Professional Documents

Culture Documents

Im Trox Compact Controller Easy

Uploaded by

michelesmiderleOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Im Trox Compact Controller Easy

Uploaded by

michelesmiderleCopyright:

Available Formats

TROX GmbH Heinrich-Trox-Platz D-47504 Neukirchen-Vluyn Telephone +49 / 28 45 / 2 02- 0 Telefax +49 / 28 45 / 2 02- 2 65 e-mail trox@trox.de www.troxtechnik.

com

VARYCONTROL Air terminal units TROX Compact-controller Instruction manual

EASY

Area of application

TROX Compact-controller

TROX Compact-controller Potentiometers Indicator light Service button Connection terminals

Tube connections for transducer Protection cover Shaft clamp

The TROX Compact-controller is a complete control device designed for VAV air terminal units. The dynamic differential pressure transducer, damper actuator and electronic controls are combined in one housing. The control signal input is wired based on the required operating mode. For variable flow rate control, a suitable room temperature controller (alternatively, an air quality controller or similar) or a DDC outstation must be used. The control signal is 0 to 10 VDC voltage. Switches or relays are used for constant flow rate control with 2 set values. The actual value of the flow rate is output as a standard linear, electrical signal. The voltage range is 0 to 10 VDC. Factory settings are min = 40 % and max = 80 %. Changes of setpoints on site by means of potentiometers. Several controllers can be connected to a common room temperature controller for parallel operation. Supply air extract air tracking control can be provided. Standard filtration in air-conditioning systems allows the use of the flow rate controller in the supply air without dust protection filters. Since a small volume flow is passed through the transducer in order to measure the flow rate, the following must be noted: With heavy dust load in the room, suitable extract air filters must be provided. If the air is contaminated with fluff or sticky particles or contains aggressive media, the TROX Compact-controller should not be used.

Proper application

The VAV terminal units are suitable for use in ventilation and air conditioning systems. Particular conditions can restrict the functioning capacity and must be taken into account during the design stage: Installation and wiring should only be carried out by specialists. During installation, wiring and commissioning, the normal rules of site working, in particular the health and safety regulations must be complied with. Safety transformers must be used. For aggressive air, only air terminal units made of plastic materials should be used after extensive tests for suitability. Galvanised sheet steel units must not be installed in contaminated environments (e.g. acetic acid). For hazardous areas, only use units with explosion proof electrical components. For protected exterior areas, only use units with membrane pressure transducers. Use in aircraft is not allowed. If there is a risk of fire due to flammable solids, the electric equipment must be rated IP 4X (see VdS 2033 fire safety guidelines or appropriate regulations).

TROX GmbH (06/2008) Leaflet No. E016NM3 Design changes reserved All rights reserved

TROX Compact-controllers are used in the air terminal units of the Easy type as follows. Technical and acoustic data see relevant leaflet:

TVR-Easy

Leaflet 5/3.5/EN/..

TVJ-/TVT-Easy

Leaflet 5/4.1/EN/..

TVZ-/TVA-Easy

Leaflet 5/1.2/EN/..

TROX GmbH Heinrich-Trox-Platz D-47504 Neukirchen-Vluyn Telephone +49 / 28 45 / 2 02- 0 Telefax +49 / 28 45 / 2 02- 2 65 e-mail trox@trox.de www.troxtechnik.com

VARYCONTROL Air terminal units TROX Compact-controller Instruction manual

EASY

Description of function

Characteristic of actual value signal

Nom (100 %)

min unit 0 Actual value signal U 10 VDC

U Actual = Nom 10

The flow rate is measured using the dynamic differential pressure principle. The effective pressure ( pw) from the differential pressure sensor is based on a partial volume flow passing through the transducer. The characteristic of effective pressure is calibrated in the controller to provide a linear actual value signal. The actual flow rate can be monitored as the voltage signal U. The measurement range is factory set to match the unit size so that the 10 VDC always corresponds to the unit nominal flow rate (Nom). The required flow rate is set by the room temperature controller or by switch contacts. The controller determines the set flow rate in accordance with the characteristic shown opposite and compares this with the actual value. The integral damper actuator is controlled based on the deviation. The factory pre-settings of min = 40 % and max = 80 % can be easily readjusted on site.

max . 100 % Nom

Flow rate

max-set value =

Characteristics of the control signal

max Adjustment range

min-set value =

min . 100 % Nom

Flow rate

Control signal range limiting

For settings between min = 0 % and max = 100 %, the control signal must be limited in the DDC outstation. In this case, the full published flow rate range can be used for future adjustment via the BMS.

min min unit 0 Control signal w 10 VDC

Flow rate control

The flow rate controller works independently of the duct pressure, i.e. the system pressure variations do not result in flow rate changes. To prevent the flow rate control becoming unstable, a dead band (hysteresis) must be built in within which the damper blade does not move. This dead band, coupled with the measuring tolerances, produces a flow rate deviation as shown opposite. If the conditions stated in the sales leaflet (e.g. minimum pressure differential, inlet flow conditions) are not observed, greater deviations must be expected.

set =

w (max min) + min 10

Pressure independent control characteristics

1000 Pa 800 Pressure differential 600 400 200 min max

20

40

60 Flow rate

80

100 % of Nom

TROX GmbH Heinrich-Trox-Platz D-47504 Neukirchen-Vluyn Telephone +49 / 28 45 / 2 02- 0 Telefax +49 / 28 45 / 2 02- 2 65 e-mail trox@trox.de www.troxtechnik.com

VARYCONTROL Air terminal units TROX Compact-controller Instruction manual

EASY

Variable volume flow

Variable flow rate control

The TROX Compact-controller controls the set flow rate, between min and max, from the control signal. Override to CLOSED or OPEN is available.

Room temperature controller, DDC-outstation etc.

Set flow rate

Actual flow rate

TROX Compact

Constant volume flow Constant flow rate control

Flow rate control setting Slave controller, monitoring etc. By wiring the control signal input terminal w via switch contacts, constant flow rates min and max, and various override controls can be achieved.

Set flow rate

Actual flow rate

TROX Compact

Supply extract tracking control Supply extract tracking control

With parallel control of the systems, an unacceptable difference between supply and extract air can occur if the pressure in one duct is too low. It is therefore preferable to use the actual value signal, usually that of the supply air, as a control signal for the slave flow rate controller. If the extract air is not controlled by the temperature controller (DDC), slave control is also implemented. Only ratio control can be implemented with the TROX Compact-controller, i.e. supply and extract air are always in the same ratio to each other under all operating conditions. The flow rate ratio is set as follows at the max-potentiometer of the slave controller.

max supp. Nom supp. . 100 % max extr. Nom extr.

Supply terminal unit Extract terminal unit TROX Compact-controller Room temperature controller

max-set value =

With the same unit sizes and flow rates, 100 % is set.

TROX GmbH Heinrich-Trox-Platz D-47504 Neukirchen-Vluyn Telephone +49 / 28 45 / 2 02- 0 Telefax +49 / 28 45 / 2 02- 2 65 e-mail trox@trox.de www.troxtechnik.com

VARYCONTROL Air terminal units TROX Compact-controller Instruction manual

EASY

Flow rate adjustment on site

Potentiometers

There are potentiometers for the adjustment of the flow rate limits. The values can be calculated using the formula on page 2 or determined from the flow rate scale which is on each unit.

Flow rate scale

(example for TVR-Easy 200)

TVR-Easy

0

% m3/h 0 l/s 0 50 100 150 200 250 300 350 400 200 400 600 800 1000 1200 1400

D 200

20 30 40 50 60 70 80 90 100

10

Variable flow rate control

80 90 70 100 60 50 40 0 30 20 10 80 90 70 100 60 50 40 0 30 20 10

The required flow rates must be adjusted by the customer. If min is set higher than max, then min is provided as a constant flow rate, even if a control signal is transmitted. If min is set on 0 %, then control is between shut-off and max. If the control signal falls below 0.1 VDC, the control damper closes (leakage flow only).

Constant flow rate control

70 60 50 40 30 80 90 100 70 60 50 40 30 80 90 100

The constant flow rate can be set with the min-potentiometer. The setting of the max-potentiometer is unimportant.

20 10

20 10

BMS operation

70 60 50 40 30 80 90 100 70 60 50 40 30 80 90 100

If the flow rate is set by the BMS, the min-potentiometer must be set at 0 % and the max-potentiometer must be set at 100 %. If the control signal falls below 0.1 VDC, the control damper closes (leakage flow only).

20 10

20 10

Factory setting

70 60 50 40 30 80 90 100 70 60 50 40 30 80 90 100

For delivery, settings are, min = 40 % and max = 80 %.

20 10

20 10

TROX GmbH Heinrich-Trox-Platz D-47504 Neukirchen-Vluyn Telephone +49 / 28 45 / 2 02- 0 Telefax +49 / 28 45 / 2 02- 2 65 e-mail trox@trox.de www.troxtechnik.com

VARYCONTROL Air terminal units TROX Compact-controller Instruction manual

EASY

The circumstances mentioned below result in protection level IP23 (see photograph): Damper blade shaft vertically, TROX Compact-controller on top. Transparent protection cover in place.

Terminal allocation

1 -

2

~

1 -

2

~

+ w U TROX Compact

1, , 2, ~, + w U

: : : :

Ground, neutral 24 V supply voltage Control signal input 0 to 10 VDC Actual value signal output 0 to 10 VDC

Wiring

The 24 V supply voltage must be wired by the customer. Safety transformers must be used (EN 60742). If several flow rate controllers are connected to one 24 V network, it is important to ensure that a common neutral or ground wire is used and that this is not connected to other wires. Wiring must be carried out in compliance with local legal regulations!

Electrical safety

1. Contact safety of the connection terminals In addition to the pertinent EMC standards for compliance with the Electromagnetic Compatibility (EMC) Directive, actuators and compact controllers must comply with the following standards: DIN EN 60335: Safety of electric devices for household use and similar purposes (part 1: general requirements). DIN EN 60730: Automatic electric regulators and controllers for household use and similar applications (part 1: general requirements; parts 2-14: special requirements for electric actuators). According to these standards, a touchable component (screw-type terminals, for example) is considered inactive if there is a safety extra low voltage (SELV). SELV must have a peak value of 42.4 V or less for alternating current and 42.5 V or less for direct current. The TROX Compact-controller is compliant with the above standards according to protection class III with a protection rating of IP20.

2. Operation in areas subjected to moisture or vapour Installation locations must meet ambient conditions of 0-50 C at 5-95 % relative humidity without condensation. IP20 does not protect against dripping water, but IP54 also offers no protection against vapour condensation inside the actuator (not moisture tight). The printed circuit boards do have a lacquer coating, which insulates the circuit paths. The solder joints are also insulated because of the fluxing agent used. 3. Strain relief on connecting cables The connection terminals are designed according to DIN VDE 0631-1 section 10 and exhibit the corresponding retention forces for the wire gauges indicated therein. For a tightening torque of up to 0.4 Nm (see standard and manufacturer specifications), this results in a retention force of 20 N for a flexible cable with a cross section of 0.75 mm2. A wire clamping bracket is fixed to the casing of all air terminal units of the Easy type.

Summary

The TROX Compact-controller meets the standards for compliance with the Low Voltage Directive. The controller is also compliant with the Electromagnetic Compatibility (EMC) Directive. The manufacturers statement has been justified and the product may be marketed with a CE mark.

TROX GmbH Heinrich-Trox-Platz D-47504 Neukirchen-Vluyn Telephone +49 / 28 45 / 2 02- 0 Telefax +49 / 28 45 / 2 02- 2 65 e-mail trox@trox.de www.troxtechnik.com

VARYCONTROL Air terminal units TROX Compact-controller Instruction manual

EASY

Room temperature control

Room temperature controller

Room temperature control

24 V

A dedicated room temperature controller or a DDC outstation with 0 to 10 VDC output is connected as shown opposite. If the controllers is on the same mains make sure that terminal 1 of the TROX Compact is identical to the ground of the control signal.

Parallel control

1 2

~

1 -

2

~

+ w U TROX Compact

Several flow rate controllers (supply or extract air) are run in parallel by one controller. If the air terminal units are of the same size and the min- and max-values are set the same, all units will control to the same flow rate. If there are different settings, then the controls will maintain a constant percentage between the flow rates.

1 -

2

~

1 -

2

~

+ w U TROX Compact

Tracking control

24 V

Room temperature controller

Supply extract tracking control

If the units are controlled in parallel and if the pressure in one duct area is too low there may be an undesirable difference in flow rate between supply and extract air. It is therefore more beneficial to use the actual value signal, usually that of the supply air, as the control signal for the slave flow rate (extract) controller.

1 -

2

~

1 -

2

~

+ w U TROX Compact

1 -

2

~

1 -

2

~

+ w U TROX Compact

Control using 0 to 20 mA

500 0.5 W Control signal 0 to 20 mA

Control using 0 to 20 mA

It is possible to control using 0 to 20 mA by wiring a 500 resistor to ground and input w in parallel.

1 -

2

~

1 -

2

~

+ w U TROX Compact

TROX GmbH Heinrich-Trox-Platz D-47504 Neukirchen-Vluyn Telephone +49 / 28 45 / 2 02- 0 Telefax +49 / 28 45 / 2 02- 2 65 e-mail trox@trox.de www.troxtechnik.com

VARYCONTROL Air terminal units TROX Compact-controller Instruction manual

EASY

Constant flow rate control

As soon as the 24 V supply voltage is applied, the controller runs the set min-value as a constant flow rate.

Constant flow rate control

24 V

1 -

2

~

1 -

2

~

+ w U TROX Compact

. . Vmin / Vmax changeover

24 V

. . Vmin / Vmax changeover

The switch S1 enables a changeover between the two constant flow rates of min and max. Switch S1 open: min Switch S1 closed: max

S1

1 -

2

~

1 -

2

~

+ w U TROX Compact

Changeover of multiple controllers

24 V

Changeover of multiple controllers

When there is parallel connection of multiple TVR-Easy controllers, the switch S1 must be used as changeover switch and the contact for the min operation must be connected to the ground (terminal 1).

S1

1 -

2

~

1 -

2

~

+ w U TROX Compact

Override controls OPEN / CLOSED

24 VAC

Override controls OPEN / CLOSED

The override control to provide OPEN and CLOSED can be achieved using external switches (potential-free contacts), only for a.c. voltage. Switch S2 closed: Damper blade CLOSED Switch S3 closed: Damper blade OPEN All override controls can be combined among themselves and with the different circuit options.

S2 S3

Diode 1N 4007

1 -

2

~

1 -

2

~

+ w U TROX Compact

TROX GmbH Heinrich-Trox-Platz D-47504 Neukirchen-Vluyn Telephone +49 / 28 45 / 2 02- 0 Telefax +49 / 28 45 / 2 02- 2 65 e-mail trox@trox.de www.troxtechnik.com

VARYCONTROL Air terminal units TROX Compact-controller Instruction manual

EASY

Commissioning

Functional test

Check wiring Connect supply voltage Connect air supply systems Press service button

With the service button and the indicator light a functional test can easily be carried out. Press service button for at least 1 second Actuator opens damper blade Actuator closes damper blade Actuator returns damper blade to previous position When the set flow rate is controlled the indicator light remains permantly on. In many cases, incorrect wiring can be the reason for malfunctions. Therefore a close examination of all connections should be made. Wires in terminals 3 and 4 should be disconnected. The flow rate control is checked by setting a setpoint to which the actual value must correspond after a short time. The setpoint signal is a voltage signal or a switch contact.

Record actual value signal U for override control min Record actual value signal U for override control max

Fault finding check

no Supply voltage within specifications? yes Actual value signal U consistent? yes Actuator opens and closes yes Flow rate min? yes Flow rate max? yes no no no no Damper obstructed? no Controller faulty Check transformer

Replacement controller

When replacing a faulty controller only the unit type (e.g. TVR-Easy) must be specified when ordering a replacement controller. This information could be taken from the label of the unit. The flow rate adjustment is than done on site.

Duct pressure sufficient? Measuring tubes damaged?

Available TROX Compact-controllers:

Check room temperature controller

Control signal? yes no Override controls?

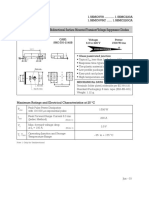

M466DC3 or M466DD7

for TVR-Easy

Check window switch, relays, etc.

M466EP9

for TVZ/TVA-Easy

Order example spare controller

TROX Compact-controller for TVR-Easy No. M466DD7

M466DB4

for TVJ/TVT-Easy

You might also like

- EGAT Head OfficeDocument33 pagesEGAT Head OfficeJasper_HVACNo ratings yet

- Continuous-Flow Rice Husk Gasifier-Belonio-2010 0Document18 pagesContinuous-Flow Rice Husk Gasifier-Belonio-2010 0Erick Marzan AlvarezNo ratings yet

- Chilled Beams in Heating: Design Criteria and Case StudyDocument8 pagesChilled Beams in Heating: Design Criteria and Case StudyarjantinNo ratings yet

- Jet Nozzles DUKDocument14 pagesJet Nozzles DUKKerx EndranoNo ratings yet

- hp39gs Manual PDFDocument314 pageshp39gs Manual PDFMatheus Paes PeçanhaNo ratings yet

- 3rd QTR - Seminar Invitation (Lto - Mimaropa)Document1 page3rd QTR - Seminar Invitation (Lto - Mimaropa)Maria GinalynNo ratings yet

- Silver Hammer Construction & Supplies: Warranty ConditionsDocument2 pagesSilver Hammer Construction & Supplies: Warranty ConditionsLimelily PensionNo ratings yet

- Proposal To AEPCDocument10 pagesProposal To AEPCBimal BhattaraiNo ratings yet

- Technical Seminar Invitation - September 22Document1 pageTechnical Seminar Invitation - September 22Mike PosktovaNo ratings yet

- Simpson, RobertDocument101 pagesSimpson, RobertKai JieNo ratings yet

- Kiểm Tra Bởi: Checked by:: PH AÀN ĐỒDocument1 pageKiểm Tra Bởi: Checked by:: PH AÀN ĐỒtran viet hungNo ratings yet

- Silencer Selection InstructionsDocument9 pagesSilencer Selection InstructionsRyo TevezNo ratings yet

- Basic Fs Training PresentationDocument53 pagesBasic Fs Training PresentationDick HarryNo ratings yet

- Quick Selection Guide 2017 Linked VersionDocument82 pagesQuick Selection Guide 2017 Linked VersionjdanastasNo ratings yet

- NMEJ Case StudyDocument15 pagesNMEJ Case StudyS V RAJAGOPALANNo ratings yet

- Fabric DuctDocument4 pagesFabric Duct'Ahmed AslamNo ratings yet

- Sound Formulae SheetDocument2 pagesSound Formulae SheetSohJiaJieNo ratings yet

- Bypass Vav Terminal UnitDocument3 pagesBypass Vav Terminal Unitfarshan296015No ratings yet

- Jet DiffuserDocument12 pagesJet DiffuserSam JoseNo ratings yet

- Prefunctional Test Checklist-12 - VavDocument6 pagesPrefunctional Test Checklist-12 - Vavlong minn2No ratings yet

- GATE Tutor (ME) - Heat&Mass Transfer 1Document30 pagesGATE Tutor (ME) - Heat&Mass Transfer 1SabariMechy0% (1)

- Incorporating Outside Air in VRV Systems: ASHRAE 62. - Ventilation For Acceptable Indoor Air QualityDocument10 pagesIncorporating Outside Air in VRV Systems: ASHRAE 62. - Ventilation For Acceptable Indoor Air QualityAR RmsNo ratings yet

- Titus VavDocument46 pagesTitus VavSantiago J. ramos jrNo ratings yet

- Fabric Duct AshraeDocument42 pagesFabric Duct Ashraehotmar ruNo ratings yet

- Fabric Ducting&Diffusers: Technical DataDocument32 pagesFabric Ducting&Diffusers: Technical DataJeghiNo ratings yet

- Heat Exchanger - WaterCoilDocument115 pagesHeat Exchanger - WaterCoilPrem KumarNo ratings yet

- DuctSox 230215Document32 pagesDuctSox 230215Aeon SystemsNo ratings yet

- Application of Hydronic Radiant & Beam SystemsDocument86 pagesApplication of Hydronic Radiant & Beam SystemsDhirendra Singh Rathore100% (1)

- The National Building Code of The Philippines 2005 - Vicente B. FozDocument390 pagesThe National Building Code of The Philippines 2005 - Vicente B. FozJean Ann D. WapelleNo ratings yet

- Low Energy Consumption Hvac Systems For Green Buildings Using Chilled Beam TechnologyDocument9 pagesLow Energy Consumption Hvac Systems For Green Buildings Using Chilled Beam TechnologyIAEME PublicationNo ratings yet

- APN069 ParkingGarage WEB 1 8 15Document8 pagesAPN069 ParkingGarage WEB 1 8 15Rafael Leonardo GomezNo ratings yet

- Lokring I Single Ring 01.07.2013Document58 pagesLokring I Single Ring 01.07.2013Sandra Mabel Leguizamon100% (1)

- R&AC Lecture 30Document17 pagesR&AC Lecture 30Denise Koh Chin HuiNo ratings yet

- Dr. Fixit Newcoat 105 1 PDFDocument3 pagesDr. Fixit Newcoat 105 1 PDFmohdrashidNo ratings yet

- Basic Technical Drawing For Grade 11 12 2Document36 pagesBasic Technical Drawing For Grade 11 12 2Robert kite ClementeNo ratings yet

- Damper Actuator - BelimoDocument80 pagesDamper Actuator - BelimoaudithanNo ratings yet

- Parking Structures Guidelines enDocument8 pagesParking Structures Guidelines enbudi budihardjoNo ratings yet

- Selection and Application Manual: Fifth Edition April 2003Document20 pagesSelection and Application Manual: Fifth Edition April 2003Anonymous ixIhrPM2No ratings yet

- TITUS Diffusers 2017Document216 pagesTITUS Diffusers 2017Anonymous 7z6OzoNo ratings yet

- Fire and Smoke Protection PDFDocument393 pagesFire and Smoke Protection PDFBülent KabadayiNo ratings yet

- AHRI Standard 885 2008 Duct Discharge Calculation SpreadsheetDocument17 pagesAHRI Standard 885 2008 Duct Discharge Calculation SpreadsheetbinishNo ratings yet

- Advanced Air Duct Design Part 2Document29 pagesAdvanced Air Duct Design Part 2Timothy Bryant100% (1)

- Air Diffuser Architecture PDFDocument28 pagesAir Diffuser Architecture PDFBranislavPetrovicNo ratings yet

- New Pumping Station at Jabel Haffet Base EPC Contract No:-N-16297Document60 pagesNew Pumping Station at Jabel Haffet Base EPC Contract No:-N-16297unnicyriacNo ratings yet

- Sound Power LevelDocument22 pagesSound Power LevelAbu Bakar KhanNo ratings yet

- SKM FCU High Static DetailDocument28 pagesSKM FCU High Static DetailInzamamNo ratings yet

- What Is External Static Pressure of A FanDocument2 pagesWhat Is External Static Pressure of A Fansahiloct11969100% (3)

- Product Data: Features/BenefitsDocument60 pagesProduct Data: Features/BenefitsBJNE01No ratings yet

- UFAD PresentationDocument42 pagesUFAD Presentationsenthilarasu5No ratings yet

- Karnataka Electrical Inspectorate) Rules, 2018Document38 pagesKarnataka Electrical Inspectorate) Rules, 2018Babu BabuNo ratings yet

- Zoning Reference GuideDocument20 pagesZoning Reference GuideqwincyNo ratings yet

- Duct Loop and VAVDocument10 pagesDuct Loop and VAVengomar76No ratings yet

- Camel Intro 2Document34 pagesCamel Intro 2Inventor SolidworksNo ratings yet

- ME 415B Prelim ExamDocument1 pageME 415B Prelim ExamStephanie ParkNo ratings yet

- Air Terminal CatalogeDocument114 pagesAir Terminal CatalogeRamadan RashadNo ratings yet

- Aircraft Flying Project (PRINT OUT)Document24 pagesAircraft Flying Project (PRINT OUT)Priyanka KumariNo ratings yet

- Fisa Tehnica Tema 1FVDocument26 pagesFisa Tehnica Tema 1FVDeeaNo ratings yet

- Constantflow Volume Flow Controllers: For Constant Volume Systems Type ENDocument12 pagesConstantflow Volume Flow Controllers: For Constant Volume Systems Type ENDODYNo ratings yet

- Reference Guide To Useful Electronic Circuits And Circuit Design Techniques - Part 2From EverandReference Guide To Useful Electronic Circuits And Circuit Design Techniques - Part 2No ratings yet

- Ultrasound Analysis for Condition Monitoring: Applications of Ultrasound Detection for Various Industrial EquipmentFrom EverandUltrasound Analysis for Condition Monitoring: Applications of Ultrasound Detection for Various Industrial EquipmentRating: 4.5 out of 5 stars4.5/5 (3)

- Orion-Fws - : Feed Weighing ComputerDocument4 pagesOrion-Fws - : Feed Weighing ComputermichelesmiderleNo ratings yet

- MAtek PBD-XT60Document1 pageMAtek PBD-XT60michelesmiderleNo ratings yet

- Quadcopter PID ExplainedDocument11 pagesQuadcopter PID ExplainedmichelesmiderleNo ratings yet

- Emax BLHeli ESC ManualDocument1 pageEmax BLHeli ESC ManualmichelesmiderleNo ratings yet

- PROJECT MOCKINGBIRD v3 - UR65 v1Document35 pagesPROJECT MOCKINGBIRD v3 - UR65 v1michelesmiderleNo ratings yet

- Golf Clash - MasterlistDocument1 pageGolf Clash - MasterlistmichelesmiderleNo ratings yet

- KillerDocument83 pagesKillermichelesmiderle100% (1)

- VRD 3Document7 pagesVRD 3michelesmiderleNo ratings yet

- Osisense Xs Xs612b1nal2Document2 pagesOsisense Xs Xs612b1nal2TB11SDNo ratings yet

- FNC42060F / FNC42060F2: Motion SPM 45 SeriesDocument17 pagesFNC42060F / FNC42060F2: Motion SPM 45 SeriesSergio ReyesNo ratings yet

- Omnidirectional Dynamic Microphones: (OVER)Document2 pagesOmnidirectional Dynamic Microphones: (OVER)Ahmed SamiNo ratings yet

- Fargo NamurDocument2 pagesFargo NamurCostel CojocaruNo ratings yet

- Mil HDBK 454Document221 pagesMil HDBK 454AliNo ratings yet

- TPC8116 HDocument7 pagesTPC8116 HCristina NistorNo ratings yet

- Eee 1003 VitDocument71 pagesEee 1003 VitAlok100% (1)

- EN FANOXTD MANU SIA OCEFSecondaryDist SIAB-STANDARD-CT R015Document147 pagesEN FANOXTD MANU SIA OCEFSecondaryDist SIAB-STANDARD-CT R015Bruno CarvalhoNo ratings yet

- Buchholzrelay MBR For Liquid Immersed Transformers and Reactors With Conservator in Accordance With EN 50216-2Document13 pagesBuchholzrelay MBR For Liquid Immersed Transformers and Reactors With Conservator in Accordance With EN 50216-2snooty.eli.gamedogsNo ratings yet

- User Manual (SZGH-SD Series) v2.0Document66 pagesUser Manual (SZGH-SD Series) v2.0DmytroKrNo ratings yet

- DCDC Traco TMR 1 - 2411SMDocument4 pagesDCDC Traco TMR 1 - 2411SMJoão Oliveira BentesNo ratings yet

- Solar Micro InverterDocument23 pagesSolar Micro InverterHassan SouleymanNo ratings yet

- MCBDocument6 pagesMCBvicky gosaviNo ratings yet

- Weidmuller PRO MAX 960W 24V 40A enDocument5 pagesWeidmuller PRO MAX 960W 24V 40A enUmair MalikNo ratings yet

- H25 Incremental EncoderDocument4 pagesH25 Incremental EncoderEdgar AllamNo ratings yet

- TeSys D - LC1D32N7Document4 pagesTeSys D - LC1D32N7areleemeanNo ratings yet

- Introduction To VLSI TechnologyDocument19 pagesIntroduction To VLSI TechnologyVikas KumarNo ratings yet

- VC CatalogDocument36 pagesVC CatalogRazvan SasuNo ratings yet

- TXTFront HalfDocument4 pagesTXTFront HalfAnonymous v9es4eABNo ratings yet

- 01 Power ElectronicsDocument134 pages01 Power Electronicspunith gowda75% (4)

- The State-of-the-Art of Silicon-on-Sapphire CMOS RF SwitchesDocument4 pagesThe State-of-the-Art of Silicon-on-Sapphire CMOS RF SwitchesAhmed AtefNo ratings yet

- DC Machine PDFDocument35 pagesDC Machine PDFPulkit Kumar Chauhan92% (24)

- Earthing SystemsDocument25 pagesEarthing SystemsRudra Pratap100% (1)

- Tesla Wall - Connector - Installation - Manual - 80A - en - US PDFDocument37 pagesTesla Wall - Connector - Installation - Manual - 80A - en - US PDFBryan SalamatNo ratings yet

- BJT FabricationDocument26 pagesBJT Fabricationabhinavbhatnagar0% (1)

- Solutions Chapter 02, 03, 04 Network Analysis 3rd Edition - M. E. v. ValkenburgDocument163 pagesSolutions Chapter 02, 03, 04 Network Analysis 3rd Edition - M. E. v. ValkenburgPankaj Kumar89% (18)

- Brochure Bushing 2016 English 1 PDFDocument2 pagesBrochure Bushing 2016 English 1 PDFSSDNo ratings yet

- 1.5SMC100 To 1.5SMC220CADocument7 pages1.5SMC100 To 1.5SMC220CAZoulou77No ratings yet

- Checklist For Erection Power TransformerDocument6 pagesChecklist For Erection Power Transformersasikumar67% (3)

- 1746 Ni8Document20 pages1746 Ni8Jefferson Dussan CubiNo ratings yet