Professional Documents

Culture Documents

نسخة Report33

Uploaded by

AJ 9995Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

نسخة Report33

Uploaded by

AJ 9995Copyright:

Available Formats

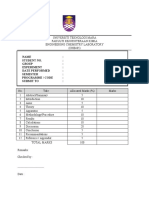

DEPARTMENT OF MECHANICAL ENGINEERING

(ME-322)

Thermo-Fluid lab

Experiment title Various orifice jet trajectories

Experiment No. 3

Experiment date 10/2/2022

Student name ID Section

1 Meshal saad alshayeb 438021516 3

2 Faisal Abdulrahman Alghamdi 440018203 3

3 Rami Abdulrahman Alhomeed 440013128 3

Instructor: Dr. Murugesan Palaniappan

Evaluation sheet (Official use)

Marks

checklist Details Marks Remarks

Deducted

Cover Page 5

Plagiarism in results & discussion part

Table of Content 5

Introduction

10

(Experiment objectives, theory, etc.) ± 5 marks, depending

must be < 50

on the nature of

Contents

20

department/lab

Data, Results & calculations 25

Discussion and/or Conclusion 10

References, Standard, appendix, etc. 5

Subtotal 80 Min. 48

Text 12 Regular, with Spacing 1.5 4

Heading 14 Bold 2

Standard Front Type 2

Formatting

Paragraph: Justified 2

Figures/Tables/Equations:Numbered,

10

Caption & cited in text

Subtotal 20 Min. 12

Total 100

Thermo-Fluid Lab ME-322

Page1

Table of Contents

1.Introduction ....................................................................................................... 3

1.1.Objectives ...................................................................................................... 3

1.2.Background / Theory ...................................................................................... 3

2.Experiment Procedure and Setup .................................................................... 5

2.1.Apparatus/device description .......................................................................... 5

2.2.Procedure ...................................................................................................... 6

3.Results ................................................................................................................. 7

3.1.Observations .................................................................................................. 7

3.2.Calculations ................................................................................................... 8

3.3.Graph ............................................................................................................ 9

4.Discussion / Analysis ........................................................................................ 10

5.Conclusion ........................................................................................................ 10

6.References ......................................................................................................... 10

Thermo-Fluid Lab ME-322

Page2

1.Introduction

We'll look at orifice and jet trajectory tests in this experiment. A hole in the side or bottom of a

tank or reservoir that permits liquids to be jetted out. The fluid's head (H) above the orifice level

will decide the discharge. The term "small orifice" refers to the size of the aperture in relation to

the flow head. Bernoulli's equation is used to calculate the amount of water that can be ejected

from an aperture in a basic and straightforward manner. On the other hand, experimental tests

frequently produce a result that is only around 65 percent of the solution given by the simple

analysis.

1.1.Objectives

To compare between theoretical and calculated jet trajectories.

1.2.Background / Theory

What precisely is an orifice? An orifice is a device that can be used to monitor a fluid's flow rate

by reducing the pressure or regulating the flow; the latter is also known as a restriction plate. An

orifice plate is a thin plate with a hole in it that is inserted into a pipe or a tank to let fluid to flow

through it while being forced to converge its velocity at the expense of it pressure. As showen in

the figure 1.

Figure 1: orifice device

Thermo-Fluid Lab ME-322

Page.3

The velocity is at its highest and the pressure is at its lowest at the vena contracts point. also,

Development of a free jet's flow field: Many scholars have looked at the flow structure of a free

jet. According to the experimental findings on the velocity field, there are four separate zones

associated to velocity decay along the flow direction. Initial Zone, Transition Zone, and Final

Zone are the four zones

Figure 2: Velocity projectile

The flow rate can then be computed using Bernoulli's equation with constants at the top and

bottom of the orifice level as the pressure rises. In this experiment, you'll look at a variety of

orifices, including smooth and sharp orifices, to see which has the best flow rate (velocity) and

how it impacts jet velocity. A nozzle that is used to release a high-velocity fluid into the

environment is

known as a jet.

Figure 3: Jet strike

The potential energy of the water head is turned into the kinetic energy of the water jet performed

by the orifice when the water tank filled with water is emptied via the orifice. The kinetic energy

is equivalent to the potential energy in the absence of a loss.

½𝑚. 𝑣2 = 𝑚𝑔ℎ (1.1)

where g is the acceleration due to gravity and h the height of the water. This equation can be

rearranged to give an equation for the velocity v

𝑉 = √2𝑔ℎ (1.2)

Thermo-Fluid Lab ME-322

Page.4

2.Experiment Procedure and Setup

2.1.Apparatus/device description

Figure 4: HM 150.09 Horizontal flow from a tank

Table 1: The parts of device:

1 tank with adjustable overflow.

2 Water supply which is connected from the pump to the

container.

3 Water overflow pipe.

4 Water outlet We can use many types of orifices, such as a

sharp or smooth output.

5 Adjustable probe rods, which help us to graph the flow.

The device consists of 5 things, including the water supply, through which water is introduced

into the device. There is also a water overflow so that the excess water goes down. And through

the water outlet the water comes out and we measure points gauge for the water jet, and we will

know through them what the y axis points are.

Thermo-Fluid Lab ME-322

Page.5

2.2.Procedure

1-Select one of the orifices and insert it into the orifice fitting device. Fit this to the bottom of the

header tank.

2-Connect the apparatus to the water supply of the basic hydraulics bench and start the pump. 3-

Adjust the water head to a specified level (say 400 mm) by means of the adjustable overflow

pipe. Make sure the level of the water remains stable. If it appears that the level of water is not

remaining stable at the desired height, adjust the main valve on the Hydraulics Bench.

4-Once the water level in the head tank is stable, adjust the probes so that they come in contact

with the jet. Start from the right-side probe so that the jet trajectory is not disturbed.

5-Read the y-positions of the jet and mark them on the graph paper located behind the probes as

well as in the observation table.

6-Repeat the experiment with a different orifice and/or different water level in the head tank. 7-

After completion, stop the HM-150 pump and allow the header tank to drain completely.

Figure 5: HM 150.09 Horizontal flow from a tank

Thermo-Fluid Lab ME-322

Page.6

3.Results

3.1.Observations

Table 1: Recordable data

Nozzle diameter: 4 mm Nozzle type: sharp Nozzle diameter: 4mm Nozzle type: smooth

Head(h) x-position y-(measured) y-(calculated) Head(h) x-position y-(measured) y-(calc.)

in (m) in (m) in (m) in (m) in (m) in (m) in (m) in (m)

0 0 0 0 0 0

0.07 0.025 0.003 0.07 0.075 0.003

0.14 0.088 0.0122 0.14 0.127 0.0122

0.21 0.146 0.0275 0.21 0.168 0.0275

0.28 0.191 0.049 0.28 0.206 0.049

0.4 0.35 0.226 0.0765 0.4 0.35 0.234 0.0765

0.42 0.252 0.110 0.42 0.254 0.110

0.49 0.266 0.150 0.49 0.266 0.150

0.56 0.304 0.196 0.56 0.302 0.196

Nozzle diameter:8mm Nozzle type: sharp Nozzle diameter:8mm Nozzle type: smooth

Head(h) X- y-(measured) Head(h) x- y-(measured) y-(calc)

y-(calculated)

in (m) position in in (m) in (m) position in (m) in (m)

in (m)

(m) in (m)

0 0 0 0 0 0

0.07 0.045 0.003 0.07 0.077 0.003

0.14 0.104 0.0122 0.14 0.130 0.0122

0.21 0.157 0.0275 0.21 0.171 0.0275

0.28 0.198 0.049 0.28 0.208 0.049

0.4 0.35 0.231 0.0765 0.4 0.35 0.236 0.0765

0.42 0.255 0.110 0.42 0.257 0.110

0.49 0.300 0.150 0.49 0.300 0.150

0.56 0.308 0.196 0.56 0.306 0.196

3.2. Calculations

E=E (3.3)

PK=KE (3.4) 𝑚𝑔ℎ =

½𝑚 (3.5)

𝑔ℎ = ½𝑣 2 (3.6)

2𝑔ℎ = 𝑣2 (3.7)

ẋ = √2𝑔ℎ (3.8)

ẏ = 𝑔𝑡 (3.9)

y = ½ a 𝑥2/2gh (3.10)

𝑥2

y=

4ℎ

• h = 0.4, x = 0.07

0.072

ycalculated = 4×0.4= 0.03 m

• h = 0.4, x = 0.14

0.142

ycalculated = 4×0.4= 0.0122 m

• h = 0.4, x = 0.21

0.212

ycalculated = 4×0.4= 0.0275 m

Thermo-Fluid Lab ME-322

Page.8

3.3 .Graphs

Figure 6: Water Flow Diagram

Figure 7: Theoretical Diagram

Thermo-Fluid Lab ME-322

Page.9

4.Discussion / Analysis

We compared theoretical and calculated jet trajectories in this experiment, and we tried to find

our calculation from the smooth and sharp for both (4mm) and (8mm). We can observe in the

theoretical diagram that the value of y-calculated is increasing in relation to the value of x. We

can also see that the smooth one is reducing slowly, whereas the sharp one is decreasing rapidly.

However, we notice that the values in our readings are close together, and we know that Jet

Velocity is the velocity of a jet that can be the fluid's exit velocity after it accelerates via bit

nozzles. Finally, we find that all the curves are approaching a point where there is no significant

difference.

5.Conclusion

In our experiment, we tried to make each sample smooth and sharp so that we could compare

theoretical and calculated results. We're seeing an increase in calculated. The initial velocity of

the jet or the initial velocity head of the flow when it leaps free into the environment should

always be used when computing the trajectory of a free jet. The initial velocity of jets overtopping

dams can be approximated with fair precision using Rouse's formulas for measuring the flow's

brink depth.

6.References

1-https://uta.pressbooks.pub/appliedfluidmechanics/chapter/experiment-6/

2-https://www.theprojectdefinition.com/jet-velocity/

3-Engineering Fluid Mechanics (Clayton Crow) Book Ninth Edition.

4-https://armfield.co.uk/product/f1-17-orifice-and-free-jet-flow/

5-https://www.gunt.de/en/products/fluid-mechanics/transient-flow/transient-drainage-

processes/horizontal-flow-from-a-tank/070.15009/hm150-09/glct-1:pa-148:ca-783:pr-556

Thermo-Fluid Lab ME-322

You might also like

- 3.design of BracketDocument39 pages3.design of BracketmahalakshmiNo ratings yet

- FCTM Normal ProceduresDocument211 pagesFCTM Normal ProceduresChristiano Santos0% (1)

- Forecasting Expected Returns in the Financial MarketsFrom EverandForecasting Expected Returns in the Financial MarketsRating: 4.5 out of 5 stars4.5/5 (2)

- Physics Lab Manual (2018 Onwards)Document48 pagesPhysics Lab Manual (2018 Onwards)Ranique GreenNo ratings yet

- Descriptive Statistic F2025Document11 pagesDescriptive Statistic F2025eikanordin2405No ratings yet

- 10 Ultrasonic Testing Rev - 0 21.06.2019Document8 pages10 Ultrasonic Testing Rev - 0 21.06.2019Priya Kumari100% (1)

- Unit Test Plan TemplateDocument9 pagesUnit Test Plan TemplateBrendan Furey100% (1)

- Injection Molding Report Group 3Document22 pagesInjection Molding Report Group 3faruq haziqNo ratings yet

- Thermal and Adhesive Bonding of Non-WovensDocument31 pagesThermal and Adhesive Bonding of Non-WovensAyesha Shaikh100% (1)

- التجربة الثالثه اخر تعديلDocument12 pagesالتجربة الثالثه اخر تعديلAJ 9995No ratings yet

- نسخة حسابات لنا فقطDocument14 pagesنسخة حسابات لنا فقطAJ 9995No ratings yet

- Experiment Number 2 - 2Document9 pagesExperiment Number 2 - 2Fuu HouHouNo ratings yet

- CE332 Ex3 TurbidityDocument7 pagesCE332 Ex3 Turbiditykas.kk1221No ratings yet

- CE332 Ex4 TVSTFSDocument8 pagesCE332 Ex4 TVSTFSkas.kk1221No ratings yet

- CE332 - Ex4 - TVSTFS WeDocument9 pagesCE332 - Ex4 - TVSTFS Wekas.kk1221No ratings yet

- Lab 2. LatheDocument14 pagesLab 2. LatheNawafNo ratings yet

- Ex 2 RollingDocument11 pagesEx 2 RollingNawafNo ratings yet

- Expermen 1Document9 pagesExpermen 1AJ 9995No ratings yet

- Lab Report Qroup 2ADocument9 pagesLab Report Qroup 2AFuu HouHouNo ratings yet

- Experiment Title: Experiment # 1: MAE 157 - Basic Mechanical Engineering LaboratoryDocument12 pagesExperiment Title: Experiment # 1: MAE 157 - Basic Mechanical Engineering LaboratoryHanna KristantoNo ratings yet

- Instructions For Creating Laboratory ReportDocument4 pagesInstructions For Creating Laboratory ReportPatricia Mae LapuzNo ratings yet

- Format Laporan MEM564 (5 Jan 2011)Document4 pagesFormat Laporan MEM564 (5 Jan 2011)Hakim HalimNo ratings yet

- Lab Hand-Out 5Document1 pageLab Hand-Out 5Umer MushtaqNo ratings yet

- BEE20901 MKS 2 ELECTRONICS ENGINEERING LABORATORY II Speed Control SystemDocument26 pagesBEE20901 MKS 2 ELECTRONICS ENGINEERING LABORATORY II Speed Control SystemAnie SaidNo ratings yet

- 1983 Whitson NTNU Lab ManualDocument64 pages1983 Whitson NTNU Lab ManualPorfirio AguileraNo ratings yet

- Lab Report GuidelineDocument9 pagesLab Report GuidelineAnonymous KpLy2NeNo ratings yet

- CEB 2032 Chemical Engineering Lab I Format and Rubric (September 2022)Document7 pagesCEB 2032 Chemical Engineering Lab I Format and Rubric (September 2022)MuhammadHaziqUllahNo ratings yet

- Cover Page and Report Guidelines Templete S.O.MaterialDocument5 pagesCover Page and Report Guidelines Templete S.O.Materialvtcnissaaan71No ratings yet

- Report Format For Industrial Training StudentsDocument20 pagesReport Format For Industrial Training Studentssidath thiranjayaNo ratings yet

- نسخة Exp - 2 - Hydrostatic - pressure11 (grob 2Document11 pagesنسخة Exp - 2 - Hydrostatic - pressure11 (grob 2AJ 9995No ratings yet

- Final Version of LabReportTemplateDocument8 pagesFinal Version of LabReportTemplatePorkkodi SugumaranNo ratings yet

- Lab Welding Bending TestDocument12 pagesLab Welding Bending TestIdham DanialNo ratings yet

- Writing Lab Report CHE414-2022Document5 pagesWriting Lab Report CHE414-2022Karar Haidar AltalibiNo ratings yet

- Filing, Marking, Cutting, Drilling, Taping, and Dyeing - Reprot - The FINAL ReportDocument22 pagesFiling, Marking, Cutting, Drilling, Taping, and Dyeing - Reprot - The FINAL ReportBabong KobNo ratings yet

- Course Work - 1 PRP - m3h824921 - Sem B 2020-21 (Rev)Document9 pagesCourse Work - 1 PRP - m3h824921 - Sem B 2020-21 (Rev)Michael GregoryNo ratings yet

- BEH41902 Sem 1 20182019 Assignment 2Document4 pagesBEH41902 Sem 1 20182019 Assignment 2Pratama AjiNo ratings yet

- Bernoulli's Equation Lab ReportDocument14 pagesBernoulli's Equation Lab Reportarslan shahidNo ratings yet

- Name: Student No.: Group: Experiment: Date Performed: Semester: Programme / Code: Submit ToDocument1 pageName: Student No.: Group: Experiment: Date Performed: Semester: Programme / Code: Submit TonazirulNo ratings yet

- Guidelines For Btech Industrial Training EedDocument6 pagesGuidelines For Btech Industrial Training EedhimanshuNo ratings yet

- MTSkeletonDocument29 pagesMTSkeletonMd. Asadullah-Al-GalibNo ratings yet

- Grading SheetDocument1 pageGrading Sheetoigres725No ratings yet

- Lab Report Performance of A Steam Plant LatestDocument16 pagesLab Report Performance of A Steam Plant LatestM Asrar SidonNo ratings yet

- Report Format 2023 24Document17 pagesReport Format 2023 24nchaudhari9922No ratings yet

- Manukau Institute of Technology Faculty of Engineering & Trades School of Professional EngineeringDocument4 pagesManukau Institute of Technology Faculty of Engineering & Trades School of Professional Engineeringrohit22eNo ratings yet

- Mechanical Engineering Workshop Ii SEM 2 SESSION 2018/19Document9 pagesMechanical Engineering Workshop Ii SEM 2 SESSION 2018/19Zul SyahmiNo ratings yet

- CE 341A Soil Mechanics LaboratoryDocument7 pagesCE 341A Soil Mechanics Laboratoryomotoriogun samuelNo ratings yet

- Laboratory Report Submission FormDocument11 pagesLaboratory Report Submission FormDaniel IsmailNo ratings yet

- Chemical Engineering Department: Particulate Technology Practical ManualDocument33 pagesChemical Engineering Department: Particulate Technology Practical ManualGinpachiNo ratings yet

- Lab 3 - Group 3 - Bto3003Document19 pagesLab 3 - Group 3 - Bto3003najwaNo ratings yet

- MEC353 - Lab Report Format2021Document5 pagesMEC353 - Lab Report Format2021خالد بن فهدNo ratings yet

- Ent530 Guideline and Template Mac 2022Document5 pagesEnt530 Guideline and Template Mac 2022Farhana OthmanNo ratings yet

- Submitted To: Master of Business AdministrationDocument70 pagesSubmitted To: Master of Business AdministrationNandhu NandhuNo ratings yet

- A Study On Capital Budgeting at TVS Motor Company, HosurDocument70 pagesA Study On Capital Budgeting at TVS Motor Company, HosurBalakrishna ChakaliNo ratings yet

- Bakhtaj Thesis MSC1307Document57 pagesBakhtaj Thesis MSC1307bilalNo ratings yet

- Contoh WATER JET PDFDocument17 pagesContoh WATER JET PDFWAN AHMAD FARISH DANIAL WAN HUSNINo ratings yet

- Te-Internship Report Format 2022-23Document15 pagesTe-Internship Report Format 2022-23Rahul JoshiNo ratings yet

- Plain Slide 2022 Marking GuideDocument20 pagesPlain Slide 2022 Marking GuidechukwuebukasunnyvalNo ratings yet

- Class AssessmentDocument13 pagesClass Assessmentnzb1234No ratings yet

- PHP Training ReportDocument17 pagesPHP Training ReportVikas Yadav57% (14)

- Case Study Report FORMAT - NUDocument4 pagesCase Study Report FORMAT - NUjrfarrelNo ratings yet

- Cover Page Lab ReportDocument1 pageCover Page Lab ReportImran AzmyNo ratings yet

- Name: Student No.: Group: Experiment: Date Performed: Semester: Programme / Code: Submit ToDocument1 pageName: Student No.: Group: Experiment: Date Performed: Semester: Programme / Code: Submit ToImran AzmyNo ratings yet

- Calculation Slab Product YardDocument12 pagesCalculation Slab Product YardNURUL IZZAHNo ratings yet

- Dry Cooler Outdoor Installation: 200-5775-CV-201 Overland Conveyor #1 Length: 6515m Lift: 146m Power: 2 X 6000kWDocument1 pageDry Cooler Outdoor Installation: 200-5775-CV-201 Overland Conveyor #1 Length: 6515m Lift: 146m Power: 2 X 6000kWRavenShieldXNo ratings yet

- Process Vessels 93851 - 18ADocument21 pagesProcess Vessels 93851 - 18Aakarcz6731No ratings yet

- Fins ExamplesDocument4 pagesFins ExamplesMalik Mustafa MohammedNo ratings yet

- Geep 104Document6 pagesGeep 104Srinivas100% (1)

- Module 7: Testing The Tensile Strength of Steel BarsDocument5 pagesModule 7: Testing The Tensile Strength of Steel BarsPrincess Tamani ManzanoNo ratings yet

- Data SHEET SEPARADOR 3Document1 pageData SHEET SEPARADOR 3Diego RuanoNo ratings yet

- 30HXY HXC CatalogDocument15 pages30HXY HXC CatalogCoolequipment CeeNo ratings yet

- Chapter-8 Introduction To Reliefs PDFDocument18 pagesChapter-8 Introduction To Reliefs PDFgreen goblinNo ratings yet

- Blue-Tip Screw BoltDocument16 pagesBlue-Tip Screw BoltRajed MaglinteNo ratings yet

- External Forced Convection: Heat and Mass Transfer: Fundamentals & ApplicationsDocument16 pagesExternal Forced Convection: Heat and Mass Transfer: Fundamentals & ApplicationsAhmad AlbabNo ratings yet

- Aazokhi Waruwu - The Compaction Potential in Increasing Compressive and Shear Strength at Peat SoilDocument9 pagesAazokhi Waruwu - The Compaction Potential in Increasing Compressive and Shear Strength at Peat SoilSiska Novelia ZaiNo ratings yet

- ARCHITECTURAL ACOUSTICS-module 2-Part2Document65 pagesARCHITECTURAL ACOUSTICS-module 2-Part2ardra m oNo ratings yet

- Pdfmachine Trial Version: StudentDocument10 pagesPdfmachine Trial Version: Studentjhon milliNo ratings yet

- ATC-DG3 Presentation Slides 2021-11-17sDocument13 pagesATC-DG3 Presentation Slides 2021-11-17sEng.wissam SafaaNo ratings yet

- Coastal Currents in American SamoaDocument24 pagesCoastal Currents in American Samoaplayer_jr2004No ratings yet

- 1 4571a316ti69Document2 pages1 4571a316ti69Admir TalicNo ratings yet

- Irrigation & Drainage Review Class 072106Document354 pagesIrrigation & Drainage Review Class 072106Reenalyn Dela CruzNo ratings yet

- BeerVM11e PPT Ch16Document67 pagesBeerVM11e PPT Ch16brayanNo ratings yet

- Theory of Plasticity: December 2018Document28 pagesTheory of Plasticity: December 2018Angga Fajar SetiawanNo ratings yet

- Catalyst HandBook - Second Edition - JMDocument290 pagesCatalyst HandBook - Second Edition - JMAhmed NagyNo ratings yet

- Liner EncoderDocument48 pagesLiner EncoderShahzad AnwarNo ratings yet

- APROS Models For Thermal Hydraulic Analyses of Forsmark's NPPS, Kärnteknik 2008Document3 pagesAPROS Models For Thermal Hydraulic Analyses of Forsmark's NPPS, Kärnteknik 2008Otso CronvallNo ratings yet

- ConclusionDocument3 pagesConclusionnehal vaghelaNo ratings yet

- L4 Exam QuestionDocument7 pagesL4 Exam QuestionRoqaya BadawyNo ratings yet

- An Introduction To Transitional Metal ChemistryDocument131 pagesAn Introduction To Transitional Metal ChemistryHafsa KhanNo ratings yet