Professional Documents

Culture Documents

Pump Specification

Uploaded by

edgar rico0 ratings0% found this document useful (0 votes)

17 views2 pagesOriginal Title

3239 F 590 T

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

17 views2 pagesPump Specification

Uploaded by

edgar ricoCopyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You are on page 1of 2

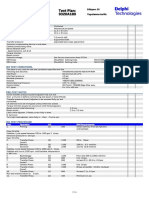

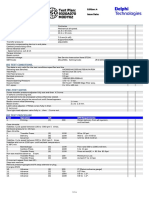

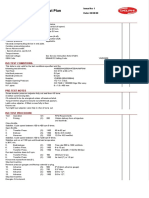

Test Plan: 3239590

Applic: Perkins Vista A 80 KVA

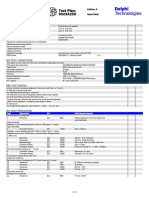

Issue No: 5 Remove pressure gauges and fit stop solenoid or plug.

Date: 00/00/00 50Hz Governor settings/checks only, tests 8 to 14 .

Pumps covered: 3239F590T 3239F591T 8. Delivery (C) 750 As test ( 7) ± 0.5 mm3/st.

9. Governor (S) 790 5.0 to 15.0 mm3/st.

Run test machine down to 750 rpm.

PUMP SPECIFICATION. 10. Delivery (C) 775 91 to 101 mm3/st.

Rotation: Clockwise. If high wind droop adjuster in, if low wind droop adjuster out.

Governor type: Mechanical all-speed with Droop Feature. If incorrect or adjusted, stop machine and repeat from test (7 ).

Gov. Link Length: 9.7 ± 0.2 mm. 11. Gov. cut-off (C) 820 Maximum 5.0 mm3/st.

Governor spring position : 6. If incorrect reset droop adjuster to pre-test notes and repeat

Plunger Diameter: 7.0 mm (4 off). from test (7 ).

Drive Type: Uprated with supported shaft. 12. Delivery (C) 750 As test ( 7) ± 0.5 mm3/st.

Advance Type: Light Load. If incorrect reset droop adjuster to pre-test notes and repeat

Adjusting plate max. fuel delivery control. from test (7 ).

Solenoid voltage: See Service Instruction Note DT294 13. Advance - (S) 750 0.8to 1.2° 40to

OEM Code: 2643B315 Setting Code: LY/6/- 58mm3/st

Light load Adjust throttle actuator tool

& shim as required.

ISO TEST CONDITIONS. 14. Advance - (S) 750 3.3to 3.7° 20to

This data is only valid for the test conditions specified and the 49mm3/st

following test benches: HA3000/HA2500/HA700/AVM/PGM Light load Adjust throttle actuator tool

Test Fluid: ISO 4113 at 40 ± 2°C. & shim as required.

Inlet feed pressure: 0.3 bar If adjusted repeat from test (13).

Backleak pressure: 0 bar 60Hz Governor settings/checks only, tests 15 to 19 .

Nozzles: BDL0S6889 (YDB287) 15. Delivery (C) 900 115 to 135 mm3/st.

Nozzle Opening Pressure: 172 + 3 - 0 bar. 16. Governor (S) 945 10 to 20 mm3/st.

Nozzle Holder: ISO 7440 + YDB288 Edge filter assy. Run test machine down to 900 rpm.

H.P. pipes: 6 x 1.8 x 450 mm 17. Delivery (C) 925 100 to 110 mm3/st.

If high wind droop adjuster in, if low wind droop adjuster out.

If incorrect or adjusted, stop machine and repeat from test (15).

PRE-TEST NOTES 18. Gov. cut-off (C) 960 Maximum 5.0 mm3/st.

If incorrect reset droop adjuster to pre-test notes and repeat

Screw Metering Valve Droop Adjuster fully in & then out 1.5

from test (15).

turns.

Lock throttle lever in the fully open position. 19. Delivery (C) 900 As test (15) ± 1.0 mm3/st.

20. Shut-off - (C) 200 De-energise solenoid, wait 5 seconds.

Fit throttle actuator tool YDT265.

Adjust Light Load Advance by shim (0.5 to 3.5 mm total). Solenoid Max. 2.0 mm3/st.

Stop test machine.

21. Delivery (C) 150 Minimum 45.0 mm3/st.

22. Timing S/C Outlet 'U ', Pressure 55 bar

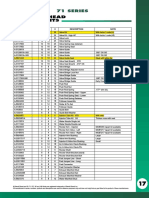

ISO TEST PROCEDURE Indexing tool at 99.0°, Scribe line.

1. Priming (C) 200 Obtain delivery from all injectors

Depressurise. Rotate drive 231.0° to

and backleak.

pos'n 330.0°. Slide washer and torque

2. Stabilisation (C) 750 Run pump for 3 minutes to stabilise.

shaft locking screw to 17.0 Nm.

Cycle pump between 750 rpm and 800 rpm 5 times

PRE-OVERCHECK NOTES

(to remove air from Governor unit).

.

3. Delivery S/C 750 125.0 ± 1.0 mm3/st.

The Overcheck section of this plan has been developed in

4. Transfer Press. (C) 100 Minimum 0.7 bar, ( 10psi).

conjunction with the Original Equipment Manufacturer.

5. Transfer Press. (S) 750 4.9 to 5.6 bar( 71 to 81 psi)

Providing all values are achieved, the pump settings will

6. Back leakage. (C) 750 33 to 87 cm3 per 100 strokes.

maintain the original homologated engine performance. Failure to

Flow rate 250 to 650 cm3/min.

attain any one of the values will indicate a pump setting or

7. Delivery (S) 750 125.0 ± 0.5 mm3/st.

function failure and require further investigation.

Stop test machine.

.

No adjustments to be made unless otherwise stated.

.

ISO OVERCHECK PROCEDURE

23. Timing S/C For validation:

Indexing tool set to 330.0 ± 0.5°

24. Priming (C) 200 Obtain delivery from all injectors

and backleak.

Cycle pump between 750 rpm and 800 rpm 5 times

(to remove air from Governor unit).

25. Shut-off - (C) 200 De-energise solenoid, wait 5 seconds.

Solenoid Max. 2.0 mm3/st.

Stop test machine.

26. Delivery (C) 150 Minimum 40.0 mm3/st.

27. Stabilisation (C) 750 Run pump for 3 minutes to stabilise.

50Hz Governor settings/checks only, tests 28 to 32 .

28. Delivery (C) 750 122 to 128 mm3/st.

29. Delivery (C) 775 86 to 101 mm3/st.

30. Delivery (C) 790 Maximum 20.0 mm3/st.

31. Delivery (C) 820 Maximum 5.0 mm3/st.

32. Advance - (C) 750 0.8to 1.2° 49 ±

13mm/3st.

Light load Use throttle actuator tool.

60Hz Governor settings/checks only, tests 33 to 36 .

33. Delivery (C) 900 Minimum 115 mm3/st.

34. Delivery (C) 925 90 to 110 mm3/st.

35. Delivery (C) 945 Maximum 25.0 mm3/st.

36. Delivery (C) 960 Maximum 5.0 mm3/st.

You might also like

- EAU2 - I - 04 - Ruins of The Lost RealmDocument127 pagesEAU2 - I - 04 - Ruins of The Lost RealmHache73% (15)

- NU632 Unit 4 Discussion CaseDocument2 pagesNU632 Unit 4 Discussion CaseMaria Ines OrtizNo ratings yet

- Dynamometer: Theory and Application to Engine TestingFrom EverandDynamometer: Theory and Application to Engine TestingNo ratings yet

- Common Rail Hino - ToyotaDocument41 pagesCommon Rail Hino - Toyota0808833892% (24)

- Common Rail Hino - ToyotaDocument41 pagesCommon Rail Hino - Toyota0808833892% (24)

- Common Rail Hino - ToyotaDocument41 pagesCommon Rail Hino - Toyota0808833892% (24)

- Mic Fright and Camera PanicDocument5 pagesMic Fright and Camera PanicNica Arizapa100% (1)

- Tesla in ChinaDocument9 pagesTesla in ChinaÁi Nhân Huỳnh NguyễnNo ratings yet

- Testplan 3239590Document2 pagesTestplan 3239590Fx_2050% (1)

- 3349F330Document2 pages3349F330marco rod100% (1)

- 3340F322 Lionn Auto SoftwaresDocument2 pages3340F322 Lionn Auto SoftwaresLIONN ONESOLUTIONNo ratings yet

- Test Plan: Pump SpecificationDocument2 pagesTest Plan: Pump SpecificationClarice Alves de FreitasNo ratings yet

- Test Plan: 8923A050: Pump SpecificationDocument2 pagesTest Plan: 8923A050: Pump SpecificationveshatNo ratings yet

- 3230f582T PTDocument2 pages3230f582T PTHeitor Gael Alves de FreitasNo ratings yet

- 3239F592TDocument2 pages3239F592TAnderson London67% (3)

- Test Plan Delphi TechnologiesDocument2 pagesTest Plan Delphi TechnologiesFRANCISCONo ratings yet

- 8921A091WDocument2 pages8921A091WLTurboNo ratings yet

- 8961A020WDocument2 pages8961A020WLTurboNo ratings yet

- Testplan 3238360Document1 pageTestplan 3238360Fx_205No ratings yet

- 9320A185H TestplanDocument4 pages9320A185H TestplanBaytolga canNo ratings yet

- Test Plan: Pump SpecificationDocument3 pagesTest Plan: Pump SpecificationBaytolgaNo ratings yet

- Test Plan: 9320A530: Pump SpecificationDocument4 pagesTest Plan: 9320A530: Pump SpecificationVyacheslav ShatalovNo ratings yet

- Test Plan: 9521A030: Pump SpecificationDocument3 pagesTest Plan: 9521A030: Pump Specificationjohnny sabinNo ratings yet

- Test Plan 8523a320Document2 pagesTest Plan 8523a320taniaNo ratings yet

- 9323a251g PTDocument3 pages9323a251g PTClarice Alves de FreitasNo ratings yet

- Test Plan: Pump SpecificationDocument4 pagesTest Plan: Pump SpecificationBaytolgaNo ratings yet

- Test Plan: Pump SpecificationDocument2 pagesTest Plan: Pump SpecificationClarice Alves de FreitasNo ratings yet

- 9521A030H DATA CatalogDocument3 pages9521A030H DATA CatalogLIONN SOFTWARES100% (1)

- 9323A271G Catalog DATADocument4 pages9323A271G Catalog DATALIONN SOFTWARESNo ratings yet

- 9320a075g Test DataDocument4 pages9320a075g Test DataPedro AbellanNo ratings yet

- 9320a217 TabelaDocument4 pages9320a217 TabelaLIONN SOFTWARESNo ratings yet

- Test Plan: 9320A070 MODY02: Pump SpecificationDocument7 pagesTest Plan: 9320A070 MODY02: Pump SpecificationUserfabian215No ratings yet

- 9320a225g Plano LHDocument3 pages9320a225g Plano LHForteLubNo ratings yet

- 9320A093GDocument4 pages9320A093GKevin TtitoNo ratings yet

- Test Plan: 3443890: Pump SpecificationDocument2 pagesTest Plan: 3443890: Pump SpecificationLTurboNo ratings yet

- 8920A360 - New Holland 7740 TractorDocument13 pages8920A360 - New Holland 7740 TractorBaytolgaNo ratings yet

- 3042f843 Plano de TesteDocument1 page3042f843 Plano de TesteJose Alexandre Sunhega100% (1)

- 3230F250 DATA CatalogDocument1 page3230F250 DATA CatalogLIONN TESTE2021No ratings yet

- 3340F401G Plano de Teste DelphiDocument2 pages3340F401G Plano de Teste DelphiJunior Iung100% (1)

- Test Plan: Pump SpecificationDocument2 pagesTest Plan: Pump Specificationmecanik.veracruzNo ratings yet

- 8924A141WDocument2 pages8924A141WLTurboNo ratings yet

- TestplanDocument3 pagesTestplanGiorgio Di CesareNo ratings yet

- Test Plan 3340f370gDocument1 pageTest Plan 3340f370gLIONN SOFTWARESNo ratings yet

- 3233F390 TabelaDocument1 page3233F390 TabelaOFFICE DANACNo ratings yet

- Test Plan: 8522A130: Pump SpecificationDocument2 pagesTest Plan: 8522A130: Pump SpecificationJose Alexandre SunhegaNo ratings yet

- DPC 8443b184bDocument2 pagesDPC 8443b184bBaytolgaNo ratings yet

- Testplan 3343010Document1 pageTestplan 3343010Fx_205No ratings yet

- Bomba Dpa 3340f371g - TesteDocument2 pagesBomba Dpa 3340f371g - TesteOseasJuniorNo ratings yet

- Test Plan: 9320A210: Pump SpecificationDocument7 pagesTest Plan: 9320A210: Pump SpecificationBaytolgaNo ratings yet

- Test Plan 8443B250DDocument2 pagesTest Plan 8443B250DЕвгенийNo ratings yet

- 9322A010Document5 pages9322A010BaytolgaNo ratings yet

- Test Plan: 9320A210: Pump Specification Iso Test ProcedureDocument3 pagesTest Plan: 9320A210: Pump Specification Iso Test ProcedureBaytolga100% (1)

- Delphi 9322a000Document5 pagesDelphi 9322a000BaytolgaNo ratings yet

- 9520A192G - PlanDocument3 pages9520A192G - PlanMihai-Eugen Popa100% (1)

- 9320A070GDocument7 pages9320A070GBaytolgaNo ratings yet

- Test PlanDocument1 pageTest PlanOFFICE DANACNo ratings yet

- 9320A020GDocument6 pages9320A020GBaytolgaNo ratings yet

- PressedDocument79 pagesPressedANDRES LOPEZNo ratings yet

- 8520A060A TestplanDocument2 pages8520A060A TestplanBaytolga can100% (1)

- Testplan 3242920Document1 pageTestplan 3242920Fx_205No ratings yet

- Richard VargasDocument1 pageRichard VargasRicardo NarvaezNo ratings yet

- 8520A020A TestplanDocument2 pages8520A020A TestplanBaytolga canNo ratings yet

- 8444B622B Tabela PDFDocument2 pages8444B622B Tabela PDFJaqueline S. S. MaicáNo ratings yet

- A 090Document3 pagesA 090birimpompaNo ratings yet

- JCB DELPHI PUMP-9520A500-509S03 - Iss 03Document7 pagesJCB DELPHI PUMP-9520A500-509S03 - Iss 03Ravikant Saini100% (2)

- 8443A260EDocument2 pages8443A260EMiguel ChaconNo ratings yet

- Test Plan: 9320A530: Pump SpecificationDocument4 pagesTest Plan: 9320A530: Pump SpecificationVyacheslav ShatalovNo ratings yet

- Robert Bosch GMBH Stuttgart: Inline Pump Test Specification Pump/Governor SettingsDocument3 pagesRobert Bosch GMBH Stuttgart: Inline Pump Test Specification Pump/Governor Settingsedgar ricoNo ratings yet

- Robert Bosch GMBH Stuttgart: Inline Pump Test Specification Pump/Governor SettingsDocument3 pagesRobert Bosch GMBH Stuttgart: Inline Pump Test Specification Pump/Governor Settingsedgar ricoNo ratings yet

- 0 460 424 057 CalibracionDocument3 pages0 460 424 057 Calibracionedgar ricoNo ratings yet

- QR-390 Tech DataDocument1 pageQR-390 Tech Dataedgar ricoNo ratings yet

- Air Starters CatalogDocument92 pagesAir Starters CatalogJetmanUSA2010No ratings yet

- FA10i Parts Information AirToolProDocument44 pagesFA10i Parts Information AirToolProIrving Antonio Flores Alegria100% (1)

- Governador 3406Document4 pagesGovernador 3406edgar ricoNo ratings yet

- Price List: Heavy Duty Foodwaste Disposers and Electrical ControlsDocument39 pagesPrice List: Heavy Duty Foodwaste Disposers and Electrical Controlsedgar ricoNo ratings yet

- Grundfos CR Series InstructionsDocument20 pagesGrundfos CR Series Instructionsbedilu77No ratings yet

- Price List: Heavy Duty Foodwaste Disposers and Electrical ControlsDocument39 pagesPrice List: Heavy Duty Foodwaste Disposers and Electrical Controlsedgar ricoNo ratings yet

- Grundfos CR Series InstructionsDocument20 pagesGrundfos CR Series Instructionsbedilu77No ratings yet

- Grundfos CR Series InstructionsDocument20 pagesGrundfos CR Series Instructionsbedilu77No ratings yet

- 16V71 Detroit DieselDocument1 page16V71 Detroit Dieseledgar ricoNo ratings yet

- D 600 AP - enDocument253 pagesD 600 AP - enDedvirtualAutopeçasOnLineNo ratings yet

- Yanmar 4jh4 Te LRDocument2 pagesYanmar 4jh4 Te LRRifkiHabibiNo ratings yet

- QGS - 20-25-30-40 - Parts Manual May 30 2020Document288 pagesQGS - 20-25-30-40 - Parts Manual May 30 2020edgar ricoNo ratings yet

- DHHD 0910 PDFDocument32 pagesDHHD 0910 PDFDaniel AndradeNo ratings yet

- Cotización Mc-Bee Detroit Diesel 149 2Document1 pageCotización Mc-Bee Detroit Diesel 149 2edgar ricoNo ratings yet

- Alfa Laval Manual Model Mab 103 (+B) Parts BookDocument56 pagesAlfa Laval Manual Model Mab 103 (+B) Parts BookMery A. Dominguez75% (8)

- Yanmar Brochure SD60Document4 pagesYanmar Brochure SD60hastaNo ratings yet

- 104136-1022 Zexel Fuel-Injection PumpDocument5 pages104136-1022 Zexel Fuel-Injection Pumpedgar rico100% (1)

- Motor A - 6BG1 - Oc - 02Document115 pagesMotor A - 6BG1 - Oc - 02edgar ricoNo ratings yet

- Air Compressor 2475 Parts ListDocument24 pagesAir Compressor 2475 Parts Listedgar ricoNo ratings yet

- Air Compressor 2475 Parts ListDocument24 pagesAir Compressor 2475 Parts Listedgar ricoNo ratings yet

- Yanmar 4jh4 Te LRDocument2 pagesYanmar 4jh4 Te LRRifkiHabibiNo ratings yet

- Isuzu Diesel Engine 4LB1, 4LC1, 4LE1: Instruction ManualDocument104 pagesIsuzu Diesel Engine 4LB1, 4LC1, 4LE1: Instruction Manualedgar rico100% (2)

- Petroleum Products KolkataDocument3 pagesPetroleum Products KolkatabrijeshkynNo ratings yet

- Soil Resources Inventory For Land Use PlanningDocument9 pagesSoil Resources Inventory For Land Use PlanningmehNo ratings yet

- Orallichenplanus 170929075918Document40 pagesOrallichenplanus 170929075918Aymen MouradNo ratings yet

- Shear Strength Prediction of Crushed Stone Reinforced Concrete Deep Beams Without StirrupsDocument2 pagesShear Strength Prediction of Crushed Stone Reinforced Concrete Deep Beams Without StirrupsSulaiman Mohsin AbdulAziz100% (1)

- Daftar PustakaDocument2 pagesDaftar PustakaJohny Iskandar Arsyad NstNo ratings yet

- Tank Vessel Overflow Line SizingDocument4 pagesTank Vessel Overflow Line SizingSteve Wan100% (1)

- B-64603en-1 - 01 (v3) - Vol2 - 0if Connection Manual (Function)Document900 pagesB-64603en-1 - 01 (v3) - Vol2 - 0if Connection Manual (Function)SergioNo ratings yet

- Fluke Acess TemperatureDocument4 pagesFluke Acess TemperatureJuan José Villavicencio CantoNo ratings yet

- Analisis Sensori Produk Stik Sukun (Artocarpus Altilis) Dengan Perlakuan Pendahuluan Blanching Dan Perendaman Dalam Larutan Kalsium KloridaDocument6 pagesAnalisis Sensori Produk Stik Sukun (Artocarpus Altilis) Dengan Perlakuan Pendahuluan Blanching Dan Perendaman Dalam Larutan Kalsium KloridaTommy ChandraNo ratings yet

- Model SS ChecklistDocument30 pagesModel SS ChecklistAnonymous PeuxGWWy8tNo ratings yet

- Engrave-O-Matic Custom Laser Engraving CatalogDocument32 pagesEngrave-O-Matic Custom Laser Engraving Catalogds8669No ratings yet

- Document GDocument30 pagesDocument GWLLM100% (2)

- Natal Chart ReportDocument23 pagesNatal Chart ReportEvelyn WilsonNo ratings yet

- Lab 6 - Wide Flange BeamDocument4 pagesLab 6 - Wide Flange BeamJanithNo ratings yet

- Thermal Engineering IDocument30 pagesThermal Engineering IRamphani NunnaNo ratings yet

- Weapon Type Code Range L M H Traits Category: Wong Rong Jing (Order #7811643)Document1 pageWeapon Type Code Range L M H Traits Category: Wong Rong Jing (Order #7811643)John SmithNo ratings yet

- Drugs For The Heart in Perioperative When To Stop and When To StartDocument38 pagesDrugs For The Heart in Perioperative When To Stop and When To StartnureNo ratings yet

- ProgrammableFlow Intro - Sep2011Document39 pagesProgrammableFlow Intro - Sep2011Serge StasovNo ratings yet

- Vray MaterialsDocument206 pagesVray MaterialsDodeptrai BkNo ratings yet

- Adverb of TimeDocument5 pagesAdverb of TimeIsha kaleNo ratings yet

- Principle of Virtual Work and Its ApplicationDocument7 pagesPrinciple of Virtual Work and Its Applicationprem adhikari100% (1)

- Aiwa CX jn5 ETDocument78 pagesAiwa CX jn5 ETluzmarospiNo ratings yet

- n 3n+1 5n−2 n (−1) n n 12n +73n −18n +9 25n +2n n n n +1 n 2 n 1 n n n n nπ 3Document1 pagen 3n+1 5n−2 n (−1) n n 12n +73n −18n +9 25n +2n n n n +1 n 2 n 1 n n n n nπ 3Prashanth SridharNo ratings yet

- Design and Assembly Analysis of Piston, Connecting Rod & CrankshaftDocument12 pagesDesign and Assembly Analysis of Piston, Connecting Rod & CrankshaftD MasthanNo ratings yet

- Chapter 22-The Pre Cam Brian EarthDocument38 pagesChapter 22-The Pre Cam Brian Earthncl12142No ratings yet

- Nature of The JivaDocument4 pagesNature of The JivaSivasonNo ratings yet