Professional Documents

Culture Documents

MASONRYcblm Carpentry

Uploaded by

Junalyn DajotoyCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

MASONRYcblm Carpentry

Uploaded by

Junalyn DajotoyCopyright:

Available Formats

Output-Based Instructional Material

Course Title : ROUGH AND FINISH CARPENTRY

Module Title : STAKING-OUT BUILDING LINES

AGUSAN DEL SUR STATE COLLEGE OF AGRICULTURE AND TECHNOLOGY

Bunawan, Agusan del Sur

Email add: asscat_op@yahoo.com

Date Document No.

Developed:

August. 2020 Issued

Carpentry by:

Page 1 of 66

Staking-out Building Raymond F.

Gabica

Lines Revision #

00

HOW TO USE THIS OUTPUT-BASED INSTRUCTIONAL MATERIAL

Welcome!

This output-based instructional material is compose of learning activities

that comprises the knowledge, skills and attitudes required for a graduate of

this course to possess. To gain these skills, you must learn basic concepts and

terminology.

Each module contains training materials and activities for you to

complete. You are required to go through a series of learning activities in order

to complete each learning outcome of the module. In each learning outcome are

Information Sheets, Self-Checks, Operation Sheets and Job Sheets. Follow

these activities on your own. If you have questions, don’t hesitate to ask your

instructor for assistance.

This instructional material was prepared to help you achieve the required

competency in Staking-out Building Line. This will be the source of information

for you to acquire the knowledge and skills in this particular module

independently and at your own pace with minimum supervision or help from

your instructor.

In doing the activities to be completed as required in this module, please

be guided by the following:

Work through all information and complete the activities in each

section.

Read the information sheets and complete the self checks provided.

Your trainer will tell you about the important things you need to consider

when you are completing the activities and it is important that you listen and

take notes.

You will be given plenty of opportunities to ask questions and practice on

the job. Make sure to practice your new skills during regular work shifts. This

way you will improve both your speed and memory and also your confidence.

Use the Self-Check Job Sheets and Operation Sheets at the end of each

section to test your own progress. Use the performance Criteria Checklist or

Procedural Checklist used after the sheet to check your own performance.

Date Document No.

Developed:

August. 2019 Issued

Rough and Finish by:

Carpentry

Page 2 of 66

Raymond F.

Staking-out Building Gabica

Lines Revision #

00

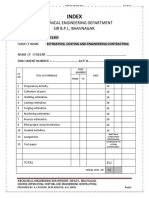

TABLE OF CONTENTS

No. Module Title Page

1. Staking-out Building Line

2. Fabricating Formworks

Installing Form work

3.

Components

Stripping Formwork

4.

Components

5. Installing Framing Works

Date Document No.

Developed:

August. 2019 Issued

Rough and Finish by:

Carpentry

Page 3 of 66

Raymond F.

Staking-out Building Gabica

Lines Revision #

00

PROGRAM/COURSE : Rough and Finish Carpentry

MODULE : Staking-out Building Lines

Introduction:

This module covers the knowledge, skills and attitude in preparing

materials for stake-outbuilding lines, setting batter boards, fixing building

lines.

LEARNING OUTCOMES:

Upon completion of this module you MUST be able to:

1. Prepare materials for stake-out building lines

2. Stake-out and set batter boards

3. Fix building lines

ASSESSMENT CRITERIA:

1. Plans and details are correctly interpreted and identified according

to job requirements

2. Materials, tools and equipment are identified consistent with job

requirements

3. Materials and tools are properly stored and freed from defects.

4. Appropriate PPE are selected according to job requirements.

5. Stakes are set out from pre-determined building lines

6. Batter board materials are measured, laid out and cut according to

specification

7. Stakes are set 0.75-1.00 meter away from the pre-determined

building lines

8. Batter boards are properly secured with tolerance for dimensions

at+- 5 mm, and levelness of +-3 mm.

9. Building lines are squared with end tolerance of +- 3 mm

10. Building lines are measured and set

LEARNING OUTCOME SUMMARY

Date Document No.

Developed:

August. 2019 Issued

Rough and Finish by:

Carpentry

Page 4 of 66

Raymond F.

Staking-out Building Gabica

Lines Revision #

00

Prepare materials for stake-outbuilding

Learning Outcome 1

lines

Contents:

Interpretation of Plans and Details

Material Specifications

Board Foot Computations

Tools, Materials and Equipment for Staking-out Building Lines

Company Rules and Regulation

ASSESSMENT CRITERIA:

1. Plans and details are correctly interpreted and identified according to

job requirements

2. Materials, tools and equipment are identified consistent with job

requirements

3. Materials and tools are properly stored and freed from defects.

4. Appropriate PPE are selected according to job requirements.

CONDITIONS:

Students/Trainees must be provided with the following:

1.WORKPLACE LOCATION

2.TOOLS AND EQUIPMENT

Hammer Marking Tools

Measuring Tools Steel Square Try-square

Hand Saw Chalk Line

Water Hose Level Plumb Bob

PPE Circular Saw

3.TRAINING MATERIALS

Learning Packages Bond paper

Ball pens Manuals

Related References

ASSESSMENT METHOD:

Portfolio

LEARNING EXPERIENCES

Date Document No.

Developed:

August. 2019 Issued

Rough and Finish by:

Carpentry

Page 5 of 66

Raymond F.

Staking-out Building Gabica

Lines Revision #

00

Prepare Materials for

Learning Outcome #1

Staking-out Building Lines

Learning Activities Special Instructions

Read Information Sheet No. 1.1-1 on

Construction Plans and Details

Compare your answer to the

Answer Self-Check No.1.1-1

answer key

Read Information Sheet No. 1.1-

on Construction Material

Specifications

Compare your answer with Answer

Answer Self-Check No.1.1-2

Key 1.1-2

Read Information Sheet No. 1.1-3 on

Board Foot Computations

Compare your answer with Answer

Answer Self-Check No.1.1-3

Key 1.1-3

Read Information Sheet No. 1.1-4

on Tools, Materials and Equipment

for Staking-out Building Lines

Answer Self-Check No.1.1-4 Compare your answer with the

Answer Key 1.1-4

Read Information Sheet No. 1.1-5

on Company Rules and Regulations

Compare your answer with Answer

Answer Self-Check 1.1-5

Key 1.1-5

Information Sheet 1.1-1

Date Document No.

Developed:

August. 2019 Issued

Rough and Finish by:

Carpentry

Page 6 of 66

Raymond F.

Staking-out Building Gabica

Lines Revision #

00

Construction Plans and Details

Learning Objective:

Upon completing this section, you should be able to

1. Be familiar and interpret different construction plans and details

Systems of architectural and construction symbols are used to indicate

commonly used materials and features that have been developed over the

years. To read an architectural plan readily, you must have a good

understanding of what the symbols represent on a drawing. It is not necessary

to develop total recall of each symbol, but is important to recognize what

material or component each symbol represents in a construction drawing.

Symbols are designed to approximate the appearance of the material, fixture,

or component. There are hundreds of different types of symbols some of the

more commonly seen symbols on a construction plan are the door, window,

and electrical symbol.

Construction Drawings

Construction drawings consist mostly of right angle and perpendicular

views prepared by draftsmen using standard technical drawing techniques,

symbols, and other designations as stated in military standards (MIL-STDS).

The first section of the construction drawings consists of the site plan,

plot plan, foundation plans, floor plans, and framing plans. General drawings

consist of plans (views from above) and elevations (side or front views) drawn

on a relatively small scale. Both types of drawings use a standard set of

architectural symbols.

Figure 1 illustrates the conventional symbols for the more common types

of material used on structures.

Date Document No.

Developed:

August. 2019 Issued

Rough and Finish by:

Carpentry

Page 7 of 66

Raymond F.

Staking-out Building Gabica

Lines Revision #

00

Figure 1. Architectural Symbols for Plans and Elevations

Date Document No.

Developed:

August. 2019 Issued

Rough and Finish by:

Carpentry

Page 8 of 66

Raymond F.

Staking-out Building Gabica

Lines Revision #

00

Windows and Doors

Figure 2 shows the more common symbols used for doors and windows.

Figure 2. Symbols for Doors and Windows

Roof Truss

Roof trusses are structural components of

houses or commercial buildings, support the

weight of roof timbers and coverings. Usually,

they are constructed from pieces of timber or

steel which are nailed, bolted, or pegged together

to form a mutually supporting and strong base

for a roof. Roof trusses should never be removed

or altered without the advice of a structural

engineer. Unsanctioned changes to a truss could

result in part – or even all – of a roof collapsing.

Figure 3.Commonly Used Roof Trusses

Date Document No.

Developed:

August. 2019 Issued

Rough and Finish by:

Carpentry

Page 9 of 66

Raymond F.

Staking-out Building Gabica

Lines Revision #

00

Site Plan

A site plan (Figure 4) shows the contours, boundaries, roads, utilities,

trees, structures, and any other significant physical features on or near the

construction site. The locations of proposed structures are shown in outline.

This plan shows comer locations with reference to reference lines shown on the

plot that can be located at the site. Showing both existing and finished

contours is an essential data for the graders.

Figure 4. Site Plan

Plot Plan

The plot plan shows the survey marks with the elevations and the

grading requirements. The plot plan is used by the Engineering Aids to set up

the corners and perimeter of the building using batter boards and line stakes,

as shown in figure ___ Thus, the plot plan furnishes the essential data for

laying out the building.

Date Document No.

Developed:

August. 2019 Issued

Rough and Finish by:

Carpentry Page 10 of

Raymond F. 66

Staking-out Building Gabica

Lines Revision #

00

Figure 5. Plot Plan

Foundation Plan

A foundation plan is a plane view of a structure. That is, it looks as if it

were projected onto a horizontal plane and passed through the structure. In

the case of the foundation plan, the plane is slightly below the level of the top

of the foundation wall. The plan in Figure 6 shows that the main foundation

consists of 12-inch and 8-inch concrete masonry unit (CMU) walls measuring

28 feet lengthwise and 22 feet crosswise. The lower portion of each lengthwise

section of wall is to be 12 inches thick to provide a concrete ledge 4 inches

wide.

A girder running through the center of the building will be supported at

the ends by two 4-by- 12-inch concrete pilasters butting against the end

foundation walls. Intermediate support for the girder will be provided by two

12-by-12-inch concrete piers, each supported on 18-by- 18-inch spread

footings, which are 10 inches deep. The dotted lines around the foundation

walls indicate that these walls will also rest on spread footings.

Date Document No.

Developed:

August. 2019 Issued

Rough and Finish by:

Carpentry Page 11 of

Raymond F. 66

Staking-out Building Gabica

Lines Revision #

00

Figure 6. Foundation Plan

Floor Plan

Figure 7 shows the way a floor plan is developed: from elevation, to

cutting plane, to floor plan. An architectural or structural floor plan shows the

structural characteristics of the building at the level of the plane of projection.

A mechanical floor plan shows the plumbing and heating systems and any

Date Document No.

Developed:

August. 2019 Issued

Rough and Finish by:

Carpentry Page 12 of

Raymond F. 66

Staking-out Building Gabica

Lines Revision #

00

other mechanical components other than those that are electrical. An electrical

floor plan shows the lighting system and any other electrical systems.

Figure 7. Floor Plan Development

Figure 8 is a floor plan showing the lengths, thicknesses, and character

of the outside walls and partitions at the particular floor level. It also shows the

number, dimensions, and arrangement of the rooms, the widths and locations

of doors and windows, and the locations and character of bathroom, kitchen,

and other utility features.

Figure 8. Floor Plan

Date Document No.

Developed:

August. 2019 Issued

Rough and Finish by:

Carpentry Page 13 of

Raymond F. 66

Staking-out Building Gabica

Lines Revision #

00

Elevations

The front, rear, and sides of a structure, as they would appear projected

on vertical planes, are shown in elevations. Studying the elevation drawing

gives you a working idea of the appearance and layout of the structure.

Elevations for a small building are shown in Figure 9. Note that the wall

surfaces of this house will consist of brick and the roof covering of composition

shingles. The top of the rafter plate will be 8 feet 2 1/4 inches above the level of

the finished first floor, and the tops of the finished door and window openings 7

feet 13/4 inches above the same level. The roof will be a gable roof with 4

inches of rise for every 12 inches length. Each window shown in the elevations

is identified by a capital letter that goes with the window schedule.

Figure 9. Elevations

Date Document No.

Developed:

August. 2019 Issued

Rough and Finish by:

Carpentry Page 14 of

Raymond F. 66

Staking-out Building Gabica

Lines Revision #

00

Framing Plans

Framing plans show the size, number, and location of the structural

members (steel or wood) that make up the building framework. Separate

framing plans may be drawn for the floors, walls, and roof. The floor framing

plan must specify the sizes and spacing of joists, girders, and columns used to

support the floor. When detail drawings are needed, the methods of anchoring

joists and girders to the columns and foundation walls or footings must be

shown.

Wall framing plans show the location and method of framing openings and

ceiling heights so that studs and posts can be cut. Roof framing plans show the

construction of the rafters used to span the building and support the roof. Size,

spacing, roof slope, and all details are shown.

Floor Framing plans for floors are basically plane views of the girders and

joists. Figure 10 is an example of a typical floor framing plan.

The unbroken, double-

line symbol is used to

indicate joists, which are

drawn in the positions they

will occupy in the completed

building. Double framing

around openings and

beneath bathroom fixtures is

shown where used. Bridging

is shown by a double-line

symbol that runs

perpendicular to the joists.

The number of rows of cross

bridging is controlled by the

span of the joists; they

should not be placed more

than 7 or 8 feet apart. A 14-

foot span needs only one row

of bridging, but a 16-foot

Figure 10. Floor Framing Plan

span needs two rows.

Date Document No.

Developed:

August. 2019 Issued

Rough and Finish by:

Carpentry Page 15 of

Raymond F. 66

Staking-out Building Gabica

Lines Revision #

00

Notes are used to identify floor openings, bridging, and girts or plates.

Nominal sizes are used in specifying lumber. Dimensions need not be given

between joists. Such information is given along with notes. For example, 1" x 6"

joists @ 2'-0" cc indicates that the joists are to be spaced at intervals of2 feet 0

inches from center to center. Lengths might not be indicated in framing plans.

If you find this to be the case, the overall building dimensions and the

dimensions for each bay or distances between columns or posts provide such

information.

Roof Framing Plans for roofs are drawn in the same manner as floor framing

plans. A Builder should visualize the plan as looking down on the roof before

any of the roofing material (sheathing) has been added. Rafters are shown in

the same reamer as joists.

Sectional Views

Sectional views, or sections, provide important information about the

height, materials, fastening and support systems, and concealed features of a

structure.

Figure11. Typical small building cutting plane A-A and section developed from

the cutting plane

Date Document No.

Developed:

August. 2019 Issued

Rough and Finish by:

Carpentry Page 16 of

Raymond F. 66

Staking-out Building Gabica

Lines Revision #

00

Typical sections represent the average condition throughout a structure

and are used when construction features are repeated many times. Figure 12

shows typical wall section A-A of the foundation plan in Figure 6.

Details Figure 12. Typical Section of a Masonry Building

Details are large-scale drawings that show the builders of a structure

how its various parts are to be connected and placed. Detail drawings are used

whenever the information provided in elevations, plans, and sections is not

clear enough for the constructors on the job. The construction of doors,

windows, and eaves is customarily shown in detail drawings of buildings.

Typical door and window details are shown in Figure 13.

Figure 13. Door and Window Details

Date Document No.

Developed:

August. 2019 Issued

Rough and Finish by:

Carpentry Page 17 of

Raymond F. 66

Staking-out Building Gabica

Lines Revision #

00

Self-Check 1.1-1

MULTIPLE CHOICE: Identify the types of plans on the following

statement. Choose the letter of the correct answer.

1. It shows the contours, boundaries, roads, utilities, trees, structures, and

other significant physical features on or near the construction site.

a. Floor plan c. Plot plan

b. Foundation plan d. Site plan

2. This plan shows the survey marks with elevations and grading

requirements and aids in setting up corners and perimeter of

the buildings using batter boards and line stakes.

a. Floor plan c. Plot plan

b. Foundation plan d. Site plan

3. It is a plane view of a structure and looks as if it were projected onto a

horizontal plane and passes through the structure.

a. Floor plan c. Plot plan

b. Foundation plan d. Sectional view

4. This shows the structural characteristics of the building at the level

of the plane of projection.

a. Architectural/structural floor plan c. Elevation

b. Details d. Sectional view

5. The front, rear, and sides of a structure, projected on vertical planes, are

shown in this drawing and give a working idea of the appearance and

layout of the structure.

a. Architectural/structural floor plan c. Elevation

b. Details d. Sectional view

6. Plan showing the size, number, and location of the structural members

(steel or wood) that make up the building framework.

a. Architectural/structural floor plan c. Framing plan

b. Elevation d. Sectional view

7. It provides information about the height, materials, fastening and

support systems, and concealed features of a structure.

a. Architectural/structural floor plan c. Framing plan

b. Elevation d. Sectional view

8. These are large-scale drawings that show how a structure’s various parts

are to be connected and placed.

a. Details c. Framing plan

Date Document No.

Developed:

August. 2019 Issued

Rough and Finish by:

Carpentry Page 18 of

Raymond F. 66

Staking-out Building Gabica

Lines Revision #

00

b. Foundation plan d. Sectional view

Answer Key 1.1-1

Check your answer with the answer key below. If you fail to get it right, refer

back to corresponding resources until you make it perfect.

1. D

2. C

3. B

4. A

5. C

6. C

7. D

8. A

Date Document No.

Developed:

August. 2019 Issued

Rough and Finish by:

Carpentry Page 19 of

Raymond F. 66

Staking-out Building Gabica

Lines Revision #

00

Information Sheet 1.1-2

Construction Materials Specifications

Learning Objective:

Upon completing this section, you should be able to

1. Identify different types construction materials and its types and

uses

The primary components used in frame construction are lumber and

hardware. This section includes information on the types and sizes of lumber

as well as a description of various metal fasteners used in construction.

LUMBER

Lumber varies greatly in structural characteristics. A carpenter must

learn about lumber so that he can choose the most suitable material for each

job.

1. Grades

Lumber, as it comes from the saw mill, is divided into three main

classes: yard lumber, structural material; and factory and shop lumber.

It is classified on the basis of quality. The carpenter must choose a

quality that is suitable for the intended purpose. At the same time, he must

exercise economy by not choosing a better (and therefore more expensive) grade

than is required.

Lumber is subdivided into classifications of select lumber and common

lumber.

•Select Lumber -Select lumber is of good appearance and finishing. It is

identified by the following grade names for comparison of quality:

Grade A is suitable for natural finishes and is practically clear.

Grade B is suitable for natural finishes, is of high quality, and is

generally clear.

Grade C is suitable for high-quality paint finishes.

Grade D is suitable for paint finishes between high-finishing grades and

common grades and has somewhat the nature of both.

Date Document No.

Developed:

August. 2019 Issued

Rough and Finish by:

Carpentry Page 20 of

Raymond F. 66

Staking-out Building Gabica

Lines Revision #

00

•Common Lumber - Common lumber is suitable for general construction and

utility purposes. It is identified by the following grade names for comparison of

quality:

No. 1 common is suitable for use without waste, it is sound and tight knotted,

and it may be considered watertight lumber.

No. 2 common is less restricted in quality than No. 1, but of the same general

quality. It is used for framing, sheathing, and other structural forms

where the stress or strain is not too great.

No. 3 common permits some waste, and it is lower in quality than No. 2. It is

used for such rough work as footing, guard rails, and rough flooring.

No. 4 common permits waste, is of low quality, and may have coarse features

such as decay and holes. It is used for sheathing, subfloors, and roof

boards in the cheaper types of construction, but its most important

industrial outlet is for boxes and crates.

No. 5 common is not produced in some kinds of lumber. It is used for boxes,

crates, and dunnage, for which the quality requirement is very low.

Table 1. Code for Surfaced Lumber

Code Meaning

S1E Surfaced 1 edge

S2E Surfaced 2 edges

S1S Surfaced 1 side

2S Surfaced 2 sides

S1S1E Surfaced 1 side and 1 edge

S2SIE Surfaced 2 sides and 1 edge

S1S2E Surfaced 2 sides and 2 edges

S4S Surfaced 4 sides

2. Uses of Lumber

a. Frames

Date Document No.

Developed:

August. 2019 Issued

Rough and Finish by:

Carpentry Page 21 of

Raymond F. 66

Staking-out Building Gabica

Lines Revision #

00

Building frames are the wood forms constructed to support the finished

members of a structure. These include posts, girders (beams), scabs, joists,

subfloors, sole plates, girts, knee braces, top plates, and rafters. No. 2 common

lumber is used for framing. Heavy frame components, such as beams and

girders, are made by combining several pieces of framing material.

b. Walls

The exterior wall of a frame structure usually has three layers:

sheathing, building paper, and siding. Sheathing and siding lumber are

normally grade No. 2 common softwood, which is with solid knots, no voids.

Siding is either vertically or horizontally applied. Theater construction may

limit available material to lap siding for both horizontal and vertical surfaces.

For local procurement, there are several types of drop and bevel siding, which

is applied horizontally.

3. Sizes

Lumber is usually sawed into standard dimensions (length, width, and

thickness). This allows uniformity in planning structures and in ordering

materials. Table 1 lists the common widths and thicknesses of wood in rough

and in dressed dimensions in the US. Standards have been established for

dimension differences between the quoted size of lumber and its standard sizes

when dressed.

Quoted size refers to dimensions prior to surfacing. These dimension

differences must be taken into consideration. A good example of the

dimension difference is the common 2 x 4. As shown in Table 1, the

familiar quoted size 2 x 4 is the rough or nominal dimension, but the

actual dressed size is 1 1/2 x 3 1/2 inches. Lumber is sawn in standard

sizes used for light framing.

• Thickness: 1, 2, and 4 inches.

• Width: 2, 4, 6, 8, 10, and 12 inches.

• Length: 8, 10, 12, 14, 16, 18, and 20 feet.

The actual dimensions of dressed lumber are less than the sawn

dimensions because of drying and planing (or finishing). For the relative

difference between sawn (standard or nominal) dimensions and actual sizes of

construction lumber, see Table 2-1.

Plywood is usually 4 x 8 feet and varies from 1/8 to 1 inch in thickness.

Date Document No.

Developed:

August. 2019 Issued

Rough and Finish by:

Carpentry Page 22 of

Raymond F. 66

Staking-out Building Gabica

Lines Revision #

00

Table 2. Nominal and dressed sizes of lumber

FASTENERS

Construction fasteners are those that are used in the construction

business. These fasteners include thousands of variety of screws, nuts, bolts,

pins, and hinges. Traditionally, fasteners that are used for construction

purposes are heavy and sturdy compared to deck fasteners or normal screws

and bolts.

Date Document No.

Developed:

August. 2019 Issued

Rough and Finish by:

Carpentry Page 23 of

Raymond F. 66

Staking-out Building Gabica

Lines Revision #

00

Construction fasteners are used for commercial, residential, and

industrial purposes. Every type of construction requires fasteners, from small

house to a large factory.

Fasteners are usually selected based on their function and the material

that is to be fastened. This means that a fastener required for joining two

wooden beams is different from a fastener that is used for fastening steel rods.

Other factors that determine the selection of a fastener are - application, body

design, diameter of the body of a fastener, thread type, material, and drive

types.

It is important that a construction fastener meets the requirements and

quality standards laid down by the government. The tensile strength and the

shear values should be accurately determined to avoid any breakage or

untimely fatigue failure of the machinery or construction in which the fastener

is to be used.

Nails

In woodworking and construction, a nail is a pin-shaped object

of metal (or wood, called a treenail or "trunnel") which is used as a fastener, as

a peg to hang something, or sometimes as a decoration. Generally, nails have a

sharp point on one end and a flattened head on the other, but headless nails

are available. Nails are made in a great variety of forms for specialized

purposes. The most common is a wire nail. Other types of nails

include pins, tacks, brads, and spikes.

Nails are typically driven into the work piece by a hammer,

a pneumatic nail gun, or a small explosive charge or primer. A nail holds

materials together by friction in the axial direction and shear strength laterally.

The point of the nail is also sometimes bent over or clinched after driving to

prevent pulling out.

Types of Nails

Using nails is an effective way of fixing or joining pieces of softwood

together. Hardwoods can be difficult to join with nails as they tend to bend

under the impact of the hammer. Below is a range of nails that can be used

depending on the type of wood and the nature of the work to be attempted.

Date Document No.

Developed:

August. 2019 Issued

Rough and Finish by:

Carpentry Page 24 of

Raymond F. 66

Staking-out Building Gabica

Lines Revision #

00

Common Wire Nail - This is used for

general work. It is not attractive in

shape and it can split wood when

hammered in position

Oval Wire Nail - This is a long nail and

care must be taken when it is

hammered into the wood. It is unlikely

to split the wood.

Lost Head Nail - This is ideal if it is

necessary to hide the head of the nail as

a punch can be used to hammer the

head beneath the surface level.

Panel Pin - A very popular way of

joining woods although glue is usually

included as part of the join.

Tack - Can be used for fixing textile

materials to wood for example, fixing

upholstery to furniture.

Sprig - This no head and is generally

used for fixing glass to glass in wood

frames.

Annular Nail - The teeth of this nail

hold it in place firmly. Therefore, it is

used for fixing plywood and other

materials.

Hardboard Pin - The diamond shaped

head is hidden when used in materials

like hardboard

Corrugated Fastener - This will hold

the corners of wood frames firmly

together

Self-Check 1.1-2

Date Document No.

Developed:

August. 2019 Issued

Rough and Finish by:

Carpentry Page 25 of

Raymond F. 66

Staking-out Building Gabica

Lines Revision #

00

TRUE OR FALSE:

Directions: Write T if the statement is TRUE and F is the statement is

FALSE.

_____ 1. The primary components used in frame construction are lumber and

hardware.

_____ 2. Wood varies greatly in structural characteristics.

_____ 3. Lumber is subdivided into classification of select lumber and common

lumber.

_____ 4. Select lumber is suitable for general construction and utility purposes.

_____ 5. Grade B lumber is suitable for natural finishes and is practically clear.

_____ 6. Lost head nail has no head and is generally used for fixing glass to

glass in wood frames.

_____ 7. Building frames are the wood forms constructed to support the

finished members of a structure.

_____ 8. The interior walls of a frame structure usually have three layers.

_____ 9. Quoted size refers to dimensions prior to surfacing.

_____10. The exact dimensions of dressed lumber are less than the sewn

dimensions because of drying and planning.

Answer Key 1.1-2

Date Document No.

Developed:

August. 2019 Issued

Rough and Finish by:

Carpentry Page 26 of

Raymond F. 66

Staking-out Building Gabica

Lines Revision #

00

Check your answer with the answer key below. If you fail to get it right, refer

back to corresponding resources until you make it perfect.

1. T

2. F

3. T

4. F

5. F

6. F

7. T

8. F

9. T

10. F

Information Sheet 1.1-3

Date Document No.

Developed:

August. 2019 Issued

Rough and Finish by:

Carpentry Page 27 of

Raymond F. 66

Staking-out Building Gabica

Lines Revision #

00

Board Foot Computation

Learning Objective:

Upon completing this section, you should be able to:

1. Compute for board foot

Board foot is the unit by which a lumber is ordered. A board foot (BF) is

a unit measure representing an area of 1 foot by 1 foot, 1 inch thick. Thus, a

board that is 1 inch thick, 1 foot wide, and 1 foot long measures 1 board foot. A

board that is 1 inch thick, 1 foot wide, and 12feet long measures 12 board feet.

Methods of Computing Board Foot (BF)

1. Rapid Estimate

You can estimate BF rapidly by using Table 3. For example, reading the

table, you can see that if a 2-inch by 12-inchboard is 16 feet long; your

board feet would be 32.

Table 3. Board Foot Conversion Table

2. Arithmetic Method

Date Document No.

Developed:

August. 2019 Issued

Rough and Finish by:

Carpentry Page 28 of

Raymond F. 66

Staking-out Building Gabica

Lines Revision #

00

To determine the number of BF in one or more pieces of lumber use the

following formula:

NOTE:

If the unit of measure for length is in inches, divide by144 instead of 12.

Sample Problem 1:

Find the number of BF in a piece of lumber 2inches thick, 10 inches wide,

and 6 feet long (Figure 13).

Sample Problem 2:

Find the number of BF in 10 pieces of lumber 2inches thick, 10 inches

wide, and 6 feet long.

Sample Problem 3:

Find the number of BF in a piece of lumber 2inches thick, 10 inches wide,

and 18 inches long.

Figure 13.

Lumber Dimension

Date Document No.

Developed:

August. 2019 Issued

Rough and Finish by:

Carpentry Page 29 of

Raymond F. 66

Staking-out Building Gabica

Lines Revision #

00

3. Tabular Method

The standard Essex board measure table (Figure14) is a quick aid in

computing BF. It is located on the back of the blade of the framing square.

In using the board measure table, make all computations on the basis of 1-

inch thickness. The inch markings along the outer edge of the blade represent

the width of a board 1 inch thick. The third dimension (length) is provided in

the vertical column of figures under the 12-inch mark.

Figure 14. Essex board measure table

Sample Problem:

To compute the number of BF in a piece of lumber that is 8 inches wide, 14

feet long, and 4 inches thick-1.

1. Find the number 14 in the vertical column under the 12-

inchmark.

2. Follow the guideline under number 14 laterally across the blade until it

reaches the number on that line that is directly under the inch mark

matching the width of the lumber.

Example:

Under the 8-inch mark on the guideline, moving left from 14, the numbers 9

and 4 appear (9 and 4 should be

on the same line as14). The

number to the left of the vertical

line represents feet; the number to

the right represents inches.3.The total

number is 37 1/3 BF. BF

will never appear in a decimal form.

Example solution:

Date Document No.

Developed:

August. 2019 Issued

Rough and Finish by:

Carpentry Page 30 of

Raymond F. 66

Staking-out Building Gabica

Lines Revision #

00

1" x 4" x 8' x 14'

NOTE:

1" x 4" = Always multiply the number of pieces by the thickness and multiply

the feet and inches by the sum of pieces and thickness.

Self-Check 1.1-3

Check your mastery in board foot and its computation by completing the

tasks below.

DIRECTIONS: Use any method for computing the board foot of the

given measurements.

1. 1” x 4” x 6’ = ____ 7. 2” x 6” x 8’ =____

2. 2” x 4” x 12’ = ____ 8. 2” x 6” x 6’ =____

3. 1” x 10” x 8’ =____ 9. 1” x 4” x 12’ =____

4. 2” x 6” x 16’ =____ 10. 1” x 14” x 10’ =____

5. 4” x 4” x 8’ =____ 11. 4” x 4” x 12’ =____

6. 6” x 6” x 6’ =____ 12. 6” x 6” x 16’ =____

Answer Key 1.1-3

Date Document No.

Developed:

August. 2019 Issued

Rough and Finish by:

Carpentry Page 31 of

Raymond F. 66

Staking-out Building Gabica

Lines Revision #

00

Check your answer with the answer key below. If you fail to get it right, refer back to

corresponding resources until you make it perfect.

1. 2 BF

2. 8 BF

3. 6.67 or 7 BF

4. 48 BF

5. 10.67 or 11 BF

6. 18 BF

7. 8 BF

8. 6 BF

9. 4 BF

10. 11.67 or 12 BF

11. 16 BF

12. 48 BF

Information Sheet 1.1-4

Tools, Materials, and Equipment for Staking-out Building Lines

Date Document No.

Developed:

August. 2019 Issued

Rough and Finish by:

Carpentry Page 32 of

Raymond F. 66

Staking-out Building Gabica

Lines Revision #

00

Learning Objective:

Upon completing this section, you should be able to

1. Recognize/Identify the different tools materials and

equipment used in staking-out building lines

It is very important to know that the name and proper use of each of the

various tools we need in our works. In addition, application on their

proper care and maintenance will give you the following advantages: efficiency

of the work, quality speed and accomplishment and accuracy.

A. Tools and Equipments

Pencil is used

for more accurate marking

and a longer-

lasting point. It can easily

be sharpened to a chisel-

point.

Claw Hammer

Although this tool is basically for nailing

and extracting nails, it has also been widely

used over the years by using the side of the

head as an alternative to the wooden mallet.

The claw is also used for a limited amount of

leverage work, such as separating nailed

boards, etc.

Water hose levels are used to measure an exact, level height

across a surface, such as a wall or a board.

Spirit Level

Date Document No.

Developed:

August. 2019 Issued

Rough and Finish by:

Carpentry Page 33 of

Raymond F. 66

Staking-out Building Gabica

Lines Revision #

00

This is an essential tool for plumbing and leveling operations. When

checking or setting up a level or plumb position, be sure that the bubbles

equally settled between the lines on the vial for accurate readings.

Plumb Bob

It is a cone shaped metal suspended on a string

used to check the verticalness of a particular

object.

Tape Rule or Pull Push Rule

This is essential for fast, efficient measuring on

site work. For this type of carrying-rule, sizes

vary between 2 m and 10 m. Models with

lockable, power-return blades and belt clips,

one of 3.5 m and one of 8 m length are

recommended.

Try Square

It is used like the steel square

but in small works square.

Steel Square

Date Document No.

Developed:

August. 2019 Issued

Rough and Finish by:

Carpentry Page 34 of

Raymond F. 66

Staking-out Building Gabica

Lines Revision #

00

It is a L-shaped with one arm forming a perfect right angle to the other. It

used to check the squareness of a corner.

Ripping/Wrecking Bar

This is used to pull out long nails. This may be straight or gooseneck. It

has a nail slot for pulling out spikes and wedging apart nailed boards.

Ax or Hatchet

An ax or hatchet is used during the

staking out operation to sharpen the

ends of batter board posts and corner

stakes.

Crosscut Saw

This is for cutting timber across the

grain. When crosscutting, the

saw should be at an approximate angle of

45° to the timber.

Bolo

It is used to cut pegs for stake-out.

Date Document No.

Developed:

August. 2019 Issued

Rough and Finish by:

Carpentry Page 35 of

Raymond F. 66

Staking-out Building Gabica

Lines Revision #

00

Sledge Hammer

A sledge hammer or maul is needed to sink

corner stakes or batter board posts.

Engineer's Transit or Leveling Instrument

The engineer's transit or leveling instrument is used

to establish a proper reference or grade line from

which the builder may build up or down with

consistent accuracy as to vertical level.

Rip Saw

This is use to cut along the grain of wood.

B. Materials

Nylon String

Date Document No.

Developed:

August. 2019 Issued

Rough and Finish by:

Carpentry Page 36 of

Raymond F. 66

Staking-out Building Gabica

Lines Revision #

00

It is used to indicate the sides of the building.

Common Wire Nail - This is used for

general work. It is not attractive in shape

and it can split wood when hammered in

position

Posts or Stakes

Batter board posts are made to the desired lengths from

2 by 4's or4 by 4's. Corner stakes are made from 4 by 4's,

and batter boards from 1by 4's or 1 by 6's.

Self-Check 1.1-4

Check your mastery in types of tools and materials used in staking out

building lines by completing the tasks below.

Directions: Identify the tool materials asked for. Write your answer on the

space provided before the number.

Date Document No.

Developed:

August. 2019 Issued

Rough and Finish by:

Carpentry Page 37 of

Raymond F. 66

Staking-out Building Gabica

Lines Revision #

00

________________1.It is used to drive pegs for stake-out

________________ 2.It is used to check the verticalness

________________ 3.It is used to layout measurements

________________ 4.It is used to check squareness

________________ 5.It is used to drive and pull out nails

________________ 6.It is used to check the levelness

________________ 7.It is used to cut along the grain of wood

_______________ 8.It is used to indicate the sides of a building

________________ 9.It is used to make pegs for stake-out

________________10.It is used for cutting across the grain of wood.

Answer Key 1.1-4

Check your answer with the answer key below. if you fail to get it right, refer

back to corresponding resources until you make it perfect.

1.SLEDGE HAMMER

Date Document No.

Developed:

August. 2019 Issued

Rough and Finish by:

Carpentry Page 38 of

Raymond F. 66

Staking-out Building Gabica

Lines Revision #

00

2.PLUMB BOB

3.TRY SQUARE

4.PULL PUSH RULE/TAPE RULE

5.CLAW HAMMER

6.SPIRIT LEVEL

7.RIP SAW

8.NYLON STRING

9.BOLO

10.CROSS CUT SAW

Information Sheet 1.1-5

Company Rules and Regulations

Learning Objective:

Upon completing this section, you should be able to

Date Document No.

Developed:

August. 2019 Issued

Rough and Finish by:

Carpentry Page 39 of

Raymond F. 66

Staking-out Building Gabica

Lines Revision #

00

1. Identify the proper authorities that can provide important

documents before constructing a building

To avoid headache and unnecessary expenses, make sure that all

necessary permits are secured from local authorities concerned before starting

any activity in the construction site.

Things to consider before construction

1. Relocate the boundaries of the construction, especially lots without

existing reference point or adjoining structures. This job is to be given to

a geodetic engineer.

2. Clear all sites of any existing structures, trees and elements that will

obstruct the construction activities. Cutting of trees requires permit from

the Department of Energy and Natural Resources.

3. Allocate space for warehousing, workers’ quarter and construction office

which are usually requirements in the construction embodied in

the specification contract.

4. Apply and secure temporary electric power connections and water

supply.

5. The site of the construction must be securely fenced to protect

theconstruction activities from onlookers and passersby and to alsoprote

ct the materials from pilferage both from the outside and the inside.

6. Determine the building set back from the road line. Install the stake on

the ground at a reasonable spacing that will fit into the length of the

batter board available

Self-Check 1.1-5

Check your mastery in determining the proper authorities who can provide the

following permit/document needed in construction.

Date Document No.

Developed:

August. 2019 Issued

Rough and Finish by:

Carpentry Page 40 of

Raymond F. 66

Staking-out Building Gabica

Lines Revision #

00

Directions: On a separate sheet of paper, identify the proper

agency/authority that can help you in securing the following documents

before erecting a building.

1. Building permit

2. Electrical permit

3. Sanitary and plumbing permit

4. Zoning clearance

5. Fencing permit

6. Permit to cut trees

7. Water installation permit

8. Excavation and ground preparation permit

9. Enclosure permit

10. Mechanical permit

11. Scaffolding permit

12. Sidewalk construction permit

Answer Key 1.1-5

Check your answer with the answer key below. If you fail to get it right, refer

back to corresponding resources until you make it perfect.

Date Document No.

Developed:

August. 2019 Issued

Rough and Finish by:

Carpentry Page 41 of

Raymond F. 66

Staking-out Building Gabica

Lines Revision #

00

1. Engineering Office

2. Electric Company

3. Engineering Office

4. Registry of Deeds

5. DENR

6. Water district

7. Engineering Office

8. Engineering Office

9. Engineering Office

10. Engineering Office

11. Engineering Office

12. Engineering Office

LEARNING OUTCOME #2: STAKE-OUT AND SET BATTER BOARDS

CONTENTS:

Concepts of setting batter boards

Work inspection procedure

Date Document No.

Developed:

August. 2019 Issued

Rough and Finish by:

Carpentry Page 42 of

Raymond F. 66

Staking-out Building Gabica

Lines Revision #

00

Types and uses of materials and tools

ASSESSMENT CRITERIA:

Stakes are set out from pre-determined building lines

Batter board materials are measured, laid out and cut according to

specification

Stakes are set 0.75-1.00 meter away from the pre-determined building

lines

Batter boards are properly secured with tolerance for dimensions at

5 mm, and levelness of 3 mm.

Appropriate PPE is used according to job requirements

CONDITIONS:

Students/Trainees must be provided with the following:

Tools Equipment

Claw Hammer Personal Protective Equipment

Pencil/marking pen Automatic level

Pull-push rule

Water hose level

Nylon String

Plumb Bob

Steel Square Materials

Try-square Plan and working drawings

Hand Saw Lumber

Chalk Line Nails

Bolo

Sledge Hammer

ASSESSMENT METHOD:

Portfolio

LEARNING EXPERIENCES

Date Document No.

Developed:

August. 2019 Issued

Rough and Finish by:

Carpentry Page 43 of

Raymond F. 66

Staking-out Building Gabica

Lines Revision #

00

STAKE-OUT AND SET BATTER

Learning Outcome #2

BOARDS

Learning Activities Special Instructions

Read Information Sheet No. 1.2-1

on Setting Batter Boards

Compare your answers to the

Answer Self-Check No.1.2-1

answer key.

Evaluate your own work using the

Perform Job Sheet No.1.2-1 Performance Criteria

on Installing Batter Boards Present your work to your trainer for

evaluation

Keep a copy of your work for the next

activities

Perform Operation Sheet No. Evaluate your own work using the

Performance Criteria

1.2-1a on Lay-outing the Present your work to your trainer for

Rectangular Site evaluation

Evaluate your own work using the

Perform Operation Sheet No. 1.2-1b

Performance Criteria

on Setting and Staking Procedures

Present your work to your trainer for

evaluation

Perform Operation Sheet No. 1.2-1c Evaluate your own work using the

on Determining the location of the Performance Criteria

batter boards and constructing them Present your work to your

trainer for evaluation

Information Sheet 1.2-1

Setting Batter Boards

Learning Objectives:

Upon completing this section, you should be able to:

Date Document No.

Developed:

August. 2019 Issued

Rough and Finish by:

Carpentry Page 44 of

Raymond F. 66

Staking-out Building Gabica

Lines Revision #

00

1. Identify the things to prepare and consider before setting batter

boards

2. Set and stake batter boards properly

Setting the batter boards crucial to building a foundation exactly as the

plans specify, and certain elements of their construction must be exact.

Properly installed batter boards help ensure the corners of the foundation are

at exactly the right angles and locations.

Batter boards consist of two vertical members and a horizontal

crosspiece. The vertical members usually are two-by-fours, and the horizontals

are one-by-fours. The vertical boards are pointed stakes, which are driven into

the ground with a sledgehammer. The horizontal members are screwed to the

verticals.

A. Setting Batter Boards

Batter boards are a temporary framework used to assist in locating

corners when laying out a foundation.

Batter-board posts are made from 2 x 4

or 4 x 4 material

Corner stakes are made from 2 x 2s

Batter boards are made from 1 x 4 or 1

x 6 pieces

B. Staking Procedures

Corner stakes are driven to mark the

exact corners of the project. Excavating for a

foundation will disturb the stakes, so batter

boards are set up outside the boundary

established by the stakes to preserve definite

and accurate building lines. Heavy cord

or fine wire is stretched from one batter

Figure 15 . Right-angle Batter Boards

board to another to mark these lines.

C. Location of Batter Boards

Date Document No.

Developed:

August. 2019 Issued

Rough and Finish by:

Carpentry Page 45 of

Raymond F. 66

Staking-out Building Gabica

Lines Revision #

00

The illustration below on the left side shows how to locate batter boards.

Right-angle batter boards are erected 3 or 4 feet outside of each corner stake.

Straight batter boards are erected 3 or 4 feet outside of the line stakes.

. Batter Boards

D. Construction of Batter Boards

Right-angle batter boards should be fastened to the posts after the posts

are sunk. Since the boards should be at the exact height of the top of the

foundation, it may be desirable to adjust the height by nailing the boards to the

stakes after the stakes have been sunk. Right-angle batter boards may be

nailed close to perpendicular by using a framing square and should be leveled

by means of a carpenter's

level before they are

secured. Then, angle saw

cuts may be made or nails

driven into the tops of the

boards to hold the lines in

place. Separate cuts or

nails may be used for the

building line, the

foundation line, the footing

line, and excavation lines.

These grooves permit the

removal and replacement

of the lines in the correct

position. Figure 17 . Construction of Batter Boards

E. Extending Lines

The following procedure applies to a simple layout as shown below, and

must be amended to apply to different or more complex layout problems:

Date Document No.

Developed:

August. 2019 Issued

Rough and Finish by:

Carpentry Page 46 of

Raymond F. 66

Staking-out Building Gabica

Lines Revision #

00

Step 1. After locating and sinking

stakes A and B. erect batter

boards 1, 2,3, and 4. Extend

a chalk line (X) from batter

board 1 to batter board 3,

over stakes A and B.

Step 2. After locating and sinking

stake C, erect batter

boards 5 and 6.Extend

chalk line Y from batter

board 2 over stakes A and

C to batter board 6.

Step 3. After locating and sinking

stake D, erect batter

boards 7 and 8.Extend

chalk line Z from batter

board 5 to batter board 7,

over stakes C and D.

Step 4. Extend line O from batter

board 8 to batter board 4,

over stakes D and B.

Where foundation walls are Figure 18 . Laying-out Building Lines

wide at the bottom and extend

beyond the outside dimensions of Figure 18 . Extending Lines

the building, the excavation must

be larger than the laid-out size. To lay

out dimensions of this excavation,

measure out as far as required from

the building line on each batter board

and stretch lines between these

points, outside the first layout.

The lines may be at a right

angle where they cross the corner layout stakes, found by holding a plumb bob

over the corner layout stakes and adjusting the lines until they touch

the plumb-bob line. All lines should be checked with a line level or a

carpenter's level.

Date Document No.

Developed:

August. 2019 Issued

Rough and Finish by:

Carpentry Page 47 of

Raymond F. 66

Staking-out Building Gabica

Lines Revision #

00

Self-Check 1.2-1

Check your understanding on the previous lesson by answering this activity

MODIFIED TRUE OR FALSE:

Directions: Analyze the underlined word in each sentence. If it make the

statement correct, write T. If the underlined word is wrong, write F and

provide the correct answer.

1. Batter boards are a temporary framework used to assist in locating

corners when laying out a foundation.

2. The horizontal crosspieces are tied to the verticals.

3. The excavation must be smaller than the laid-out size.

4. Straight batter boards are erected 3 or 4 feet outside of the line stakes.

5. All lines should be checked with a pull push rule.

6. Right-angle batter boards should be fastened to the posts before the

posts are sunk.

7. Batter boards consist of two vertical members and a horizontal

crosspiece.

8. The horizontal boards are pointed stakes, which are driven into the

ground with a sledgehammer.

Answer Key 1.2-1

Date Document No.

Developed:

August. 2019 Issued

Rough and Finish by:

Carpentry Page 48 of

Raymond F. 66

Staking-out Building Gabica

Lines Revision #

00

Check your answer with the answer key below. If you fail to get it right, refer

back to corresponding resources until you make it perfect.

1. T

2. F – Screwed/Nailed

3. F – larger

4. T

5. F – Line level or carpenter’s level

6. F – after

7. T

8. F - vertical

JOB SHEET 1.2-1

Date Document No.

Developed:

August. 2019 Issued

Rough and Finish by:

Carpentry Page 49 of

Raymond F. 66

Staking-out Building Gabica

Lines Revision #

00

Title: Install Batter Boards

Performance Objective: Given the necessary materials, you should be

able to install batter boards

Supplies and Materials: Working Drawing/ Plan, Lumber, plywood,

fasteners

Tools and Equipment: Hammer Marking Tools Nylon String

Measuring Tools Steel Square Try-square

Hand Saw Chalk Line Plumb Bob

Water Hose Level Hand Saw PPE

Circular Saw

Steps/Procedure:

a. Lay out the site (refer to Operation Sheet No. 1.2-1a on Laying-out

the Site)

1. Establish the maximum outer perimeter.

2. Establish the desired distance at which the project will parallel the

established front line.

3. Establish the rear line.

4. Establish the sidelines.

b. Set and stake batter boards. Drive the corner stakes to mark the

exact corners of the project (refer to Operation Sheet No.1.2-1b on

Setting and Staking Batter Board)

c. Locate and construct batter boards (refer to Operation Sheet No. 1.2-

1c).

1. Drive the posts into the ground.

2. Fasten the right-angle batter boards with a framing square toensure

that the boards are perpendicular.

3. Use a carpenter's level to level the batter board before nailing.

4. Saw grooves or notches and run the string lines.

d. Extend and square the lines (refer to Operation Sheet No.1.3-1 on

Extending and Squaring the Lines)

1. Use the plumb bob over the corner layout stake and adjust the lines

until the lines intersect or touch the plumb bob line.

2. Check all the lines for levelness by using a line level or carpenter's

level.

3. Square the lines by using both the 6-8-10 and the diagonal method.

Assessment Method:

Date Document No.

Developed:

August. 2019 Issued

Rough and Finish by:

Carpentry Page 50 of

Raymond F. 66

Staking-out Building Gabica

Lines Revision #

00

Portfolio Assessment using the Performance Criteria Checklist

Performance Criteria Checklist

Job Sheet 1.2-1

Trainee’s Name__________________________ Date________________

Task: Install Batter Boards

Criteria YES NO

1. Are the stakes set out from the pre-determined

building lines?

2. Did I measure, laid out and cut batter board

materials according to specifications?

3. Are the stakes set 0.75-1.00 meter away from the

pre-determined building lines?

4. Did I secure all the batter boards properly with

tolerance for dimensions at ± 5 mm, and

levelness of ± 3 mm

OPERATION SHEET 1.2-1a

Date Document No.

Developed:

August. 2019 Issued

Rough and Finish by:

Carpentry Page 51 of

Raymond F. 66

Staking-out Building Gabica

Lines Revision #

00

Title: Lay Out the Site (Rectangular)

Performance Objective: Given the necessary materials, you should be able to

lay-out the rectangular site from the given drawing.

Supplies and Materials: Working Drawing/ Plan, Lumber, plywood, fasteners

Tools and Equipment: Hammer Marking Tools Nylon String

Measuring Tools Steel Square Try-square

Hand Saw Chalk Line Plumb Bob

Water Hose Level Hand Saw PPE

Circular Saw

Steps/Procedure:

1. Work from an established line (or front line), such as a road or

property line, parallel to construction and establish the maximum outer

perimeter (AB, CD, AC, BD) of the building area.

2. Measure away from the front line (AB) along the side lines (AC and BD) the

distances (AO and BO) to the desired dimensions of the project that is to run

Date Document No.

Developed:

August. 2019 Issued

Rough and Finish by:

Carpentry Page 52 of

Raymond F. 66

Staking-out Building Gabica

Lines Revision #

00

parallel to the front line.

3. Stretch a line from point O on the left-side dimension to point O on the right-

side dimension. This marks the frontage of the project.

4. Measure in from lines AC and BD along line OO one half the differences

between the length of line OO and the actual

dimensionof the project parallel to lines AB. This will designate themeasure

ment for points X. Both points X represent the two front corners of the

project.

EXAMPLE: If line OO = 30 feet and if the actual dimension of the

project parallel to lines AB = 20 then, 30 feet - 20 feet = 10 feet

(difference between the OO and actual dimension of the project) 10

feet divided by 2 = 5 feet between the property line and the actual

project on all sides.

5. The two distances OX and XO establish distances E and F. Extend lines from

the two front corner points X and X, parallel to lines

ACand BD respectively, for the other required dimension of therectangle or

project. This provides sidelines XG and XH.

6. Join point G and H to provide the rear line of the rectangle or project (GH).

7. Drive stakes at each corner once each of the four-corner points (X,X, G, and

H) have been located. Erect batter boards at this time.

Assessment Method:

Portfolio Assessment using the Performance Criteria Checklist

Performance Criteria Checklist

Operation Sheet 1.2-1a

Date Document No.

Developed:

August. 2019 Issued

Rough and Finish by:

Carpentry Page 53 of

Raymond F. 66

Staking-out Building Gabica

Lines Revision #

00

Trainee’s Name__________________________ Date________________

Task: Lay-out the Site (Rectangular)

Criteria YES NO

1. Are the plans and details correctly interpreted and

identified according to job requirements?

2. Have I established the perimeter of the building

area according to the drawing?

3. Did I locate and drive stakes at the four corners of

the lot?

OPERATION SHEET 1.2-1b

Title: Set and Stake-out Building Lines

Performance Objective: Given the necessary materials, you should be able

to set and stake building lines

Supplies and Materials: Working Drawing/ Plan, Lumber, plywood, fasteners

Tools and Equipment: Hammer Marking Tools Nylon String

Measuring Tools Steel Square Try-square

Hand Saw Chalk Line Plumb Bob

Water Hose Level Hand Saw PPE

Circular Saw

Steps/Procedure:

1. Set batter boards.

a. Use 2- by 4-inch or 4- by 4-inch material to make batter board posts.

b. Use 1- by 4-inch or 1- by 6-inch material to make batter boards.

c. Use 2- by 2-inch material to make corner stakes.

Date Document No.

Developed:

August. 2019 Issued

Rough and Finish by:

Carpentry Page 54 of

Raymond F. 66

Staking-out Building Gabica

Lines Revision #

00

2. Use the following staking procedures:

a. Drive corner stakes to mark the exact corners of the project.

b. Use batter boards to preserve definite and accurate building lines since

corner stakes will be disturbed during excavation.

Assessment Method:

Portfolio Assessment using the Performance Criteria Checklist

Performance Criteria Checklist

Operation Sheet 1.2-1b

Trainee’s Name__________________________ Date________________

Task: Set and Stake-out Building Lines

Criteria YES NO

1. Did I use the proper materials in setting batter

boards?

- Did I use 2- by 4-inch or 4- by 4-inchmaterial

to make batter board posts?

- Did I use 1- by 4-inch or 1- by 6-inchmaterial

to make batter boards?

- Did I use 2- by 2-inch material to make corner

stakes?

Date Document No.

Developed:

August. 2019 Issued

Rough and Finish by:

Carpentry Page 55 of

Raymond F. 66

Staking-out Building Gabica

Lines Revision #

00

2. Did I follow the procedure in staking?

3. Are stakes set out at 0.75-1.00 meter away from

the pre-determined building lines?

OPERATION SHEET 1.2-1c

Title: Determine the location of the batter boards and

construct it

Performance Objective: Given the necessary materials, you should be able

to determine location of batter board and construct it

Supplies and Materials: Working Drawing/ Plan, Lumber, plywood, fasteners

Tools and Equipment: Hammer Marking Tools Nylon String

Measuring Tools Steel Square Try-square

Hand Saw Chalk Line Plumb Bob

Hand Saw PPE

Circular Saw Water Hose Level

Steps/Procedure:

1. Determine the location of the batter boards.

a. Erect right angle batter boards 3 feet to 4 feet outside of each corner

stake.

b. Stake straight batter boards 3 feet or 4 feet outside of the line stakes.

c. Stretch heavy cord or fine wire from one batter board to another to mark

the building lines.

2. Construct batter boards.

a. Fasten right-angle batter boards to the posts after the posts are driven

into the ground.

Date Document No.

Developed:

August. 2019 Issued

Rough and Finish by:

Carpentry Page 56 of

Raymond F. 66

Staking-out Building Gabica

Lines Revision #

00

b. Fasten batter boards at the exact height of the top of the foundation.

c. Erect right angle batter boards by using a framing square to ensure that

the boards are as close to perpendicular as possible. Ensure that the

batter board is level by using a carpenter's level before nailing the batter

board in place.

d. Saw notches or grooves or drive nails into the top of the batter board to

hold the lines in place.

e. Use separate grooves or nails to indicate the building line, foundation

line, footing line, or excavation line. The grooves permit removal of the

line as needed and replacement of the lines in the correct position

Assessment Method:

Portfolio Assessment using the Performance Criteria Checklist

Performance Criteria Checklist

Operation Sheet 1.2-1c

Trainee’s Name__________________________ Date________________

Task: Determine Location of Batter Board and Construct it

Criteria YES NO

1. Have I determined the correct location of the batter

boards?

2. Are batter boards fastened to the exact height of

the top of the foundation?

3. Are the right angle batter board perpendicular

with each other as possible?

4. Did I make sure that batter boards are leveled?

Date Document No.

Developed:

August. 2019 Issued

Rough and Finish by:

Carpentry Page 57 of

Raymond F. 66

Staking-out Building Gabica

Lines Revision #

00

5. Are all lines on top of the batter board secured and

in placed?

LEARNING OUTCOME #3 Fix Building Lines

CONTENTS:

Types, functions uses of testing/leveling tools

Occupational Health and Safety Practices in the workplace

Work inspection procedure

ASSESSMENT CRITERIA:

1. Building lines are squared with end tolerance of 3 mm

2. Building lines are measured and set

3.Appropriate PPE is used according to job requirements

CONDITIONS:

Trainees must be provided with the following:

1.WORKPLACE LOCATION

2.TOOLS AND EQUIPMENT

Hammer Hand Saw

Marking Tools Chalk Line

Measuring Tools Plumb Bob

Steel Square Water Hose Level

Try-square PPE

Circular Saw

Date Document No.

Developed:

August. 2019 Issued

Rough and Finish by:

Carpentry Page 58 of

Raymond F. 66

Staking-out Building Gabica

Lines Revision #

00

3.TRAINING MATERIALS

Learning Packages

Bond paper

Ball pens

Manuals

Related References

ASSESSMENT METHOD:

Portfolio Assessment

LEARNING EXPERIENCES

Learning Outcome #3 Fix Building Line

Learning Activities Special Instructions

Read Information Sheet No. 1.3-1

on Squaring Lines

Answer Self-Check No.1.3-1 Compare your answers with

Answer Key 1.3-1.

You are required to get all answers

correct.

If not, Read the information sheets

again to answer all questions

correctly.

Perform Operation Sheet No. 1.3-1 on Evaluate your own work using

Squaring and Fixing Lines the Performance Criteria

Present your work to your trainer

for evaluation

Keep a copy of your work for the

next activities

Date Document No.

Developed:

August. 2019 Issued

Rough and Finish by:

Carpentry Page 59 of

Raymond F. 66

Staking-out Building Gabica

Lines Revision #

00

Information Sheet 1.3-1

Squaring and Fixing Lines

Learning Objectives:

Upon completing this section, you should be able to:

1. Determine the methods in squaring building lines

2. List down safety practices to be observed in staking-out building

lines

3. Fix building lines

The last stage in staking-out building lines is fixing building lines.

The types, functions and uses of different testing and leveling tools are

discussed in Information Sheet No.1.1-4 on Tools, Materials and

Equipment for Staking-out Building Lines and Extending Lines on

Information Sheet No. 1.2-1 for your reference.

Also known as a setback line, a building line is the distance from the

ends and the sides of a lot beyond which building construction is not allowed

to extend. The exact location of the building line is determined by the

municipality in which the lot is located.

Squaring Line

The two methods commonly used for squaring extended lines are the 6-

8-10 method and the diagonal method.

A. The 6-8-10 Method

Date Document No.

Developed:

August. 2019 Issued

Rough and Finish by:

Carpentry Page 60 of

Raymond F. 66

Staking-out Building Gabica

Lines Revision #

00

After extended lines are in place, measure line EF for a distance of 6 feet.

Measure line EG for a distance of 8 feet. Adjust the lines (Y and X) until FG

equals 10 feet. Multiples of 6-8-10 may be used for large layouts; for example,

12-16-20 for a layout 50 feet by 100 feet. For accuracy, never start with a

measurement of less than 6 feet.

B. The Diagonal Method

If the layout is rectangular, cutting the rectangle from opposing corners

will form two triangles as shown below. If the rectangle is perfect, these lines

will be equal in length and the corners perfectly square. If lines are not equal in

length, adjust the corners by moving the lines right or left until H and are

equal.

Figure 19. Squaring Lines Using Diagonal Method

Safety Practices in Staking-out Building Lines

Construction is a high hazard industry that comprises a wide range of

activities involving construction, alteration, and/or repair.

It’s important to maintain good housekeeping throughout all phases of

construction.

Date Document No.

Developed:

August. 2019 Issued

Rough and Finish by:

Carpentry Page 61 of

Raymond F. 66

Staking-out Building Gabica

Lines Revision #

00

All workers must equip themselves with suitable clothing, shirts, and

long pants for protection against both the weather and workplace

hazards.

Unless otherwise agreed upon, workers are also responsible for providing

their own work gloves, safety headgear, and safety footwear.

Footwear must protect the ankle, sole, and toes. Safety footwear with a

CSA green triangle symbol meets these requirements. It is the worker’s

responsibility to keep personal safety footwear in good repair.

Material or equipment must be placed, stacked, or stored so it will not

cause injury to workers.

Ensure there are no protruding nails on loose or fixed materials.

Self-Check 1.3-1

ENUMERATION: Supply the answer being asked for. Write your answer on

a separate sheet of paper.

1. List down the two methods of squaring lines.

a. ________________________________

b. ________________________________

2. Give four (4) safety practices that should be observed in staking – out

building lines.

a. _____________________________________________________

b. _____________________________________________________

c. _____________________________________________________

d. _____________________________________________________

e. _____________________________________________________

Answer Key 1.3-1

Date Document No.

Developed:

August. 2019 Issued

Rough and Finish by:

Carpentry Page 62 of

Raymond F. 66

Staking-out Building Gabica

Lines Revision #

00

1. a. 6-8-10 Method

b. Diagonal Method

2. (These can be in any order)

It’s important to maintain good housekeeping throughout all

phases of construction.

All workers must equip themselves with suitable clothing, shirts,

and long pants for protection.

Workers are also responsible for providing their own work gloves,

safety headgear, and safety footwear.

Footwear must protect the ankle, sole, and toes.

Material or equipment must be placed, stacked, or stored so it will

not cause injury to workers.

Ensure there are no protruding nails on loose or fixed materials.

OPERATION SHEET 1.3-1

Title: Extend and Square Lines

Performance Objective: Given the necessary materials, you should be

able to extend and square lines

Supplies and Materials: Hammer Marking Tools Nylon

String

Measuring Tools Steel Square Try-square

Hand Saw Chalk Line Plumb Bob

Hand Saw PPE

Circular Saw Water Hose Level

Steps/Procedure:

a. Perform a simple layout.

Step 1. Follow the placement of stakes A and B, erect batter

boards number 1 through 4. Extend a chalk

Date Document No.

Developed:

August. 2019 Issued

Rough and Finish by:

Carpentry Page 63 of

Raymond F. 66

Staking-out Building Gabica

Lines Revision #

00

line (X) from the batter board numbers 1 to 3, over stakes A and B.

Step 2. Follow the placement of stake C, erect batter boards number 5 and 6.

Extend chalk line (Y) from batter boards number 2 and 6, over stakes

A and C.

Step 3. Follow the placement of stake D, erect batter boards number7 and 8.

Extend chalk line (Z) from batter board number 5 to 7, over stakes C

and D.

Step 4. Extend line (O) from batter boards number 8 to 4, over stakes D and B.

1. Lay out dimensions for excavation lines, footer lines, or

reference lines other than building lines. Use the building line marks on

the batter boards as a reference. Adjust the measurement as required to

obtain the desired dimensions for the reference line. NOTE: Lines may

cross and form right angles at the corner layout stakes.

2. Verify exact placement of the cross lines by holding a plumb bob over the

corner layout stake. Adjust the lines until the lines intersect or touch the

plumb bob line.3.Use a line or carpenter's level to ensure that the lines

are level.