains are presented. This is the convention used in all the topology figures throughout this paper. The

solution to the optimal control problem assumes a positive feedback and the signs on the individual gains

can be negative or positive. With that said, the gains for the example problem as shown in Figure 3 are

⎡ ⎤ ⎡ ⎤

Kss 0.8735

⎢ ⎥ ⎢ ⎥

⎣ KAz ⎦ = ⎣ 0.0395 ⎦

Kq 0.1568

Clearly, no integrator is needed in the optimal solution and the regulation problem solves the tracker

problem. It should be noted that there is a large, almost instantaneous non-minimum phase response. The

large undershoot (the same magnitude as the command) is caused by having the system capable of infinite

rate while moving the fin. Note: a canard controlled missile will not have the problem of moving in the

wrong direction and the two state system minimizing the weighted integral of the acceleration error and

control deflection may well be the way to pose the autopilot design problem. However, it seems likely the

8 of 29

American Institute of Aeronautics and Astronautics

Two State Open Loop Magnitude

20

15

10

Magnitude (dB)

5

−5

−10

−1 0 1 2

10 10 10 10

Frequency (Hz)

Figure 4. Two State Open Loop Magnitude

canard controlled missile will have a different problem in that Control Actuation System (CAS) dynamics

will have to be included so that the command doesn’t produce an instantaneous response at the commanded

G level for high values of the acceleration error weighting. In other words, it is easy to make over-responsive

solutions for canard controlled missiles that will be susceptible to noise and unmodeled dynamics. The

weight on the acceleration error must be small enough so that there is a delay in achieving the desired G

level. It is interesting to note that for non-minimum phase systems there is a limit as to how fast the system

will respond with this cost function. The value of Q11 for this example is 2, but a value of 1000 gives about

the same gains. It seems that once the initial response is equal to the command, the limit on the speed of

response using this optimal control problem is defined. For minimum phase systems this is not the case.

Now let’s look at the open loop Bode plot of the optimal system of the example. The loop will be broken

at the input to the plant. This will give a measure of robustness. Writing the plant as a transfer function

instead of in state space, the plant is

Azm N Az

= δ

δp ∆

and

qm Nq

= δ

δp ∆

The open loop transfer function is

δ out Kq Nδq − KAz NδAz

=

δ in ∆

For the example this transfer function is

δ out 0.5334s2 − 52.6178s − 1835

=

δ in s2 + 1.06s − 290.26

The Bode Plots are shown in Figures 4 and 5. The optimal solution has a crossover frequency of about 12

Hz. Notice how the phase starts at −180 degrees because it is non-minimum phase.

IV. Penalizing the Control Rate — Three Loop Topologies

Since the previous setup required infinite control rate we could penalize the control rate instead of the

control deflection. The cost function would then be

Z ∞³ ´

2

min J = Q11 A2zm + R11 δ̇ p dt

δ̇p 0

9 of 29

American Institute of Aeronautics and Astronautics

Two State Open Loop Phase

−120

−130

−140

−150

Phase (deg)

−160

−170

−180

−190

−200

−1 0 1 2

10 10 10 10

Frequency (Hz)

Figure 5. Two State Open Loop Phase

Therefore, we need the control rate as the input to the system. We can augment the dynamic system with

the additional differential equation

δ̇ p = u

and add the control as a state. The regulator problem is then

Z ∞³ ´

2

min J = Q11 A2zm + R11 δ̇ p dt

δ̇ p 0

s.t. ẋa = Aa xa + Ba ua

y = Ca xa + Da ua

z = Ha xa + La ua

The actual determination of the gains was made using

Qa = HaT Q11 Ha Ra = R

The actual MATLAB call is

[P, eigAcl, −Kopt ] = care(Aa , Ba , Qa , Ra )

We will also switch to a tracking problem at this point, since we know it has the same solution as the

regulator problem. Thus, we wish to solve

Z ∞h i

2 2

min J = Q11 (Azm − Kss Azc ) + R11 δ̇ p dt (5)

δ̇ p 0

s.t. ẋ = Ax + Bu

y = Cx + Du − K̃ss r

We need an additional measurement if we don’t want to create an estimator, so let’s assume the control

deflection is indeed measurable. The system would then become

ẋ1 = A1 x1 + B1 u1

y1 = C1 x1 + D1 u1 − K̃ss r

z = H1 x1 + L1 u1 − Kss r

where

10 of 29

American Institute of Aeronautics and Astronautics

⎡ ⎤ ⎡ ⎤

α Azm − Kss r

⎢ ⎥ ⎢ ⎥

x1 = ⎣ q ⎦ u1 = δ̇ p y1 = ⎣ qm ⎦

δp δp

and

" # " # " #

A B [0] Kss

A1 = B1 = K̃ss =

[0] 0 1 [0]

" # " #

C D [0]

C1 = D1 = H1 = C1 (1, :) L1 = [0]

[0] 1 0

A note on the notation; [0] denotes a zero matrix of the proper dimensions and x() is the notation used by

MATLAB to designate portions of a larger matrix. For example C1 (1, :) is the first row of the C1 matrix.

Since the plant is strictly proper the optimal solution can be found using the coordinate transform

x2 = C1 x1 = y1

so that the dynamic system is

C1−1 ẋ2 = A1 C1−1 x2 + B1 u

y = x2

or

ẋ2 = C1 A1 C1−1 x2 + C1 B1 u

y = x2

The optimal gains can be found using

[P, eigAcl, −Kopt ] = care(C1 A1 C1−1 , C1 B1 , Q2 , R2 )

where ¡ ¢T

Q2 = C1−1 H1T Q11 H1 C1−1 R2 = R11

The optimal tracking solution is

⎡ ⎤

h i Azm − Kss Azc

⎢ ⎥

uopt = −2.0740 11.7514 −119.0269 ⎣ qm ⎦

δp

Following the previous derivation the steady state gain can be determined from the same equations that

have been transformed into the new variables with D1 = L1 = 0. Let

¡ ¢

Ac = C1 A1 C1−1 + B1 Kopt

⎡ ⎤

Kss

⎢ ⎥

Bc = −C1 B1 Kopt ⎣ 0 ⎦ = −Bc0 Kss

0

Cc = H1 C1−1

and ⎤ ⎡

1

⎢ ⎥

Bc0 = C1 B1 Kopt ⎣ 0 ⎦

0

11 of 29

American Institute of Aeronautics and Astronautics

100

80

60

Control (deg/sec)

40

20

−20

−40

0 0.1 0.2 0.3 0.4 0.5

Time(sec)

Figure 6. Control Rate Usage

In order to insure zero steady state error

Az

lim = 1

s→0 Azc

= −Cc A−1

c Bc

£ −1 0

¤

= Cc Ac Bc Kss

Therefore £ ¤

0 −1

Kss = Cc A−1

c Bc

For this example Kss = 0.6819. The results of the feedback simulation are presented in Figures 6 and 7.

For this set up, the plant is now strictly proper and there are three states. Since the control rate is

penalized the non-minimum phase behavior is not as pronounced as in the original set up. This is because

direct feed through of the acceleration command to the actuator is not allowed. Since

δ̇ p = uopt

we can solve for the control deflection by substitution. The optimal control results in a first order dynamic

equation in δ p . The fin command could be written as

" #

119.0269 h i A −K A

zm ss zc

δp = −0.0174 0.0987

s + 119.0269 qm

As can be seen the gains are less for this solution than the two state problem. Actually the gains and the

response approach the solution to the first problem as the weight on the acceleration state is made large,

but the solution cannot reach the previous solution time response because of the restriction on the direct

feed through of the command which results in a pure lag that gets faster and faster but never goes away.

At this point, two different optimal control problems have been identified as potential problem statements

for autopilot design. The difference is not in how the state weight enters the cost function but instead the

variable used for the control weighting. The first formulation uses the fin deflection, the second uses the fin

rate. The first formulation leads to a direct feed through of the acceleration command into the plant and

since there is a “D” term in the plant, the acceleration response, for a tail controlled missile, instantly jumps

in the wrong direction at the start of the step response. These are two loop topologies, as they have two

feedback gains. The second approach does not allow the direct feed through of the command into the plant.

This is accomplished by augmenting an integrator to the system. This approach results in a slower response

12 of 29

American Institute of Aeronautics and Astronautics

1.5

Acceleration (g)

0.5

−0.5

0 0.1 0.2 0.3 0.4 0.5

Time(sec)

Figure 7. Acceleration Response to a Step Input

than the first, and is called a three loop topology, as it has three feedback gains. In general, it is much

more practical for missile autopilot design, and therefore we will examine it more closely. In the follow-on

paper by Mracek and Ridgely,3 we will look at all possible three loop topologies, given the performance

index defined thus far.

A. LQR Transformation of the Three Loop Topology

Now let’s try to solve the problem slightly differently. In the example of Section 4, we made the three loop

controller look more like a two loop controller by assuming the control deflection was not available, and using

a filter instead. Note that this is still a three loop topology, however, as the command is filtered. Let’s try

to find a coordinate transformation so that we don’t need the filter in the problem formulation. Following

Adams and Conrardy,2 the dynamic system is

ẋ = Ax + Bu

y = Cx + Du − K̃ss r

where " # " #

α Azm − Kss Azc

x= u = δp y=

q qm

and " #

Kss

K̃ss =

0

The states are augmented with the control, the control is replaced with the derivative of the control and the

output is augmented with the derivative of the angular rate. Notice that no new information is introduced

into the plant. The additional dynamic equation is the identity δ̇p = u1 = δ̇p. The only impact is that a

pole is introduced at the origin. The plant is rewritten as

ẋ1 = A1 x1 + B1 u1 (6)

y1 = C1 x1 + D1 u1 − K̃ss1 r

z̃1 = H1 x1 + L1 u1 − Kss r

13 of 29

American Institute of Aeronautics and Astronautics

where ⎡ ⎤ ⎡ ⎤ ⎡ ⎤

α Azm − Kss Azc Kss

⎢ ⎥ ⎢ ⎥ ⎢ ⎥

x1 = ⎣ q ⎦ u1 = δ̇ p y1 = ⎣ qm ⎦ K̃ss1 =⎣ 0 ⎦

δp q̇m 0

Using the aforementioned notation, the transformation is

" # " #

A B [0]

A1 = B1 =

[0] 0 1

" # " #

C D [0]

C1 = D1 =

A(2, :) B(2, :) 0

The state transformation x1 = C1−1 y1 can now be used. The transformed plant is

ẋ2 = A2 x2 + B2 u2

y2 = x2

where ⎤ ⎡

Azm

⎢ ⎥

x2 = ⎣ qm ⎦ u2 = δ̇ p

q̇m

and

A2 = C1 A1 C1−1 B2 = C1 B1

Now we can set up the cost function

Z ∞ h i

2

min J = Q11 (Azm − Kss Azc )2 + R11 δ̇ p dt

δ̇p 0

so that

H1 = C1 (1, :) L1 = [0]

The LQR solution can now be determined in a straightforward manner. The gains are found through

[P, eigAcl, −Kopt ] = care(A2 , B2 , Q2 , R2 )

where ¡ ¢T

Q2 = C1−1 H1T Q11 H1 C1−1 R2 = R11

The control law is ⎡ ⎤

Azm − Kss Azc

⎢ ⎥

uopt = Kopt ⎣ qm ⎦ = δ̇ p (7)

q̇m

where Kss is determined from

£ ¤

0 −1

Kss = Cc A−1

c Bc

where

Ac = A2 + B2 Kopt

⎡ ⎤ ⎤ ⎡

Kss 1

⎢ ⎥ ⎢ ⎥

Bc = −B2 Kopt ⎣ 0 ⎦ = −Bc0 Kss where Bc0 = B2 Kopt ⎣ 0 ⎦

0 0

Cc = H1 C1−1

14 of 29

American Institute of Aeronautics and Astronautics

1.5

Acceleration (g)

0.5

−0.5

0 0.1 0.2 0.3 0.4 0.5

Time(sec)

Figure 8. Closed Loop Step Response

Using these equations with the unstable plant and the values used for Q11 and R11 thus far results in

h i

Kopt = −1.3028 11.7514 0.3277 Kss = 1.0855

Notice how this approach has as the cost function a weighting on the acceleration error and the control rate,

just as in the example in Section 4 above.

In the current setup, q̇m is not measurable. Notice that the optimal control u2 is actually δ̇ p , so if we

simply integrate both sides of Equation 7 since we have a linear system, the control δ p would be (assuming

constant gains at the design point)

⎡ Z ⎤ ⎡ Z ⎤

(Azm − Kss Azc ) dt (Azm − Kss Azc ) dt

⎢ ⎥ ⎢ ⎥

δ p = Kopt ⎢ R ⎥ = Kopt ⎢ R ⎥

⎣ q dt ⎦ ⎣ qm dt ⎦

R m

q̇m dt qm

This formulation results in the so called classic three loop autopilot. The closed loop step response using

this formulation is presented in Figure 8, which is identical to Figure 7.

The classical three loop topology is presented in Figure 9. The optimal controller is given by

- @n - KIA - @n - @n

Azc + + R + δp

- Kss - -

¡ z ¡ ¡

− 6 + 6 + 6

Azm

Kθ Kq

qm 6 6

Figure 9. Classic Three Loop Topology

KIAZ = 1.3028 Kθ = 11.7514 Kq = 0.3277 Kss = 1.0855

15 of 29

American Institute of Aeronautics and Astronautics

n- K̂ n - n n

Azc + + R + + δ pc

- K̂ -@¡ -@¡ -@¡ -@¡ -

ss IAz

− 6 + 6 + 6 + 6

K̂θ K̂Az

Azm 6 6

K̂q

qm 6

Figure 10. Four Loop Autopilot Topology

Clearly, since we know our plant, we could reconstruct the angular acceleration in terms of Azm , qm , and

δ p and we would find that the optimal control would be exactly the same as we found previously. We will

see this is a general result (same closed loop system), but there are definite differences between the two

nonetheless.

The question then is which of the topologies are “better”? The closed loop responses are identical.

However, the feedback mechanisms are different and therefore the open loop properties will be different.

This means that different topologies will have different robustness properties for a given level of performance.

This is examined in a follow-on paper.3

V. Neoclassic Four Loop Topology

The neoclassic four loop topology is shown in Figure 10. From this figure we see that the control law

is given by Z h i

δ pc = K̂IAz (K̂ss Azc − Azm ) + K̂θ qm dt + K̂Az Azm + K̂q qm

or with constant gains

Z Z Z

δ pc = K̂IAz K̂ss Azc dt − K̂IAz Azm dt + K̂Az Azm + K̂θ qm dt + K̂q qm

The feedback portion of the neoclassic four loop autopilot is proportional plus integral on the angular rate

and proportional plus integral on the linear acceleration. Again the acceleration command enters the system

through an integrator. Clearly, setting K̂IAz = KIAz , K̂θ = Kθ , K̂q = Kq , K̂ss = Kss and K̂Az = 0,

results in the neoclassic design reducing to the classic three loop design. The addition of the K̂Az gain gives

added design flexibility without compromising the original design philosophy.

Now let’s take a close look at the neoclassic four loop autopilot. Introduce a first order lag into the

system that captures relevant unmodeled dynamics (we will tend to refer to these as CAS dynamics, but

they can be general unmodeled dynamics reflected to the input of the plant). In other words, let

δ̇ p = τ (δ pc − δ p )

Now let the states be augmented with the fin position and fin command, and the control be set to the

derivative of the fin command. The output is the derivative of the linear acceleration, the derivative of the

angular rate, the linear acceleration and the angular rate. The new state space representation is

ẋ1 = A1 x1 + B1 u1 (8)

y1 = C1 x1 + D1 u1 − K̃ss2 r

16 of 29

American Institute of Aeronautics and Astronautics

where ⎡ ⎤ ⎡ ⎤ ⎡ ⎤

α Azm − Kss r Kss

⎢ ⎥ ⎢ ⎥ ⎢ ⎥

⎢ q ⎥ ⎢ qm ⎥ ⎢ 0 ⎥

x1 = ⎢ ⎥ u1 = δ̇ pc y1 = ⎢ ⎥ K̃ss2 = ⎢ ⎥

⎣ δp ⎦ ⎣ Ȧzm ⎦ ⎣ 0 ⎦

δ pc q̇m 0

The new plant is ⎡ ⎤ ⎡ ⎤

A B [0] [0]

⎢ ⎥ ⎢ ⎥

A1 = ⎣ [0] −τ τ ⎦ B1 = ⎣ 0 ⎦

[0] 0 0 1

The output can be determined from " #

Ȧzm

= C ẋ + Dδ̇ p

q̇m

where

δ̇ p = τ (δ pc − δ p )

The output equations are then

" # " #

C D [0] [0]

C1 = D1 =

CA CB − Dτ Dτ [0]

Again the system is strictly proper, but this time additional dynamics are included in the plant model.

Following the development of Section IV.A, we will minimize the performance index

Z ∞h i

2 2

min J = Q11 (Azm − Kss Azc ) + R11 δ̇ pc dt

δ̇pc 0

The optimal LQR problem can be solved directly, and the control is

⎡ Z ⎤

− (Azm − Kss Azc ) dt

⎢ R ⎥

⎢ ⎥

δ pc = K ⎢

⎢

qm dt ⎥

⎥

⎣ Azm ⎦

qm

where ⎡ ⎤ ⎡ ⎤

KIAz 1.2241

⎢ ⎥ ⎢ ⎥

⎢ Kθ ⎥ ⎢ 20.0583 ⎥

K=⎢ ⎥=⎢ ⎥

⎣ KAz ⎦ ⎣ 0.0524 ⎦

Kq 0.4182

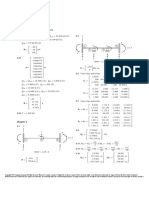

and Kss = 1.1553 for τ = 20Hz, Q11 = 2 and R11 = 1. This topology can now be examined. First, the

frequency of the additional first order dynamics is varied and the optimal gains are computed. It is shown

in Figure 11 that all four gains go to the classic three loop topology gain values as the frequency becomes

large.

Next, closed-loop step responses for four different CAS frequencies were examined, as seen in Figure 12.

These are plotted against the responses of the 3-loop optimal gains with the CAS dynamics present in the

system (indicating robustness of the 3-loop design to the CAS dynamics). Note that, as expected, the 4-loop

designs are very robust to the CAS dynamics, as they are designed with explicit knowledge of the dynamics.

The 3-loop designs start to suffer badly as the CAS dynamics approach the bandwidth of the system.

Finally, we will examine the robustness of the 4-loop controller versus the 3-loop controller at the input

and output of the plant and to plant variations when various CAS dynamics are present in the system.

Figure 13 shows the vector margin (margin defined from nearness to the critical point on the Nyquist plot

σ0 = min |1 + L(jω)|

ω

17 of 29

American Institute of Aeronautics and Astronautics

Integral Acceleration Gain KIAz Integral Rate Gain KTheta

1.35 30

3 Loop 3 Loop

4 Loop 4 Loop

1.3 25

Gain

Gain

1.25 20

1.2 15

1.15 10

1 2 3 4 1 2 3 4

10 10 10 10 10 10 10 10

CAS Frequency (Hz) CAS Frequency (Hz)

Acceleration Gain KAz Rate Gain Kq

0.5

3 Loop 3 Loop

4 Loop 4 Loop

0.45

0.1

Gain

Gain

0.4

0.05

0.35

0

0.3

1 2 3 4 1 2 3 4

10 10 10 10 10 10 10 10

CAS Frequency (Hz) CAS Frequency (Hz)

Figure 11. Gain Variation in the 4 Loop Topology with CAS Frequency

Robustness Test with CAS Dynamics, 10 Hz CAS Robustness Test with CAS Dynamics, 20 Hz CAS

1.5 1.5

3 Loop 3 Loop

4 Loop 4 Loop

1 1

Acceleration (G)

Acceleration (G)

0.5 0.5

0 0

−0.5 −0.5

0 0.2 0.4 0.6 0.8 1 0 0.2 0.4 0.6 0.8 1

Time (sec) Time (sec)

Robustness Test with CAS Dynamics, 50 Hz CAS Robustness Test with CAS Dynamics, 100 Hz CAS

1.5 1.5

3 Loop 3 Loop

4 Loop 4 Loop

1 1

Acceleration (G)

Acceleration (G)

0.5 0.5

0 0

−0.5 −0.5

0 0.2 0.4 0.6 0.8 1 0 0.2 0.4 0.6 0.8 1

Time (sec) Time (sec)

Figure 12. Step Responses for the 3 and 4 Loop Controllers with CAS Dynamics Present

18 of 29

American Institute of Aeronautics and Astronautics

Input Sensitivity, 10 Hz CAS Input Sensitivity, 20 Hz CAS

1 1

0.8 0.8

Vector Margin

Vector Margin

0.6 0.6

0.4 0.4

0.2 0.2

0 3 Loop 0 3 Loop

4 Loop 4 Loop

−0.2 −0.2

0 100 200 300 0 100 200 300

Time Constant (msec) Time Constant (msec)

Input Sensitivity, 50 Hz CAS Input Sensitivity, 100 Hz CAS

1 1

0.8 0.8

Vector Margin

Vector Margin

0.6 0.6

0.4 0.4

0.2 0.2

0 3 Loop 0 3 Loop

4 Loop 4 Loop

−0.2 −0.2

0 100 200 300 0 100 200 300

Time Constant (msec) Time Constant (msec)

Figure 13. Vector Margin at the Plant Input for the 3- vs. 4-Loop Topology with Various CAS Dynamics

where L(jω) is the loop transfer function) broken at the input to the plant plotted against rise time (various

choices of Q11 ) for various CAS frequencies. Note that the CAS dynamics “eat up” some of the ideal margin

of 1.0 in the 4-loop topology, and this is worse as the CAS frequency becomes lower. Plant uncertainties

are examined in Figure 14. Again, the CAS dynamics tend to “eat up” much of the robustness to plant

variations in the 3-loop system, and this effect is worse as the CAS frequency gets lower. For the actual

method of determining the robustness to plant variations see Mracek and Ridgely.3

The results with the loops broken at the rate sensor and the accelerometer are shown in Figures 15 and

16, respectively. These show some very interesting results. In general, for slower systems (larger rise times)

the 3-loop topology is “more robust” to output uncertainties than the 4-loop system. This is because the

4-loop topology is optimized for what looks like an input uncertainty, and must therefore give up something

at the output. In general, the uncertainties at the output of the system are at higher frequencies than those

at the input, so the uncertainty at the output will tend to be smaller over frequencies of interest. The

designer would have to adjust this trade as appropriate for the particular system in question. In particular,

this definitely implies that the margins at the output of the plant should be examined. Overall, the 4-loop

topology looks very promising and further studies on this topology are warranted.

VI. Higher Order Dynamics

What if we include higher order dynamics in our model? Let’s assume the unmodeled dynamics are such

that

δ̈ p = −(τ 1 + τ 2 )δ̇ p + τ 1 τ 2 (δ pc − δ p )

Then let the plant states be augmented with the fin position, the fin rate and fin command and let the

control be set to the derivative of the fin command. The outputs are the linear acceleration and the angular

rate, the first derivative of the angular rate and the linear acceleration, the second derivative of the angular

rate and the linear acceleration, and the fin command. We will not use all of these outputs, as seen shortly.

19 of 29

American Institute of Aeronautics and Astronautics

Plant Sensitivity, 10 Hz CAS Plant Sensitivity, 20 Hz CAS

1 1

3 Loop 3 Loop

4 Loop 4 Loop

0.8 0.8

Vector Margin

Vector Margin

0.6 0.6

0.4 0.4

0.2 0.2

0 0

0 10 20 30 40 50 0 10 20 30 40 50

Delta Perturbation (%) Delta Perturbation (%)

Plant Sensitivity, 50 Hz CAS Plant Sensitivity, 100 Hz CAS

1 1

3 Loop 3 Loop

4 Loop 4 Loop

0.8 0.8

Vector Margin

Vector Margin

0.6 0.6

0.4 0.4

0.2 0.2

0 0

0 10 20 30 40 50 0 10 20 30 40 50

Delta Perturbation (%) Delta Perturbation (%)

Figure 14. Vector Margin at the Plant Input with Different Plant Uncertainties 3- vs. 4-Loop Topology with

Various CAS Dynamics

Output Sensitivity − Rate, 10 Hz CAS Output Sensitivity − Rate, 20 Hz CAS

1 1

0.8 0.8

Vector Margin

Vector Margin

0.6 0.6

0.4 0.4

0.2 0.2

0 3 Loop 0 3 Loop

4 Loop 4 Loop

−0.2 −0.2

0 100 200 300 0 100 200 300

Time Constant (msec) Time Constant (msec)

Output Sensitivity − Rate, 50 Hz CAS Output Sensitivity − Rate, 100 Hz CAS

1 1

0.8 0.8

Vector Margin

Vector Margin

0.6 0.6

0.4 0.4

0.2 0.2

0 3 Loop 0 3 Loop

4 Loop 4 Loop

−0.2 −0.2

0 100 200 300 0 100 200 300

Time Constant (msec) Time Constant (msec)

Figure 15. Vector Margin at the Rate Output for the 3- vs. 4-Loop Topology with Various CAS Dynamics

20 of 29

American Institute of Aeronautics and Astronautics

Output Sensitivity − Accel, 10 Hz CAS Output Sensitivity − Accel, 20 Hz CAS

1 1

0.8 0.8

Vector Margin

Vector Margin

0.6 0.6

0.4 0.4

0.2 0.2

0 3 Loop 0 3 Loop

4 Loop 4 Loop

−0.2 −0.2

0 100 200 300 0 100 200 300

Time Constant (msec) Time Constant (msec)

Output Sensitivity − Accel, 50 Hz CAS Output Sensitivity − Accel, 100 Hz CAS

1 1

0.8 0.8

Vector Margin

Vector Margin

0.6 0.6

0.4 0.4

0.2 0.2

0 3 Loop 0 3 Loop

4 Loop 4 Loop

−0.2 −0.2

0 100 200 300 0 100 200 300

Time Constant (msec) Time Constant (msec)

Figure 16. Vector Margin at the Accelerometer Output for the 3- vs. 4-Loop Topology with Various CAS

Dynamics

The new state space representation is

ẋ1 = A1 x1 + B1 u1

ȳ = C̄x1 + D̄u1 − K̃ss3 r

where ⎡ ⎤ ⎡ ⎤

Azm − Kss r Kss

⎡ ⎤ ⎢ ⎥ ⎢ ⎥

α ⎢ qm ⎥ ⎢ 0 ⎥

⎢ ⎥ ⎢ ⎥ ⎢ ⎥

⎢ q ⎥ ⎢ Ȧzm ⎥ ⎢ 0 ⎥

⎢ ⎥ ⎢ ⎥ ⎢ ⎥

x1 = ⎢ δp ⎥ u1 = δ̇ pc ȳ = ⎢

⎢ q̇m ⎥

⎥ K̃ss3 =⎢

⎢ 0 ⎥

⎥

⎢ ⎥ ⎢ ⎥ ⎢ ⎥

⎣ δ̇ p ⎦ ⎢ Äzm ⎥ ⎢ 0 ⎥

⎢ ⎥ ⎢ ⎥

δ pc ⎣ q̈m ⎦ ⎣ 0 ⎦

δ pc 0

The state space matrices are then

⎡ ⎤ ⎡ ⎤

A B [0] [0] [0]

⎢ ⎥ ⎢ ⎥

⎢ [0] 0 1 0 ⎥ ⎢ 0 ⎥

A1 = ⎢ ⎥ B1 = ⎢ ⎥

⎣ [0] −τ 1 τ 2 −(τ 1 + τ 2 ) τ 1 τ 2 ⎦ ⎣ 0 ⎦

[0] 0 0 0 1

⎡ ⎤ ⎡ ⎤

C D [0] [0] [0]

⎢ CA CB D [0] ⎥ ⎢ [0] ⎥

⎢ ⎥ ⎢ ⎥

⎢ ⎥ ⎢ ⎥

C̄ = ⎢ − − − − − − − −− − − − − −− −−− ⎥ D̄ = ⎢ −− ⎥

⎢ ⎥ ⎢ ⎥

⎣ CA2 CAB − τ 1 τ 2 D CB − (τ 1 + τ 2 )D τ 1τ 2D ⎦ ⎣ [0] ⎦

[0] 0 0 1 0

21 of 29

American Institute of Aeronautics and Astronautics

- @n- KIAz - @n - @n - - @n -@n -pc

Azc + + + R + + δ

- Kss

¡ ¡ ¡ ¡ ¡

− 6 + 6 − 6 + 6 + 6

Kθ KIδ KAz

Azm 6 6 6

Kq

qm 6

δ pc

Figure 17. Five Loop Autopilot Topology

We only want 5 outputs, since we only have 5 states and we want C1 to be invertible. Above the dashed

lines in C̄ and D̄ represents 4 outputs we must keep, so that we need to choose 1 from the 3 below. We

cannot choose q̈m , since its D term is zero and that will leave C1 with a column of zeros. If we choose

Äzm , then when we integrate δ̇ pc to get the control law, we will still have an Ȧzm term, which implies we

would have PID control on the acceleration. While the derivative could be formed through the dynamics,

this introduces additional noise and errors, so we will not pursue this further here. That only leaves δ pc as

a possible output (the last row), which results in

⎡ ⎤ ⎡ ⎤

C D [0] [0] [0]

⎢ ⎥ ⎢ ⎥

C1 = ⎣ CA CB D [0] ⎦ D1 = ⎣ [0] ⎦

[0] 0 0 1 0

The system is strictly proper and C1−1 exists, but notice that we are back to the situation where not all

of the outputs are directly measurable. While we can replace this with a lag, this leads to systems that are

not as robust. In particular we should not expect the input vector margin to be unity. Again following the

development of Section IV.A, we will minimize the performance index

Z ∞h i

2 2

min J = Q11 (Azm − Kss Azc ) + R11 δ̇ pc dt

δpc 0

The optimal LQR problem can be solved directly, and the control is

⎡ Z ⎤

⎢ − (Azm − Kss Azc ) dt ⎥

⎢ R ⎥

⎢ qm dt ⎥

⎢ ⎥

δ pc = K ⎢ Azm ⎥

⎢ ⎥

⎢ ⎥

⎣ q ⎦

R m

− δ pc dt

where ⎡ ⎤ ⎡ ⎤

KIAz 1.8136

⎢ Kθ ⎥ ⎢ 17.8562 ⎥

⎢ ⎥ ⎢ ⎥

⎢ ⎥ ⎢ ⎥

K=⎢ KAz ⎥=⎢ 0.0180 ⎥

⎢ ⎥ ⎢ ⎥

⎣ Kq ⎦ ⎣ 0.2772 ⎦

KIδ 87.7615

and Kss = 0.7798 for τ 1 = τ 2 = 20Hz, Q11 = 2 and R11 = 1. The resulting 5-loop topology is shown in

Figure 17.

22 of 29

American Institute of Aeronautics and Astronautics

Integral Acceleration Gain KIAz Integral Rate Gain KTheta

2.2 30

3 Loop

2 4 Loop

5 Loop

25

1.8

3 Loop

Gain

Gain

1.6 4 Loop 20

5 Loop

1.4

15

1.2

1 10

1 2 3 4 1 2 3 4

10 10 10 10 10 10 10 10

CAS Frequency (Hz) CAS Frequency (Hz)

Acceleration Gain KAz Rate Gain Kq

3 Loop 3 Loop

4 Loop 0.5 4 Loop

5 Loop 5 Loop

0.1 0.4

Gain

Gain

0.3

0.05 0.2

0.1

0

0

1 2 3 4 1 2 3 4

10 10 10 10 10 10 10 10

CAS Frequency (Hz) CAS Frequency (Hz)

Figure 18. Gains for the 3-, 4-, and 5-Loop Systems

The gains for the classic 3-loop, the neoclassic 4-loop, and the 5-loop system above are given in Figures

18 and 19. Clearly, these gains do NOT go to the classic gains as the frequency of the additional dynamics

gets large.

The time responses and various vector margins in the face of the CAS dynamics are shown in Figures 20

through 23. Note that all of these figures show the results for the 3- and 4-loop systems with the quadratic

CAS dynamics included. The overall conclusion here is that the 4-loop topology is probably the superior

one unless the frequency of the CAS dynamics is very low and a very fast response is required. Notice also

the 5-loop did not recover the unity vector margin when the loop is broken at the input. In fact it has

relatively poor performance for slower overall system response.

We will need to reformulate the feedback if we wish to recover the 4-loop and 3-loop characteristics. In

particular, we will need to use the second derivative of the fin deflection as feedback, and to model the higher

order dynamics as two cascaded real poles. The problem would be formulated as

δ̈ p = −(τ 1 + τ 2 )δ̇ p + τ 1 τ 2 (δ pc − δ p )

⎡ ⎤ ⎡ ⎤

A B [0] [0] [0]

⎢ ⎥ ⎢ ⎥

⎢ [0] 0 1 0 ⎥ ⎢ 0 ⎥

A1 = ⎢ ⎥ B1 = ⎢ ⎥

⎣ [0] −τ 1 τ 2 −(τ 1 + τ 2 ) τ 1 τ 2 ⎦ ⎣ 0 ⎦

[0] 0 0 0 1

⎡ ⎤ ⎤⎡

C D [0] [0] [0]

⎢ ⎥ ⎢ ⎥

C = ⎣ CA CB D [0] ⎦ D = ⎣ [0] ⎦

[0] −τ 1 τ 2 −(τ 1 + τ 2 ) τ 1 τ 2 0

Selecting the first time constant to τ 1 = 20(Hz) and letting the other time constant vary, the gains for

four and five loop controllers are presented in Figures 24 and 25. The feedback would involve the rate of the

23 of 29

American Institute of Aeronautics and Astronautics

Integral Deflection Gain, KIdelta

100

4 Loop

90 5 Loop

80

70

60

50

Gain

40

30

20

10

−10

1 2 3 4

10 10 10 10

CAS Frequency (Hz)

Figure 19. KIδ Gains for the 3-, 4-, and 5-Loop Systems

Robustness Test with CAS Dynamics, 10 Hz CAS Robustness Test with CAS Dynamics, 20 Hz CAS

1.5 1.5

1 1

Acceleration (G)

Acceleration (G)

0.5 0.5

0 0

3 Loop 3 Loop

4 Loop 4 Loop

5 Loop 5 Loop

−0.5 −0.5

0 0.2 0.4 0.6 0.8 1 0 0.2 0.4 0.6 0.8 1

Time (sec) Time (sec)

Robustness Test with CAS Dynamics, 50 Hz CAS Robustness Test with CAS Dynamics, 100 Hz CAS

1.5 1.5

1 1

Acceleration (G)

Acceleration (G)

0.5 0.5

0 0

3 Loop 3 Loop

4 Loop 4 Loop

5 Loop 5 Loop

−0.5 −0.5

0 0.2 0.4 0.6 0.8 1 0 0.2 0.4 0.6 0.8 1

Time (sec) Time (sec)

Figure 20. Time Responses for 3-, 4-, and 5-Loop Systems with CAS Dynamics Present

24 of 29

American Institute of Aeronautics and Astronautics

Input Sensitivity, 10 Hz CAS Input Sensitivity, 20 Hz CAS

3 Loop 3 Loop

1 4 Loop 1 4 Loop

5 Loop 5 Loop

0.8 0.8

Vector Margin

Vector Margin

0.6 0.6

0.4 0.4

0.2 0.2

0 0

−0.2 −0.2

0 100 200 300 0 100 200 300

Time Constant (msec) Time Constant (msec)

Input Sensitivity, 50 Hz CAS Input Sensitivity, 100 Hz CAS

3 Loop 3 Loop

1 4 Loop 1 4 Loop

5 Loop 5 Loop

0.8 0.8

Vector Margin

Vector Margin

0.6 0.6

0.4 0.4

0.2 0.2

0 0

−0.2 −0.2

0 100 200 300 0 100 200 300

Time Constant (msec) Time Constant (msec)

Figure 21. Vector Margins at the Plant Input for the 3-, 4-, and 5-Loop Systems with Varying CAS Frequencies

Output Sensitivity − Rate, 10 Hz CAS Output Sensitivity − Rate, 20 Hz CAS

3 Loop 3 Loop

1 4 Loop 1 4 Loop

5 Loop 5 Loop

0.8 0.8

Vector Margin

Vector Margin

0.6 0.6

0.4 0.4

0.2 0.2

0 0

−0.2 −0.2

0 100 200 300 0 100 200 300

Time Constant (msec) Time Constant (msec)

Output Sensitivity − Rate, 50 Hz CAS Output Sensitivity − Rate, 100 Hz CAS

3 Loop 3 Loop

1 4 Loop 1 4 Loop

5 Loop 5 Loop

0.8 0.8

Vector Margin

Vector Margin

0.6 0.6

0.4 0.4

0.2 0.2

0 0

−0.2 −0.2

0 100 200 300 0 100 200 300

Time Constant (msec) Time Constant (msec)

Figure 22. Vector Margins at the Rate Output for the 3-, 4-, and 5-Loop Systems with Varying CAS Frequencies

25 of 29

American Institute of Aeronautics and Astronautics

Output Sensitivity − Accel, 10 Hz CAS Output Sensitivity − Accel, 20 Hz CAS

3 Loop 3 Loop

1 4 Loop 1 4 Loop

5 Loop 5 Loop

0.8 0.8

Vector Margin

Vector Margin

0.6 0.6

0.4 0.4

0.2 0.2

0 0

−0.2 −0.2

0 100 200 300 0 100 200 300

Time Constant (msec) Time Constant (msec)

Output Sensitivity − Accel, 50 Hz CAS Output Sensitivity − Accel, 100 Hz CAS

3 Loop 3 Loop

1 4 Loop 1 4 Loop

5 Loop 5 Loop

0.8 0.8

Vector Margin

Vector Margin

0.6 0.6

0.4 0.4

0.2 0.2

0 0

−0.2 −0.2

0 100 200 300 0 100 200 300

Time Constant (msec) Time Constant (msec)

Figure 23. Vector Margins at the Acceleration Output for the 3-, 4-, and 5-Loop Systems with Varying CAS

Frequencies

controller but this could easily be formed by using the transfer function and creating a lead.

δ̇ p τ 1τ 2s

= 2

δ pc s + (τ 1 + τ 2 )s + τ 1 τ 2

This implementation results in the robustness characteristics presented in Figures 26 to 28. Now the trends

follow the same course as moving from the three to the four loop. The input sensitivity is now better for the

five loop when compared to both the three and four loop systems. The input sensitivity is not unity because

the loop is broken after the lead but before the CAS. The margins with the plant broken at the outputs

continue to deteriorate as the system response is slower. It is interesting to note the margins do not change

significantly for the four CAS frequencies.

The final option would be to make the control the second derivative of δ pc , which would require six states

and six outputs. Pitch rate and acceleration could be used as outputs (using up to the second derivative of

each), so that the double integral of the control would result in measured variables and up to their double

integrals. Unfortunately, the resulting C1 matrix would be singular. Also, this would correspond to a

different performance index, since we’d be penalizing the acceleration of the control deflection, and would

lead to a 6-loop topology. This could be a topic of further research though the authors do not believe this

will provide useful autopilot designs for missiles.

VII. Conclusions

This paper has posed and solved the classical autopilot design problem as an optimal control problem.

Minimizing the performance index of acceleration error and fin deflection leads to a 2-loop autopilot topology

with gains on the pitch rate and acceleration. This solution uses infinite control deflection rate to achieve

a fast response. The classic 3-loop autopilot topology is a direct result of solving the weighted sum of

acceleration error and fin rate. It was shown that there are multiple three loop topologies. These topologies

are examined further in Mracek and Ridgely.3

A 4-loop “neoclassic” topology was presented. It was shown this new topology adds little complexity

to the problem, but can account for additional first order dynamics directly. This 4-loop topology becomes

26 of 29

American Institute of Aeronautics and Astronautics

Integral Acceleration Gain KIAz Integral Rate Gain KTheta

1.3 35

4 Loop

1.25 5 Loop

1.2 30

1.15

Gain

Gain

1.1 25

1.05

1 20

0.95 4 Loop

5 Loop

0.9 15

1 2 3 4 1 2 3 4

10 10 10 10 10 10 10 10

CAS Frequency (Hz) CAS Frequency (Hz)

Acceleration Gain KAz Rate Gain Kq

0.2

4 Loop 4 Loop

5 Loop 0.65 5 Loop

0.15 0.6

0.55

Gain

Gain

0.1 0.5

0.45

0.05 0.4

0.35

0 0.3

1 2 3 4 1 2 3 4

10 10 10 10 10 10 10 10

CAS Frequency (Hz) CAS Frequency (Hz)

Figure 24. Gains for the 4-, and 5-Loop Systems Using δ̇ for feedback

Integral Deflection Gain, KIdelta

0.02

4 Loop

5 Loop

0.015

0.01

Gain

0.005

−0.005

−0.01

1 2 3 4

10 10 10 10

CAS Frequency (Hz)

Figure 25. Gains for the 4-, and 5-Loop Systems Using δ̇ for feedback

27 of 29

American Institute of Aeronautics and Astronautics

Input Sensitivity, 10 Hz CAS Input Sensitivity, 20 Hz CAS

1 1

0.8 0.8

Vector Margin

Vector Margin

0.6 0.6

0.4 0.4

0.2 0.2

3 Loop 3 Loop

0 4 Loop 0 4 Loop

5 Loop 5 Loop

−0.2 −0.2

0 100 200 300 0 100 200 300

Time Constant (msec) Time Constant (msec)

Input Sensitivity, 50 Hz CAS Input Sensitivity, 100 Hz CAS

1 1

0.8 0.8

Vector Margin

Vector Margin

0.6 0.6

0.4 0.4

0.2 0.2

3 Loop 3 Loop

0 4 Loop 0 4 Loop

5 Loop 5 Loop

−0.2 −0.2

0 100 200 300 0 100 200 300

Time Constant (msec) Time Constant (msec)

Figure 26. Vector Margins at the Plant Input for the 3-, 4-, and Alternate 5-Loop Systems with Varying CAS

Frequencies

Output Sensitivity − Rate, 10 Hz CAS Output Sensitivity − Rate, 20 Hz CAS

3 Loop 3 Loop

1 4 Loop 1 4 Loop

5 Loop 5 Loop

0.8 0.8

Vector Margin

Vector Margin

0.6 0.6

0.4 0.4

0.2 0.2

0 0

−0.2 −0.2

0 100 200 300 0 100 200 300

Time Constant (msec) Time Constant (msec)

Output Sensitivity − Rate, 50 Hz CAS Output Sensitivity − Rate, 100 Hz CAS

3 Loop 3 Loop

1 4 Loop 1 4 Loop

5 Loop 5 Loop

0.8 0.8

Vector Margin

Vector Margin

0.6 0.6

0.4 0.4

0.2 0.2

0 0

−0.2 −0.2

0 100 200 300 0 100 200 300

Time Constant (msec) Time Constant (msec)

Figure 27. Vector Margins at the Rate Output for the 3-, 4-, and Alternate 5-Loop Systems with Varying

CAS Frequencies

28 of 29

American Institute of Aeronautics and Astronautics

Output Sensitivity − Accel, 10 Hz CAS Output Sensitivity − Accel, 20 Hz CAS

3 Loop 3 Loop

1 4 Loop 1 4 Loop

5 Loop 5 Loop

0.8 0.8

Vector Margin

Vector Margin

0.6 0.6

0.4 0.4

0.2 0.2

0 0

−0.2 −0.2

0 100 200 300 0 100 200 300

Time Constant (msec) Time Constant (msec)

Output Sensitivity − Accel, 50 Hz CAS Output Sensitivity − Accel, 100 Hz CAS

3 Loop 3 Loop

1 4 Loop 1 4 Loop

5 Loop 5 Loop

0.8 0.8

Vector Margin

Vector Margin

0.6 0.6

0.4 0.4

0.2 0.2

0 0

−0.2 −0.2

0 100 200 300 0 100 200 300

Time Constant (msec) Time Constant (msec)

Figure 28. Vector Margins at the Acceleration Output for the 3-, 4-, and Alternate 5-Loop Systems with

Varying CAS Frequencies

exactly the classic 3-loop topology as the frequency of the CAS dynamics becomes large, so it shares the

same robustness properties of the classic 3-loop topology. See the follow-on paper3 for more details on the

robustness properties of the classic 3-loop topology.

Finally, two 5-loop topology that accounts for 2nd order CAS dynamics directly was introduced. Unfor-

tunately, one topology relies on feedback of δ pc , which would have to be replaced with a lag filter. Thus,

it does not share the robustness properties of the classic 3-loop topology. The second relies on feedback of

δ̇ pc . Both 5-loop topologies result in lead compensation. Any higher order topologies either result in second

or higher integrations of the acceleration command or result in the 4-loop topology with leads. The added

lead continues to increase in complexity as further dynamics are added to the plant.

References

1 Paul Zarchan, Tactical and Strategic Missile Guidance, Fourth Edition. AIAA Volume 199 Progress in Astronautics and

Aeronautics, Reston, VA, 2002

2 R. J. Adams and N.M. Conrardy. “Design Plant Manipulations for Implementation of an LQR Controller in a Classical

Three Loop Autopilot.” Technical Report, Raytheon Missile Systems, Apr. 2003

3 C.P. Mracek and D.B. Ridgely, “Missile Longitudinal Autopilots: Comparison of Multiple Three Loop Topologies”, AIAA

GNC Conference, San Francisco CA, Aug. 2005

4 F.L. Lewis and V.L. Syrmos, “Optimal Control, Second Edition”, John Wiley & Sons, Inc. New York, New York, 1995

29 of 29

American Institute of Aeronautics and Astronautics

View publication stats

You might also like

- Quantum Mechanics - Homework Assignment 4: Alejandro G Omez Espinosa October 10, 2012Document8 pagesQuantum Mechanics - Homework Assignment 4: Alejandro G Omez Espinosa October 10, 2012Ale GomezNo ratings yet

- 747 Longitudinal DynamicsDocument6 pages747 Longitudinal DynamicsKore BenceNo ratings yet

- Aircraft Control and Simulation 9781118870983 PDFDocument2 pagesAircraft Control and Simulation 9781118870983 PDFMirza Muneeb Ahsan100% (1)

- MM ModelsDocument14 pagesMM ModelsLuca PilottiNo ratings yet

- Matlab Project - Quarter Vehicle: Name: Sebastian Preil Student ID: 1256334 Winter Semester 2015/16Document29 pagesMatlab Project - Quarter Vehicle: Name: Sebastian Preil Student ID: 1256334 Winter Semester 2015/16RezaNo ratings yet

- MULTIPLE CHOICE. Choose The One Alternative That Best Completes The Statement or Answers The Question. Write The Coordinates For Each PointDocument12 pagesMULTIPLE CHOICE. Choose The One Alternative That Best Completes The Statement or Answers The Question. Write The Coordinates For Each PointAmi RANo ratings yet

- Stability of Balsa Wood GliderDocument34 pagesStability of Balsa Wood Glidermenonharsh100% (9)

- Optimal Approach Autopilot TopologiesDocument30 pagesOptimal Approach Autopilot TopologiesDpt HtegnNo ratings yet

- Applied Sciences: Aeroaocustic Numerical Analysis of The Vehicle ModelDocument20 pagesApplied Sciences: Aeroaocustic Numerical Analysis of The Vehicle ModelBarış ÇitNo ratings yet

- THE K-Epsilon-R-T TURBULENCE CLOSURE: Engineering Applications of Computational Fluid Mechanics June 2009Document10 pagesTHE K-Epsilon-R-T TURBULENCE CLOSURE: Engineering Applications of Computational Fluid Mechanics June 2009Leo LonardelliNo ratings yet

- Simionescu 2016Document15 pagesSimionescu 2016hilmy yusuf maulanaNo ratings yet

- A Comparative Study On Effectiveness of Robust Facts Stabilizers For Power System Stability EnhancementDocument8 pagesA Comparative Study On Effectiveness of Robust Facts Stabilizers For Power System Stability EnhancementMary MorseNo ratings yet

- Kakanov 2020Document5 pagesKakanov 2020fscenterNo ratings yet

- We Are Intechopen, The World'S Leading Publisher of Open Access Books Built by Scientists, For ScientistsDocument17 pagesWe Are Intechopen, The World'S Leading Publisher of Open Access Books Built by Scientists, For ScientistsAtiso OtisaNo ratings yet

- National Advisory Committee For Aeronautics: IwhwcDocument46 pagesNational Advisory Committee For Aeronautics: Iwhwcaustin00012No ratings yet

- Flow3d Sediment PDFDocument9 pagesFlow3d Sediment PDFyashNo ratings yet

- A Convex Guidance Algorithm For Formation Reconfiguration, 6.2006-6070Document17 pagesA Convex Guidance Algorithm For Formation Reconfiguration, 6.2006-6070Mehmed BrkićNo ratings yet

- Supplementary Materials For: A Biomimetic Robotic Platform To Study Flight Specializations of BatsDocument14 pagesSupplementary Materials For: A Biomimetic Robotic Platform To Study Flight Specializations of BatsBilal BilalNo ratings yet

- Analytic Design Evaluation of Induction MachinesDocument43 pagesAnalytic Design Evaluation of Induction MachinesAli HashemiNo ratings yet

- Chapter 16 - CFD PDFDocument28 pagesChapter 16 - CFD PDFdeepakNo ratings yet

- LONGITUDINAL DYNAMICS ANALYSIS of BOEING 747-400Document7 pagesLONGITUDINAL DYNAMICS ANALYSIS of BOEING 747-400Brenda Abigail Villa DíazNo ratings yet

- AIrcraft Control Laws For Envelope ProtectionDocument10 pagesAIrcraft Control Laws For Envelope Protectionabhi singhNo ratings yet

- Discrete Model of Hybrid Stepper Motor by Optimal State Space ControlDocument8 pagesDiscrete Model of Hybrid Stepper Motor by Optimal State Space ControlJhon Bairon Velásquez MiraNo ratings yet

- (PDF) Solucion Eje 3Document9 pages(PDF) Solucion Eje 3Keiner ZarateNo ratings yet

- Modal and Frequency Based Substructuring Using RotDocument15 pagesModal and Frequency Based Substructuring Using RotMarwa BouslemaNo ratings yet

- Two-Equation Eddy-Viscosity Turbulence Model For Computing Drag Force On Axisymmetric Underwater Vehicle Hull FormDocument7 pagesTwo-Equation Eddy-Viscosity Turbulence Model For Computing Drag Force On Axisymmetric Underwater Vehicle Hull FormElyas Nur FridayanaNo ratings yet

- Retracted: A Simple Predictive Tool For Monitoring Steam Loss in TrapsDocument5 pagesRetracted: A Simple Predictive Tool For Monitoring Steam Loss in TrapsUcokNo ratings yet

- Computation of Axisymmetric Turbulent Viscous FlowDocument12 pagesComputation of Axisymmetric Turbulent Viscous FlowFurkan YildirimNo ratings yet

- Aerospace: Semi-Empirical Prediction of Airfoil HysteresisDocument8 pagesAerospace: Semi-Empirical Prediction of Airfoil HysteresisdimasNo ratings yet

- Use of The Soltzmann Equation To Simulate Lattice-Gas AutomataDocument4 pagesUse of The Soltzmann Equation To Simulate Lattice-Gas Automatazhaojie qinNo ratings yet

- Finite Elements in Rotordynamics: SciencedirectDocument15 pagesFinite Elements in Rotordynamics: SciencedirectAlex HustleNo ratings yet

- Quadcopter Dynamics and Simulation - Andrew GibianskyDocument24 pagesQuadcopter Dynamics and Simulation - Andrew GibianskywelltonarrudaNo ratings yet

- Research Article: Optimal On-Off Attitude Control For The Brazilian Multimission Platform SatelliteDocument17 pagesResearch Article: Optimal On-Off Attitude Control For The Brazilian Multimission Platform SatelliteSimone DascanioNo ratings yet

- Alireza Bahadori 2012Document5 pagesAlireza Bahadori 2012german Arrieta ZapaNo ratings yet

- ME389 MEM04 PendulumGantry GuidelineDocument14 pagesME389 MEM04 PendulumGantry GuidelineTarikuNo ratings yet

- Relations Between Molecular and Continuum Gas DynamicsDocument34 pagesRelations Between Molecular and Continuum Gas DynamicsGiuseppeNo ratings yet

- Equations of Motion For A Three-Mass-Spring-Damper Model (Tire-Suspension-Driver)Document10 pagesEquations of Motion For A Three-Mass-Spring-Damper Model (Tire-Suspension-Driver)newlife73No ratings yet

- Klerk Et Al. - This Document Is Downloaded From DR-NTU, Nanyang Technological University Library, Singapore - 2008Document16 pagesKlerk Et Al. - This Document Is Downloaded From DR-NTU, Nanyang Technological University Library, Singapore - 2008xjohannNo ratings yet

- (Sici) 1097-0207 (19970130) 40 2 357 Aid-Nme71 3.0.co 2-pDocument25 pages(Sici) 1097-0207 (19970130) 40 2 357 Aid-Nme71 3.0.co 2-pYouTube GuyNo ratings yet

- SE 514 OPTIMAL CONTROL FOR SINGLE AND DOUBLE INVERTED PENDULUM Project ReportDocument36 pagesSE 514 OPTIMAL CONTROL FOR SINGLE AND DOUBLE INVERTED PENDULUM Project ReportDragan ErcegNo ratings yet

- Kassimali Matrix Analysis Structures 2nd TXTBKDocument3 pagesKassimali Matrix Analysis Structures 2nd TXTBKSoro PenoNo ratings yet

- Estimator Design - Pole Placement: Esat-Scd-SistaDocument16 pagesEstimator Design - Pole Placement: Esat-Scd-SistaAnonymous HsoXPyNo ratings yet

- Plastic Buckling Analysis of Thick Plates Using P-Ritz MethodDocument17 pagesPlastic Buckling Analysis of Thick Plates Using P-Ritz Methodguojie zhouNo ratings yet

- Transonic Speed Flutter Analysis of A Rectangular Wing Using The OpenFOAM Computational Fluid Dynamics Code and The Dynamic Stiffness MethodDocument16 pagesTransonic Speed Flutter Analysis of A Rectangular Wing Using The OpenFOAM Computational Fluid Dynamics Code and The Dynamic Stiffness MethodFurkan KesimNo ratings yet

- Theory Important 2Document9 pagesTheory Important 2Anik MondalNo ratings yet

- Applsci 09 04411Document16 pagesApplsci 09 04411burchandadiNo ratings yet

- Performance of Three Turbulence ModDocument12 pagesPerformance of Three Turbulence Modkanbur.191No ratings yet

- V European Conference On Computational Fluid Dynamics Eccomas CFD 2010 J. C. F. Pereira and A. Sequeira (Eds) Lisbon, Portugal, 14-17 June 2010Document20 pagesV European Conference On Computational Fluid Dynamics Eccomas CFD 2010 J. C. F. Pereira and A. Sequeira (Eds) Lisbon, Portugal, 14-17 June 2010Sagnik BanikNo ratings yet

- Engineering ReportDocument14 pagesEngineering ReportMirudulaPuguajendiNo ratings yet

- 16.323 Principles of Optimal Control: Mit OpencoursewareDocument4 pages16.323 Principles of Optimal Control: Mit OpencoursewareMohand Achour TouatNo ratings yet

- Contractor ReportDocument56 pagesContractor ReportDan LNo ratings yet

- Flutter Analysis at Transonic Speeds Using A Coupled CFD-CSD SolverDocument9 pagesFlutter Analysis at Transonic Speeds Using A Coupled CFD-CSD SolverFurkan KesimNo ratings yet

- 2017elisionaltechwe4t NiqueofplottingcampbelldiagramsDocument9 pages2017elisionaltechwe4t NiqueofplottingcampbelldiagramsSmileNo ratings yet

- Turbulence Modeling For BeginnersDocument20 pagesTurbulence Modeling For BeginnersMohammed BaassiriNo ratings yet

- b009 PDFDocument7 pagesb009 PDFalagarg137691No ratings yet

- On The Application of Particle Swarm Optimization in Minimum Time Launch Vehicle Trajectory Optimization ProblemDocument8 pagesOn The Application of Particle Swarm Optimization in Minimum Time Launch Vehicle Trajectory Optimization ProblemTJPRC PublicationsNo ratings yet

- Teoria de Control IIDocument11 pagesTeoria de Control IIRicardo ZapataNo ratings yet

- Balancing Methodology of A Rigid Rotor Using ArtificialDocument8 pagesBalancing Methodology of A Rigid Rotor Using ArtificialJuan Angel Martinez RamirezNo ratings yet

- Paper 2Document4 pagesPaper 2Yessica RosasNo ratings yet

- Detailed Investigation of An Atomizing Air Compressor: July 2007Document9 pagesDetailed Investigation of An Atomizing Air Compressor: July 2007KR PANo ratings yet

- Design of Spiral Reinforcement PDFDocument53 pagesDesign of Spiral Reinforcement PDFrifkynetNo ratings yet

- Simulation and Analysis of Integral LQR Controller For Inner Control Loop Design of A Fixed Wing Micro Aerial Vehicle (MAV)Document8 pagesSimulation and Analysis of Integral LQR Controller For Inner Control Loop Design of A Fixed Wing Micro Aerial Vehicle (MAV)mahendra ANo ratings yet

- Factorization of Boundary Value Problems Using the Invariant Embedding MethodFrom EverandFactorization of Boundary Value Problems Using the Invariant Embedding MethodNo ratings yet

- AE/ME5313 Homework #3 Due 11/1/23Document1 pageAE/ME5313 Homework #3 Due 11/1/23JohnNo ratings yet

- 5313 HW 3 f2023Document2 pages5313 HW 3 f2023JohnNo ratings yet

- Surface Waves Rev2 F2020Document66 pagesSurface Waves Rev2 F2020JohnNo ratings yet

- AE/ME 5313 Fall 2022 Homework # 1 Due 9/13/2022Document2 pagesAE/ME 5313 Fall 2022 Homework # 1 Due 9/13/2022JohnNo ratings yet

- 2022 Fall - 2228 Ae 5310 002Document6 pages2022 Fall - 2228 Ae 5310 002JohnNo ratings yet

- Ae5310midterm 2022 OctoberDocument6 pagesAe5310midterm 2022 OctoberJohnNo ratings yet

- Grade Allocation: Total Grade Is Constituted of 50% HW, 50% Project. See Grading Information DetailsDocument9 pagesGrade Allocation: Total Grade Is Constituted of 50% HW, 50% Project. See Grading Information DetailsJohnNo ratings yet

- IE 4351: Fundamentals of Systems Engineering (Section 001) & IE 5351: Introduction To Systems Engineering (Sections 001/002/003)Document6 pagesIE 4351: Fundamentals of Systems Engineering (Section 001) & IE 5351: Introduction To Systems Engineering (Sections 001/002/003)JohnNo ratings yet

- Instructor Information: Mohammad - Jahanbakht@uta - EduDocument7 pagesInstructor Information: Mohammad - Jahanbakht@uta - EduJohnNo ratings yet

- Pepe Martinez For SHPE NUR BioDocument2 pagesPepe Martinez For SHPE NUR BioJohnNo ratings yet

- AHASpecialBulletin House3Trillion FinalDocument5 pagesAHASpecialBulletin House3Trillion FinalJohnNo ratings yet

- Laurent Series, Residues, and The Residue Theorem: AE 5332 - Professor Dora E. MusielakDocument18 pagesLaurent Series, Residues, and The Residue Theorem: AE 5332 - Professor Dora E. MusielakJohn100% (1)

- Midterm - Instructions Summer 2021Document3 pagesMidterm - Instructions Summer 2021JohnNo ratings yet

- AE 5332 - Professor Dora E. Musielak: Residue Theorem and Solution of Real Indefinite IntegralsDocument12 pagesAE 5332 - Professor Dora E. Musielak: Residue Theorem and Solution of Real Indefinite IntegralsJohnNo ratings yet

- Infinite Series of Complex Functions: AE 5332 - Professor Dora E. MusielakDocument17 pagesInfinite Series of Complex Functions: AE 5332 - Professor Dora E. MusielakJohnNo ratings yet

- AE 5332 - Professor Dora Elia Musielak: Residue Theorem and Solution of Real Indefinite IntegralsDocument13 pagesAE 5332 - Professor Dora Elia Musielak: Residue Theorem and Solution of Real Indefinite IntegralsJohnNo ratings yet

- AE 5332 - Professor Dora Elia Musielak: Complex Infinite SeriesDocument16 pagesAE 5332 - Professor Dora Elia Musielak: Complex Infinite SeriesJohnNo ratings yet

- Tensor Flow QDocument39 pagesTensor Flow Qvicky8595No ratings yet

- Adaptive Resonance TheoryDocument5 pagesAdaptive Resonance Theoryjoseph458No ratings yet

- 2018-EE-430 (Jaweria Zafar) Lab Manual-10Document24 pages2018-EE-430 (Jaweria Zafar) Lab Manual-10Jaweria ZafarNo ratings yet

- Optimal Tank Farm OperationDocument15 pagesOptimal Tank Farm OperationVELNo ratings yet

- Assignment 1Document7 pagesAssignment 1julyhopingNo ratings yet

- BAYESIANDocument8 pagesBAYESIANGhubaida HassaniNo ratings yet

- Systems of Inequalities Word Problem WorksheetDocument2 pagesSystems of Inequalities Word Problem WorksheetBrandeice BarrettNo ratings yet

- انظمة واشاراتDocument4 pagesانظمة واشاراتhamzeh basemNo ratings yet

- TH - jAK8fRvif4wCvHwb4Ug - Baier - Efficient Order Reduction of Parametric ModelsDocument9 pagesTH - jAK8fRvif4wCvHwb4Ug - Baier - Efficient Order Reduction of Parametric Modelshassan tawratiNo ratings yet

- HmetisDocument11 pagesHmetissriNo ratings yet

- Matlab Laboratory (ELEC-323) Session III: Second-Order Systems 1. OverviewDocument4 pagesMatlab Laboratory (ELEC-323) Session III: Second-Order Systems 1. Overviewfancy_maskNo ratings yet

- PV PQ Bus Switching Power Flow Pscc2008 - 128Document7 pagesPV PQ Bus Switching Power Flow Pscc2008 - 128kcirrenwodNo ratings yet

- OLMP Lab6Document27 pagesOLMP Lab6Siyu LiuNo ratings yet

- Practice Midterm Questions 1 and 2Document4 pagesPractice Midterm Questions 1 and 2Mandapalli SatishNo ratings yet

- NP CompleteDocument10 pagesNP Complete李葵慶No ratings yet

- A Two Step Clustering Method For Mixed Categorical and Numerical DataDocument9 pagesA Two Step Clustering Method For Mixed Categorical and Numerical Dataaparna_yedlaNo ratings yet

- Online Time Table Management SystemDocument4 pagesOnline Time Table Management SystemsashankreddyyarradlaNo ratings yet

- GoalDocument7 pagesGoalAshishNo ratings yet

- The Cricket Winner Prediction With Application of Machine Learning and Data AnalyticsDocument6 pagesThe Cricket Winner Prediction With Application of Machine Learning and Data AnalyticsJobExpertNo ratings yet

- L18Document76 pagesL18Ramandeep SinghNo ratings yet

- Final Analisis Cuantitativo - LFSDocument5 pagesFinal Analisis Cuantitativo - LFSISABEL CRISTINA ECHEVERRY OSORIONo ratings yet

- Format CV 1Document2 pagesFormat CV 1Kishan hariNo ratings yet

- Orlin NF Chapter4Document6 pagesOrlin NF Chapter4Abdulganiyu IsmaeelNo ratings yet

- 15-2 The Hamming Code: Check BitsDocument3 pages15-2 The Hamming Code: Check BitshaiqalNo ratings yet

- DIP3E - Chapter05 - Art - Image SegmentationDocument34 pagesDIP3E - Chapter05 - Art - Image SegmentationImad AhmadNo ratings yet

- Fresher Resume Sample17Document2 pagesFresher Resume Sample17sachchida101No ratings yet

- Programs On StackDocument9 pagesPrograms On StackAman SinghNo ratings yet