Professional Documents

Culture Documents

Richard Vargas

Uploaded by

Ricardo NarvaezOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Richard Vargas

Uploaded by

Ricardo NarvaezCopyright:

Available Formats

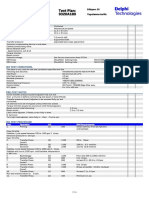

Test Plan: 3432900

Applic: John Deere 3-179 DF Transfer press. (C) 1000 4.1 to 4.8 bar.

Issue No: 4 7. Advance (C) 1000 6.75 to 7.25 ° ( 5.4 to 5.8mm)

Date: 02/09/87 (Full load) Tool 7244-590, SIN RD/TOOLS 18

Pumps covered: 3432F900 R3432F900 8. Backleakage (C) 1000 25 to 45 cm3 per 100 shots.

0.25 to 0.45 litre per minute.

SIN RD/PUMPS 64

PUMP SPECIFICATION 9. Cambox pressure (C) 1000 0.24 to 0.44 bar. SIN RD/PUMPS 8.

Rotation: Clockwise 10. Max. delivery (S) 1000 57 ± 0.5 mm3/st.

Plunger Diameter: 9 mm Max. spread 3.0 mm3/st.

Roller to roller: 49.95 mm 11. Delivery (C) 100 As test(10) - 10 mm3/st.

Advance Type: Automatic speed. 12. Advance (C) 200 Maximum 0.5 ° ( 0.4mm) 7244-590

Governor type: Mechanical all-speed. 13. Stop solenoid (C) 400 0.6 cm3 max., De-energize solenoid.

Gov. Link Length: 53.3 ± 0.2 mm Stop test machine & wait 10 sec. min. Cambox press. 0.1 bar max.

Gov. arm hole No.: 3 Energise solenoid shut-off with 12 V.

Throttle lever link hole : 1 14. Throttle test (C) 400 1 cm3 maximum, Throttle closed.

Drive type: Standard supported - 20 mm dia. 15. Idling screw (S) 400 1.9 to 2.1 cm3,

Stop solenoid 12 V. 16. Gov. delivery (C) 1250 Record average delivery.

17. Gov. operation (S) 1340 28 to 33 mm3/st.

18. Gov. cut-off (C) 1400 Maximum 2 cm3, Line max. 2.6 cm3.

ISO TEST CONDITIONS. 19. Gov. delivery (C) 1250 Minimum as test(16) - 0.4 cm3.

This data is only valid for the test conditions specified and the 20. Int. & Ext. S/C HP outlet'U ',Press 30 bar,Letter'F '

following test benches: HA3000/HA2500/HA1150/HA1100MkII/HA875 Timing Angle 89.5°,1804-530 ,7244-026E

HA700/HA400/AVM/PGM (1804-003 & 7244-027) SIN RD/TOOLS 5

Test Fluid: ISO 4113 at 40 ± 2 °C. REFER TO STATEMENT AT END OF EXPLANATORY NOTES REGARDING MAXIMUM

Nozzles: ISO 4010. FUEL AND SPEED SETTING AND VARIATIONS IN ENGINE PERFORMANCE.

Nozzle opening pressure: 172 +3 -0 bar.

H.P. pipes: 6 x 2 x 600 mm (ISO 4093.1)

Test machine drive: ADC30/2

Test machine drive in unsupported position.

Inlet feed pressure: 0.1 bar

H.P. Outlets: 7123-503A or 7139-354 with pressurising valves.

PRE-TEST NOTES

ISO Derived pump.

Timing: -To accurately set the internal and external timing,

use

the following tools: 1804-003/7244-027

Minimum piston spring cap shim thickness 0.5 mm.

Additional shimming of (0.0 to 3.0 mm) may be required.

ISO TEST PROCEDURE

Test Operation S/C RPM Requirements

1. Priming (C) 100 Obtain delivery from all injectors.

-500 No air in pump backleak.

2. T. P Vacuum (C) 500 0.27 bar vacuum. 30 seconds maximum.

3. Transfer press. (C) 100 0.8 bar minimum.

4. Transfer press. (S) 600 2.75 to 3.45 bar.

5. Advance (S) 600 3.5 to 4 ° ( 2.8 to 3.2mm)

(Full load) Tool 7244-590, SIN RD/TOOLS 18

6.

You might also like

- Influence of System Parameters Using Fuse Protection of Regenerative DC DrivesFrom EverandInfluence of System Parameters Using Fuse Protection of Regenerative DC DrivesNo ratings yet

- 8444B622B Tabela PDFDocument2 pages8444B622B Tabela PDFJaqueline S. S. MaicáNo ratings yet

- DPC 8443b184bDocument2 pagesDPC 8443b184bBaytolgaNo ratings yet

- Test Plan: 3443890: Pump SpecificationDocument2 pagesTest Plan: 3443890: Pump SpecificationLTurboNo ratings yet

- 3233F390 TabelaDocument1 page3233F390 TabelaOFFICE DANACNo ratings yet

- 8921A091WDocument2 pages8921A091WLTurboNo ratings yet

- Testplan 3238360Document1 pageTestplan 3238360Fx_205No ratings yet

- 8961A020WDocument2 pages8961A020WLTurboNo ratings yet

- Testplan 3242920Document1 pageTestplan 3242920Fx_205No ratings yet

- Test PlanDocument1 pageTest PlanOFFICE DANACNo ratings yet

- Test Plan 8443B250DDocument2 pagesTest Plan 8443B250DЕвгенийNo ratings yet

- Test Plan: 8923A050: Pump SpecificationDocument2 pagesTest Plan: 8923A050: Pump SpecificationveshatNo ratings yet

- 3042f843 Plano de TesteDocument1 page3042f843 Plano de TesteJose Alexandre Sunhega100% (1)

- Test Plan: Pump SpecificationDocument3 pagesTest Plan: Pump SpecificationBaytolgaNo ratings yet

- Test Plan 8523a320Document2 pagesTest Plan 8523a320taniaNo ratings yet

- 9320a225g Plano LHDocument3 pages9320a225g Plano LHForteLubNo ratings yet

- Testplan 3343010Document1 pageTestplan 3343010Fx_205No ratings yet

- Test Plan: 9320A070 MODY02: Pump SpecificationDocument7 pagesTest Plan: 9320A070 MODY02: Pump SpecificationUserfabian215No ratings yet

- Test Plan: Pump SpecificationDocument2 pagesTest Plan: Pump Specificationmecanik.veracruzNo ratings yet

- 3230F250 DATA CatalogDocument1 page3230F250 DATA CatalogLIONN TESTE2021No ratings yet

- 8444B360ADocument2 pages8444B360ABaytolgaNo ratings yet

- 9320a075g Test DataDocument4 pages9320a075g Test DataPedro AbellanNo ratings yet

- 9323a251g PTDocument3 pages9323a251g PTClarice Alves de FreitasNo ratings yet

- 9521A030H DATA CatalogDocument3 pages9521A030H DATA CatalogLIONN SOFTWARES100% (1)

- Test Plan 3340f370gDocument1 pageTest Plan 3340f370gLIONN SOFTWARESNo ratings yet

- Test Plan: Pump SpecificationDocument2 pagesTest Plan: Pump SpecificationClarice Alves de FreitasNo ratings yet

- Test Plan Delphi TechnologiesDocument2 pagesTest Plan Delphi TechnologiesFRANCISCONo ratings yet

- 8443A260EDocument2 pages8443A260EMiguel ChaconNo ratings yet

- Test Plan: 9521A030: Pump SpecificationDocument3 pagesTest Plan: 9521A030: Pump Specificationjohnny sabinNo ratings yet

- TestplanDocument3 pagesTestplanGiorgio Di CesareNo ratings yet

- 8920A360 - New Holland 7740 TractorDocument13 pages8920A360 - New Holland 7740 TractorBaytolgaNo ratings yet

- 3349F330Document2 pages3349F330marco rod100% (1)

- 9320a217 TabelaDocument4 pages9320a217 TabelaLIONN SOFTWARESNo ratings yet

- Test Plan: 9320A530: Pump SpecificationDocument4 pagesTest Plan: 9320A530: Pump SpecificationVyacheslav ShatalovNo ratings yet

- 9320A093GDocument4 pages9320A093GKevin TtitoNo ratings yet

- 8550A223ADocument2 pages8550A223ALTurboNo ratings yet

- Test Plan: 9320A210: Pump Specification Iso Test ProcedureDocument3 pagesTest Plan: 9320A210: Pump Specification Iso Test ProcedureBaytolga100% (1)

- 9320A185H TestplanDocument4 pages9320A185H TestplanBaytolga canNo ratings yet

- 9323A271G Catalog DATADocument4 pages9323A271G Catalog DATALIONN SOFTWARESNo ratings yet

- Test Plan: 9320A210: Pump SpecificationDocument7 pagesTest Plan: 9320A210: Pump SpecificationBaytolgaNo ratings yet

- 3340F401G Plano de Teste DelphiDocument2 pages3340F401G Plano de Teste DelphiJunior Iung100% (1)

- Test Plan: 8522A130: Pump SpecificationDocument2 pagesTest Plan: 8522A130: Pump SpecificationJose Alexandre SunhegaNo ratings yet

- Testplan 3239590Document2 pagesTestplan 3239590Fx_2050% (1)

- 3230f582T PTDocument2 pages3230f582T PTHeitor Gael Alves de FreitasNo ratings yet

- Test Plan: Pump SpecificationDocument2 pagesTest Plan: Pump SpecificationClarice Alves de FreitasNo ratings yet

- 8520A060A TestplanDocument2 pages8520A060A TestplanBaytolga can100% (1)

- Pump SpecificationDocument2 pagesPump Specificationedgar ricoNo ratings yet

- 093000-1613 Hi̇no PDFDocument2 pages093000-1613 Hi̇no PDFBaytolgaNo ratings yet

- Test Plan: Pump SpecificationDocument4 pagesTest Plan: Pump SpecificationBaytolgaNo ratings yet

- 8924A141WDocument2 pages8924A141WLTurboNo ratings yet

- 3340F322 Lionn Auto SoftwaresDocument2 pages3340F322 Lionn Auto SoftwaresLIONN ONESOLUTIONNo ratings yet

- P9000 Schaevitz-990Document6 pagesP9000 Schaevitz-990Asadollah KhakpourNo ratings yet

- P 9000Document6 pagesP 9000Jeff Gomez PerezNo ratings yet

- Injection Pump Test Specifications: Manu-Facturer Engine Type Vehicle ModelDocument2 pagesInjection Pump Test Specifications: Manu-Facturer Engine Type Vehicle ModelKevin Ttito100% (1)

- MRT 460 Multi-Range Transducer Data SheetDocument6 pagesMRT 460 Multi-Range Transducer Data SheetBlAdE 12No ratings yet

- A 090Document3 pagesA 090birimpompaNo ratings yet

- Heavy Duty Pressure Transmitter: Data SheetDocument4 pagesHeavy Duty Pressure Transmitter: Data SheetДима ПолищукNo ratings yet

- HF2100 enDocument4 pagesHF2100 enBhakti PermanaNo ratings yet

- Injection Pump Test Specifications: Manu-Facturer Engine Type Vehicle ModelDocument2 pagesInjection Pump Test Specifications: Manu-Facturer Engine Type Vehicle ModelJunior IungNo ratings yet

- Instantaneous HeatersDocument8 pagesInstantaneous HeatersKhalid Ali Saif Al-ShamsiNo ratings yet

- Ferramenta Bomba Stanadyne PDFDocument19 pagesFerramenta Bomba Stanadyne PDFAnderson BombistaNo ratings yet

- Be Prepared With Lutz: Safety Is Our ConcernDocument16 pagesBe Prepared With Lutz: Safety Is Our ConcernJhonatan QuispeNo ratings yet

- Final QuationsDocument6 pagesFinal QuationsAgros OrganicNo ratings yet

- Fuel System 4Document5 pagesFuel System 4Falgon IslamNo ratings yet

- EH1700 Hydraulic Training Manual - HTT1700!10!1007Document82 pagesEH1700 Hydraulic Training Manual - HTT1700!10!1007Jacques Van Niekerk100% (2)

- 12V Mtu 4000Document248 pages12V Mtu 4000Mig Vazq100% (5)

- Eberspacher Hydronic B4WSC Technical Overview Document and InstructionsDocument50 pagesEberspacher Hydronic B4WSC Technical Overview Document and InstructionsDavid ButlerNo ratings yet

- Evaporative Condenser in Stainless SteelDocument11 pagesEvaporative Condenser in Stainless Steeljose luisNo ratings yet

- HYD Micro-ProjectDocument14 pagesHYD Micro-ProjectSanjay kshirsagarNo ratings yet

- Vibratory Plate: Operator S ManualDocument42 pagesVibratory Plate: Operator S ManualAristocles Gregor FloresNo ratings yet

- National Oilwell 1400-PT Performance ChartDocument1 pageNational Oilwell 1400-PT Performance ChartMilan KareliyaNo ratings yet

- Sinamics v20 enDocument18 pagesSinamics v20 enPhúcMậpNo ratings yet

- Technical Spec EVC Pump - R0Document18 pagesTechnical Spec EVC Pump - R0AyahKenzieNo ratings yet

- Understanding CompressorsDocument15 pagesUnderstanding CompressorsArben MontellanoNo ratings yet

- Instructions: Rotary Lobe BlowersDocument15 pagesInstructions: Rotary Lobe BlowersKumarNo ratings yet

- SKF Eddy Current Probes SystemsDocument64 pagesSKF Eddy Current Probes SystemsAnonymous Uk3JxlHA100% (1)

- Robot Greasing R-2000iC 125 210 R FDocument13 pagesRobot Greasing R-2000iC 125 210 R FMarketing TechroboticsNo ratings yet

- Valves in Piping DesignDocument5 pagesValves in Piping DesigndasubhaiNo ratings yet

- Self Priming Mud Pump - Maintenance ManualDocument7 pagesSelf Priming Mud Pump - Maintenance ManualCairo Oil Refining Co.No ratings yet

- Manual Og200c (S)Document148 pagesManual Og200c (S)Muhammad HaekalNo ratings yet

- Unit 4& 5Document9 pagesUnit 4& 5hariharanbook0% (1)

- FMM SyllabusDocument2 pagesFMM SyllabusM Vinoth kumarNo ratings yet

- Vacuum Pump: Type: Liquid Ring Vacuum Pump Make: Nash MODEL: AT-1006EDocument46 pagesVacuum Pump: Type: Liquid Ring Vacuum Pump Make: Nash MODEL: AT-1006EAmit Balot100% (2)

- Thermofluid Lab 2-Part ADocument19 pagesThermofluid Lab 2-Part ABennAbdullah0% (1)

- FPT Catalog Eng HiDocument126 pagesFPT Catalog Eng HiGenes CristinelNo ratings yet

- Design of A Filter-Separator Test Facility ForDocument140 pagesDesign of A Filter-Separator Test Facility ForParthaprotim NathNo ratings yet

- Dry - Wet Riser SystemDocument4 pagesDry - Wet Riser SystemXinbby BeexinNo ratings yet

- Iom Manual Ivp enDocument47 pagesIom Manual Ivp enmohamed hamedNo ratings yet

- GSC 125-95 - 750GPM110MDocument1 pageGSC 125-95 - 750GPM110MJwardNo ratings yet