100% found this document useful (1 vote)

582 views107 pagesEddy Current vs Ultrasonic Testing

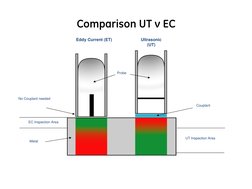

The document compares Eddy Current (EC) inspection and Ultrasonic (UT) inspection. Some key differences are:

- EC does not require a couplant between the probe and metal, while UT does require a couplant.

- EC has a smaller inspection area than UT.

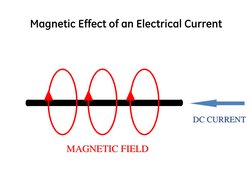

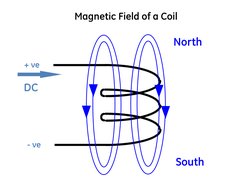

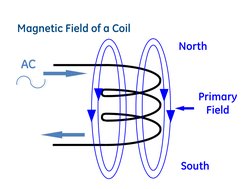

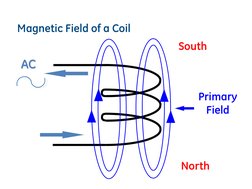

- EC relies on eddy currents induced in the metal by an alternating magnetic field from the probe, while UT relies on ultrasonic waves reflected by defects.

- Several factors affect eddy currents, including conductivity, permeability, frequency, geometry, proximity to defects, and probe handling. Impedance plane instruments can help interpret EC inspection results.

Uploaded by

CERTSCopyright

© © All Rights Reserved

We take content rights seriously. If you suspect this is your content, claim it here.

Available Formats

Download as PDF, TXT or read online on Scribd

100% found this document useful (1 vote)

582 views107 pagesEddy Current vs Ultrasonic Testing

The document compares Eddy Current (EC) inspection and Ultrasonic (UT) inspection. Some key differences are:

- EC does not require a couplant between the probe and metal, while UT does require a couplant.

- EC has a smaller inspection area than UT.

- EC relies on eddy currents induced in the metal by an alternating magnetic field from the probe, while UT relies on ultrasonic waves reflected by defects.

- Several factors affect eddy currents, including conductivity, permeability, frequency, geometry, proximity to defects, and probe handling. Impedance plane instruments can help interpret EC inspection results.

Uploaded by

CERTSCopyright

© © All Rights Reserved

We take content rights seriously. If you suspect this is your content, claim it here.

Available Formats

Download as PDF, TXT or read online on Scribd