Professional Documents

Culture Documents

Strength and Factors Affecting Concrete Strength

Uploaded by

Mahbub AlamOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Strength and Factors Affecting Concrete Strength

Uploaded by

Mahbub AlamCopyright:

Available Formats

CE6110: Advanced Concrete Technology 27/4/2021

Lecture # 03

Strength of Concrete

Lt Col Md. Jahidul Islam, PhD, Engrs

e-mail: mjislam@ce.mist.ac.bd

The strength of concrete is the property most valued by

designers and quality control engineers

The most important practical factor is the w/c ratio, but the

underlying parameter is the number and size of pores in the

hardened cement paste.

In solids, there exists a fundamental inverse relationship

between porosity (volume fraction of voids) and strength

Consequently, in multiphase materials such as concrete, the

porosity of each component of the microstructure can become

strength-limiting

Concrete strength also depends on factors such as

Compaction, curing conditions (degree of cement hydration),

aggregate size and mineralogy, admixtures types, specimen

geometry and moisture condition, type of stress, and rate of

loading

CE6110: Dr M. Jahidul Islam 2

by Dr. M. Jahidul Islam 1

CE6110: Advanced Concrete Technology 27/4/2021

The strength of a material is defined as the ability to resist

stress without failure

Micro structural investigations of ordinary concrete show that

unlike most structural materials concrete contains many fine

cracks even before it is subjected to external stresses

In concrete, therefore, strength is related to the stress

required to cause failure and it is defined as the maximum

stress the concrete sample can withstand

In tension testing, the fracture of the test piece usually

signifies failure

In compression the test piece is considered to have failed even

when no signs of external fracture are visible; however, the

internal cracking has reached such an advanced state that the

specimen is unable to carry a higher load

CE6110: Dr M. Jahidul Islam 3

In concrete design and quality control, strength is the

property generally specified

This is because, compared to most other properties, testing

of strength is relatively easy

Furthermore, many properties of concrete, such as

elastic modulus,

water-tightness or impermeability, and

resistance to weathering agents including aggressive

waters,

are believed to be dependent on strength and may therefore

be deduced from the strength data

CE6110: Dr M. Jahidul Islam 4

by Dr. M. Jahidul Islam 2

CE6110: Advanced Concrete Technology 27/4/2021

The compressive strength of concrete is several times

greater than other types of strength

Therefore a majority of concrete elements are designed to take

advantage of the higher compressive strength of the material.

Although in practice most concrete is subjected

simultaneously to a combination of compressive, shearing,

and tensile stresses in two or more directions

The uniaxial compression tests are the easiest to perform in

laboratory, and

The 28-day compressive strength of concrete determined by a

standard uniaxial compression test is accepted universally as a

general index of the concrete strength

CE6110: Dr M. Jahidul Islam 5

In general, there exists a fundamental inverse relationship

between porosity and strength of solids.

For simple homogeneous materials, it can be described by the

expression

S = S0 e−kp

where S = strength of the material which has a given porosity p

S0 = intrinsic strength at zero porosity

k = constant

For many materials the ratio S/S0 plotted against porosity

follows the same curve

Actually, the same strength porosity relationship is applicable

to a very wide range of materials, such as iron, plaster of

Paris, sintered alumina, and zirconia

CE6110: Dr M. Jahidul Islam 6

by Dr. M. Jahidul Islam 3

CE6110: Advanced Concrete Technology 27/4/2021

CE6110: Dr M. Jahidul Islam 7

Powers found that the 28-day compressive strength fc of

three different mortar mixtures was related to the

gel/space ratio, or the ratio between the solid hydration

products in the system and the total space:

f c = ax 5

where a is the intrinsic strength of the material at zero

porosity p, and

x the solid/space ratio or the amount of solid fraction in

the system, which is therefore equal to 1 − p

Powers found the value of a to be 34,000 psi (234 MPa)

The similarity of the three curves in above figure

confirms the general validity of the strength-porosity

relationship in solids

CE6110: Dr M. Jahidul Islam 8

by Dr. M. Jahidul Islam 4

CE6110: Advanced Concrete Technology 27/4/2021

Whereas in hardened cement paste or mortar the porosity

can be related to strength, with concrete the situation is

not simple

The presence of microcracks in the interfacial transition

zone between the coarse aggregate and the matrix makes

concrete too complex a material for prediction of strength

by precise strength porosity relations

The general validity of strength-porosity relation, however,

must be respected because porosities of the component

phases of concrete, including the interfacial transition

zone, indeed become strength-limiting

With concrete containing the conventional low-porosity or

high strength aggregates, the strength of the material will

be governed both by the strength of the matrix and the

strength of the interfacial transition zone

CE6110: Dr M. Jahidul Islam 9

With a material such as concrete, which contains void

spaces of various size and shape in the matrix and

microcracks at the interfacial transition zone,

The failure modes under stress are very complex and vary with

the type of stress

A brief review of the failure modes, however, will be useful

in understanding and control of the factors that influence

concrete strength

Under uniaxial tension, relatively less energy is needed for

the initiation and growth of cracks in the matrix

Rapid propagation and interlinkage of the crack system,

consisting of preexisting cracks at the interfacial transition

zone and newly formed cracks in the matrix, account for

the brittle failure

CE6110: Dr M. Jahidul Islam 10

by Dr. M. Jahidul Islam 5

CE6110: Advanced Concrete Technology 27/4/2021

In compression, the failure mode is less brittle because

considerably more energy is needed to form and to extend

cracks in the matrix

In a uniaxial compression test on medium- or low-strength

concrete, no cracks are initiated in the matrix up to about

30 percent of the failure stress; at this stage a stable

system of cracks, called shear-bond cracks, already exists

in the vicinity of coarse aggregate

At higher stress levels, cracks are initiated within the

matrix; their number and size increases progressively with

increasing stress levels

The cracks in the matrix and the interfacial transition zone

(shearbond cracks) eventually join up, and generally a

failure surface develops at about 20° to 30° from the

direction of the load

CE6110: Dr M. Jahidul Islam 11

Very fine bond cracks exist at the interface between

coarse aggregate and hydrated cement paste even prior to

the application of load due to differences in stress-strain

behaviour, and in thermal and moisture movements.

Stress-strain relations for the aggregate and cement paste

are linear, but the stress-strain relation for concrete

becomes curvilinear at higher stresses.

At stresses above 30% of the ultimate strength, micro-

cracks begin to increase in length, width and number.

At this stage strain increases at a faster rate than the

stress.

At 70 to 90 % of the ultimate strength, cracks open

through the mortar matrix and thus bridge the bond cracks

so that a continuous crack pattern is formed.

CE6110: Dr M. Jahidul Islam 12

by Dr. M. Jahidul Islam 6

CE6110: Advanced Concrete Technology 27/4/2021

CE6110: Dr M. Jahidul Islam 13

The ratio of lateral strain to At this stage, the specimen

axial strain (i.e Poisson’s is no longer a continuous

ratio) is constant for body; there is a change

stresses below from a slow contraction in

approximately 30 % of the volume to a rapid increase

ultimate strength. in volume.

Beyond this point, Poisson’s

ratio increases slowly, and

at 70 – 90% of the ultimate

strength, it increases

rapidly due to the formation

of mainly vertical unstable

cracks.

CE6110: Dr M. Jahidul Islam 14

by Dr. M. Jahidul Islam 7

CE6110: Advanced Concrete Technology 27/4/2021

The response of concrete to applied stress depends not

only on the stress type but also on how a combination of

various factors affects porosity of the different structural

components of concrete

The factors include properties and proportions of

materials that make up the concrete mixture, degree of

compaction, and conditions of curing

From the standpoint of strength, the relationship

between water-cement ratio and porosity is undoubtedly

the most important factor because, independent of other

factors, it affects the porosity of both the cement mortar

matrix and the interfacial transition zone between the

matrix and the coarse aggregate

CE6110: Dr M. Jahidul Islam 15

CE6110: Dr M. Jahidul Islam 16

by Dr. M. Jahidul Islam 8

CE6110: Advanced Concrete Technology 27/4/2021

Direct determination of porosity of the individual

structural components of concrete—the matrix and the

interfacial transition zone—is impractical, and therefore

precise models of predicting concrete strength cannot

be developed

Although the actual response of concrete to applied

stress is a result of complex interactions between

various factors

To facilitate a clear understanding of these factors they

can be separately discussed under three categories:

Characteristics and proportions of materials,

Curing conditions, and

Testing parameters

CE6110: Dr M. Jahidul Islam 17

Before making a concrete mixture, the selection of proper

component materials and their proportions is the first step

toward obtaining a product that would meet the specified

strength

It should be emphasized again that, in practice, many

mixture design parameters are interdependent, and

therefore their influences cannot really be separated

Some of the aspects that are important from the

standpoint of concrete strength are considered here

Water-cement ratio

Air entrainment

Cement type

Aggregate

Mixing water

Admixtures

CE6110: Dr M. Jahidul Islam 18

by Dr. M. Jahidul Islam 9

CE6110: Advanced Concrete Technology 27/4/2021

In 1918, as a result of extensive testing at the Lewis

Institute, University of Illinois, Duff Abrams found that a

relation existed between water-cement ratio and

concrete strength

Popularly known as Abrams’ water-cement ratio rule, this

inverse relation is represented by the expression

A

c = 1.5( w / c )

B

where w/c represents the water-cement ratio of the

concrete mixture and A and B are empirical constants

Typical curves illustrating the relationship between

water-cement ratio and strength at a given moist-curing

age are shown in the following figure

CE6110: Dr M. Jahidul Islam 19

CE6110: Dr M. Jahidul Islam 20

by Dr. M. Jahidul Islam 10

CE6110: Advanced Concrete Technology 27/4/2021

In low- and medium-strength concrete made with normal

aggregate, both the interfacial transition zone porosity and

the matrix porosity determine the strength, and a direct

relation between the water-cement ratio and the concrete

strength holds

For water-cement ratios under 0.3, disproportionately high

increases in the compressive strength can be achieved with

very small reductions in water-cement ratio

The phenomenon is attributed mainly to a significant

improvement in the strength of the interfacial transition

zone at very low water-cement ratios

Furthermore, with low water-cement ratio the crystal size

of the hydration products is much smaller and the surface

area is correspondingly higher

CE6110: Dr M. Jahidul Islam 21

For the most part, it is the water-cement ratio that

determines the porosity of the cement paste matrix at a

given degree of hydration;

However, when air voids are incorporated into the system,

either as a result of inadequate compaction or through the

use of an air-entraining admixture, they also have the

effect of increasing the porosity and decreasing the

strength of the system

At a given water-cement ratio, the effect on the

compressive strength of concrete of increasing the volume

of entrained air is shown by the following curves

CE6110: Dr M. Jahidul Islam 22

by Dr. M. Jahidul Islam 11

CE6110: Advanced Concrete Technology 27/4/2021

CE6110: Dr M. Jahidul Islam 23

It has been observed that the extent of strength loss as a result of

entrained air depends not only on the water-cement ratio of the

concrete mixture, but also on the cement content

In short, as a first approximation, the strength loss due to air

entrainment can be related to the general level of concrete

strength

At a given water-cement ratio, high-strength concretes (containing

a high cement content) suffer a considerable strength loss with

increasing amounts of entrained air, whereas low-strength

concretes (containing a low cement content) tend to suffer only a

little strength loss or may actually gain some strength as a result of

air entrainment

The influence of the water-cement ratio and cement content on

the response of concrete to applied stress can be explained from

the two opposing effects caused by incorporation of air into

concrete CE6110: Dr M. Jahidul Islam 24

by Dr. M. Jahidul Islam 12

CE6110: Advanced Concrete Technology 27/4/2021

By increasing the porosity of the matrix, entrained air will

have an adverse effect on the strength of the composite

material

On the other hand, by improving the workability and

compactibility of the mixture, entrained air tends to

improve the strength of the interfacial transition zone

(especially in mixtures with very low water and cement

contents) and thus improves the strength of concrete

It seems that with concrete mixtures of low cement

content, when air entrainment is accompanied by a

significant reduction in the water content, the adverse

effect of air entrainment on the strength of the matrix is

more than compensated by the beneficial effect on the

interfacial transition zone

CE6110: Dr M. Jahidul Islam 25

The degree of cement hydration has a direct effect on porosity

and consequently on strength

At ordinary temperature ASTM Type III portland cement, which

has a higher fineness, hydrates more rapidly than other types;

therefore, at early ages of hydration (e.g., 1, 3, and 7 days)

and a given water-cement ratio, a concrete containing Type III

portland cement will have a lower porosity and correspondingly

a higher strength

On the other hand, compared to ASTM Type I, Type II, and Type

III portland cements, the rates of hydration and strength

development with Type IV and Type V cements, and with

portland-slag and portland pozzolan cements are slower up to

28 days

However, the differences usually disappear thereafter when

they have achieved a similar degree of hydration

CE6110: Dr M. Jahidul Islam 26

by Dr. M. Jahidul Islam 13

CE6110: Advanced Concrete Technology 27/4/2021

In concrete technology, an overemphasis on the

relationship between water-cement ratio and strength has

caused some problems

For instance, the influence of aggregate on concrete

strength is not generally appreciated

It is true that aggregate strength is usually not a factor in

normal strength concrete because, with the exception of

lightweight aggregates, the aggregate particle is several

times stronger than the matrix and the interfacial

transition zone in concrete

In other words, with most natural aggregates the strength

of the aggregate is hardly utilized because the failure is

determined by the other two phases

CE6110: Dr M. Jahidul Islam 27

There are, however, aggregate characteristics other than

strength, such as the size, shape, surface texture, grading

(particle size distribution), and mineralogy, which are

known to affect concrete strength in varying degrees

Frequently the effect of aggregate characteristics on

concrete strength can be traced to a change of water-

cement ratio

A change in the maximum size of well-graded coarse

aggregate of a given mineralogy can have two opposing

effects on the strength of concrete

With the same cement content and consistency, concrete

mixtures containing larger aggregate particles require less

mixing water than those containing smaller aggregate

CE6110: Dr M. Jahidul Islam 28

by Dr. M. Jahidul Islam 14

CE6110: Advanced Concrete Technology 27/4/2021

On the contrary, larger aggregates tend to form weaker

interfacial transition zone containing more microcracks

The net effect will vary with the water-cement ratio of

the concrete and the type of applied stress

CE6110: Dr M. Jahidul Islam 29

Aggregate

At lower water-cement ratios the reduced porosity of the interfacial

transition zone begins to play an important role in the concrete

strength

Furthermore, since the interfacial transition zone characteristics have

more effect on the tensile strength of concrete compared to the

compressive strength, it is to be expected that with a given concrete

mixture any changes in the coarse aggregate properties would

influence the tensile-compressive strength ratio of the material

For instance, a decrease in the size of coarse aggregate, at a given

water-cement ratio, will increase the tensile-compressive strength

ratio

A change in the aggregate grading without any change in the maximum

size of coarse aggregate, and with water-cement ratio held constant,

can influence the concrete strength when this change causes a

corresponding change in the consistency and bleeding characteristics

of the concrete mixture

CE6110: Dr M. Jahidul Islam 30

by Dr. M. Jahidul Islam 15

CE6110: Advanced Concrete Technology 27/4/2021

CE6110: Dr M. Jahidul Islam 31

Aggregate

It has been observed that a concrete mixture containing a rough-

textured or crushed aggregate would show somewhat higher

strength (especially tensile strength) at early ages

Stronger physical bond between the aggregate and the hydrated

cement paste is assumed to be responsible for this

At later ages, when chemical interaction between the aggregate

and the cement paste begins to take effect, the influence of the

surface texture of aggregate on strength may be reduced

Also, with a given cement content, somewhat more mixing water

is usually needed to obtain the desired workability in a concrete

mixture containing rough-textured aggregates

Thus the small advantage due to a better physical bonding may

be lost as far as the overall strength is concerned

CE6110: Dr M. Jahidul Islam 32

by Dr. M. Jahidul Islam 16

CE6110: Advanced Concrete Technology 27/4/2021

Aggregate

Differences in the mineralogical composition of aggregates are

also known to affect the concrete strength. This may be due to

the higher interfacial bond strength with limestone aggregate at

late ages

CE6110: Dr M. Jahidul Islam 33

Mixing water

Impurities in water used for mixing concrete, when excessive,

may affect not only the concrete strength but also setting time,

efflorescence (deposits of white salts on the surface of concrete),

and the corrosion of reinforcing and pre-stressing steel

In general, mixing water is rarely a factor in concrete strength

Many specifications for making concrete mixtures require that the

quality of water used should be fit for drinking, and municipal

drinking waters seldom contain dissolved solids in excess of 1000

ppm

As a rule, a water that is unsuitable for drinking may not

necessarily be unfit for mixing concrete

CE6110: Dr M. Jahidul Islam 34

by Dr. M. Jahidul Islam 17

CE6110: Advanced Concrete Technology 27/4/2021

Mixing water

Slightly acidic, alkaline, salty, brackish, colored, or foulsmelling

water should not be rejected outright

This is important because of the water shortage in many areas of

the world

Also, recycled waters from cities, mining, and many industrial

operations can be safely used as mixing waters for concrete

The best way to determine the suitability of a water of unknown

performance for making concrete is to compare the setting time

of cement and the strength of mortar cubes made with the

unknown water with reference water that is clean

Seawater, which contains about 35,000 ppm dissolved salts, is not

harmful to the strength of plain concrete

CE6110: Dr M. Jahidul Islam 35

Admixtures

By their ability to reduce the water content of a concrete

mixture, at a given consistency, the water-reducing

admixtures can enhance both the early and the ultimate

strength of concrete

At a given water-cement ratio, the presence of water-

reducing admixtures in concrete generally has a positive

influence on the rates of cement hydration and early

strength development

Admixtures capable of accelerating or retarding cement

hydration obviously would have a great influence on the

rate of strength gain; however, the ultimate strengths may

not be significantly affected

CE6110: Dr M. Jahidul Islam 36

by Dr. M. Jahidul Islam 18

CE6110: Advanced Concrete Technology 27/4/2021

Admixtures

However, the ability of a mineral admixture to react at normal

temperatures with calcium hydroxide (present in the hydrated

portland cement paste) and to form additional calcium silicate

hydrate can lead to significant reduction in porosity of both the

matrix and the interfacial transition zone

Consequently, considerable improvements in the ultimate

strength and watertightness of concrete are achievable by

incorporation of mineral admixtures

It should be noted that mineral admixtures are especially

effective in increasing the tensile strength of concrete

CE6110: Dr M. Jahidul Islam 37

Admixtures

CE6110: Dr M. Jahidul Islam 38

by Dr. M. Jahidul Islam 19

CE6110: Advanced Concrete Technology 27/4/2021

The term curing of concrete involves a combination

of conditions that promote the cement hydration,

namely time, temperature, and humidity conditions

immediately after the placement of a concrete

mixture into formwork

At a given water-cement ratio, the porosity of a

hydrated cement paste is determined by the degree

of cement hydration

Under normal temperature conditions some of the

constituent compounds of portland cement begin to

hydrate as soon as water is added

The hydration reactions slow down considerably when

the products of hydration coat the anhydrous cement

grains

CE6110: Dr M. Jahidul Islam 39

This is because hydration can proceed satisfactorily

only under conditions of saturation; it almost stops

when the internal relative humidity drops below

about 80% and eventually strength development will

be arrested

Such reduction will be greater in the case of high

strength concrete (low w/c ratio)

Time and humidity are therefore important factors in

the hydration process controlled by water diffusion

Also, like all chemical reactions, temperature has an

accelerating effect on the hydration reactions

CE6110: Dr M. Jahidul Islam 40

by Dr. M. Jahidul Islam 20

CE6110: Advanced Concrete Technology 27/4/2021

Time

It should be noted that the time-strength relations in

concrete technology generally assume moist-curing

conditions and normal temperatures

At a given water-cement ratio, the longer the moist

curing period the higher the strength assuming that the

hydration of anhydrous cement particles is still going on

In thin concrete elements, if water is lost by evaporation

from the capillaries, air-curing conditions prevail, and

strength will not increase with time

The evaluation of compressive strength with time is of

great concern to structural engineers

ACI Committee 209 recommends the following

relationship for moist cured concrete made with normal

portland cement (ASTM Type I)

CE6110: Dr M. Jahidul Islam 41

t

f cm ( t ) = f c 28

4 + 0.85t

CE6110: Dr M. Jahidul Islam 42

by Dr. M. Jahidul Islam 21

CE6110: Advanced Concrete Technology 27/4/2021

For concrete specimens cured at 20°C, the CEB-FIP

Models Code (1990) suggests the following relationship:

CE6110: Dr M. Jahidul Islam 43

The most desirable objective is to continuously moist cure

the concrete as long as possible-obviously this is seldom a

practical proposition

Generally, moist curing for about 7 days will ensure that

the 28-day moist-cured strength will eventually be

reached

The ACI Standard Practice for Curing (ACI 308) suggest 7

days of moist curing for most structural concrete or the

time necessary to attain 70% of the specified strength

These recommendation are for concretes placed and

cured at temperatures above 4C

CE6110: Dr M. Jahidul Islam 44

by Dr. M. Jahidul Islam 22

CE6110: Advanced Concrete Technology 27/4/2021

Humidity

The influence of the curing humidity on concrete strength is

obvious from the data, which show that after 180 days at a

given water-cement ratio, the strength of the continuously

moist-cured concrete was three times greater than the

strength of the continuously air-cured concrete

Furthermore, probably as a result of microcracking in the

interfacial transition zone caused by drying shrinkage, a slight

retrogression of strength occurs in thin members of moist-cured

concrete when they are subjected to air drying

The rate of water loss from concrete soon after the placement

depends not only on the surface/volume ratio of the concrete

element but also on temperature, relative humidity, and

velocity of the surrounding air

CE6110: Dr M. Jahidul Islam 45

Humidity

Water is held in larger capillary pores by surface tension forces below

100% RH

The cement can draw on these water reservoirs for further hydration

But the rate will become slower as the RH within the paste is lowered

Water is used first within its localized area of the paste, and those

areas that hydrate more rapidly will become starved for water

Additional water will move to those area rapidly in a fully saturated

system, but more slowly in a partially saturated system

Therefore, concrete that is sealed against moisture loss hydrates and

gains strength more slowly than concrete that is continuously moist

cured under water

Water cannot enter the sealed concrete, and the consumption of water

during hydration lower the internal RH

CE6110: Dr M. Jahidul Islam 46

by Dr. M. Jahidul Islam 23

CE6110: Advanced Concrete Technology 27/4/2021

Humidity

A minimum period of 7 days of moist-curing is generally

recommended with concrete containing normal portland cement

With concrete mixtures containing either a blended portland cement

or a mineral admixture, longer curing period is desirable to ensure

strength contribution from the pozzolanic reaction

Moist curing is provided by spraying or ponding or by covering the

concrete surface with wet sand, sawdust, or cotton mats

Since the amount of mixing water used in a concrete mixture is

usually more than needed for portland cement hydration (estimated

to be about 30 percent by weight of cement), proper application of

an impermeable membrane soon after the concrete placement

provides an acceptable way to maintain the strength development at

a satisfactory rate

However, moist-curing should be the preferred method when control

of cracking due to autogenous shrinkage or thermal shrinkage is

important

CE6110: Dr M. Jahidul Islam 47

Temperature

With moist-cured concrete the influence of temperature on

strength depends on the time-temperature history of casting

and curing

In the temperature range 5 to 46°C, when concrete is cast and

cured at a specific constant temperature, it is generally

observed that up to 28 days, the higher the temperature the

more rapid the cement hydration and the strength gain

On the other hand, it has been observed that the higher the

casting and curing temperature, the lower will be the ultimate

strength

From microscopic studies many researchers have concluded

that, with low temperature casting, a relatively more uniform

microstructure of the hydrated cement paste (especially the

pore size distribution) accounts for the higher strength

CE6110: Dr M. Jahidul Islam 48

by Dr. M. Jahidul Islam 24

CE6110: Advanced Concrete Technology 27/4/2021

CE6110: Dr M. Jahidul Islam 49

Temperature

It should be noted that curing at low temperatures can result in a

higher ultimate strength, even though the initial rate of strength is low

Thus, as a rule, the higher the initial temperature of the concrete, the

lower its later strength

For 28-day strengths, the optimum initial temperature is 4C for a Type

I cement

In general, the tensile strength is similarly affected by the curing

temperature

CE6110: Dr M. Jahidul Islam 50

by Dr. M. Jahidul Islam 25

CE6110: Advanced Concrete Technology 27/4/2021

Temperature

Since the hydration reactions of portland cement compounds are

slow, it appears that adequate temperature levels must be

maintained for a sufficient time to provide the needed activation

energy for the reactions to begin

This enables the strength development process that is associated with

progressive filling of voids with hydration products, to proceed

unhindered

The influence of time-temperature history on concrete strength has

several important applications in the concrete construction practice

The curing temperature is far more important to the strength than

the placement temperature

CE6110: Dr M. Jahidul Islam 51

It is not always appreciated that the results of concrete

strength tests are significantly affected by parameters

involving the test specimen and loading conditions

Specimen parameters include the

influence of size, geometry, and the moisture state of

concrete;

loading parameters include stress level and duration,

and

the rate at which stress is applied

CE6110: Dr M. Jahidul Islam 52

by Dr. M. Jahidul Islam 26

CE6110: Advanced Concrete Technology 27/4/2021

Specimen parameter

CE6110: Dr M. Jahidul Islam 53

In the United States, the standard specimen for testing

the compressive strength of concrete is a 15- by 30-cm

cylinder

While maintaining the height/diameter ratio equal to 2, if

a concrete mixture is tested in compression with

cylindrical specimens of varying diameter, the larger the

diameter the lower will be the strength

The average strength of 5- by 10-cm and 7.5- by 15-cm

cylindrical specimens was 106 and 108 percent,

respectively, as compared to the standard specimen

When the diameter is increased beyond 45 cm (18 in.), a

much smaller reduction in strength is observed

CE6110: Dr M. Jahidul Islam 54

by Dr. M. Jahidul Islam 27

CE6110: Advanced Concrete Technology 27/4/2021

CE6110: Dr M. Jahidul Islam 55

Moisture State

Because of the effect of moisture state on the concrete

strength, the standard procedure requires that the specimens

continue to be in a moist condition at the time of testing

In compression tests it has been observed that oven-dried

specimens show 10 to 15 percent higher strength than

corresponding specimens tested in a saturated condition

The reason for this are not completely understood

It may be due to change in the structure of C-S-H on dying

It may simply represent a change in the internal friction and cohesion

on a macroscopic level; that is moisture may have a “lubricating”

effect, allowing particles to slip by each other in shear more easily

The lower strength of the saturated concrete is attributed to

the development of internal pore pressure as a load is applied

CE6110: Dr M. Jahidul Islam 56

by Dr. M. Jahidul Islam 28

CE6110: Advanced Concrete Technology 27/4/2021

Moisture State

The effect of moisture content on strength becomes an

important consideration when testing drilled cores

ASTM C 42 recommends that concrete core be conditioned

to a moisture state most representative of the state of

the in-place concrete

Drying of the cores as specified will most commonly lead

to specimens with a moisture gradient from the outside to

the center

This will lead to lower measured strengths than those

obtained on specimens with a uniform moisture content

CE6110: Dr M. Jahidul Islam 57

Temperature

For reasons that are also not fully understood, the

temperature of the specimen at the time of testing will

affect the strength

Higher test temperature will result in lower strengths,

even for concretes that were identically cured in standard

conditions

CE6110: Dr M. Jahidul Islam 58

by Dr. M. Jahidul Islam 29

CE6110: Advanced Concrete Technology 27/4/2021

CE6110: Dr M. Jahidul Islam 59

by Dr. M. Jahidul Islam 30

You might also like

- Weekly HSE Report Format.Document2 pagesWeekly HSE Report Format.Binay100% (5)

- REINFORCED CONCRETE STRENGTHDocument6 pagesREINFORCED CONCRETE STRENGTHKrizza Joy Lintag CaspeNo ratings yet

- Tesis Mirip 2Document11 pagesTesis Mirip 2Doddy UskonoNo ratings yet

- Beushausen e AlexanderBondstrengthdevelopmentbetweenconcretesofdifferentagesDocument11 pagesBeushausen e AlexanderBondstrengthdevelopmentbetweenconcretesofdifferentagesLuis Felipe VerasNo ratings yet

- Construction and Building Materials: Gelen Gael Chewe Ngapeya, Danièle Waldmann, Franck ScholzenDocument16 pagesConstruction and Building Materials: Gelen Gael Chewe Ngapeya, Danièle Waldmann, Franck ScholzenFauziah AzizNo ratings yet

- Effects of Bonding Ajent and Surface PreperationDocument9 pagesEffects of Bonding Ajent and Surface PreperationPremasiri KarunarathnaNo ratings yet

- Research On Different Types of Cracks in Plain and Reinforced ConcreteDocument3 pagesResearch On Different Types of Cracks in Plain and Reinforced ConcreteSnehal AbhyankarNo ratings yet

- Experimental Study On Lateral-Load-Resisting CapacDocument17 pagesExperimental Study On Lateral-Load-Resisting CapacravirajNo ratings yet

- Masonry Wall StrengtheningDocument14 pagesMasonry Wall StrengtheningJ ChoyNo ratings yet

- Bond Behavior of Reinforcement in Self-Compacting ConcreteDocument9 pagesBond Behavior of Reinforcement in Self-Compacting ConcreteSaif BayyariNo ratings yet

- Effect of Age On Concrete Core Strength Results: October 2015Document5 pagesEffect of Age On Concrete Core Strength Results: October 2015Javer HumbertoNo ratings yet

- Construction and Building Materials: Yu Chen, Kejin Wang, Xuhao Wang, Wenfang ZhouDocument8 pagesConstruction and Building Materials: Yu Chen, Kejin Wang, Xuhao Wang, Wenfang ZhoumargarethsmNo ratings yet

- High Ductility ConcreteDocument6 pagesHigh Ductility ConcreteKurniawan PittaNo ratings yet

- International Journal of Impact Engineering: Taggedpjun Li, Chengqing Wu, Hong Hao, Yu Su, Zhong-Xian LiDocument13 pagesInternational Journal of Impact Engineering: Taggedpjun Li, Chengqing Wu, Hong Hao, Yu Su, Zhong-Xian LiDanNo ratings yet

- Roziere 2015Document9 pagesRoziere 2015'Vanessa VogtNo ratings yet

- An Appropriate Relationship Between Flexural Stren PDFDocument10 pagesAn Appropriate Relationship Between Flexural Stren PDFarjunNo ratings yet

- Acee 2011Document11 pagesAcee 2011Willy SusantoNo ratings yet

- Designing Walls to Resist Explosions and Natural HazardsDocument23 pagesDesigning Walls to Resist Explosions and Natural HazardsfilipeNo ratings yet

- Effect of age on concrete core strength test resultsDocument5 pagesEffect of age on concrete core strength test resultsvande gntNo ratings yet

- Effect of Concrete Core Age on Strength ResultsDocument5 pagesEffect of Concrete Core Age on Strength ResultsChidananda GNo ratings yet

- Cement and Cocnrete ResearchDocument6 pagesCement and Cocnrete Researchalexjos1No ratings yet

- Experimental Determination of Fracture Energy by RILEM MethodDocument10 pagesExperimental Determination of Fracture Energy by RILEM MethodtheijesNo ratings yet

- 203º Artigo (Buildings)-2024Document19 pages203º Artigo (Buildings)-2024daigodelgasNo ratings yet

- Effect of Concrete Mixture Components, Proportioning, and Compressive Strength On Fracture ParametersDocument14 pagesEffect of Concrete Mixture Components, Proportioning, and Compressive Strength On Fracture ParametersLương Chiến ThắngNo ratings yet

- Effect of Age On Concrete Core Strength ResultsDocument5 pagesEffect of Age On Concrete Core Strength ResultsYoussouf OumarNo ratings yet

- Construction and Building MaterialsDocument10 pagesConstruction and Building MaterialskashifNo ratings yet

- Engineering Structures: V. Sarhosis, S.W. Garrity, Y. ShengDocument11 pagesEngineering Structures: V. Sarhosis, S.W. Garrity, Y. ShengOktayNo ratings yet

- The Effect of Polypropylene Fibres On The Compressive Strength, Impact andDocument16 pagesThe Effect of Polypropylene Fibres On The Compressive Strength, Impact andmudasar205No ratings yet

- Materials 14 03043 v2Document25 pagesMaterials 14 03043 v2Bevelyn Ginhawa ManaloNo ratings yet

- Hanjari 2011Document11 pagesHanjari 2011Nora al-anssariNo ratings yet

- Structural Concrete - 2020 - Haavisto - Compressive Strength of Core Specimens Drilled From Concrete Test CylindersDocument13 pagesStructural Concrete - 2020 - Haavisto - Compressive Strength of Core Specimens Drilled From Concrete Test CylindersDananjaya K GNo ratings yet

- Relationship Between Compressive and Tensile Strengths of Roller-Compacted ConcreteDocument9 pagesRelationship Between Compressive and Tensile Strengths of Roller-Compacted ConcreteChidananda GNo ratings yet

- Construction and Building MaterialsDocument12 pagesConstruction and Building Materialschristian ricaldiNo ratings yet

- Fracture JournalDocument2 pagesFracture Journalkierjohn237343No ratings yet

- Assessing Concrete Durability from Permeation PropertiesDocument11 pagesAssessing Concrete Durability from Permeation Propertieslahcen essNo ratings yet

- Journal of Structural EngineeringDocument12 pagesJournal of Structural EngineeringDima OvsiiNo ratings yet

- Concrete Quality Evaluation With Electrical Resistivity MethodDocument1 pageConcrete Quality Evaluation With Electrical Resistivity MethodRoberto MuselliNo ratings yet

- De Ection Behavior of Concrete Beams Reinforced With PVA Micro-FibersDocument11 pagesDe Ection Behavior of Concrete Beams Reinforced With PVA Micro-FibersMohcene BoukhezarNo ratings yet

- Electrical Resistivity of Concrete For Durability Evaluation: A ReviewDocument31 pagesElectrical Resistivity of Concrete For Durability Evaluation: A ReviewEhsanul KabirNo ratings yet

- MS - Unit 4Document9 pagesMS - Unit 4sushant metriNo ratings yet

- Effects of Environment on Fracture Toughness of CompositesDocument7 pagesEffects of Environment on Fracture Toughness of CompositesNikhil KanojiNo ratings yet

- 2023 - CBM - 계면부착 리뷰Document15 pages2023 - CBM - 계면부착 리뷰이호진No ratings yet

- Influences of Random Imperfection Distribution On The Compressive Properties of Interlocking Block WallDocument19 pagesInfluences of Random Imperfection Distribution On The Compressive Properties of Interlocking Block WallGuanyu XieNo ratings yet

- Tensile Properties of Very-High-Strength Concrete For Penetration-Resistant StructuresDocument10 pagesTensile Properties of Very-High-Strength Concrete For Penetration-Resistant StructuresVinicius CoimbraNo ratings yet

- 2015-Abbagana Mohammed-Fracture Energy of Full Scale and Half Scale Masonry BricksDocument7 pages2015-Abbagana Mohammed-Fracture Energy of Full Scale and Half Scale Masonry BricksAbd ElRahman Abd AllahNo ratings yet

- M2 - Reinforced Concrete PropertiesDocument7 pagesM2 - Reinforced Concrete PropertiesKrushna LokareNo ratings yet

- J Conbuildmat 2021 123025Document12 pagesJ Conbuildmat 2021 123025Nadal201No ratings yet

- In Uence of Design Durability On Concrete Columns Fire PerformanceDocument10 pagesIn Uence of Design Durability On Concrete Columns Fire PerformanceSamuel Mendoza SNo ratings yet

- 2012 - Compressive Strength of Concrete After Early LoadingDocument7 pages2012 - Compressive Strength of Concrete After Early LoadingafuhcivNo ratings yet

- Non-Destructive Evaluation of Concrete Using Ultrasonic Pulse VelocityDocument6 pagesNon-Destructive Evaluation of Concrete Using Ultrasonic Pulse VelocityanpyaaNo ratings yet

- Acfrogcv8wyw7 Xgi1cleggs2fsynhkofcmdt1kbx4lzg It VM Kkxmtpl9tnf7f78 V2bocn1phzckeiug8cpqwtz9pvhrlogve XQHWL Wt5f Vfafoig6ahoykxnrtey5bwzvs2j0drladdmDocument23 pagesAcfrogcv8wyw7 Xgi1cleggs2fsynhkofcmdt1kbx4lzg It VM Kkxmtpl9tnf7f78 V2bocn1phzckeiug8cpqwtz9pvhrlogve XQHWL Wt5f Vfafoig6ahoykxnrtey5bwzvs2j0drladdmmd ashraful alamNo ratings yet

- Fracture Mechanics Applications in Structural SafetyDocument5 pagesFracture Mechanics Applications in Structural SafetyShwetha JNo ratings yet

- Cracking Tendency of Self-Compacting Concrete Due To Restrained Shrinkage Experimental Study and ModelingDocument10 pagesCracking Tendency of Self-Compacting Concrete Due To Restrained Shrinkage Experimental Study and ModelingahmadNo ratings yet

- Development of Compressive Strength and Ultrasonic Pulse Velocity Relationship of Microbial Concrete Using Bacillus Subtilis BacteriaDocument10 pagesDevelopment of Compressive Strength and Ultrasonic Pulse Velocity Relationship of Microbial Concrete Using Bacillus Subtilis BacteriaIJAR JOURNALNo ratings yet

- 표면조도 다이얼게이지_240229_151202Document17 pages표면조도 다이얼게이지_240229_151202이호진No ratings yet

- Effect of Maximum Aggregate Size On The Bond Strength of Reinforcements in ConcreteDocument6 pagesEffect of Maximum Aggregate Size On The Bond Strength of Reinforcements in Concreteengineersalam786No ratings yet

- Construction Materials Strength AssessmentDocument11 pagesConstruction Materials Strength AssessmentSwëêt Rãsçäl SëlvåNo ratings yet

- Matecconf cs2022 07006Document8 pagesMatecconf cs2022 07006SC MichalNo ratings yet

- Hou Et Al., Effects of CoarseDocument12 pagesHou Et Al., Effects of CoarseÁlvaro MendozaNo ratings yet

- Mediam of InstructionDocument1 pageMediam of InstructionMahbub AlamNo ratings yet

- Coupled Shear Wall StructuresDocument38 pagesCoupled Shear Wall StructuresMahbub AlamNo ratings yet

- CE 6109-Chapter 2Document17 pagesCE 6109-Chapter 2Mahbub AlamNo ratings yet

- Capillary Rise Method For The Measurement of The Contact Angle of SoilsDocument15 pagesCapillary Rise Method For The Measurement of The Contact Angle of SoilsMahbub AlamNo ratings yet

- Core StructuresDocument26 pagesCore StructuresMahbub AlamNo ratings yet

- PVD & PHDDocument9 pagesPVD & PHDMahbub AlamNo ratings yet

- CE 6109 Chapter-5Document34 pagesCE 6109 Chapter-5Mahbub AlamNo ratings yet

- Western Engineering Materials RequirementDocument1 pageWestern Engineering Materials RequirementMahbub AlamNo ratings yet

- CE 6505: Structural Design of Pavements (3.0 CR) : Course OutlineDocument27 pagesCE 6505: Structural Design of Pavements (3.0 CR) : Course OutlineMahbub AlamNo ratings yet

- Pavement Design Guide For RHDDocument12 pagesPavement Design Guide For RHDMohammad Imran NewazNo ratings yet

- Structural Design of Pavement Lec_ Composite Pavement_Mechanistic-Empirical (MEDocument19 pagesStructural Design of Pavement Lec_ Composite Pavement_Mechanistic-Empirical (MEMahbub AlamNo ratings yet

- Final Lec JointsDocument54 pagesFinal Lec JointsMahbub AlamNo ratings yet

- Plan of Road Madani Ave - Link Road - Plan and ProfileDocument6 pagesPlan of Road Madani Ave - Link Road - Plan and ProfileMahbub AlamNo ratings yet

- ROW Protection Work-All Package (Modified-14-06-2022, Engr. Mahbub Alam)Document6 pagesROW Protection Work-All Package (Modified-14-06-2022, Engr. Mahbub Alam)Mahbub AlamNo ratings yet

- Prestressed - Solved ExamplesDocument4 pagesPrestressed - Solved ExamplesSofya Sa91% (11)

- BoQ of Brick WorkDocument1 pageBoQ of Brick WorkMahbub AlamNo ratings yet

- Testing 7-Wire Strand For PDFDocument22 pagesTesting 7-Wire Strand For PDFeltopo2No ratings yet

- Modulus ElasticityDocument8 pagesModulus ElasticityLhizaNo ratings yet

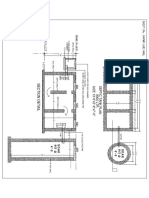

- Corrected Drawing of RailingDocument1 pageCorrected Drawing of RailingMahbub AlamNo ratings yet

- RCC Pipe & U DrainDocument1 pageRCC Pipe & U DrainMahbub AlamNo ratings yet

- MULTI-STRAND POSTENSIONING SYSTEM FEATURESDocument30 pagesMULTI-STRAND POSTENSIONING SYSTEM FEATURESMahbub AlamNo ratings yet

- Elevation of LB-04 With RailingDocument1 pageElevation of LB-04 With RailingMahbub AlamNo ratings yet

- Term Paper-Non Destructive Test of ConcreteDocument8 pagesTerm Paper-Non Destructive Test of ConcreteMahbub AlamNo ratings yet

- Lecture # 06 Aggregate: LT Col Md. Jahidul Islam, PHD, EngrsDocument25 pagesLecture # 06 Aggregate: LT Col Md. Jahidul Islam, PHD, EngrsMahbub AlamNo ratings yet

- Report of Case StudyDocument21 pagesReport of Case StudyMahbub AlamNo ratings yet

- CE 6105 - Lecture-9 Time Dependent DeformationDocument31 pagesCE 6105 - Lecture-9 Time Dependent DeformationMahbub AlamNo ratings yet

- BOQ of Railing LB-04Document1 pageBOQ of Railing LB-04Mahbub AlamNo ratings yet

- CE6110 Lecture on Advanced Concrete TechnologyDocument13 pagesCE6110 Lecture on Advanced Concrete TechnologyMahbub AlamNo ratings yet

- Lecture # 05 Cement: LT Col Md. Jahidul Islam, PHD, EngrsDocument28 pagesLecture # 05 Cement: LT Col Md. Jahidul Islam, PHD, EngrsMahbub AlamNo ratings yet

- Design Basis Report - 22 Sep08Document26 pagesDesign Basis Report - 22 Sep08Bejil ShresthaNo ratings yet

- Septic Tank DetailDocument1 pageSeptic Tank DetailVishnu PrajapatiNo ratings yet

- Water Treatment Plant: F/W Tank Raw WaterDocument1 pageWater Treatment Plant: F/W Tank Raw WaterRezky MasturaNo ratings yet

- The Impact of Stripping Gas Flow Rate On Triethylene Glycol Losses Fromglycol Regeneration Unit Simulation Study 2157 7048 1000337Document7 pagesThe Impact of Stripping Gas Flow Rate On Triethylene Glycol Losses Fromglycol Regeneration Unit Simulation Study 2157 7048 1000337arispriyatmonoNo ratings yet

- Sewage Treatment PlantDocument22 pagesSewage Treatment PlantJordan Allen BarriosNo ratings yet

- Determination of Solids in WaterDocument7 pagesDetermination of Solids in WaterManoj KarmakarNo ratings yet

- Ncert CH 16 - RemovedDocument11 pagesNcert CH 16 - RemovedAwesome WorldNo ratings yet

- Water As A Polar MoleculeDocument13 pagesWater As A Polar MoleculeAyaan Asim KhanNo ratings yet

- Fire Stone Via KermesDocument4 pagesFire Stone Via Kermesforest ravensonNo ratings yet

- Measuring Turbidities Using a NephelometerDocument5 pagesMeasuring Turbidities Using a NephelometerNazrul IzdhamNo ratings yet

- Environment Department, Room No. 217, 2nd Floor, Mantralaya, Annexe, Mumbai-400 032. Date:July 23, 2019 Suraj Estate Developers Pvt. LTD SubjectDocument12 pagesEnvironment Department, Room No. 217, 2nd Floor, Mantralaya, Annexe, Mumbai-400 032. Date:July 23, 2019 Suraj Estate Developers Pvt. LTD SubjectrotscribdNo ratings yet

- Fades Models Sandy Fluvial Systems: Exi Is)Document9 pagesFades Models Sandy Fluvial Systems: Exi Is)Sandra ValdezNo ratings yet

- Soal Latihan Ipa 8 PDFDocument12 pagesSoal Latihan Ipa 8 PDFFitria Istikomah DewiNo ratings yet

- Geography MCQs From Past Papers PPSC,NTS,OTS,FPSCDocument38 pagesGeography MCQs From Past Papers PPSC,NTS,OTS,FPSCShahroz AsifNo ratings yet

- Heat Rate Monitoring: Soumyajit MukherjeeDocument38 pagesHeat Rate Monitoring: Soumyajit MukherjeentpckanihaNo ratings yet

- D1426-15 Standard Test Methods For Ammonia Nitrogen in WaterDocument9 pagesD1426-15 Standard Test Methods For Ammonia Nitrogen in Waterastewayb_964354182No ratings yet

- TimeDocument67 pagesTimeUnnati AgarwalNo ratings yet

- IUBAT-International University of Business Agriculture and TechnologyDocument25 pagesIUBAT-International University of Business Agriculture and TechnologyJesan sakin0% (1)

- Hakdog Na Performance TaskDocument7 pagesHakdog Na Performance TaskAshley DalaguitNo ratings yet

- Concept Map of ImbibitionDocument1 pageConcept Map of ImbibitionDeasserei TatelNo ratings yet

- UntitledDocument6 pagesUntitledNimish GoyalNo ratings yet

- HDPE CatalogDocument56 pagesHDPE CatalogSalwa AlsamnehNo ratings yet

- Matter Classification WorksheetDocument7 pagesMatter Classification WorksheetAsru Rojam100% (1)

- Class Notes - Fishing in DenmarkDocument3 pagesClass Notes - Fishing in DenmarkJoséAlexandreKozelNo ratings yet

- Operating instructions for washing machineDocument96 pagesOperating instructions for washing machineSasa GloginjicNo ratings yet

- 12Document22 pages12samuel pinedaNo ratings yet

- Pollution in California's Drinking Water Pollution in California's Drinking WaterDocument14 pagesPollution in California's Drinking Water Pollution in California's Drinking Waterapi-549042757No ratings yet

- Review of Permeable Pavement Systems in Malaysia ConditionsDocument10 pagesReview of Permeable Pavement Systems in Malaysia ConditionsEkki GustiNo ratings yet

- CBLM Uc2-1Document30 pagesCBLM Uc2-1May Mutya0% (1)