Professional Documents

Culture Documents

P.K.Metha CONCRETE - Microstructure Properties and Materials - 34

Uploaded by

Eng.Hesham AL-HelaleeOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

P.K.Metha CONCRETE - Microstructure Properties and Materials - 34

Uploaded by

Eng.Hesham AL-HelaleeCopyright:

Available Formats

34 CHAPTER 3.

STRENGTH

In general, there exists a fundamental inverse relation- of the failure modes, however, will be useful in under-

ship between porosity and strength of solids which, for standing and controlling the factors that influence con-

simple homogeneous materials, can be described by the crete strength.

expression

Under uniaxial tension, relatively less energy is need

S = S0 e−kp (3.1)

for the initiation and growth of cracks in the matrix. Rapid

where S is the strength of the material which has a given propagation and interlinkage of the crack system, consist-

porosity p; S0 is the intrinsic strength at zero porosity; ing or preexisting cracks at the transition zone and newly

and k is a constant. For many materials the ration S/S0 formed cracks in the matrix, account for the brittle fail-

plotted against porosity follows the same curve. For in- ure. In compression, the failure mode is less brittle be-

stance, the data in Fig. 3-1a represent normally cured ce- cause considerably more energy is needed to form and to

ments, autoclaved cements, and a variety of aggregates. extend cracks in the matrix. It is generally agreed that

Actually, the strength-porosity relationship is applicable in a uniaxial compression test on medium-or low-strength

to a very wide range of materials, such as iron, stainless concrete, no cracks are initiated in the matrix up to about

steel, plaster of paris, sintered alumina, and zirconia (Fig. 50 percent of the failure stress; at this stage a stable sys-

3-1b). tem of cracks, called shear-bond cracks, already exists in

Powers1 found that the 28-day compressive strength the vicinity of coarse aggregate. At higher stress levels,

f c of three different mortar mixtures was related to the cracks are initiated within the matrix; their number and

gel/space ratio, or the ratio between the solid hydration size increases progressively with increasing stress levels.

products in the system and the total space: The cracks in the matrix and the transition zone (shear-

bond cracks) eventually join up, and generally a failure

f c = ax 3 (3.2) surface develops at about 20 to 30◦ from the direction of

where (a) is the intrinsic strength of the material at zero the load, as shown in Fig. 3-2.

porosity ( p) and (x) the solid/space ratio or the amount

of solid fraction in the system, which is therefore equal to

(1 − p). Powers’s data are shown in Fig. 3-1c; he found COMPRESSIVE STRENGTH AND FACTORS AF-

the value of (a) to be 34,000 psi (234 MPa). The simi- FECTING IT

larity of the three curves in Fig. 3-1 confirms the general ‘The response of concrete to applied stress depends

validity of the strength-porosity relationship in solids. not only on the stress type but also on how a combination

Whereas in hardened cement paste or mortar the of various factors affects porosity of the different struc-

porosity can be related to strength, with concrete the sit- tural components of concrete. The factors include proper-

uation is not simple. The presence of microcracks in the ties and proportions of materials that make up the concrete

transition zone between the coarse aggregate and the ce- mixture, degree of compaction, and conditions of curing.

ment paste matrix makes concrete too complex a material From the standpoint of strength, the water/cement ratio-

for prediction of strength by precise strength-porosity re- porosity relation is undoubtedly the most important factor

lations. The general validity of strength-porosity relation, because, independent of other factors, it affects the poros-

however, must be respected because porosities of the com- ity of both the cement paste matrix and the transition zone

ponent phases of concrete, including the transition zone, between the matrix and the coarse aggregate.

indeed become strength limiting. With concrete contain-

ing the conventional low-porosity of high-strength aggre- Direct determination of porosity of the individual

gates, the strength of the material will be governed both structural components of concrete – the matrix and the

by the strength of the cement paste matrix and the strength transition zone – is impractical, and therefore precise

of the transition zone. Typically, at early ages the transi- models of predicting concrete strength cannot be devel-

tion zone is weaker than the matrix, but at later ages the oped. However, over a period of time many useful em-

reverse seems to be the case. pirical relations have been found which for practical use

provide enough indirect information about the influence

of numerous factors on compressive strength (compres-

FAILURE MODES IN CONCRETE sive strength being widely used as an index of all other

With a material such as concrete, which contains void types of strength). Although the actual response of con-

spaces of various size and shape in the matrix and mi- crete to applied stress is a result of complex interactions

crocracks at the transition zone between the matrix and between various factors, to simplify and understanding of

coarse aggregates, the failure modes under stress are very these factors they are discussed separately under three cat-

complex and vary with the type of stress. A brief review egories: (1) characteristics and proportions of materials,

1 T.C. Powers, J. Am. Ceram. Soc., Vol. 41, No. 1, pp. 1-6, 1958.

You might also like

- The Mechanical Properties of Wood: Including a Discussion of the Factors Affecting the Mechanical Properties, and Methods of Timber TestingFrom EverandThe Mechanical Properties of Wood: Including a Discussion of the Factors Affecting the Mechanical Properties, and Methods of Timber TestingNo ratings yet

- REINFORCED CONCRETE STRENGTHDocument6 pagesREINFORCED CONCRETE STRENGTHKrizza Joy Lintag CaspeNo ratings yet

- Testing Concrete Compressive StrengthDocument2 pagesTesting Concrete Compressive Strengthsmartman35No ratings yet

- Compression Response of Normal and High Strength Pervious Concrete 2016 Construction and Building MaterialsDocument11 pagesCompression Response of Normal and High Strength Pervious Concrete 2016 Construction and Building MaterialsNoéMestasNo ratings yet

- 20 & 22 Sep Lecture - 220922 - 172810Document104 pages20 & 22 Sep Lecture - 220922 - 172810darshan_pokharelNo ratings yet

- Metals 12 01586 v3Document13 pagesMetals 12 01586 v3rxx1218No ratings yet

- Shi 2017Document20 pagesShi 2017ifb.mirzaNo ratings yet

- Construction and Building Materials: Alessio Cascardi, Fabio Longo, Francesco Micelli, Maria Antonietta AielloDocument15 pagesConstruction and Building Materials: Alessio Cascardi, Fabio Longo, Francesco Micelli, Maria Antonietta AielloHussein ElsanadedyNo ratings yet

- Using FRP Sheets to Retrofit Structures EfficientlyDocument8 pagesUsing FRP Sheets to Retrofit Structures EfficientlyhwaichungwuNo ratings yet

- Failure Modes of ElastomersDocument8 pagesFailure Modes of ElastomersPaulo Venicio Alves VieiraNo ratings yet

- Composite Structures: Edgaras Atutis, Juozas Valivonis, Mantas AtutisDocument8 pagesComposite Structures: Edgaras Atutis, Juozas Valivonis, Mantas AtutisBanNo ratings yet

- Assignment 3Document1 pageAssignment 3Azouz AbdullahNo ratings yet

- Creton 2000 2Document15 pagesCreton 2000 2Satyam BhuyanNo ratings yet

- w4-Interface-stuDocument21 pagesw4-Interface-stuTuğbaNo ratings yet

- A. Ramachandra Murthy (2013)Document7 pagesA. Ramachandra Murthy (2013)Kashif NaukhezNo ratings yet

- The Effect of Fiber Volume Fraction On Filament Wound - 2001 - Composites Part B PDFDocument17 pagesThe Effect of Fiber Volume Fraction On Filament Wound - 2001 - Composites Part B PDFAhmed HassanNo ratings yet

- Journal of Structural EngineeringDocument12 pagesJournal of Structural EngineeringDima OvsiiNo ratings yet

- Mechanical Behavior of Particle Filled Elastomers: Jörgen S. Bergström and Mary C. BoyceDocument24 pagesMechanical Behavior of Particle Filled Elastomers: Jörgen S. Bergström and Mary C. BoyceoreamigNo ratings yet

- Fracture Mechanics of Concrete and Its Role in Explaining Structural BehaviourDocument11 pagesFracture Mechanics of Concrete and Its Role in Explaining Structural Behaviours s kattiNo ratings yet

- Experimental Investigation of Compressive Strength and CompressiveDocument18 pagesExperimental Investigation of Compressive Strength and CompressiveAlvaro Ore EspinozaNo ratings yet

- Strengthening Effects of DFRCC Layers Applied To RC Flexural Members-Numerical Investigation only-SK Shin-2011Document6 pagesStrengthening Effects of DFRCC Layers Applied To RC Flexural Members-Numerical Investigation only-SK Shin-2011sardarumersialNo ratings yet

- A Physically-Based Abrasive Wear Model For Composite MaterialsDocument10 pagesA Physically-Based Abrasive Wear Model For Composite MaterialsTRNADEWNo ratings yet

- 1973 Singh Continuum Characterization of Jointed Rock MassesDocument25 pages1973 Singh Continuum Characterization of Jointed Rock MassesNicolas Pino TorresNo ratings yet

- FTPDocument16 pagesFTPEstudiante2346No ratings yet

- Aggregate Shape and Composition Effect on Concrete Triaxial BehaviorDocument13 pagesAggregate Shape and Composition Effect on Concrete Triaxial BehaviorpandeshantanuNo ratings yet

- Constitutive Model For Fibre Reinforced Concrete by Coupling The Fibre andDocument19 pagesConstitutive Model For Fibre Reinforced Concrete by Coupling The Fibre andDaniel De Andrade SouzaNo ratings yet

- Cracking_and_damage_on_concrete_structurDocument48 pagesCracking_and_damage_on_concrete_structurDaniel GuirardiNo ratings yet

- Engineering Fracture Mechanics: I. Christodoulou, P.J. TanDocument22 pagesEngineering Fracture Mechanics: I. Christodoulou, P.J. TanSUBHASHIS SAHOONo ratings yet

- Extended AbstractDocument10 pagesExtended AbstractRohan ReddyNo ratings yet

- Gonzalez Valadez2010Document7 pagesGonzalez Valadez2010Avinash SajwanNo ratings yet

- A Finite Element Study of Hemispherical Elasoplastic Contact Against A Rigid Flat (Robert Jackson)Document12 pagesA Finite Element Study of Hemispherical Elasoplastic Contact Against A Rigid Flat (Robert Jackson)Raphael LemosNo ratings yet

- 2021 - James R. Martinez - Laminated Composite PlatesDocument15 pages2021 - James R. Martinez - Laminated Composite PlatesArpita SaxenaNo ratings yet

- Theory of Adhesion: Role of Surface Roughness: Articles You May Be Interested inDocument15 pagesTheory of Adhesion: Role of Surface Roughness: Articles You May Be Interested inDrRajat SrivastavaNo ratings yet

- Modeling The Nonlinear Hysteretic Response in DAE Experiments of Berea Sandstone: A Case-StudyDocument9 pagesModeling The Nonlinear Hysteretic Response in DAE Experiments of Berea Sandstone: A Case-StudyAndika PerbawaNo ratings yet

- The Pressure Dependence of PermeabilityDocument11 pagesThe Pressure Dependence of Permeabilityheberth julian rodriguezNo ratings yet

- Snap Back For ConcreteDocument15 pagesSnap Back For ConcreteKILARUDIVYANo ratings yet

- A New Explanation For Size Effects On The Flexural Strength of ConcreteDocument9 pagesA New Explanation For Size Effects On The Flexural Strength of ConcreteRagip INCENo ratings yet

- Lecture 5Document19 pagesLecture 5ewaqasak2013No ratings yet

- Dhan ShekarDocument13 pagesDhan ShekarPiyush TiwariNo ratings yet

- Strength and Factors Affecting Concrete StrengthDocument30 pagesStrength and Factors Affecting Concrete StrengthMahbub AlamNo ratings yet

- Hakamada 2007Document9 pagesHakamada 2007Luis CarranzaNo ratings yet

- Zoubek-2016 - Seismic Response of Dowel Connections in RC Structures 1Document8 pagesZoubek-2016 - Seismic Response of Dowel Connections in RC Structures 1Mocanu IonutNo ratings yet

- 1 s2.0 S0167844220302986 Main PDFDocument16 pages1 s2.0 S0167844220302986 Main PDFDaniela Gonzalez BetancurNo ratings yet

- Influence of Local Buckling On Global Instability: Simplified, Large Deformation, Post-Buckling Analyses of Plane TrussesDocument15 pagesInfluence of Local Buckling On Global Instability: Simplified, Large Deformation, Post-Buckling Analyses of Plane TrussesnctfatNo ratings yet

- Theory of Reinforcement: CL 630 Composite Materials (3 0 0 6)Document35 pagesTheory of Reinforcement: CL 630 Composite Materials (3 0 0 6)SnigdhaChakrabortyNo ratings yet

- Correa 2007Document10 pagesCorrea 2007Eduardo Fernandez SanchezNo ratings yet

- Mechanics of shotcrete roof support in hard rock tunnelsDocument6 pagesMechanics of shotcrete roof support in hard rock tunnelsAlexandre GomesNo ratings yet

- 1 s2.0 S2352710218313858 MainDocument10 pages1 s2.0 S2352710218313858 Mainr.reynauNo ratings yet

- Aluminium Alloys StudyDocument12 pagesAluminium Alloys StudyPrabakaran BalasubramaniamNo ratings yet

- BEHAVIORDocument26 pagesBEHAVIORRosenda Cordova0% (1)

- Behaviour of Strain-Hardening Cement-Based Composites (SHCC) Under Monotonic and Cyclic Tensile LoadingDocument9 pagesBehaviour of Strain-Hardening Cement-Based Composites (SHCC) Under Monotonic and Cyclic Tensile LoadingUDDOM CHHENGNo ratings yet

- Literature ReviewDocument24 pagesLiterature ReviewPrabhu G HiCET AUTO FACULTYNo ratings yet

- J Conbuildmat 2021 123025Document12 pagesJ Conbuildmat 2021 123025Nadal201No ratings yet

- Cohesion of Soil Particles and The IntriDocument8 pagesCohesion of Soil Particles and The IntriRida BoualilNo ratings yet

- Liang 2018Document6 pagesLiang 2018Immanuel MarcelinoNo ratings yet

- Scale Effects in Uniaxially Compressed ConcreteDocument9 pagesScale Effects in Uniaxially Compressed ConcreteWalid Mahmoud BirouNo ratings yet

- Textile Reinforced Concrete - Overview, Experimental and Theoretical InvestigationsDocument8 pagesTextile Reinforced Concrete - Overview, Experimental and Theoretical InvestigationsHanna MarshellaNo ratings yet

- 3D CZM Ductile Crack Growth TriaxialityDocument23 pages3D CZM Ductile Crack Growth TriaxialityfrvdabeeNo ratings yet

- 9an Explanation of The Different Regimes Os Friction and Wear Using Asperity Deformation Models PDFDocument15 pages9an Explanation of The Different Regimes Os Friction and Wear Using Asperity Deformation Models PDFAnderson JuniorNo ratings yet

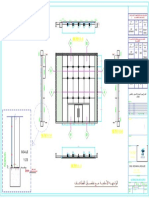

- Details of external facade glass wall systemDocument1 pageDetails of external facade glass wall systemEng.Hesham AL-HelaleeNo ratings yet

- 12 Microstructure and Properties of Hardened ConcreteDocument1 page12 Microstructure and Properties of Hardened ConcreteEng.Hesham AL-HelaleeNo ratings yet

- CH7 FEM FOR TWO DIMENSIONAL SOLIDS - v2Document22 pagesCH7 FEM FOR TWO DIMENSIONAL SOLIDS - v2Eng.Hesham AL-HelaleeNo ratings yet

- Chapter 8. Admixtures 281Document1 pageChapter 8. Admixtures 281Eng.Hesham AL-HelaleeNo ratings yet

- 16 Microstructure and Properties of Hardened ConcreteDocument1 page16 Microstructure and Properties of Hardened ConcreteEng.Hesham AL-HelaleeNo ratings yet

- PreviewDocument1 pagePreviewEng.Hesham AL-HelaleeNo ratings yet

- Numerical Methods Guide - Truncation Errors, Differentiation Formulas, Integration TechniquesDocument1 pageNumerical Methods Guide - Truncation Errors, Differentiation Formulas, Integration TechniquesEng.Hesham AL-HelaleeNo ratings yet

- CH4 FEM FOR TRUSSES - v2Document13 pagesCH4 FEM FOR TRUSSES - v2Eng.Hesham AL-HelaleeNo ratings yet

- Structural Strengtheningrepair of Reinforced Concrete RC Beams by Different Fiberreinforced Cementitious Materials A STDocument15 pagesStructural Strengtheningrepair of Reinforced Concrete RC Beams by Different Fiberreinforced Cementitious Materials A STEng.Hesham AL-HelaleeNo ratings yet

- Design of Elevated TanksDocument24 pagesDesign of Elevated TanksEng.Hesham AL-HelaleeNo ratings yet

- EXAM of Engineering Mechanics Model (A)Document2 pagesEXAM of Engineering Mechanics Model (A)Eng.Hesham AL-HelaleeNo ratings yet

- SteelDesign Composite Fu NewDocument6 pagesSteelDesign Composite Fu NewEng.Hesham AL-HelaleeNo ratings yet

- CH3 Fundamentals For Finite Element Method - v2Document8 pagesCH3 Fundamentals For Finite Element Method - v2Eng.Hesham AL-Helalee100% (1)

- CH1 An Introduction To The Finite Element Method - v2Document21 pagesCH1 An Introduction To The Finite Element Method - v2Eng.Hesham AL-HelaleeNo ratings yet

- 4 6043837262641234834Document3 pages4 6043837262641234834Eng.Hesham AL-HelaleeNo ratings yet

- Glasscon Project Report - Rotschild 48 Tel Aviv IsraelDocument33 pagesGlasscon Project Report - Rotschild 48 Tel Aviv IsraelEng.Hesham AL-HelaleeNo ratings yet

- 4 6037227067454523239Document4 pages4 6037227067454523239Eng.Hesham AL-HelaleeNo ratings yet

- Negative Skin Friction: Example 11.15Document5 pagesNegative Skin Friction: Example 11.15Eng.Hesham AL-HelaleeNo ratings yet

- 4 5956424765383116753Document9 pages4 5956424765383116753Eng.Hesham AL-HelaleeNo ratings yet

- Mass Concrete RMC Plum Concrete: Created By: Jay S. Singhania en No:146490306107 Civil-B Sem-5 Sir Bpti, BVNDocument36 pagesMass Concrete RMC Plum Concrete: Created By: Jay S. Singhania en No:146490306107 Civil-B Sem-5 Sir Bpti, BVNEng.Hesham AL-HelaleeNo ratings yet

- Beam.: Note:-Answer Ouestions OnlvDocument1 pageBeam.: Note:-Answer Ouestions OnlvEng.Hesham AL-HelaleeNo ratings yet

- CamScanner Scans PDFs from PhotosDocument3 pagesCamScanner Scans PDFs from PhotosEng.Hesham AL-HelaleeNo ratings yet

- Plastic Analysis GhaliDocument19 pagesPlastic Analysis GhaliEng.Hesham AL-HelaleeNo ratings yet

- Types of WeirsDocument8 pagesTypes of WeirsEng.Hesham AL-HelaleeNo ratings yet

- HPSR 2009 Road ScheduleDocument214 pagesHPSR 2009 Road Schedulerajinder kutaal70% (20)

- Rotational MoldingDocument12 pagesRotational MoldingPrithviraj Daga100% (3)

- FA Estrolith H2000 171102 1008 Print GBDocument4 pagesFA Estrolith H2000 171102 1008 Print GBYórgos DedisNo ratings yet

- DLL English 7Document31 pagesDLL English 7Jocelyn AnavesaNo ratings yet

- Injection Molding Lab ReportDocument9 pagesInjection Molding Lab ReportEdgar ThorpeNo ratings yet

- PTSC MC-Piping Design Training-Basic Piping-LATESTDocument31 pagesPTSC MC-Piping Design Training-Basic Piping-LATESTNguyen Anh Tung50% (2)

- AWS Material Trace AbilityDocument2 pagesAWS Material Trace AbilitySanthosh NairNo ratings yet

- WallART Rezilience BrochureDocument2 pagesWallART Rezilience Brochurebackch9011No ratings yet

- Blanking or Stamping or Punching of Sheet Metal Project Report (Punch and Die)Document44 pagesBlanking or Stamping or Punching of Sheet Metal Project Report (Punch and Die)gopi_krishnan_2986% (22)

- Comparison Between Dry Lamination and Extrusion LaminationDocument26 pagesComparison Between Dry Lamination and Extrusion LaminationRicardo PratiwiharjaNo ratings yet

- Cast in Place ConcreteDocument62 pagesCast in Place ConcreteTaher AmmarNo ratings yet

- MasterCast 121 multi-purpose adhesiveDocument3 pagesMasterCast 121 multi-purpose adhesiveNatalieNo ratings yet

- FIELD ENGR EXAM SUPERVISOR MATERIAL TAKE-OFFDocument11 pagesFIELD ENGR EXAM SUPERVISOR MATERIAL TAKE-OFFDwinix John CabañeroNo ratings yet

- HDPE Pipe Butt Welding ProceduresDocument7 pagesHDPE Pipe Butt Welding ProceduresRaden Armanadi100% (4)

- Schedule 40 PVC Fittings GuideDocument2 pagesSchedule 40 PVC Fittings Guidedanis paramoNo ratings yet

- Metakaolin ReviewDocument22 pagesMetakaolin ReviewRAGHUNo ratings yet

- QUOTATION-cast Iron - KUWANA IndustrialDocument4 pagesQUOTATION-cast Iron - KUWANA IndustrialBenedick Conrad GlifuniaNo ratings yet

- All StaticDocument17 pagesAll StaticbogdanmichaelNo ratings yet

- Estimation & CostingDocument5 pagesEstimation & CostingHanamanagouda BevoorNo ratings yet

- Sanitary Engineering Licensure Exam PrepDocument15 pagesSanitary Engineering Licensure Exam PrepDan UnabiaNo ratings yet

- Stainless Steel Pipe DesignationsDocument4 pagesStainless Steel Pipe DesignationsSTL Pipe & SupplyNo ratings yet

- BT Joe Quiz 1Document1 pageBT Joe Quiz 1corazon philNo ratings yet

- Adk Cizer Adk Stab: Polymer AdditivesDocument10 pagesAdk Cizer Adk Stab: Polymer AdditivesEliton S. MedeirosNo ratings yet

- WTP& Collection WellDocument431 pagesWTP& Collection Wellsubramanyam kumarNo ratings yet

- Balcony and toilet waterproofing treatmentDocument1 pageBalcony and toilet waterproofing treatmentprabhu81No ratings yet

- PDH Post Tensioned Concrete Design PDFDocument8 pagesPDH Post Tensioned Concrete Design PDFabdulmananNo ratings yet

- Effects of Rice Husk Ash on Wear Properties of Al6063 MMCsDocument7 pagesEffects of Rice Husk Ash on Wear Properties of Al6063 MMCsShrwan GyawaliNo ratings yet

- Advanced High-Strength Steels Drive Weight Reduction in Mercedes-BenzDocument19 pagesAdvanced High-Strength Steels Drive Weight Reduction in Mercedes-BenzAbhishek KumarNo ratings yet

- Produktleitfaden Kubus 2016 - GBDocument56 pagesProduktleitfaden Kubus 2016 - GBAlexandru PelinNo ratings yet

- Brick Construction GuideDocument13 pagesBrick Construction Guidecmms88100% (2)

- Nuclear Energy in the 21st Century: World Nuclear University PressFrom EverandNuclear Energy in the 21st Century: World Nuclear University PressRating: 4.5 out of 5 stars4.5/5 (3)

- Functional Safety from Scratch: A Practical Guide to Process Industry ApplicationsFrom EverandFunctional Safety from Scratch: A Practical Guide to Process Industry ApplicationsNo ratings yet

- Piping and Pipeline Calculations Manual: Construction, Design Fabrication and ExaminationFrom EverandPiping and Pipeline Calculations Manual: Construction, Design Fabrication and ExaminationRating: 4 out of 5 stars4/5 (18)

- Trevor Kletz Compendium: His Process Safety Wisdom Updated for a New GenerationFrom EverandTrevor Kletz Compendium: His Process Safety Wisdom Updated for a New GenerationNo ratings yet

- The Periodic Table of Elements - Post-Transition Metals, Metalloids and Nonmetals | Children's Chemistry BookFrom EverandThe Periodic Table of Elements - Post-Transition Metals, Metalloids and Nonmetals | Children's Chemistry BookNo ratings yet

- Gas-Liquid And Liquid-Liquid SeparatorsFrom EverandGas-Liquid And Liquid-Liquid SeparatorsRating: 3.5 out of 5 stars3.5/5 (3)

- Guidelines for Chemical Process Quantitative Risk AnalysisFrom EverandGuidelines for Chemical Process Quantitative Risk AnalysisRating: 5 out of 5 stars5/5 (1)

- Well Control for Completions and InterventionsFrom EverandWell Control for Completions and InterventionsRating: 4 out of 5 stars4/5 (10)

- Robotics: Designing the Mechanisms for Automated MachineryFrom EverandRobotics: Designing the Mechanisms for Automated MachineryRating: 4.5 out of 5 stars4.5/5 (8)

- An Introduction to the Periodic Table of Elements : Chemistry Textbook Grade 8 | Children's Chemistry BooksFrom EverandAn Introduction to the Periodic Table of Elements : Chemistry Textbook Grade 8 | Children's Chemistry BooksRating: 5 out of 5 stars5/5 (1)

- Guidelines for Siting and Layout of FacilitiesFrom EverandGuidelines for Siting and Layout of FacilitiesNo ratings yet

- Guidelines for Developing Quantitative Safety Risk CriteriaFrom EverandGuidelines for Developing Quantitative Safety Risk CriteriaNo ratings yet

- An Applied Guide to Water and Effluent Treatment Plant DesignFrom EverandAn Applied Guide to Water and Effluent Treatment Plant DesignRating: 5 out of 5 stars5/5 (4)

- Bow Ties in Risk Management: A Concept Book for Process SafetyFrom EverandBow Ties in Risk Management: A Concept Book for Process SafetyNo ratings yet

- Guidelines for Vapor Cloud Explosion, Pressure Vessel Burst, BLEVE, and Flash Fire HazardsFrom EverandGuidelines for Vapor Cloud Explosion, Pressure Vessel Burst, BLEVE, and Flash Fire HazardsNo ratings yet

- Understanding Process Equipment for Operators and EngineersFrom EverandUnderstanding Process Equipment for Operators and EngineersRating: 4.5 out of 5 stars4.5/5 (3)

- Physical and Chemical Equilibrium for Chemical EngineersFrom EverandPhysical and Chemical Equilibrium for Chemical EngineersRating: 5 out of 5 stars5/5 (1)

- Guidelines for Engineering Design for Process SafetyFrom EverandGuidelines for Engineering Design for Process SafetyNo ratings yet

- Conduct of Operations and Operational Discipline: For Improving Process Safety in IndustryFrom EverandConduct of Operations and Operational Discipline: For Improving Process Safety in IndustryRating: 5 out of 5 stars5/5 (1)

- Perfume Engineering: Design, Performance and ClassificationFrom EverandPerfume Engineering: Design, Performance and ClassificationRating: 4 out of 5 stars4/5 (5)

- Process Steam Systems: A Practical Guide for Operators, Maintainers, and DesignersFrom EverandProcess Steam Systems: A Practical Guide for Operators, Maintainers, and DesignersNo ratings yet

- Major Accidents to the Environment: A Practical Guide to the Seveso II-Directive and COMAH RegulationsFrom EverandMajor Accidents to the Environment: A Practical Guide to the Seveso II-Directive and COMAH RegulationsNo ratings yet