Professional Documents

Culture Documents

Sid 57-10-04

Uploaded by

Jorge Fernandez100%(1)100% found this document useful (1 vote)

55 views5 pagesNDT Cessna

Original Title

SID 57-10-04

Copyright

© © All Rights Reserved

Available Formats

PDF or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentNDT Cessna

Copyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

100%(1)100% found this document useful (1 vote)

55 views5 pagesSid 57-10-04

Uploaded by

Jorge FernandezNDT Cessna

Copyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

You are on page 1of 5

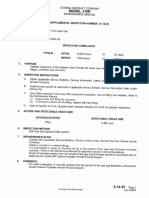

CESSNA AIRCRAFT COMPANY

MODEL 310R

MAINTENANCE MANUAL

SUPPLEMENTAL INSPECTION NUMBER: 57-10-04

4. TITLE

Lower Wing Rear Spar Cap at Splice

2. EFFECTIVITY

310R0001 Thru 310R2140

INSPECTION COMPLIANCE

TYPICAL: INTIAL 5,000 Hours Or 10 Years

REPEAT — 1,000 Hours Or 3 Years

PURPOSE

Detailed inspection of the fastener holes common to the lower rear spar cap flanges and the lower

rear spar cap splice angles for cracks due to fatigue, overload, and corrosion,

INSPECTION INSTRUCTIONS

A. Remove access panels in the aft auxiliary spar. Refer to the Maintenance Manual.

B. Remove wing access panels immediately outboard of the engine nacelle in the upper and lower skin.

Refer to the Maintenance Manual.

©. Refer to Section 5-15-34, Supplemental Inspection Number 57-10-04, for specific instructions.

D. _ Inspect the rear spar for corrosion. Special attention should be given to the spar in the areas directly

behind the exhaust ducts and near the flap attachments.

E. Reinstall wing access panels and auxiliary spar access panels in compliance with the Maintenance

Manual

5. ACCESS AND DETECTABLE CRACK SIZE

ACCESSILOCATION DETECTABLE CRACK SIZE

Wing 0.080 Inch

6. INSPECTION METHOD

Bolt Hole and Surface Eddy Current

7. REPAIR/MODIFICATION

It is permissible to repair by blending out up to ton percent of the spar cap thickness to remove

corrosion. Refer to the Maintenance Manual for approved corrosion removal procedures. If corrosion

is caused by exhaust gases, contact Cessna Propeller Aircraft Product Support for additional

instructions,

Repair of corrosion caused by exhaust gases, corrosion greater than ten percent of the spar cap

thickness or any repair not covered by recommendations in the Maintenance Manuel should be

coordinated prior to beginning the repair with Cessna Propeller Aircraft Product Support.

8. COMMENTS

If a crack is detected, or repair for corrosion is required beyond the defined limits, contact Cessna

Propeller Aircraft Product Support.

5-14-34 Paget

© Cessna Acta Comeany ‘Jan 3/2005

CESSNA AIRCRAFT COMPANY

MODEL 310R

MAINTENANCE MANUAL.

‘SUPPLEMENTAL INSPECTION NUMBER: 57-10-04

4. TLE

Lower Wing Rear Spar Cap Splice

2. EFFECTIVITY

310R0001 Thru 310R2140

3. DESCRIPTION

Inspect for fatigue cracks in the wing lower rear spar cap flanges and the lower rear spar splice angles.

4. PREPARATION

‘A. Remove four fasteners [310R0001 - 310R0500] or two fasteners [310R0001 - 310R2140] common to

the lower rear spar cap flanges and the lower rear spar cap splice angles at the outboard end of the

splice. Refer to Figure 1.

8B. Clean the inspection area with solvent to remove dirt, grease, oll and other substances that may

interfere with the inspection.

INSPECTION METHOD

Bolt Hole and Surface Eddy Current

CRACK SIZE

Minimum detectable crack size: 0.80 Inch

EQUIPMENT

‘The following equipment was used to develop this procedure. Equivalent eddy current test equipment

may be used providing the equipment is capable of achieving the required frequency range and test

sensitivity. Refer to Section 5-13-01, for eddy current inspection requirements,

PART NUMBER QUANTITY DESCRIPTION

NDT 19¢" 1 IMPEDANCE PLANE EDDY CURRENT

INSTRUMENT

Staveley Instruments, Inc.

421 North Quay

Kennewick, WA 99336

Vi1018S 5/32 1 5132 INCH BOLT HOLE EDDY CURRENT PROBE

VM Products.

11208 62 Ave.

Puyallup, WA 98373

MP905-60/500K 1 48 INCH SURFACE EDDY CURRENT PROBE

100-500 kHz NDT Engineering Corp.

19620 Russell Rd.

Kent, WA 98032

‘Aluminum Bolt Hole 1 REFERENCE STANDARD

Reference Standard: A commercially available bolt hole standard for

EDM comer notch (NIST calibration of unit

traceable) size: 0.050 x

0.050 inch.

Aluminum Surface 1 REFERENCE STANDARD

Reference Standard: A commercially available surface standard for

EDM comer notch (NIST calibration of unit.

traceable) depth: 0.020 inch,

5-15-34 Paget

(© Cessna Aircraft Company Jan 3/2005

CESSNA AIRCRAFT COMPANY

MODEL 310R

MAINTENANCE MANUAL

INSPECTION INSTRUCTIONS

A.

Bolt Hole inspection

(1) Connect the bolt hole probe (0.156 inch diameter) to the eddy current Instrument and adjust the

instrument frequency to 200 kHz.

(2) Null the probe in the appropriate reference standard hole away from the calibration notch.

(3) Adjust the lift-off on impedance plane instrumentation so the deflection of the lift-off trace is

horizontal and deflects from right to left as the probe is lifted from the part surface.

(4) Adjust the instrument gain controls to obtain a signal amplitude response from the calibration

notch that is a minimum of 2 major screen divisions.

(5) Inspect the inner circumference of each hole common to the wing lower rear spar cap flanges.

and the lower rear spar cap splice angles at WS 80.13. Refer to Figure 1

(a) Inspect the entire depth of each hole.

(b) Observe the phase and amplitude changes on the eddy current instrument.

(c)__Ifan indication is noted, carefully repeat the inspection in the opposite direction of probe

rotation to verify the indication.

(6) _Ifno crack is found, reinstall MS20426AD fasteners of appropriate size and grip length.

(7) Report cracks detected during this inspection to Cessna Propeller Aircraft Product Support,

along with the hole diameter, location of hole, hole edge distance, and approximate length and

depth of the crack.

Surface Inspection

(1) Standardize the eddy current instrument in accordance with the manufacturer's instructions

using an operating frequency of 200 kHz.

(2) Adjust tho instrument parameters such that the lit-of is placed horizontal and to the left of the

null point on the impedance plane.

(3) Using the surface crack standard, adjust the instrument parameters to achieve @ minimum

vertical separation of 3 major divisions between the null point and the 0.020 inch depth surface

notch indication,

(4) Perform a surface inspection immediately adjacent to the holes in the attach fing.

(2) Inspect both forward and aft side of each hole,

(0) _ Perform a surface inspection in each radius and along the free edges of the altach iting

(8) Cracks detected during this inspection shall be reported to Cessna Propeller Acraft Product

Support, along with the hole diameter, location of hole, hole edge distance, and approximate

length and depth of the crack.

5-15-34 Page 2

(© Cessna Arcraft Company Jan 3/2005

CESSNA AIRCRAFT COMPANY

MODEL 310R

MAINTENANCE MANUAL

{|

~

FwD

OUTED >

VIEW LOOKING UP AT LEFT WING

REMOVE FASTENERS AND

INSPECT ENTIRE HOLE

CIRCUMFERENCE

(4 PLACES)

LOWER WING

REAR SPAR CAP

DETAIL A

AIRPLANES 310R0001 THRU 310R0500

Lower Wing Rear Spar Cap at Splice, WS 80.13, Inspection

Figure 4 (Sheet 1)

5-15-34 Pages

© Cosena Aircraft Company Jan 3/2005

CESSNA AIRCRAFT COMPANY

MODEL 310R

MAINTENANCE MANUAL,

REMOVE FASTENERS AND

INSPECT ENTIRE HOLE

CIRCUMFERENCE

(2 PLACES)

LOWER WING

REAR SPAR CAP

peTaiL A

AIRPLANES 310R0501 THRU 310R2140

Lower Wing Rear Spar Cap at Splice, WS 80.19, Inspection

Figure 1 (Sheet 2)

5-15-34 Page 4

© Cessna Alera Company Jan 3/2005

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5806)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1091)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (842)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (589)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (897)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (345)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (401)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- NDT Main RotorDocument2 pagesNDT Main RotorJorge FernandezNo ratings yet

- Sid 54-10-00Document5 pagesSid 54-10-00Jorge FernandezNo ratings yet

- Sid 57-10-05Document5 pagesSid 57-10-05Jorge FernandezNo ratings yet

- Ndi06 32 13 05 001Document8 pagesNdi06 32 13 05 001Jorge FernandezNo ratings yet

- Sid 32-30-07Document1 pageSid 32-30-07Jorge FernandezNo ratings yet

- Ndi06 51 00 02 001Document8 pagesNdi06 51 00 02 001Jorge FernandezNo ratings yet

- Ndi06 51 00 01 001Document10 pagesNdi06 51 00 01 001Jorge FernandezNo ratings yet

- Ndi06 32 13 01 001Document6 pagesNdi06 32 13 01 001Jorge FernandezNo ratings yet

- Ndi06 53 10 01 001Document9 pagesNdi06 53 10 01 001Jorge FernandezNo ratings yet

- Ndi06 32 12 00 001Document8 pagesNdi06 32 12 00 001Jorge FernandezNo ratings yet

- Ndi06 32 12 05 001Document8 pagesNdi06 32 12 05 001Jorge FernandezNo ratings yet

- Ndi06 32 11 00 001Document8 pagesNdi06 32 11 00 001Jorge FernandezNo ratings yet

- Ipc Cessna 150Document476 pagesIpc Cessna 150Jorge FernandezNo ratings yet