Professional Documents

Culture Documents

Fire Fighting - FFS

Uploaded by

ΒΑΓΓΕΛΗΣ ΑΝΤΩΝΙΟΥOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Fire Fighting - FFS

Uploaded by

ΒΑΓΓΕΛΗΣ ΑΝΤΩΝΙΟΥCopyright:

Available Formats

FIRE FIGHTING SYSTEM

NOTES

357 CIVIL DEFENSE

FFS_N1 FIREFIGHTING SYSTEM Item Provisions Notes

Annex_FFS Notes Revisions_2021 Fifty (50) gpm hose allowance shall be added to sprinkler demand if one FHR per floor level is provided;

7.1

Item Provisions Notes 100 gpm if two or more FHR is provided per floor level.

Sprinklers maybe required in some building configurations based on the life safety 500 gpm for one standpipe (65mmØ landing valve) and additional 250gpm per addition of standpipe up

7.2

1.0 assesment. (for example non compliance to to travel distance limits . Or the Commodities to max. 1250gpm

in the building exceeded the MAQ and so on...). 1000 gpm (maximum) is acceptable for combine (sprinkler/wet standpipe) system for non-storage

7.3

2.0 Fire Blanket shall be required on all kitchens and pantries with cooking appliance. building.

Fifty(50)kg. Wheeled/Trolley type applicable fire extinguisher shall be required on all

3.0

non-sprinklered industrial and storage occupancies with areas exceeding 100 m²

Refers to sprinkler protection only (other system can be used as alternative). Comply

4.0

with NFPA 13 for all other requirements not specified in this guidelines.

Standpipe system to be used by fire department. Shall comply with NFPA 14 for all other

5.0

requirements not specified in this guidelines.

Maximum number of landing valves or outlet per floor : 100Ømm dia. Riser - two(2) 65Ømm outlets;

5.1

150Ømm dia. riser - four (4) 65Ømm outlets.

5.2 Minimum flow at outlet : 250 gpm @ 100psi

Breeching inlet or Fire Dep›t Connection shall be connected on the system side of the fire water supply

5.3 check valve: 150Ømm - 4 way type (150Ø x 4-65Ø inlets); 100Ømm - 2 way type (100Ømm x 2-65Ømm

inlets) (siamese type).

Refers to 25mmØ hose reel to be used by occupants. Comply with NFPA 14 for all other

6.0

requirements not specified in this guidelines, Min. @ 65psi

6.1 Hose reel system only : 65Ømm (min.) riser to serve up to max. 4-hose reels per floor.

Hose reels shall be connected in crossmains after the floor/zone control valve assemby(equiped with

6.2

water flow switch) in sprinklered buildings.

Provide on all floors when the building of portions of the building is protected with an automatic sprinkler

6.3

system..

Fire pumps shall comply with NFPA 20 for all other requirements not specified in this

7.0

guidelines.

CIVIL DEFENCE 358 359 CIVIL DEFENCE

FIRE FIGHTING SYSTEM NOTES FIRE FIGHTING SYSTEM NOTES

FIRE FIGHTING SYSTEM

GUIDELINES

361 CIVIL DEFENSE

Item Provisions Notes

FFS_G1 FIRE FIGHTING SYSTEM 1.5 Fire pumps shall be listed for service or approved by an authority acceptable to the Qatar Civil

Annex_FFS Guidelines Revisions_2021 Defence.

1.5 Fire Pumps

Performance curves on which the system curve and duty point shall be submitted together with hydraulic

Item Provisions Notes

calculations with the fire protection plans fire safety submission.

1.0 FIRE PROTECTION WATER SUPPLIES

1.6 Fire pumps shall be sized and selected in accordance with the NFPA 20 to meet the single largest

Water Supplies quantities shall be determined with the use of the fire code including the QCD Particular 1.6 Pump Size

1.1 Applicable Codes system demand

Requirements and the NFPA Water supplies shall be secure and dedicated for fire protection use only

2.0 RISING MAIN FOR FIRE FIGHTING

Fire Protection water storage tanks shall be constructed of non-combustible materials. They shall

2.1 The type of rising main system shall be provided appropriate to the building as follow:

be constructed with compartments that allow maintenance without impairment to the system. Each

1.2 Tank Construction. 2.1.1 Dry Rising Mains

compartment shall be not more than 50%. Water tank has to be approved from QCD Product and

Equipment Safety Divisions. 2.1..1.a Any floor at habitable height beyond 9M and not exceeding 28M above ground level.

The net effective capacity of the tanks(s) shall be sized to meet the minimum duration of flow for the fire protection 2.1.1.b One basement exceeding 1115 square meters in gross floor area.

systems determined in accordance with the applicable fire codes. 2.1.1.c One basement less than 1115 square meters in gross floor area and ≥ 6.1 m below grade.

The net effective capacity of the water tank shall be verified on the fire protection plans of the fire safety submission.

Type

2.1.1.d One up to four basement levels below Level of Exit Discharge (LED).

1.3 These drawings shall clearly indicate size and allowances for fittings, freeboard, inlet pipe arrangement, overflow Tank Capacity

2.1.2 Wet Rising Mains

pipe, suction pipe and fittings, any allowances and the clear volume of water available for use by the fire protection

2.1.2.a For building having a habitable height exceeding 28M above the ground level.

systems.

The effective capacity shall also be clearly indicated on the tank in lettering of a minimum height of 100 mm. 2.1.2.b More than Four basement levels below LED

1.4 Each water tank shall have the following minimum attachments: 2.1.3 Separate dry and wet rising main systems in a building may be permitted by QCD

Automatic infill such that the tank may be refilled from empty within a time period of 6 hours. In any 2.2 Number and distribution of rising main shall be as follow:

1.4.1

case it shall not be less than the size of the KHARAMAA supply pipe. 2.2.1 Provide in every required exit staircase as per NFPA 14-2019 Edition Section 7.4.

1.4.2 Visual water level indicator of non-combustible construction. Additional hose connection shall be provided in excess of 150 ft. (45.7 m), non-sprinklered and 200 ft.

1.4.3 Balance valve. 2.2.2 (61 m), sprinklered, travel distance from a hose connection to the most remote portion of the Number

floor level as applicable and as per NFPA 14 (2019) SEC. 7.3.2

1.4.4 Drain valve having a minimum size shall be 80mm nominal diameter. Tank Attachments

2.2.3 Subject to FF Operation Department requirements, as applicable

1.4.5 Suction connections.

2.2.4 Number (rising mains): One rising mains serving not more than 930 m² (of any floor).

1.4.6 Test return pipe(s).

1.4.7 Overflow pipe of minimum size, one diameter larger than the inlet pipe.

Position of rising mains and associated landing valves shall be located and installed in each required

Location and Installation

1.4.8 All pipe and other openings into the tank shall be fitted with devices to prevent the ingress of insects. 2.3 Exit Staircase and the Landing valve of the rising main shall be installed between 1M and 1.4M relative

Height

to the finish floor level.

CIVIL DEFENCE 362 363 CIVIL DEFENCE

FIRE FIGHTING SYSTEM GUIDELINES FIRE FIGHTING SYSTEM GUIDELINES

Item Provisions Notes Item Provisions Notes

2.4 Minimum nominal bore of rising main shall be:

100mm diameter where the rising main does not exceed 28M in habitable height and serving only one

2.4.1

landing valve per floor. Size

150mm diameter or higher where the rising main is in combination with the fire sprinkler system serving

2.4.2

two or more landing valve per floor.

2.5 The inlet to the rising main shall be located:

On an external wall or a boundary of a building and to be within 18M of the adjacent fire appliance

2.5.1 access road. Each rising main shall be fitted within a breaching inlet with non-return valve directly at the 2.7 Figure B

foot of the same riser stack.

As close as possible to the rising main they serve with any connecting pipe between the inlet and the Breeching Inlet Connection

vertical run of the rising main kept to a minimum and given a fall towards the drain valve. The total

2.5.2

pressure loss of the dry rising main shall not exceed 6bars based on the design of water flow rate. This

is correspond with maximum habitable height of 60M.

2.5.3 In a conspicuous position readily visible and accessible to the firefighters.

2.6 Figure A

2.8 Figure C

CIVIL DEFENCE 364 365 CIVIL DEFENCE

FIRE FIGHTING SYSTEM GUIDELINES FIRE FIGHTING SYSTEM GUIDELINES

Item Provisions Notes Item Provisions Notes

Clean agent systems shall be operated automatically by a QCD approved automatic fire detection

3.6 Automatic Operation

system.

The control panel shall comply with the following:

3.7

Control Panel

3.7.1 Located external to the protected areas

3.7.2 Installed near the main entrance of the protected enclosure

2.9 Figure D 3.7.3 Connected to the Main Fire Alarm Panel with indication of Alarm, Gas Discharged and Fault indications.

Clean Agent shall comply with the following:

3.8

Gas Discharge

3.8.1 Gas discharge shall only occur after predetermined time delay subject to approval by QCD.

The time delay shall be interrupted by the operation of the Abort Switch and shall re-commence on

3.8.2

release of such abort switch.

3.8.3 Minimum time delay to discharge shall be twenty (20) seconds.

3.0 CLEAN AGENT SYSTEM

3.9 Manual Release Push Button shall comply with the following:

The design, installation and testing of Clean Agent Systems shall be in accordance with these regulations Applicable Codes

3.1 3.9.1 Located external to the protected enclosure within 1.5M of the main entrance.

and the latest edition of NFPA 2001.

3.2 Only clean agents specifically approved by the Qatar Civil Defence (QCD) shall be used. More than one manual release push button may be required subject to the size and configuration of the Manual Release

3.9.2

protected enclosure.

The use of Carbon Dioxide (CO2) is prohibited without specific approval from the QCD. Such approval

3.3 will only be granted on the basis of a formal engineering analysis that concludes to the satisfaction of 3.9.3 Operation of such shall cause instant release of the clean agent.

the QCD, that alternative clean agents are not able to satisfactorily extinguish the fire. 3.10 Abort Switch shall comply with the following:

3.1 Containers/Cylinders storage location: 3.10.1 Located within the protected enclosure and mounted within 1.5M from the main entrance.

Stored outside of the protected area or enclosure; accessible within 2m from the entrance of the More than one abort switch may be required subject to the size and configuration of the protected

3.4.1 Location of Cylinders 3.10.2 Abort Switch

protected area. enclosure.

3.4.2 Permitted to be located within or outside the hazard or hazards they protect. 3.10.3 Upon continuous operation, shall interrupt the countdown timer.

3.10.4 Upon release of abort switch, reset of countdown timer to discharge clean agent gas.

A Manual Override (mechanical / electrical) means of discharging the required agent shall be provided

3.5 Manual Actuation Audible / Visible Notification devices shall be installed both inside and outside of the protected

on the storage container. 3.11 Notification

enclosure

CIVIL DEFENCE 366 367 CIVIL DEFENCE

FIRE FIGHTING SYSTEM GUIDELINES FIRE FIGHTING SYSTEM GUIDELINES

Item Provisions Notes

“DO NOT ENTER – GAS DISCHARGED” illuminated signs shall be external to the protected enclosure

and mounted above all entrances so as to be visible to any person entering. The lettering shall be a

minimum of 50mm high. It shall be visible at all times of the day. The illumination shall be activated by

a pressure switch fitted to the discharge piping.

3.12 Gas Discharge Signage

“EVACUATE NOW – GAS DISCHARGE” illuminated signs shall be provided above the exits of the

protected enclosure. The lettering shall be a minimum of 50mm high. It shall be visible at all times of

the day. Illumination shall be activated on commencement of the discharge time delay.

3.13 Enclosure shall comply with the following:

All enclosures protected by clean agent systems that are required by code to be provided with an

3.13.1 extinguishing system, in the absence of sprinkler protection, must be constructed from 2-hour fire

resistant elements.

FIRE ALARM SYSTEM

Subject to the location of the enclosure, its integrity (to be verified through testing) and the type and

3.13.2 nature of the clean agent used, ventilation system to purge the gas after discharge may be required by Enclosure Consideration

QCD. Due consideration shall be given to this aspect of the system.

All enclosures protected by clean agent systems must be subjected to an enclosure integrity test. The

3.13.3

test must be conducted by a qualified tester acceptable to QCD. The test shall verify the ability of the

protected enclosure to maintain the minimum design concentration for ten (10) minutes. The enclosure

test must be witnessed by QCD. This is a pre-condition for issue of the building’s fire safety certificate. NOTES

CIVIL DEFENCE 368 369 CIVIL DEFENSE

FIRE FIGHTING SYSTEM GUIDELINES

You might also like

- Boiler Control Systems Engineering, Second EditionFrom EverandBoiler Control Systems Engineering, Second EditionRating: 4.5 out of 5 stars4.5/5 (15)

- 201123-1609-HMR Fire Scheme ReportDocument4 pages201123-1609-HMR Fire Scheme ReportMine FollowerNo ratings yet

- Auto Transformer Fire ProtectionsDocument13 pagesAuto Transformer Fire ProtectionsTarun BhatejaNo ratings yet

- CAMPUS FIRE SAFETY STANDPIPE REQUIREMENTSDocument6 pagesCAMPUS FIRE SAFETY STANDPIPE REQUIREMENTSJuan Carlos GutiérrezNo ratings yet

- TD FMS DLT1010 11 cEN 017 1Document4 pagesTD FMS DLT1010 11 cEN 017 1rinaldo KurniawanNo ratings yet

- The Crest Phase V Fire Protection System Technical SpecificationsDocument74 pagesThe Crest Phase V Fire Protection System Technical SpecificationsamolNo ratings yet

- Compact BS9251:2014 Compliant Fire Suppression SystemDocument8 pagesCompact BS9251:2014 Compliant Fire Suppression SystemDANE80No ratings yet

- EagleBurgmann - Seal Management System - SMS - ENDocument3 pagesEagleBurgmann - Seal Management System - SMS - ENCorciu ValentinNo ratings yet

- Chapter 1Document45 pagesChapter 1Abdulqader MousaNo ratings yet

- FF Design Report - Ovid Kling - Agri-Products Market Center Project at Tafo (Ayat Site) - Rev-00Document6 pagesFF Design Report - Ovid Kling - Agri-Products Market Center Project at Tafo (Ayat Site) - Rev-00Nuhamin ZablonNo ratings yet

- Caterpillar: System Specification SheetDocument1 pageCaterpillar: System Specification SheetMaylson SenaNo ratings yet

- 24112015XAG3KELRAnnexureRiskAssesment PDFDocument16 pages24112015XAG3KELRAnnexureRiskAssesment PDFenduNo ratings yet

- Instrumentation For Fired Heaters IP 15-1-1: ScopeDocument14 pagesInstrumentation For Fired Heaters IP 15-1-1: ScopeLuis Alonso Aguirre LopezNo ratings yet

- Honeywell S4565BFDocument7 pagesHoneywell S4565BFcinefil70No ratings yet

- Nfpa3chapter - 3 StandpipeDocument16 pagesNfpa3chapter - 3 StandpipePeter LiNo ratings yet

- FireSafety - Onshore Instations 31.05.2023Document15 pagesFireSafety - Onshore Instations 31.05.2023Ashish ChaudharyNo ratings yet

- DBR - Fire Fighting - HPMC ParalaDocument16 pagesDBR - Fire Fighting - HPMC ParalaKiran LokhandeNo ratings yet

- Atlas Copco Roc L8Document1 pageAtlas Copco Roc L8Maylson SenaNo ratings yet

- TJ BrochureDocument2 pagesTJ Brochuremick2560No ratings yet

- My Refence BoqDocument6 pagesMy Refence BoqJaveedMdJaveedNo ratings yet

- Content ServerDocument7 pagesContent ServeraplicacionescdmxNo ratings yet

- Product: Precision As StandardDocument16 pagesProduct: Precision As Standardredscythe_25550No ratings yet

- Series LFII Residential Pendent Sprinklers 4.9 K-Factor: Technical Services: Tel: (800) 381-9312 / Fax: (800) 791-5500Document8 pagesSeries LFII Residential Pendent Sprinklers 4.9 K-Factor: Technical Services: Tel: (800) 381-9312 / Fax: (800) 791-5500Achraf BoudayaNo ratings yet

- Exxon IP 7-5-1 Coils For Fired Heaters and BoilersDocument5 pagesExxon IP 7-5-1 Coils For Fired Heaters and BoilersGilvan SilvaNo ratings yet

- Model EC-25 (CMDA and CMSA Applications) 25.2 (360) K-Factor (360) Upright Sprinkler Extended Coverage General DescriptionDocument4 pagesModel EC-25 (CMDA and CMSA Applications) 25.2 (360) K-Factor (360) Upright Sprinkler Extended Coverage General Descriptionekas1956No ratings yet

- S7999B System Display: ApplicationDocument76 pagesS7999B System Display: ApplicationHector MendozaNo ratings yet

- BurnerManagementSystems PresDocument12 pagesBurnerManagementSystems PressayedNo ratings yet

- Atlas Copco: System Specification SheetDocument1 pageAtlas Copco: System Specification SheetDiego LimaNo ratings yet

- Boiler Control OverviewDocument4 pagesBoiler Control OverviewMAS98No ratings yet

- Product: WM 30 Oil, Gas and Dual Fuel VersionDocument32 pagesProduct: WM 30 Oil, Gas and Dual Fuel Versionbenlly alvarezNo ratings yet

- PDFDocument32 pagesPDFJuan Carlos Cahuasquí IntriagoNo ratings yet

- Fire Pump Size Calculation: ProjectDocument3 pagesFire Pump Size Calculation: ProjectVaibhav SawantNo ratings yet

- Afex Caterpillar-D10t2Document1 pageAfex Caterpillar-D10t2enricoNo ratings yet

- Protection For High Voltage TransfromersDocument4 pagesProtection For High Voltage TransfromersMani KumarNo ratings yet

- CH-19 Furnace Safe Guard-RevisedDocument6 pagesCH-19 Furnace Safe Guard-RevisedRavi ShankarNo ratings yet

- Comparision in OISDDocument7 pagesComparision in OISDsingla.nishant1245No ratings yet

- Caterpillar: System Specification SheetDocument1 pageCaterpillar: System Specification SheetMaylson SenaNo ratings yet

- Ul555 555S 702 PDFDocument2 pagesUl555 555S 702 PDFRiaz ahmed100% (1)

- EXXON IP-10-01-01 Centrifugal PumpsDocument9 pagesEXXON IP-10-01-01 Centrifugal PumpsyerkoNo ratings yet

- Calatolo Dampers Fuego-HumoDocument24 pagesCalatolo Dampers Fuego-HumojjcorberalopezNo ratings yet

- EXXON IP-03-19-01 Piping Erection, Testing, Flushing and CleaningDocument6 pagesEXXON IP-03-19-01 Piping Erection, Testing, Flushing and CleaningJJ WeldingNo ratings yet

- Mechanical Design Criteria Technical SpecificationDocument1 pageMechanical Design Criteria Technical SpecificationKumar NawneetNo ratings yet

- Standard Information: Standards Update Notice (Sun) ISSUED: April 1, 2021Document9 pagesStandard Information: Standards Update Notice (Sun) ISSUED: April 1, 2021Muneer mahammadNo ratings yet

- Atlas Copco: System Specification SheetDocument1 pageAtlas Copco: System Specification SheetDiego LimaNo ratings yet

- TCVN 7336-2003 Fire Protection - Auto Sprinkler Systems DesidDocument25 pagesTCVN 7336-2003 Fire Protection - Auto Sprinkler Systems DesidtrungjindoNo ratings yet

- Criteria Bundwall TransformerDocument1 pageCriteria Bundwall TransformerMAHMUDNo ratings yet

- Write Up For Foam Protection SystemDocument13 pagesWrite Up For Foam Protection SystemKarthikNo ratings yet

- P45 Series Oil Pressure Cutout Controls With Built-In Time Delay RelayDocument4 pagesP45 Series Oil Pressure Cutout Controls With Built-In Time Delay RelayFreddy de los SantosNo ratings yet

- Installation Isofast Condensf35eDocument38 pagesInstallation Isofast Condensf35eBelhamri LarbiNo ratings yet

- Dear Participants Welcome To A Discussion On FSSS/ Boiler Protection System Basic Concepts and StandardsDocument24 pagesDear Participants Welcome To A Discussion On FSSS/ Boiler Protection System Basic Concepts and StandardsRupesh AnandNo ratings yet

- Ibc Case StudyDocument4 pagesIbc Case StudyzubairkkhanNo ratings yet

- Traveling Grate Boiler 50 TPH 95 KGCM 450CDocument52 pagesTraveling Grate Boiler 50 TPH 95 KGCM 450CMajid KhanNo ratings yet

- Fire Protection System NFPA 850 PresentationDocument15 pagesFire Protection System NFPA 850 Presentationbilly67% (3)

- Fire Alarm Interface of Smoke Dampers: Jason Lupa, PE Siemens Industry May 2018 Philadelphia, PennsylvaniaDocument44 pagesFire Alarm Interface of Smoke Dampers: Jason Lupa, PE Siemens Industry May 2018 Philadelphia, Pennsylvaniaenlightened1718No ratings yet

- Nfpa 850Document5 pagesNfpa 850MAHMUDNo ratings yet

- Boiler Control For Fossil-Fired Utility BoilersDocument6 pagesBoiler Control For Fossil-Fired Utility BoilersJames IzquierdoNo ratings yet

- IS 15301 (Fire Fighting Pump House)Document13 pagesIS 15301 (Fire Fighting Pump House)davesterdaveNo ratings yet

- BurnerManagementSystems PresDocument12 pagesBurnerManagementSystems Presgisaelsa100% (1)

- ROTOMOULD (POLYTHYLENE) (/index - Php/2015-07-03-06-13-41/rotomould-Polythylene) Vertical TanksDocument5 pagesROTOMOULD (POLYTHYLENE) (/index - Php/2015-07-03-06-13-41/rotomould-Polythylene) Vertical TanksΒΑΓΓΕΛΗΣ ΑΝΤΩΝΙΟΥNo ratings yet

- Geoplast Drening English SpecificationDocument1 pageGeoplast Drening English SpecificationΒΑΓΓΕΛΗΣ ΑΝΤΩΝΙΟΥNo ratings yet

- No. Capacity Diameter LengthDocument2 pagesNo. Capacity Diameter LengthΒΑΓΓΕΛΗΣ ΑΝΤΩΝΙΟΥNo ratings yet

- PROJECT: 1604 B+G+1+PH Outpatient Complex.: A. Design Criteria and DataDocument1 pagePROJECT: 1604 B+G+1+PH Outpatient Complex.: A. Design Criteria and DataΒΑΓΓΕΛΗΣ ΑΝΤΩΝΙΟΥNo ratings yet

- Horizontal TanksDocument5 pagesHorizontal TanksΒΑΓΓΕΛΗΣ ΑΝΤΩΝΙΟΥNo ratings yet

- Holding Tank Planning and Install GuidelinesDocument10 pagesHolding Tank Planning and Install GuidelinesΒΑΓΓΕΛΗΣ ΑΝΤΩΝΙΟΥNo ratings yet

- Storm Rain CalculationDocument1 pageStorm Rain CalculationΒΑΓΓΕΛΗΣ ΑΝΤΩΝΙΟΥNo ratings yet

- GRP (FIBERGLASS) (/index - Php/2015-07-03-06-13-41/grp-Fiberglass) GRP (Fiberglass) Vertical Water TankDocument6 pagesGRP (FIBERGLASS) (/index - Php/2015-07-03-06-13-41/grp-Fiberglass) GRP (Fiberglass) Vertical Water TankΒΑΓΓΕΛΗΣ ΑΝΤΩΝΙΟΥNo ratings yet

- Fire Lifts - A4Document3 pagesFire Lifts - A4ΒΑΓΓΕΛΗΣ ΑΝΤΩΝΙΟΥNo ratings yet

- Water Softener 223100Document7 pagesWater Softener 223100ΒΑΓΓΕΛΗΣ ΑΝΤΩΝΙΟΥNo ratings yet

- Refuge Floors - A1Document2 pagesRefuge Floors - A1ΒΑΓΓΕΛΗΣ ΑΝΤΩΝΙΟΥNo ratings yet

- Geoplast Drening English Technical ManualDocument40 pagesGeoplast Drening English Technical ManualΒΑΓΓΕΛΗΣ ΑΝΤΩΝΙΟΥNo ratings yet

- Fire Command Center - A5Document2 pagesFire Command Center - A5ΒΑΓΓΕΛΗΣ ΑΝΤΩΝΙΟΥNo ratings yet

- Reduction of Cooling LoadDocument29 pagesReduction of Cooling LoadΒΑΓΓΕΛΗΣ ΑΝΤΩΝΙΟΥNo ratings yet

- Homa A Series BrochureDocument8 pagesHoma A Series BrochureΒΑΓΓΕΛΗΣ ΑΝΤΩΝΙΟΥNo ratings yet

- 04 IndustrialDocument14 pages04 IndustrialΒΑΓΓΕΛΗΣ ΑΝΤΩΝΙΟΥNo ratings yet

- Fire Alarm - FasDocument4 pagesFire Alarm - FasΒΑΓΓΕΛΗΣ ΑΝΤΩΝΙΟΥNo ratings yet

- Asco firePumpSensingLine RGDocument1 pageAsco firePumpSensingLine RGΒΑΓΓΕΛΗΣ ΑΝΤΩΝΙΟΥNo ratings yet

- 1 StorageDocument18 pages1 StorageΒΑΓΓΕΛΗΣ ΑΝΤΩΝΙΟΥNo ratings yet

- 2 BusinessDocument10 pages2 BusinessΒΑΓΓΕΛΗΣ ΑΝΤΩΝΙΟΥNo ratings yet

- PipeGuard Warm - Rev6Document2 pagesPipeGuard Warm - Rev6ΒΑΓΓΕΛΗΣ ΑΝΤΩΝΙΟΥNo ratings yet

- XLTrace Fire Sprinkler DG 0110Document46 pagesXLTrace Fire Sprinkler DG 0110KarlaNo ratings yet

- MGMA GD03 Rainwater Drainage Design 1Document6 pagesMGMA GD03 Rainwater Drainage Design 1ΒΑΓΓΕΛΗΣ ΑΝΤΩΝΙΟΥNo ratings yet

- 3 DormitoryDocument10 pages3 DormitoryΒΑΓΓΕΛΗΣ ΑΝΤΩΝΙΟΥNo ratings yet

- Fire Sprinkler Freeze Protection: Design / Install GuideDocument21 pagesFire Sprinkler Freeze Protection: Design / Install GuideΒΑΓΓΕΛΗΣ ΑΝΤΩΝΙΟΥ100% (1)

- Design Worksheet - Rev0Document1 pageDesign Worksheet - Rev0ΒΑΓΓΕΛΗΣ ΑΝΤΩΝΙΟΥNo ratings yet

- Fire SuppressionDocument1 pageFire SuppressionΒΑΓΓΕΛΗΣ ΑΝΤΩΝΙΟΥNo ratings yet

- Hydraulic Calculation For Fire FightingDocument15 pagesHydraulic Calculation For Fire FightingΒΑΓΓΕΛΗΣ ΑΝΤΩΝΙΟΥNo ratings yet

- XL-Trace System: Installation and Operation Manual For Pipe Freeze Protection and Flow MaintenanceDocument62 pagesXL-Trace System: Installation and Operation Manual For Pipe Freeze Protection and Flow MaintenancesenatNo ratings yet

- Climate Control Stuhl DruckdatenDocument58 pagesClimate Control Stuhl DruckdatenMonocytogenesNo ratings yet

- Imm Ex260 SPNX Tfn34gbDocument1 pageImm Ex260 SPNX Tfn34gbPedroAntunesNo ratings yet

- Programmable Controller FP-X0 - 150 I/O Points, High Speed ProcessingDocument4 pagesProgrammable Controller FP-X0 - 150 I/O Points, High Speed ProcessingGeorge Romero Carvalho NunesNo ratings yet

- Crompton Jet Pumps Single StageDocument2 pagesCrompton Jet Pumps Single StageAriol ZereNo ratings yet

- Oeluem EkipmanlarDocument144 pagesOeluem EkipmanlarTaha BodurNo ratings yet

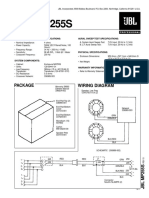

- JBL MP255S technical manual specifications and component exploded viewDocument2 pagesJBL MP255S technical manual specifications and component exploded viewMohammad FamuNo ratings yet

- Technical Reference Options and Adapters Volume 1 Apr84Document501 pagesTechnical Reference Options and Adapters Volume 1 Apr84kgrhoadsNo ratings yet

- Contents 1Document16 pagesContents 1Carlos Juarez Chunga100% (1)

- Xps 13 Plus 9320 Spec SheetDocument2 pagesXps 13 Plus 9320 Spec SheetRaluca RunceanuNo ratings yet

- Kaaz CorporationDocument1 pageKaaz CorporationIvan ĐorđijevskiNo ratings yet

- Kuliah 3 Pemesinan Dengan Abrasif 2Document17 pagesKuliah 3 Pemesinan Dengan Abrasif 2Pandu WibowoNo ratings yet

- DS 3E0510P EM 8 Port Gigabit Unmanaged PoE SwitchDocument5 pagesDS 3E0510P EM 8 Port Gigabit Unmanaged PoE SwitchRicardo HolleroNo ratings yet

- Conversion of Voltmeter To Ammeter and Vice-VersaDocument5 pagesConversion of Voltmeter To Ammeter and Vice-Versarmsh_devaNo ratings yet

- Ridgid R474 ManualDocument68 pagesRidgid R474 ManualNathanNo ratings yet

- Fundamentals of computer systems storage devicesDocument6 pagesFundamentals of computer systems storage devicesKhamisi BylalNo ratings yet

- QP MEP Q0202 Office AssistantDocument28 pagesQP MEP Q0202 Office AssistantAmbrish UpadhyayNo ratings yet

- Compound ManualDocument28 pagesCompound ManualoveladoNo ratings yet

- Fundamentals of Computer - 100 MCQ Questions MCQ SetsDocument26 pagesFundamentals of Computer - 100 MCQ Questions MCQ SetsSanket ChiksheNo ratings yet

- Service: Golf 2004 Golf Plus 2005 Passat 2006 Touran 2003Document299 pagesService: Golf 2004 Golf Plus 2005 Passat 2006 Touran 2003George Sas100% (1)

- Canon Electron Tubes & Devices Co., Ltd.Document17 pagesCanon Electron Tubes & Devices Co., Ltd.melquicedecNo ratings yet

- Control Panels: Range of Panels For Control and Protection of Lowara Electric PumpsDocument44 pagesControl Panels: Range of Panels For Control and Protection of Lowara Electric PumpsMohd HaroonNo ratings yet

- DN - 61097 Detector PuntualDocument2 pagesDN - 61097 Detector PuntualfedcortesNo ratings yet

- Dongguan Ruida Machinery and Equipment CO., LTD. Newman Industry Co., LTDDocument2 pagesDongguan Ruida Machinery and Equipment CO., LTD. Newman Industry Co., LTDGerardo BoisNo ratings yet

- HHF-1600HL Drilling Pump Parts ListDocument27 pagesHHF-1600HL Drilling Pump Parts ListDaniel RinconNo ratings yet

- Electricity QuestionsDocument24 pagesElectricity QuestionsNorKamilahMakhtarNo ratings yet

- Election Transmission Media SetupDocument66 pagesElection Transmission Media SetupCherry Quinanahan UchiNo ratings yet

- EEE121 ECA I LabDocument120 pagesEEE121 ECA I LabShah HussainNo ratings yet

- Vision Dvsdta SeriesDocument93 pagesVision Dvsdta SeriesEverton FernandesNo ratings yet

- Anritsu S361E Site Master and S3xxE User GuideDocument90 pagesAnritsu S361E Site Master and S3xxE User GuideMarck HolyNo ratings yet

- Iraq Gates Fiber Optic Testing ReportDocument2 pagesIraq Gates Fiber Optic Testing ReportAhmedNo ratings yet