Professional Documents

Culture Documents

HS Leakage

HS Leakage

Uploaded by

Shihab RahmanOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

HS Leakage

HS Leakage

Uploaded by

Shihab RahmanCopyright:

Available Formats

Unit: KYCR Section:--CCM Dept:-- Mechanical

Break Down Date :--23/08/19 Production Loss (Yes/No): -- YES Equipment Code:-- NA

Stoppage Hrs :-- 225 minute Frequency: first time Equipment Name:- C2 HS hydraulic pipe ;line

Problem Description

We were observed at 2.00 pm mill running time oil leakage from Mill cellar in side pass line C2 Hs hydraulic pipe line. Than we

checked to Found C 2 HS hydraulic pipe line welding joint, which is connected /welding C- 2 emulsion catchment pan.

Final action

First time we try to leakage to be arrested by welding but its not possible ,because leakage point was pass line in coolant

catchment pan bottom welding joint. In that time we search & found 2 nos spare pipe line.try to spare Pipeline and We want to Bypass

this hydraulic line with this pipeline but after checking we found pipeline Jam by dirty elements. And we cleaned those pipeline. After

that we Bypassed the Hydraulic line with one spare line and trial taken. Mill run for 11hrs .But after 11hrs running hydraulic leakage

from fittings due to “O”ring damaged and O ring replaced. But after running 3 hrs again Leakage found from Same Point due to O ring

damaged. This time we search the reason for frequently O ring damage and found Pitting mark on fittings which hardly visible. That’s

why again we Bypassed the line with another spare line & Problem solved.

Why Why analysis

WHY Why pipe line Leakage Because of pipe line welding crack inside

catchment try

WHY Why welding crack Because of vibration & lack of hyd. Clamp

We have 2 another spare hyd. Line, so we

are fixed spare one on line & line the run.

WHY Why again leakage Due to o ring damage, we found hyd.

Fitting corrosion, for that o ring was

damaging frequently.

WHY Why corrosion Because of spare line was open condition

from ling line, for that line was blocked by

grease & coolant scum, so the pipe line &

fittings has corrosion gradually.

After Found the problem we are taken the

another spare pipe line & fixed on line.

Trial taken . now ok.

Rectification:

Leakage pipe line has mounting with Emulsion catchment pan By welding to sealing catchments area. And this pipe line leaked from

welding joint.

Remarks:-

1. Should be Ready spare pipe line

2. Should be required more clamping near casement joint area

.

You might also like

- Experimental Glass Blowing For Boys 1920Document68 pagesExperimental Glass Blowing For Boys 1920Peter100% (3)

- Durability of Concrete Pipe in A Marine EnvironmentDocument157 pagesDurability of Concrete Pipe in A Marine Environmentandri.motoGNo ratings yet

- SADIP Catalogue, Large Diameters 2007Document62 pagesSADIP Catalogue, Large Diameters 2007diaghanemNo ratings yet

- Slickline and Coiled Tubing ProblemsDocument35 pagesSlickline and Coiled Tubing ProblemsMahmoud Eid0% (1)

- Electric Arc Welding and Related Studies: Electric Arc Welding & Related StudiesFrom EverandElectric Arc Welding and Related Studies: Electric Arc Welding & Related StudiesNo ratings yet

- Practical Guidelines For The Inspection and Repair of Hot Dip Galvanized CoatingsDocument8 pagesPractical Guidelines For The Inspection and Repair of Hot Dip Galvanized CoatingsIan FletcherNo ratings yet

- Failure and Repair of The Liner of A High Pressure Carbamate CondenserDocument10 pagesFailure and Repair of The Liner of A High Pressure Carbamate CondenserGrootNo ratings yet

- Cleaning of Heat ExchangersDocument22 pagesCleaning of Heat ExchangersFareed Alam0% (1)

- Iso 13679 Connection Testing: Test DatasheetDocument2 pagesIso 13679 Connection Testing: Test DatasheetMostafa HashemiNo ratings yet

- 2014-02 TestingCathodicProtectionSystems Slides 508Document49 pages2014-02 TestingCathodicProtectionSystems Slides 508shejin R.SNo ratings yet

- Trouble Shooting in Delayed Coker Unit Inspection Experience Gupta Sujith MRPL DCU Mumbai 2016 PDFDocument21 pagesTrouble Shooting in Delayed Coker Unit Inspection Experience Gupta Sujith MRPL DCU Mumbai 2016 PDFFayaz MohammedNo ratings yet

- Soil CompactionDocument10 pagesSoil CompactionBernie G. CatarigNo ratings yet

- MORTH Data Book-Rate Analysis 23 JULY2008Document378 pagesMORTH Data Book-Rate Analysis 23 JULY2008surendraNo ratings yet

- Failure Mode Table 2012 V8Document10 pagesFailure Mode Table 2012 V8DrMedhat Saleh100% (1)

- B.1 Passive House Building Envelope - Types of ConstructionDocument50 pagesB.1 Passive House Building Envelope - Types of ConstructionDoru FecheteNo ratings yet

- Ship Repair PresentationDocument25 pagesShip Repair Presentationkimbo0% (1)

- 015 ASP CatalogueDocument24 pages015 ASP CatalogueJavan Omiti100% (1)

- Solving Common Coating ProblemsDocument1 pageSolving Common Coating ProblemsNguyên Nguyễn100% (1)

- 2013 Serrafero Saipem Asian NandS OmegaBond Tubing Technology at GPICDocument35 pages2013 Serrafero Saipem Asian NandS OmegaBond Tubing Technology at GPICHummel Johnson0% (1)

- Textile-Enhancers - PDF MomentiveDocument17 pagesTextile-Enhancers - PDF MomentiveGokhan RamiNo ratings yet

- Excreta Drainage System PDFDocument28 pagesExcreta Drainage System PDFAprilyn Vanessa DegamoNo ratings yet

- SPARK STAR-82 Peculiar Conductor SnappingDocument1 pageSPARK STAR-82 Peculiar Conductor SnappingMohammad MahmodiNo ratings yet

- Multiple Causes (Fotos)Document8 pagesMultiple Causes (Fotos)ErickNo ratings yet

- 03-Cables CursoDocument14 pages03-Cables CursoElvis SolisNo ratings yet

- Arktite CPP - CPS Plugs and ReceptaclesDocument4 pagesArktite CPP - CPS Plugs and ReceptaclesHoangNo ratings yet

- Qurayyah Combined Cycle Power Plant: GSU 5 Transformer Bushing FailureDocument19 pagesQurayyah Combined Cycle Power Plant: GSU 5 Transformer Bushing FailureAli Al HanabiNo ratings yet

- Fittings VictaulicDocument32 pagesFittings VictaulicAndreja MilovanovićNo ratings yet

- Tubing PatcDocument2 pagesTubing PatcAminollah PayvandNo ratings yet

- SPARK STAR-08 Damage Strand On 220KVDocument1 pageSPARK STAR-08 Damage Strand On 220KVZeeshan AhmadNo ratings yet

- Galvanizing Defects RectificationsDocument28 pagesGalvanizing Defects RectificationslakshanNo ratings yet

- عیوب بکسلDocument2 pagesعیوب بکسلjahel2002No ratings yet

- Copper Vs Stainless Steel Tubes Copper Vs Stainless Steel TubesDocument7 pagesCopper Vs Stainless Steel Tubes Copper Vs Stainless Steel Tubespankaj soniNo ratings yet

- Jointing Systems: - PVC Pipe Jointing - Rubber Ring Jointing - Solvent Cement JointingDocument16 pagesJointing Systems: - PVC Pipe Jointing - Rubber Ring Jointing - Solvent Cement JointingFrancisco M. RamosNo ratings yet

- Repair Clamps CatalogDocument8 pagesRepair Clamps CatalogadjiehNo ratings yet

- 1.UPVC Column Casing Pipes CatalogDocument22 pages1.UPVC Column Casing Pipes Catalogsris802No ratings yet

- Continuous Vulcanization Cured Rubber - Versus - Mold (Lead) Cured Rubber - for-Extra-Heavy Duty (EHD) Mining Cables JacketsDocument7 pagesContinuous Vulcanization Cured Rubber - Versus - Mold (Lead) Cured Rubber - for-Extra-Heavy Duty (EHD) Mining Cables JacketsShubham BaderiyaNo ratings yet

- Sabp W 002Document7 pagesSabp W 002zoopladoNo ratings yet

- Một số lỗi về mạDocument11 pagesMột số lỗi về mạĐình Khoa PhanNo ratings yet

- 132 KV BusDocument1 page132 KV BusElectrical EngineerNo ratings yet

- C7 - D Buxton - STRAY CURRENT and Civil Infrastructure ProtectionDocument52 pagesC7 - D Buxton - STRAY CURRENT and Civil Infrastructure Protectionbasel baransiNo ratings yet

- Problematic WireDocument2 pagesProblematic WireFranciscus ManuelNo ratings yet

- Welcome YOU: Institute of Welding & Testing TechnologyDocument92 pagesWelcome YOU: Institute of Welding & Testing TechnologyHimanshu MishraNo ratings yet

- Customer Quality Complain List 2015Document16 pagesCustomer Quality Complain List 2015Sameer SaxenaNo ratings yet

- Tipos Conectores HubbellDocument24 pagesTipos Conectores HubbellGERMAN ROJASNo ratings yet

- T-OD-18000017A 132kV EB-A(喉箍)组装作业说明书(EN)√Document23 pagesT-OD-18000017A 132kV EB-A(喉箍)组装作业说明书(EN)√Abdulhanan Shaukat AliNo ratings yet

- The Effects of Water Backing On SA106Gr. B Pipe WeldsDocument8 pagesThe Effects of Water Backing On SA106Gr. B Pipe WeldschethanNo ratings yet

- RESPONSIBILITY: G - Galvanized D - Designer B - Builder/Fabricator S - Steel Type/SurfaceDocument11 pagesRESPONSIBILITY: G - Galvanized D - Designer B - Builder/Fabricator S - Steel Type/SurfaceLaxit100% (1)

- Ways To Fix Leaking Pipe in The Kitchen: Abstraction Logical ReasoningDocument1 pageWays To Fix Leaking Pipe in The Kitchen: Abstraction Logical ReasoningammarNo ratings yet

- Pending Work - Abu HamourDocument2 pagesPending Work - Abu HamourMohammed JavidNo ratings yet

- Wia Tube Crack Pre-Analysis Report: Thyssenkrupp Presta Dalian Co., Ltd. QM-LabDocument5 pagesWia Tube Crack Pre-Analysis Report: Thyssenkrupp Presta Dalian Co., Ltd. QM-LabMohamed HarisNo ratings yet

- HDG Practical GuidelinesDocument7 pagesHDG Practical GuidelinesMantasNo ratings yet

- Chapter 8 Well Completions PDFDocument40 pagesChapter 8 Well Completions PDFTarek BaoucheNo ratings yet

- Workover and Well InterventionsDocument13 pagesWorkover and Well InterventionsMuhammed ADNo ratings yet

- Piping Quality StandardsDocument31 pagesPiping Quality Standardsdeepak.vectormarineNo ratings yet

- DS W9Document3 pagesDS W9Dar FallNo ratings yet

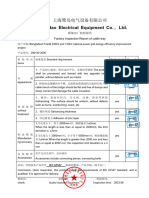

- KFW1.1 Cable Tray Routine Test Report 2023.9.18Document7 pagesKFW1.1 Cable Tray Routine Test Report 2023.9.18faulkamerNo ratings yet

- H7 U-Pin &stem Making.: Operation Gyan-VigyanDocument16 pagesH7 U-Pin &stem Making.: Operation Gyan-VigyanKamleshNo ratings yet

- CSF Weld Consumable Spec PDFDocument186 pagesCSF Weld Consumable Spec PDFShrikant UtekarNo ratings yet

- Galvanizing Defects RectificationsDocument19 pagesGalvanizing Defects RectificationskumarNo ratings yet

- Kabel Tegangan MenengahDocument18 pagesKabel Tegangan MenengahDwiki sevenfoldismNo ratings yet

- Connector & Glands Details For IP 65 JBDocument3 pagesConnector & Glands Details For IP 65 JBBasabRajNo ratings yet

- HouseDocument6 pagesHousesasikiranworksNo ratings yet

- 000 Drainage Pipes, Fiitings and JointsDocument41 pages000 Drainage Pipes, Fiitings and Jointselcid agsamosamNo ratings yet

- Root Cause For IMR Liner Latch Bolt ShearDocument1 pageRoot Cause For IMR Liner Latch Bolt ShearShihab RahmanNo ratings yet

- Corr of Power Plant ComponentsDocument34 pagesCorr of Power Plant ComponentsAnil Kumar TNo ratings yet

- How to Install Electric Bells, Annunciators, and AlarmsFrom EverandHow to Install Electric Bells, Annunciators, and AlarmsNo ratings yet

- Root Cause Analysis of POR - 10.08.20Document1 pageRoot Cause Analysis of POR - 10.08.20Shihab RahmanNo ratings yet

- Root Caause of Mill c1 Exit Side IMR Bending Hydraulic Block Bolts ShearDocument2 pagesRoot Caause of Mill c1 Exit Side IMR Bending Hydraulic Block Bolts ShearShihab RahmanNo ratings yet

- Problem DescriptionDocument1 pageProblem DescriptionShihab RahmanNo ratings yet

- Root Cause For IMR Liner Latch Bolt ShearDocument1 pageRoot Cause For IMR Liner Latch Bolt ShearShihab RahmanNo ratings yet

- UFGS 07 27 10.00 10 Building Air Barrier SystemDocument24 pagesUFGS 07 27 10.00 10 Building Air Barrier SystemPetrit AhmetiNo ratings yet

- MSDS PVC PDFDocument4 pagesMSDS PVC PDFRegian Fajar AriesandiNo ratings yet

- Hydrodemethlyation of Toluene PDFDocument1 pageHydrodemethlyation of Toluene PDFAA0809No ratings yet

- International Journal of PharmaceuticsDocument9 pagesInternational Journal of PharmaceuticsDuong TuNo ratings yet

- An Overview of Chemical Enhanced Oil Recovery: Recent Advances and ProspectsDocument32 pagesAn Overview of Chemical Enhanced Oil Recovery: Recent Advances and ProspectsDavid LópezNo ratings yet

- LulllDocument166 pagesLulllShoaib AliNo ratings yet

- Die Casting AlloysDocument5 pagesDie Casting AlloysManojm_vNo ratings yet

- Pembuatan MolibdenumDocument6 pagesPembuatan MolibdenumIzamHamMandenoNo ratings yet

- R410A Catalogue: ProductDocument11 pagesR410A Catalogue: ProductMugundan MurugananthamNo ratings yet

- Liquid Paraffin MonographDocument9 pagesLiquid Paraffin MonographPippo0% (1)

- Pipes in Parallel and SeriesDocument50 pagesPipes in Parallel and SeriesHuzaifa Iftikhar CHNo ratings yet

- Chemical Compatibility TableDocument28 pagesChemical Compatibility TableBea LubaoNo ratings yet

- 1-14#-Bod Tester PDFDocument38 pages1-14#-Bod Tester PDFscribd birdNo ratings yet

- Market Survey On Copper PDFDocument210 pagesMarket Survey On Copper PDFmujib uddin siddiquiNo ratings yet

- DATASHEET MOULD RELEASE 200 DR (HM) - 1-UpdateDocument3 pagesDATASHEET MOULD RELEASE 200 DR (HM) - 1-UpdatejackNo ratings yet

- Vipin Shukla-02.06Document6 pagesVipin Shukla-02.06vipin_12224652No ratings yet

- Restorative Package $449 Ti - $499 ZR: Tooth #Document1 pageRestorative Package $449 Ti - $499 ZR: Tooth #Jean-Christophe PopeNo ratings yet

- E-Cigarette Aerosol Analysis ReportDocument6 pagesE-Cigarette Aerosol Analysis ReportEdwinBerianzahNo ratings yet

- MS 4062 Rev A 2008Document6 pagesMS 4062 Rev A 2008Bartek HajaNo ratings yet

- Instruction manual Ecosoft media systems Руководство по монтажу и настройке систем очистки воды EcosoftDocument88 pagesInstruction manual Ecosoft media systems Руководство по монтажу и настройке систем очистки воды EcosoftIon TerusNo ratings yet

- Lightweight Composite Monocoque Heavy Goods Vehicle TrailerDocument4 pagesLightweight Composite Monocoque Heavy Goods Vehicle TrailerMatthew TurnerNo ratings yet

- Emcekrete: Ready To Use, Free Flow, High Strength, Non-Shrink GroutDocument2 pagesEmcekrete: Ready To Use, Free Flow, High Strength, Non-Shrink GroutFaisal AbbasNo ratings yet

- Price List W.E.F. 01/01/2020 Valid Till 31/12/2020: SR - No. Test Rate Per Specimen (RS.) A Chemical AnalysisDocument3 pagesPrice List W.E.F. 01/01/2020 Valid Till 31/12/2020: SR - No. Test Rate Per Specimen (RS.) A Chemical AnalysisSubrat DasNo ratings yet