Professional Documents

Culture Documents

16 Microstructure and Properties of Hardened Concrete

Uploaded by

Eng.Hesham AL-Helalee0 ratings0% found this document useful (0 votes)

7 views1 pageOriginal Title

ConcreteMicrostructurePropertiesandMaterials_40

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

7 views1 page16 Microstructure and Properties of Hardened Concrete

Uploaded by

Eng.Hesham AL-HelaleeCopyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You are on page 1of 1

16 Microstructure and Properties of Hardened Concrete

between the tensile and compressive strength is attributed to the heteroge-

neous and complex microstructure of concrete.

With many engineering materials, such as steel, the observed stress-strain

behavior when a specimen is subjected to incremental loads can be divided into

two parts (Fig. 1-11). Initially, when the strain is proportional to the applied

stress and is reversible on unloading the specimen, it is called the elastic strain.

The modulus of elasticity is defined as the ratio between the stress and the

reversible strain. In homogeneous materials, the elastic modulus is a measure

of the interatomic bonding forces and is unaffected by microstructural changes.

This is not true of the heterogeneous multiphase materials like concrete. The

elastic modulus of concrete in compression varies from 14 × 103 to 40 × 103 MPa

(2 × 106 to 6 × 106 psi). The significance of the elastic limit in structural design

lies in the fact that it represents the maximum allowable stress before the

material undergoes permanent deformation. Therefore, the engineer must know

the elastic modulus of the material because it influences the rigidity of a design.

At a high stress level (Fig. 1-11), the strain no longer remains proportional

to the applied stress, and also becomes permanent (i.e., it will not be reversed

if the specimen is unloaded). This strain is called the plastic or inelastic strain.

The amount of inelastic strain that can occur before failure is a measure of the

ductility of the material. The energy required to break the material, the prod-

uct of force times distance, is represented by the area under the stress-strain

curve. The term toughness is used as a measure of this energy. The contrast

500

Yield point

Loading and unloading

400

Stress (MPa)

300

200

100

Plastic

strain

0

0 .05 0.1 0.15 0.2

Strain

Figure 1-11 Stress-strain behavior of a steel specimen sub-

jected to incremental loads.

You might also like

- Mechanical Behavior of MaterialDocument14 pagesMechanical Behavior of MaterialNAGARAJUNo ratings yet

- 19-25 Mechanical Properties of MaterialsDocument7 pages19-25 Mechanical Properties of MaterialsChamalNo ratings yet

- Construction Materials and TestingDocument16 pagesConstruction Materials and TestingAvis pittNo ratings yet

- Assignment No. 5 JJJJJJDocument9 pagesAssignment No. 5 JJJJJJNicholas Bonn SingNo ratings yet

- Lecture # 2 Concept of Stress and StrainDocument33 pagesLecture # 2 Concept of Stress and StrainSohaibNo ratings yet

- Physical and Mechcanical Properties of Dental Materials.Document136 pagesPhysical and Mechcanical Properties of Dental Materials.Diksha SolankiNo ratings yet

- Lecture # 2 MechanicalPropertiesDocument59 pagesLecture # 2 MechanicalPropertiesAhmad ZafarNo ratings yet

- Stress Vs Strain: Stress Is The Force Applied To A Material, Divided by The Material's Cross-Sectional AreaDocument9 pagesStress Vs Strain: Stress Is The Force Applied To A Material, Divided by The Material's Cross-Sectional AreaAranas TrishaNo ratings yet

- Polymer FailureDocument58 pagesPolymer Failureomar cNo ratings yet

- Mechanical Properties of MetalsDocument16 pagesMechanical Properties of MetalsShione T MundawararaNo ratings yet

- C E D C A E: Ollege of Ngineering Epartment of Ivil & Rchitectural NgineeringDocument37 pagesC E D C A E: Ollege of Ngineering Epartment of Ivil & Rchitectural Ngineeringhend mahmoudNo ratings yet

- C E D C A E: Ollege of Ngineering Epartment of Ivil & Rchitectural NgineeringDocument37 pagesC E D C A E: Ollege of Ngineering Epartment of Ivil & Rchitectural Ngineeringhend mahmoudNo ratings yet

- A.Mechanical Properties of Engineering Materials: F/A F/ADocument11 pagesA.Mechanical Properties of Engineering Materials: F/A F/AsrknotesNo ratings yet

- Strain MeasurementDocument66 pagesStrain MeasurementSatyanarayana VenkatNo ratings yet

- Tensile PropertiesDocument4 pagesTensile Propertiesjontylee87No ratings yet

- Chapter 6 (001) Mat SciDocument32 pagesChapter 6 (001) Mat SciJay ArNo ratings yet

- Rezistenta MetalelorDocument7 pagesRezistenta Metalelorion_senNo ratings yet

- Properties of Construction Materials and Their Stress/strain BehaviourDocument15 pagesProperties of Construction Materials and Their Stress/strain BehaviourOmokhiboria JoshuaNo ratings yet

- Mechanical Properties of MaterialsDocument16 pagesMechanical Properties of MaterialsAltan UğurkanNo ratings yet

- Chapter 6 Mechanical PropertiesDocument27 pagesChapter 6 Mechanical Propertiesfajar bramantyoNo ratings yet

- Mechanical Properties of MetalsDocument258 pagesMechanical Properties of MetalsIsza Marie N. SocorinNo ratings yet

- Tensile Test LabDocument12 pagesTensile Test LabkhalilNo ratings yet

- ReviewerDocument13 pagesReviewerKris Angela Dugayo PasaolNo ratings yet

- Lecture 2 - StrainDocument4 pagesLecture 2 - StrainPaul PatropezNo ratings yet

- Design Terms: Stress-Strain RelationsDocument3 pagesDesign Terms: Stress-Strain RelationsZoe FallurinNo ratings yet

- 6.0 Mechanical Properties of Materials: Tension Compression Shear TorsionDocument40 pages6.0 Mechanical Properties of Materials: Tension Compression Shear TorsionWilliams AkandiNo ratings yet

- 242 - Suraj Patil. SomDocument12 pages242 - Suraj Patil. SomSuraj PatilNo ratings yet

- Strength of Materials Basics and Equations - Mechanics of Materials - Engineers EdgeDocument6 pagesStrength of Materials Basics and Equations - Mechanics of Materials - Engineers EdgeansarNo ratings yet

- Strenght of Material ExplanationDocument7 pagesStrenght of Material ExplanationMohamed MostafaNo ratings yet

- Chapter Three: Mechanical Properties of MaterialsDocument31 pagesChapter Three: Mechanical Properties of MaterialsOmar AlzoubiNo ratings yet

- Strength of Materials and CreepDocument14 pagesStrength of Materials and Creepfabyan mayharNo ratings yet

- Laboratory Report - DM JV LRDocument6 pagesLaboratory Report - DM JV LRLaura ReyesNo ratings yet

- Mechanical Properties of Materials NotesDocument28 pagesMechanical Properties of Materials NotesMat MatttNo ratings yet

- Strength of MaterialsDocument7 pagesStrength of Materialsletter_ashish4444100% (1)

- Special Topics in Structural Engineering: Homework Student Name: Abdulla Ibrahim Tahsin ID: 1310066Document6 pagesSpecial Topics in Structural Engineering: Homework Student Name: Abdulla Ibrahim Tahsin ID: 1310066Abdullah SimpsonNo ratings yet

- Tensile Compressive Strength DeterminationDocument7 pagesTensile Compressive Strength DeterminationSleepy SpettoNo ratings yet

- University of Technology Chemical Engineering Oil and Refining BranchDocument13 pagesUniversity of Technology Chemical Engineering Oil and Refining Branchجعفر ذيابNo ratings yet

- DEWESoft Training DocumentDocument67 pagesDEWESoft Training DocumentMustafa YildizNo ratings yet

- Chem 131......... 2Document13 pagesChem 131......... 2Nicholas Bonn SingNo ratings yet

- Stress-Strain CurveDocument8 pagesStress-Strain Curvedani chNo ratings yet

- Steel StrengthDocument8 pagesSteel StrengthVishalNo ratings yet

- Lab Report Tensile Group 5Document12 pagesLab Report Tensile Group 5Danial AqilNo ratings yet

- Cub Surg Lesson02 Presentation v2 Tedl DWCDocument15 pagesCub Surg Lesson02 Presentation v2 Tedl DWCHarendra Singh Rathore DoultpuraNo ratings yet

- EBB 220/3 Failure in PolymersDocument58 pagesEBB 220/3 Failure in PolymersespirhalNo ratings yet

- Mechanical Properties of Dental MaterialsDocument7 pagesMechanical Properties of Dental Materialsshubhe08No ratings yet

- Lecture 4Document45 pagesLecture 4SAIF ULLAHNo ratings yet

- (6a) - INTODUCTION TO TENSILE TESTINGDocument51 pages(6a) - INTODUCTION TO TENSILE TESTINGRiAn DeviNo ratings yet

- ErsdgDocument8 pagesErsdgOlle rrNo ratings yet

- Static Assigment222222Document4 pagesStatic Assigment222222mousa77dNo ratings yet

- CEC 106 Strength of Materials 2020/2021 Session Strength of MaterialsDocument7 pagesCEC 106 Strength of Materials 2020/2021 Session Strength of MaterialsAbu Muhammad AssalafiyNo ratings yet

- Strength of Materials - Wikipedia, The Free EncyclopediaDocument8 pagesStrength of Materials - Wikipedia, The Free EncyclopediaLeo Kyaw MinNo ratings yet

- Strength of Materials, Also Called Mechanics of Materials, Deals With The Behavior of Solid ObjectsDocument3 pagesStrength of Materials, Also Called Mechanics of Materials, Deals With The Behavior of Solid ObjectsZoe FallurinNo ratings yet

- Mechanical Properties of MetalsDocument15 pagesMechanical Properties of MetalsLaurence Bande Del RosarioNo ratings yet

- SDM2-session2-Mechanical Properties-ReviewDocument47 pagesSDM2-session2-Mechanical Properties-ReviewPheng SeihaksethNo ratings yet

- Mechanical Properties of MaterialsDocument33 pagesMechanical Properties of Materialsraghu_raman5364No ratings yet

- Stress-Strain GraphDocument10 pagesStress-Strain GraphEzy WaqaNo ratings yet

- Mechanistic ModelsDocument7 pagesMechanistic ModelsSivakumar MNo ratings yet

- The Mechanical Properties of Wood: Including a Discussion of the Factors Affecting the Mechanical Properties, and Methods of Timber TestingFrom EverandThe Mechanical Properties of Wood: Including a Discussion of the Factors Affecting the Mechanical Properties, and Methods of Timber TestingNo ratings yet

- Chapter 8. Admixtures 281Document1 pageChapter 8. Admixtures 281Eng.Hesham AL-HelaleeNo ratings yet

- PreviewDocument1 pagePreviewEng.Hesham AL-HelaleeNo ratings yet

- CH7 FEM FOR TWO DIMENSIONAL SOLIDS - v2Document22 pagesCH7 FEM FOR TWO DIMENSIONAL SOLIDS - v2Eng.Hesham AL-HelaleeNo ratings yet

- P.K.Metha CONCRETE - Microstructure Properties and Materials - 34Document1 pageP.K.Metha CONCRETE - Microstructure Properties and Materials - 34Eng.Hesham AL-HelaleeNo ratings yet

- المعدله التحليل العددي الى تاريخ3.11.2019 اDocument1 pageالمعدله التحليل العددي الى تاريخ3.11.2019 اEng.Hesham AL-HelaleeNo ratings yet

- 12 Microstructure and Properties of Hardened ConcreteDocument1 page12 Microstructure and Properties of Hardened ConcreteEng.Hesham AL-HelaleeNo ratings yet

- Details of Design Spider GlassDocument1 pageDetails of Design Spider GlassEng.Hesham AL-HelaleeNo ratings yet

- CH3 Fundamentals For Finite Element Method - v2Document8 pagesCH3 Fundamentals For Finite Element Method - v2Eng.Hesham AL-Helalee100% (1)

- CH1 An Introduction To The Finite Element Method - v2Document21 pagesCH1 An Introduction To The Finite Element Method - v2Eng.Hesham AL-HelaleeNo ratings yet

- SteelDesign Composite Fu NewDocument6 pagesSteelDesign Composite Fu NewEng.Hesham AL-HelaleeNo ratings yet

- CH4 FEM FOR TRUSSES - v2Document13 pagesCH4 FEM FOR TRUSSES - v2Eng.Hesham AL-HelaleeNo ratings yet

- Negative Skin Friction: Example 11.15Document5 pagesNegative Skin Friction: Example 11.15Eng.Hesham AL-HelaleeNo ratings yet

- Design of Elevated TanksDocument24 pagesDesign of Elevated TanksEng.Hesham AL-HelaleeNo ratings yet

- Structural Strengtheningrepair of Reinforced Concrete RC Beams by Different Fiberreinforced Cementitious Materials A STDocument15 pagesStructural Strengtheningrepair of Reinforced Concrete RC Beams by Different Fiberreinforced Cementitious Materials A STEng.Hesham AL-HelaleeNo ratings yet

- EXAM of Engineering Mechanics Model (A)Document2 pagesEXAM of Engineering Mechanics Model (A)Eng.Hesham AL-HelaleeNo ratings yet

- 4 6037227067454523239Document4 pages4 6037227067454523239Eng.Hesham AL-HelaleeNo ratings yet

- 4 6043837262641234834Document3 pages4 6043837262641234834Eng.Hesham AL-HelaleeNo ratings yet

- 4 5956424765383116753Document9 pages4 5956424765383116753Eng.Hesham AL-HelaleeNo ratings yet

- Plastic Analysis GhaliDocument19 pagesPlastic Analysis GhaliEng.Hesham AL-HelaleeNo ratings yet

- Mass Concrete RMC Plum Concrete: Created By: Jay S. Singhania en No:146490306107 Civil-B Sem-5 Sir Bpti, BVNDocument36 pagesMass Concrete RMC Plum Concrete: Created By: Jay S. Singhania en No:146490306107 Civil-B Sem-5 Sir Bpti, BVNEng.Hesham AL-HelaleeNo ratings yet

- Glasscon Project Report - Rotschild 48 Tel Aviv IsraelDocument33 pagesGlasscon Project Report - Rotschild 48 Tel Aviv IsraelEng.Hesham AL-HelaleeNo ratings yet

- Beam.: Note:-Answer Ouestions OnlvDocument1 pageBeam.: Note:-Answer Ouestions OnlvEng.Hesham AL-HelaleeNo ratings yet

- 4 5956424765383116754Document3 pages4 5956424765383116754Eng.Hesham AL-HelaleeNo ratings yet

- Types of WeirsDocument8 pagesTypes of WeirsEng.Hesham AL-HelaleeNo ratings yet

- Weatherford OEPS BrochureDocument5 pagesWeatherford OEPS BrochureZharick RojasNo ratings yet

- SANS 182-2 Conductors For Overhead Electrical Transmission Lines. AACDocument16 pagesSANS 182-2 Conductors For Overhead Electrical Transmission Lines. AACLaxmishankar Katiyar100% (1)

- My Side of The Mountain PDFDocument61 pagesMy Side of The Mountain PDF12333% (3)

- Propositions: A. Learning Outcome Content StandardDocument9 pagesPropositions: A. Learning Outcome Content StandardMarc Joseph NillasNo ratings yet

- Throwing Garbage in The SeaDocument3 pagesThrowing Garbage in The SeaZaramagne CaliboNo ratings yet

- Biên dịch 3Document2 pagesBiên dịch 3Nguyen Tuan AnhNo ratings yet

- Đề MINH HỌA Số 11 Luyện Thi Tốt Nghiệp THPT 2023Document7 pagesĐề MINH HỌA Số 11 Luyện Thi Tốt Nghiệp THPT 2023Minh ThưNo ratings yet

- KuchhbhiDocument6 pagesKuchhbhiAbhishek KumarNo ratings yet

- Hirac (Manhole Installation)Document7 pagesHirac (Manhole Installation)tana50% (2)

- Application of Modern Technology For Fault Diagnosis in Power Transformers Energy ManagementDocument6 pagesApplication of Modern Technology For Fault Diagnosis in Power Transformers Energy ManagementCamila Caceres FloresNo ratings yet

- Solved Numerical Problems On Porter Governor: Solution: GivenDocument5 pagesSolved Numerical Problems On Porter Governor: Solution: GivenVenkat GamingNo ratings yet

- Green Chemistry ModuleDocument17 pagesGreen Chemistry ModuleAniruddhNo ratings yet

- Once Per Year (RPM Vision Planner) : How To Schedule Your RPM Plan UpdatesDocument1 pageOnce Per Year (RPM Vision Planner) : How To Schedule Your RPM Plan Updatestrav bae0% (1)

- Aliquat-336 As A Novel Collector For Quartz FlotationDocument8 pagesAliquat-336 As A Novel Collector For Quartz FlotationMaicol PérezNo ratings yet

- Virtue Ethics: Deficiency ExcessDocument1 pageVirtue Ethics: Deficiency ExcesschristianNo ratings yet

- Sika Anchorfix®-3030: Product Data SheetDocument5 pagesSika Anchorfix®-3030: Product Data SheetReab SimanthNo ratings yet

- Short CV RJCDocument3 pagesShort CV RJCShivani KhannaNo ratings yet

- Case Paul Foster The Secret Doctrines of The Tarot PDFDocument157 pagesCase Paul Foster The Secret Doctrines of The Tarot PDFLinden100% (1)

- Euro CPKDocument20 pagesEuro CPKnovarhai100% (1)

- Vellore CaseDocument17 pagesVellore Casesai kiran gudisevaNo ratings yet

- Past Simple WH Questions Word Order Exercise 2Document3 pagesPast Simple WH Questions Word Order Exercise 2karen oteroNo ratings yet

- 3.2.5.applying The Normal Curve Concepts in Problem Solving PDFDocument3 pages3.2.5.applying The Normal Curve Concepts in Problem Solving PDFJhasmin Jane LagamayoNo ratings yet

- Internal Conflict EssayDocument8 pagesInternal Conflict EssayafabfoilzNo ratings yet

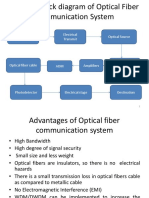

- Source of Information Electrical Transmit Optical SourceDocument37 pagesSource of Information Electrical Transmit Optical SourcesubashNo ratings yet

- Thermoports K-KB Series Operating InstructionsDocument5 pagesThermoports K-KB Series Operating InstructionsMuhammad Ali HaiderNo ratings yet

- Models of Cultural Heritage Management: Transformations in Business and Economics January 2014Document23 pagesModels of Cultural Heritage Management: Transformations in Business and Economics January 2014aaziNo ratings yet

- Operation and Control Philosophy: PROJ Kurdistan Pumping Station (KPS2)Document21 pagesOperation and Control Philosophy: PROJ Kurdistan Pumping Station (KPS2)Nobar GulajanNo ratings yet

- Math Makes Sense Practice and Homework Book Grade 5 AnswersDocument8 pagesMath Makes Sense Practice and Homework Book Grade 5 Answerseh041zef100% (1)

- PAPER (14) - Puucho PDFDocument21 pagesPAPER (14) - Puucho PDFethan tylerNo ratings yet

- Linear Inequalities in Two VariablesDocument8 pagesLinear Inequalities in Two Variableskiahjessie67% (3)