Professional Documents

Culture Documents

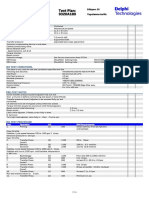

Test Plan: 8923A050: Pump Specification

Uploaded by

veshatOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Test Plan: 8923A050: Pump Specification

Uploaded by

veshatCopyright:

Available Formats

8923A050 :3

Test Plan:

Perkins T4.401 LP18 8923A050 :

PUMP SPECIFICATION

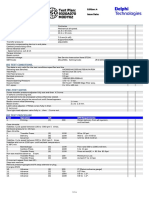

Rotation: Clockwise.

Governor type: Mechanical all-speed.

Gov. Link Length: 41.5 ± 0.5 mm.

Governor spring position : 2

Plunger Diameter: 7.0 mm (4 off).

Drive Type: Supported shaft.

Transfer pressure adjuster in end plate.

Viscosity compensating device in end plate.

Advance Type: Pressure End Cold Servo Advance (PECSA)

Scroll plate max. fuel delivery adjustment.

Torque trimmer.

Solenoid voltage: See Service Instruction Note DT294.

OEM Code: 2644F508MG Setting Code: ...../2/2360

OEM Code: 2644F528MG Setting Code: ...../2/2360

ISO TEST CONDITIONS.

This data is only valid for the test conditions specified and the

following test benches: HA3000/HA2500/HA700/AVM/PGM

Test Fluid: ISO 4113 at 40 ± 2°C.

Inlet feed pressure: 0.3 bar

Backleak pressure: 0.3 bar

Nozzles: BDL0S6844

Nozzle Opening Pressure: 172 + 3 - 0 bar.

Nozzle Holder: ISO 7440 + YDB288 Edge filter assy.

H.P. pipes: 6 x 1.8 x 450 mm

PRE-TEST NOTES

Screw transfer pressure adjuster fully in and then 9.5 turns

out before commencing test.

Advance Reading: Off the cam ring.

A 3.5mm shim is fitted to the piston spring cap on assembly.

After adjustment, shimming to be. 1.0 to 4.0 mm.

Torque trimmer plug to be wound out until thread appears.

Wax motor to be energised unless otherwise stated.

Latch Valve Adjuster, if fitted, early design - to be flush

with locknut. Later design - screw fully in then 6 turns out

Refer to SIN DT363

ISO TEST PROCEDURE

Test Operation S/C RPM Requirements

1. Priming (C) 100 Obtain delivery from all injectors

and backleak.

2. Stabilisation (C) 600 Operate throttle lever 5 times.

When adjusting transfer pressure, adjusting tool must be

disengaged before taking a reading. See SIN D032.

3. Stabilisation S/C 1100 TP 6.14 bar(89 psi)

and initial Max. fuel delivery to

settings 73.0 ± 1.0 mm3/stroke.

Run pump for 3 minutes to stabilise.

4. Advance (S) 500 0° (Datum advance gauge)

5. Backleakage (C) 1100 45 to 91 cm3 per 100 strokes.

Flow rate 500 to 1000 cm3/min.

6. Cambox Press (C) 1100 0.55 to 0.83 bar ( 8 to 12 psi).

7. Cambox Press (C) 700 0.21 to 0.83 bar ( 3 to 12 psi).

8. Advance - (S) 700 3.8 to 4.2 ° ( 2.3 to 2.6 mm).

Light load 20.0 ± 6.0 mm3/st. Use throttle.

Press at test(7 ) + 3.59 to 4.83bar

(Press at test(7 )+ 52 to 70psi)

Use TP adjuster.

9. Transfer Press (S) 1100 Press at test(6 ) + 4.56to 5.79bar

(Press at test(6 )+ 66 to 84psi)

If incorrect repeat from test (8 ).

10. Advance - (C) 700 6.8 to 7.2 ° ( 4.1 to 4.4 mm).

Light load 16.0 ± 6.0 mm3/st. Use throttle.

If incorrect repeat from test (8 ).

11. Advance - (C) 1100 0.8 to 1.2 ° ( 0.5 to 0.7 mm).

Light load 43.0 ± 11.0 mm3/st. Use throttle.

8923A050 :3

Test Plan:

Perkins T4.401 LP18 8923A050 :

ISO TEST PROCEDURE

Test Operation S/C RPM Requirements

If incorrect repeat from test (8 ).

12. Transfer Press (C) 100 Minimum 0.8 bar, ( 12psi).

Stop test machine.

Remove pressure gauges and fit stop solenoid or plug.

Prime as at test (1).

13. Max. Delivery (S) 1100 73.0 ± 0.5 mm3/st.

Maximum spread 6.0 mm3/st.

Screw torque trimmer fully in.

14. Delivery S/C 550 As test (13) - 5.0 ± 0.5 mm3/st.

Set by torque trimmer cam plug

15. Delivery (C) 1100 As test (13) ± 0.5 mm3/st.

16. Governor (S) 1190 12.0 to 16.0 mm3/st.

17. Gov. cut-off (C) 1220 Maximum 4.0 mm3/st.

18. Delivery (C) 1100 Throttle as test (16).

Minimum as test (15) - 1.0 mm3/st.

Close throttle.

19. Delivery (C) 495 Maximum 4.0 mm3/st.

20. Idle delivery (S) 495 12.0 to 15.0 mm3/st. Throttle closed.

21. Delivery (C) 630 Throttle as test(20) Max. 4.0 mm3/st

22. Delivery (C) 100 Minimum 70.0 mm3/st.

23. Delivery (C) 220 Minimum 85.0 mm3/st.

24. Delivery (C) 280 As test (23) - 25.0 ± 15.0 mm3/st.

If incorrect, adjust latch valve screw & lock or change plug if

fitted. Repeat from test (23).

25. Exhaust brake (C) 500 Exhaust brake closed. Max. 4.0 mm3/st

(If fitted)

26. Shut-off (C) 500 De-energise solenoid, wait 5 seconds.

Solenoid Max. 4.0 mm3/st.

Stop test machine.

De-energise wax motor and wait 5 minutes.

27. Advance (C) 700 3.5 to 5.9°, ( 2.1 to 3.6 mm).

Energise wax motor.

28. Advance (C) 1100 0.5° ( 0.3 mm). Max.

Stop test machine.

Remove wax motor and fit tool 7244-631.

29. Timing S/C Outlet 'W ', Pressure 55 bar

Indicator plate offset 8.0° against

pump rotation. To centralise bubble

rotate driveshaft in pump rotation.

Tighten shaft locking screw 13.0Nm.

(flange), 17.0 Nm (housing).

Remove tool 7244-631 and re-fit wax motor.

REFER TO STATEMENT AT END OF EXPLANATORY NOTES REGARDING MAXIMUM

FUEL AND SPEED SETTING AND VARIATIONS IN ENGINE PERFORMANCE.

You might also like

- 8921A091WDocument2 pages8921A091WLTurboNo ratings yet

- 8961A020WDocument2 pages8961A020WLTurboNo ratings yet

- 3042f843 Plano de TesteDocument1 page3042f843 Plano de TesteJose Alexandre Sunhega100% (1)

- 9320A185H TestplanDocument4 pages9320A185H TestplanBaytolga canNo ratings yet

- Test Plan: Pump SpecificationDocument3 pagesTest Plan: Pump SpecificationBaytolgaNo ratings yet

- Test Plan: 9320A530: Pump SpecificationDocument4 pagesTest Plan: 9320A530: Pump SpecificationVyacheslav ShatalovNo ratings yet

- 9320a217 TabelaDocument4 pages9320a217 TabelaLIONN SOFTWARESNo ratings yet

- Test Plan: Pump SpecificationDocument2 pagesTest Plan: Pump Specificationmecanik.veracruzNo ratings yet

- Test Plan Delphi TechnologiesDocument2 pagesTest Plan Delphi TechnologiesFRANCISCONo ratings yet

- 9323a251g PTDocument3 pages9323a251g PTClarice Alves de FreitasNo ratings yet

- 8924A141WDocument2 pages8924A141WLTurboNo ratings yet

- 9320A093GDocument4 pages9320A093GKevin TtitoNo ratings yet

- 9521A030H DATA CatalogDocument3 pages9521A030H DATA CatalogLIONN SOFTWARES100% (1)

- 8920A360 - New Holland 7740 TractorDocument13 pages8920A360 - New Holland 7740 TractorBaytolgaNo ratings yet

- Test Plan: 9521A030: Pump SpecificationDocument3 pagesTest Plan: 9521A030: Pump Specificationjohnny sabinNo ratings yet

- 9323A271G Catalog DATADocument4 pages9323A271G Catalog DATALIONN SOFTWARESNo ratings yet

- Test Plan: Pump SpecificationDocument4 pagesTest Plan: Pump SpecificationBaytolgaNo ratings yet

- Testplan 3239590Document2 pagesTestplan 3239590Fx_2050% (1)

- Test Plan: 9320A070 MODY02: Pump SpecificationDocument7 pagesTest Plan: 9320A070 MODY02: Pump SpecificationUserfabian215No ratings yet

- Test Plan: Pump SpecificationDocument2 pagesTest Plan: Pump SpecificationClarice Alves de FreitasNo ratings yet

- Test Plan 8523a320Document2 pagesTest Plan 8523a320taniaNo ratings yet

- 3340F401G Plano de Teste DelphiDocument2 pages3340F401G Plano de Teste DelphiJunior Iung100% (1)

- Testplan 3238360Document1 pageTestplan 3238360Fx_205No ratings yet

- 9320a075g Test DataDocument4 pages9320a075g Test DataPedro AbellanNo ratings yet

- 3349F330Document2 pages3349F330marco rod100% (1)

- Testplan 3242920Document1 pageTestplan 3242920Fx_205No ratings yet

- 9320a225g Plano LHDocument3 pages9320a225g Plano LHForteLubNo ratings yet

- Testplan 3343010Document1 pageTestplan 3343010Fx_205No ratings yet

- Test Plan: 8522A130: Pump SpecificationDocument2 pagesTest Plan: 8522A130: Pump SpecificationJose Alexandre SunhegaNo ratings yet

- 3230F250 DATA CatalogDocument1 page3230F250 DATA CatalogLIONN TESTE2021No ratings yet

- TestplanDocument3 pagesTestplanGiorgio Di CesareNo ratings yet

- 3340F322 Lionn Auto SoftwaresDocument2 pages3340F322 Lionn Auto SoftwaresLIONN ONESOLUTIONNo ratings yet

- 3233F390 TabelaDocument1 page3233F390 TabelaOFFICE DANACNo ratings yet

- Test Plan: 9320A210: Pump SpecificationDocument7 pagesTest Plan: 9320A210: Pump SpecificationBaytolgaNo ratings yet

- Test Plan: 9320A210: Pump Specification Iso Test ProcedureDocument3 pagesTest Plan: 9320A210: Pump Specification Iso Test ProcedureBaytolga100% (1)

- Test Plan: 3443890: Pump SpecificationDocument2 pagesTest Plan: 3443890: Pump SpecificationLTurboNo ratings yet

- Test Plan: Pump SpecificationDocument2 pagesTest Plan: Pump SpecificationClarice Alves de FreitasNo ratings yet

- 8520A060A TestplanDocument2 pages8520A060A TestplanBaytolga can100% (1)

- Pump SpecificationDocument2 pagesPump Specificationedgar ricoNo ratings yet

- 3230f582T PTDocument2 pages3230f582T PTHeitor Gael Alves de FreitasNo ratings yet

- Bomba Dpa 3340f371g - TesteDocument2 pagesBomba Dpa 3340f371g - TesteOseasJuniorNo ratings yet

- 9322A010Document5 pages9322A010BaytolgaNo ratings yet

- 9520A192G - PlanDocument3 pages9520A192G - PlanMihai-Eugen Popa100% (1)

- Test PlanDocument1 pageTest PlanOFFICE DANACNo ratings yet

- 9320A020GDocument6 pages9320A020GBaytolgaNo ratings yet

- 9320A070GDocument7 pages9320A070GBaytolgaNo ratings yet

- Test Plan 3340f370gDocument1 pageTest Plan 3340f370gLIONN SOFTWARESNo ratings yet

- 8550A223ADocument2 pages8550A223ALTurboNo ratings yet

- 8520A020A TestplanDocument2 pages8520A020A TestplanBaytolga canNo ratings yet

- DPC 8443b184bDocument2 pagesDPC 8443b184bBaytolgaNo ratings yet

- Delphi 9322a000Document5 pagesDelphi 9322a000BaytolgaNo ratings yet

- JCB DELPHI PUMP-9520A500-509S03 - Iss 03Document7 pagesJCB DELPHI PUMP-9520A500-509S03 - Iss 03Ravikant Saini100% (2)

- 3239F592TDocument2 pages3239F592TAnderson London67% (3)

- Test Plan: 8921A000: Pump SpecificationDocument3 pagesTest Plan: 8921A000: Pump SpecificationBaytolgaNo ratings yet

- 8443A260EDocument2 pages8443A260EMiguel ChaconNo ratings yet

- Richard VargasDocument1 pageRichard VargasRicardo NarvaezNo ratings yet

- A 090Document3 pagesA 090birimpompaNo ratings yet

- Test Plan 8443B250DDocument2 pagesTest Plan 8443B250DЕвгенийNo ratings yet

- 8444B622B Tabela PDFDocument2 pages8444B622B Tabela PDFJaqueline S. S. MaicáNo ratings yet

- SectionC 22Document1 pageSectionC 22veshatNo ratings yet

- (AD - DIESEL) - (03-10-2019) : Parts ListDocument4 pages(AD - DIESEL) - (03-10-2019) : Parts ListveshatNo ratings yet

- (AD - DIESEL) - (20-01-2020) : Parts ListDocument4 pages(AD - DIESEL) - (20-01-2020) : Parts ListveshatNo ratings yet

- (AD - DIESEL) - (27-01-2020) : Parts ListDocument4 pages(AD - DIESEL) - (27-01-2020) : Parts ListveshatNo ratings yet

- (AD - DIESEL) - (26-04-2017) :: Nozzle Holder (Ref B039)Document4 pages(AD - DIESEL) - (26-04-2017) :: Nozzle Holder (Ref B039)veshatNo ratings yet

- (AD - DIESEL) - (22-05-2017) :: Nozzle Holder (Ref B035)Document4 pages(AD - DIESEL) - (22-05-2017) :: Nozzle Holder (Ref B035)veshatNo ratings yet

- Downloaded From Manuals Search EngineDocument461 pagesDownloaded From Manuals Search EngineveshatNo ratings yet

- Mirage Probationary EmploymentDocument3 pagesMirage Probationary EmploymentIsrael FortoNo ratings yet

- Dental EthicsDocument50 pagesDental EthicsMukhtar Andrabi100% (1)

- Philosophy of LawDocument222 pagesPhilosophy of LawPriscilla Miranda100% (14)

- Manonmaniam Sundaranar University: B.B.A. - Ii YearDocument61 pagesManonmaniam Sundaranar University: B.B.A. - Ii YearLovely Dhanaa4848No ratings yet

- Defence Services Staff College, Wellington: (To Be Filled in Capital Letters As Per Matriculation (Or) X STD Mark Sheet)Document3 pagesDefence Services Staff College, Wellington: (To Be Filled in Capital Letters As Per Matriculation (Or) X STD Mark Sheet)Siddharth MuthukumarNo ratings yet

- Lectra Fashion e Guide Nurturing EP Quality Logistics Production Crucial To Optimize enDocument8 pagesLectra Fashion e Guide Nurturing EP Quality Logistics Production Crucial To Optimize eniuliaNo ratings yet

- Gas StoichiometryDocument9 pagesGas StoichiometryJoshua RomeaNo ratings yet

- Forrester Hybrid Integration PlatformDocument17 pagesForrester Hybrid Integration PlatformrtNo ratings yet

- Method Statement For Touch-Up Paint and Repair of Unitized Curtain WallDocument6 pagesMethod Statement For Touch-Up Paint and Repair of Unitized Curtain WallNESTOR YUMULNo ratings yet

- Superkids 3eDocument19 pagesSuperkids 3eiin hermiyantoNo ratings yet

- West Olympia Background Reports 14Document122 pagesWest Olympia Background Reports 14Hugo Yovera CalleNo ratings yet

- Atty. SungaDocument22 pagesAtty. SungaKris MercadoNo ratings yet

- Habeas CorpusDocument67 pagesHabeas CorpusButch AmbataliNo ratings yet

- Chap3 Laterally Loaded Deep FoundationDocument46 pagesChap3 Laterally Loaded Deep Foundationtadesse habtieNo ratings yet

- Assignment/ TugasanDocument12 pagesAssignment/ TugasanfletcherNo ratings yet

- The Double Conjunctions Worksheet (Both ... And, Neither ... Nor, Either ... Or)Document2 pagesThe Double Conjunctions Worksheet (Both ... And, Neither ... Nor, Either ... Or)Ibrahim BenamiraNo ratings yet

- Social Class 10 2019Document14 pagesSocial Class 10 2019krishnareddy_chintalaNo ratings yet

- Zalando SE Q3 2023 Financials PDFDocument7 pagesZalando SE Q3 2023 Financials PDFHjraNo ratings yet

- Carbon Trading-The Future Money Venture For IndiaDocument11 pagesCarbon Trading-The Future Money Venture For IndiaijsretNo ratings yet

- 6426c-Enu Trainerhandbook 2Document392 pages6426c-Enu Trainerhandbook 2mu771_No ratings yet

- Magness - The Tomb of Jesus and His Family - Exploring Ancient Jewish Tombs Near Jerusalem's Walls Book ReviewDocument5 pagesMagness - The Tomb of Jesus and His Family - Exploring Ancient Jewish Tombs Near Jerusalem's Walls Book Reviewarbg100% (1)

- Practical Auditing by Empleo 2022 Chapter 4 Receivables Related RevenuesDocument55 pagesPractical Auditing by Empleo 2022 Chapter 4 Receivables Related RevenuesDarence IndayaNo ratings yet

- 28-03-2023 Sed TicketsDocument8 pages28-03-2023 Sed TicketssureshhkNo ratings yet

- Ismu in EnglishDocument2 pagesIsmu in EnglishIsmilaYulianaNo ratings yet

- How To Write SpecificationsDocument9 pagesHow To Write SpecificationsLeilani ManalaysayNo ratings yet

- A Scientific Report.: Daftar PustakaDocument3 pagesA Scientific Report.: Daftar PustakaFemmy FahiraNo ratings yet

- Analisis Deskriptif Efek Samping Penggunaan Obat Anti Tuberculosis Pada Pasien TBC Di Rsud Dr. Pirngadi MedanDocument7 pagesAnalisis Deskriptif Efek Samping Penggunaan Obat Anti Tuberculosis Pada Pasien TBC Di Rsud Dr. Pirngadi MedanEva MelisaNo ratings yet

- Arnold Böcklin Was Born in Basel, Switzerland inDocument6 pagesArnold Böcklin Was Born in Basel, Switzerland inDragos PlopNo ratings yet

- Sharp Lc-26sb25e S Ru Lc-32sb25e Lc-42sb55s e RuDocument172 pagesSharp Lc-26sb25e S Ru Lc-32sb25e Lc-42sb55s e RuПетя СтойчеваNo ratings yet

- Escalation How Much Is Enough?Document9 pagesEscalation How Much Is Enough?ep8934100% (2)