Professional Documents

Culture Documents

1 0 4 7 4 5 - 4 5 0 0 (4510) Huyundai̇

1 0 4 7 4 5 - 4 5 0 0 (4510) Huyundai̇

Uploaded by

BaytolgaOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

1 0 4 7 4 5 - 4 5 0 0 (4510) Huyundai̇

1 0 4 7 4 5 - 4 5 0 0 (4510) Huyundai̇

Uploaded by

BaytolgaCopyright:

Available Formats

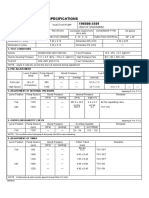

Ass'y No.

: 1 0 4 7 4 5 - 4 5 0 0

조 정 데 이 터

INJ. PUMP CALIBRATION DATA

ENG. Type :

A kind of car :

T - E/G

Grace VAN

Drawing No. : 94 - 01 - 01 - 03 Company : HYUNDAI MOTORS

General Ass'y No. : KP-VE4/10F2100RNP.... Date : 1994. 01. 01.

Pre - Stroke : Pump rotation:Clockwise-viewed from drive side

1. Test Conditions

1-1 Nozzle ; 105780-0000(KP-DN12SD12T) 1-4 Injection pipe : 2mm×6mm×840mm

1-2 Nozzle holder : 105780-2080 1-5 Fuel oil temperature : 45 + 5℃

1-3 Nozzle opening pressure : 150+5 Kgf/㎠ 1-6 Supply pump pressure : 0.2 Kgf/㎠

2. Setting Pump speed Settings Charge air Difference

(r/min) pressure(mmHg) in delivery

2-1 Timing device travel 1,250 3.6±0.2 mm

2-2 Supply pump pressure 1,250 4.8±0.3 Kgf/㎠

2-3 Full load delivery(FULL) 1,250 49.5±1.0 cc/1000st 2.5

2-4 Idle speed regulation 375 11.0±1.5 cc/1000st 2.0

2-5 Start 100 55.0~70.0 cc/1000st

2-6 Full load speed regulation 2,550 18.0±3.0 cc/1000st

2-7 Load-timer Adjustment 1,250 34.0±1.0 cc/1000st

T = 3.2±0.2 mm

3. Test Specifications Charge air pressure(mmHg)

3-1 Timing device N = r/min 600 1,250 2,100

mm 1.4±0.4 3.6±0.2 6.9±0.4

3-2 Supply pump N = r/min 600 1,250 2,100

Kgf/㎠ 3.2±0.3 4.8±0.3 6.8±0.3

3-3 Overflow delivery N = r/min 1,250 cc/1000st 420±130 BCS Pressure

3-4 Fuel injection quantities

Speed control lever Pump speed Fuel delivery Charge air 4.Dimensions

position (r/min) (cc/1000st) pressure (mmHg)

Full - load speed 600 (44.0±1.5) K 3.3±0.1

840 43.0±1.5 KF 5.8±0.1

1,250 49.5±1.0 MS 1.0±0.1

1,750 (44.0±1.5) BCS

2,100 41.5±1.5

Control lever angle

α 21。± 4。

Switch OFF Magnet valve 100 M/V OFF Q = 0 A mm

Idling stop 600 Below 3.0 β 41。± 5。

B mm

3-5 Solenoid valve Max. cut-in voltage 8V

Test voltage 12 ∼ 14 V

DOOWON PRECISION INDUSTRY Co., Ltd. Service Department

DPICO 503-5,SHINSA-DONG,KANGNAM-GU,SEOUL,KOREA TEL:(02)510-7241∼6, FAX:(02)510-7111

Ass'y No. : 104745 - 4500, 4510, 4520, 4530

※ Load timer adjustment.

1.Adjust the governor shaft so that the clearance between the end of the

flange and the end of the governor shaft is approximately 3mm and then

lock the nut.

2.Load timer adjustment.

(1)Fix the control lever in the position satisfying the following

conditions:

Boost Pressure :

Pump speed : 1,250 r/min

Fuel injection quantity : 34.0±1.0 cc/1000st

(2)With the control lever positioned as described in (1) above adjust the

governor sleeve so that the timer reduction value (△T) conforms to the

specified values (item 2-7)

T = 17∼22 N·m (1.7∼2.2 Kg.m)

3.Confirmation of Timer Characteristics.

Fix the control lever in the position satisfying the following conditions

and confirm the timer stroke.

Control lever position Specified Values

Pump speed Fuel injection q'ty Boost pressure Timer stroke Timer reduction

(r/min) (cc/1000st) (mmHg) (mm) value (mm)

49.5±1.0 3.6±0.2

1,250 34.0±1.0 3.2±0.2 (0.4)

26.5±1.0 2.4±0.4 (1.2)

375 11.0±1.5 0

You might also like

- EI5501Document4 pagesEI5501aaa bbb100% (1)

- Bomba de Inyeccion 6068TF250Document4 pagesBomba de Inyeccion 6068TF250luishernandez100% (1)

- 104740-0976 - Ford RangerDocument6 pages104740-0976 - Ford RangerBaytolgaNo ratings yet

- Dpico: Inj. Pump Calibration DataDocument2 pagesDpico: Inj. Pump Calibration DataMiguel RojasNo ratings yet

- Dpico: Inj. Pump Calibration DataDocument3 pagesDpico: Inj. Pump Calibration DataСергей ВладимировичNo ratings yet

- 780 7030Document3 pages780 7030Miguel ChaconNo ratings yet

- Dpico: Inj. Pump Calibration DataDocument2 pagesDpico: Inj. Pump Calibration DataMiguel RojasNo ratings yet

- Injection Pump Test Specifications 191000-490#Document3 pagesInjection Pump Test Specifications 191000-490#Miguel Rojas100% (1)

- Inj. Pump Calibration Data: 1. Test ConditionsDocument4 pagesInj. Pump Calibration Data: 1. Test ConditionsBrigida Torres Moreno0% (1)

- EB8870Document2 pagesEB8870Miguel RojasNo ratings yet

- Doosan Engine: Ratings (KWM/PS)Document4 pagesDoosan Engine: Ratings (KWM/PS)Vu DangNo ratings yet

- Injection Pump Test Specifications: CPS21 AVM2PC-20hpDocument2 pagesInjection Pump Test Specifications: CPS21 AVM2PC-20hpDilakartikaNo ratings yet

- Ee6790 1Document3 pagesEe6790 1Miguel RojasNo ratings yet

- Inj - P Ump Cal Ibration DataDocument3 pagesInj - P Ump Cal Ibration DataСергей ВладимировичNo ratings yet

- Injection Pump Test Specifications 196000-517#Document4 pagesInjection Pump Test Specifications 196000-517#Edinson Ariel Chavarro QuinteroNo ratings yet

- (Oto-Hui - Com) Edc Hino s05Document2 pages(Oto-Hui - Com) Edc Hino s05ahmed_eng_1500No ratings yet

- Injection Volume Adjustment Test Conditions: 6c-59-1.tifDocument33 pagesInjection Volume Adjustment Test Conditions: 6c-59-1.tifElvis Eliud HernándezNo ratings yet

- Dpico: Inj. Pump Calibration DataDocument2 pagesDpico: Inj. Pump Calibration Datamurillo_rodriguez8382No ratings yet

- S Setting Value, C Check Value) OT Outside Tolerance (X Is Set)Document4 pagesS Setting Value, C Check Value) OT Outside Tolerance (X Is Set)LIONN TESTE2021No ratings yet

- 093000-1613 Hi̇no PDFDocument2 pages093000-1613 Hi̇no PDFBaytolgaNo ratings yet

- 606 9291Document2 pages606 9291Сергей ВладимировичNo ratings yet

- Calibration Data: 104740-2670 Adjustment ConditionsDocument4 pagesCalibration Data: 104740-2670 Adjustment ConditionsMas Inyeccion ElectronicaNo ratings yet

- Test Plan 3363F841Document1 pageTest Plan 3363F841LIONN ONESOLUTIONNo ratings yet

- Injection Pump Specification ©Document4 pagesInjection Pump Specification ©Daniel Marin MoralesNo ratings yet

- 00000904Document184 pages00000904Châu TínNo ratings yet

- 9320A093GDocument4 pages9320A093GKevin TtitoNo ratings yet

- 7540Document10 pages7540pruebaNo ratings yet

- Test PlanDocument4 pagesTest PlanOFFICE DANACNo ratings yet

- 606 9460Document2 pages606 9460Alex PakitoNo ratings yet

- Dpico: Inj. Pump Calibration DataDocument2 pagesDpico: Inj. Pump Calibration Datamurillo_rodriguez8382No ratings yet

- f797 PDFDocument2 pagesf797 PDFBest Auto TechNo ratings yet

- EI3920Document4 pagesEI3920Pali SimónNo ratings yet

- 01EJ3051Document3 pages01EJ3051ForteLubNo ratings yet

- Dpico: Inj. Pump Calibration DataDocument4 pagesDpico: Inj. Pump Calibration DataGiovaniBalzaniNo ratings yet

- DTech CatalogDocument82 pagesDTech CatalogJuan Gabriel OchoaNo ratings yet

- Test Plan: 8923A050: Pump SpecificationDocument2 pagesTest Plan: 8923A050: Pump Specificationveshat100% (1)

- Test Plan: 9521A030: Pump SpecificationDocument3 pagesTest Plan: 9521A030: Pump Specificationjohnny sabinNo ratings yet

- RepuestosDocument6 pagesRepuestoscarlos puertoNo ratings yet

- 196000-6060 Injection Pump Test SpecificationsDocument4 pages196000-6060 Injection Pump Test SpecificationsMiguel RojasNo ratings yet

- EI5280Document4 pagesEI5280Miguel RojasNo ratings yet

- DATODocument1 pageDATOMiguel RojasNo ratings yet

- Test Plan 8523a320Document2 pagesTest Plan 8523a320taniaNo ratings yet

- 00000889Document182 pages00000889Владимир ШтыкNo ratings yet

- S Setting Value, C Check Value) OT Outside Tolerance (X Is Set)Document4 pagesS Setting Value, C Check Value) OT Outside Tolerance (X Is Set)Юрий ТрофимовNo ratings yet

- Dokumen - Tips - Ve Pump Denso Repair ManualDocument32 pagesDokumen - Tips - Ve Pump Denso Repair Manualko koNo ratings yet

- Injection Pump Test Bench ManualDocument15 pagesInjection Pump Test Bench ManualChew LayNo ratings yet

- VI - O55 - 6b - MotorDocument26 pagesVI - O55 - 6b - MotorDJJ ManutençãoNo ratings yet

- EE4760Document2 pagesEE4760OFFICE DANACNo ratings yet

- Toyota 3ce 096500-3051 - 096500-3050 PDFDocument13 pagesToyota 3ce 096500-3051 - 096500-3050 PDFalex100% (1)

- Dpico: Inj. Pump Calibration DataDocument6 pagesDpico: Inj. Pump Calibration DataGiovaniBalzaniNo ratings yet

- 196000-175# 096000-175#Document4 pages196000-175# 096000-175#Junior Iung100% (1)

- S Setting Value, C Check Value) OT Outside Tolerance (X Is Set)Document1 pageS Setting Value, C Check Value) OT Outside Tolerance (X Is Set)BaytolgaNo ratings yet

- 745 4410Document2 pages745 4410murillo_rodriguez8382100% (1)

- Injection Pump Test SpecificationsDocument1 pageInjection Pump Test SpecificationsMiguel RojasNo ratings yet

- Injection Pump Specification ©Document4 pagesInjection Pump Specification ©LIONN SOFTWARESNo ratings yet

- Perkins - CAT EngineDocument2 pagesPerkins - CAT EngineAnky IsmasNo ratings yet

- Injection Pump Test Specifications 093000-573#: ApproxDocument3 pagesInjection Pump Test Specifications 093000-573#: ApproxBaytolgaNo ratings yet

- Injection Pump Test Specifications 093000-573#: ApproxDocument3 pagesInjection Pump Test Specifications 093000-573#: ApproxBaytolgaNo ratings yet

- tp04 Fuel Pump Test Data in LineDocument1 pagetp04 Fuel Pump Test Data in LineBaytolgaNo ratings yet

- 104740-1022 W IsuzuDocument4 pages104740-1022 W IsuzuBaytolgaNo ratings yet

- 0 460 426 085 PDFDocument1 page0 460 426 085 PDFBaytolgaNo ratings yet

- Inj .P Ump Calibration Data Inj .P Ump Calibration DataDocument1 pageInj .P Ump Calibration Data Inj .P Ump Calibration DataBaytolgaNo ratings yet

- Brand Code Type: Carbon Zapp (AZO) Database Release v1.46.1.1Document44 pagesBrand Code Type: Carbon Zapp (AZO) Database Release v1.46.1.1BaytolgaNo ratings yet

- 0 460 426 084Document1 page0 460 426 084BaytolgaNo ratings yet

- S Setting Value, C Check Value) OT Outside Tolerance (X Is Set)Document5 pagesS Setting Value, C Check Value) OT Outside Tolerance (X Is Set)BaytolgaNo ratings yet

- Injection Pump Specification ©Document4 pagesInjection Pump Specification ©BaytolgaNo ratings yet

- Direct Evolution EnhancementDocument2 pagesDirect Evolution EnhancementBaytolgaNo ratings yet

- 9320A275K Parçalar PDFDocument10 pages9320A275K Parçalar PDFBaytolgaNo ratings yet

- Injection Pump Specification ©Document4 pagesInjection Pump Specification ©BaytolgaNo ratings yet

- Test Plan: 9320A210: Pump SpecificationDocument7 pagesTest Plan: 9320A210: Pump SpecificationBaytolgaNo ratings yet

- S Setting Value, C Check Value) OT Outside Tolerance (X Is Set)Document1 pageS Setting Value, C Check Value) OT Outside Tolerance (X Is Set)BaytolgaNo ratings yet

- 104740-6142 9 460 620 023 Opel-Isuzu Test PlanDocument5 pages104740-6142 9 460 620 023 Opel-Isuzu Test PlanBaytolgaNo ratings yet

- Test Plan: 9320A210: Pump Specification Iso Test ProcedureDocument3 pagesTest Plan: 9320A210: Pump Specification Iso Test ProcedureBaytolga100% (1)

- 104748-0230 - Mazda - Kia Ceres 2200 AyniDocument2 pages104748-0230 - Mazda - Kia Ceres 2200 AyniBaytolga100% (2)

- 104745-7770 - NissanDocument3 pages104745-7770 - NissanBaytolgaNo ratings yet

- 096000-4860 Toyata Hilux-4 Runner PDFDocument4 pages096000-4860 Toyata Hilux-4 Runner PDFBaytolgaNo ratings yet

- DP200 Pompa 9320a214g-1Document3 pagesDP200 Pompa 9320a214g-1BaytolgaNo ratings yet

- Test Plan: Pump SpecificationDocument4 pagesTest Plan: Pump SpecificationBaytolgaNo ratings yet

- 9161Document5 pages9161BaytolgaNo ratings yet

- 101401-7321 - Isuzu Şampi̇yonDocument4 pages101401-7321 - Isuzu Şampi̇yonBaytolgaNo ratings yet

- DPC 8443b184bDocument2 pagesDPC 8443b184bBaytolgaNo ratings yet

- Test Plan: Pump SpecificationDocument3 pagesTest Plan: Pump SpecificationBaytolgaNo ratings yet