Professional Documents

Culture Documents

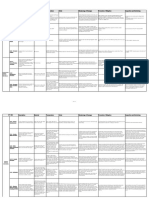

Sample of Boiler Tube Failures

Sample of Boiler Tube Failures

Uploaded by

mustafaOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Sample of Boiler Tube Failures

Sample of Boiler Tube Failures

Uploaded by

mustafaCopyright:

Available Formats

M&M Engineering’s Boiler Tube Failure Handbook

Hole—Waterside (Firetube boiler)

Locations Waterside of tube in firetube boiler

Boiler Type Firetube

Industry Process/Heating

Appearance General pitting

Mechanism Acid attack

Comments Improper chemical cleaning with hydrochloric acid can

result in severe and rapid pitting of tubes.

Mechanical & Materials Engineering

www.mmengineering.com

M&M Engineering’s Boiler Tube Failure Handbook

Hole—Waterside

Locations Waterwall

Boiler Type Power

Industry Electric Utility

Appearance Severe corrosion gouging at a weld-backing ring

Mechanism Caustic Gouging

Comments Underdeposit corrosion, may be due to poor control of

boiler water chemistry, or excessive deposits from

feedwater. Considered poor practice to install backing

rings in waterwall circuits since they provide sites for

preferential corrosion.

Mechanical & Materials Engineering

www.mmengineering.com

M&M Engineering’s Boiler Tube Failure Handbook

Hole—Waterside

Locations Economizer

Boiler Type HRSG

Industry Electric Utility

Appearance Sharply defined hole

Mechanism Corrosion Fatigue

Comments Corrosion Fatigue typically causes cracking. In this case

the cracks formed an oval section of the tube wall that

was ejected from the tube to create the failure.

Mechanical & Materials Engineering

www.mmengineering.com

M&M Engineering’s Boiler Tube Failure Handbook

Cracks—Near or in weld or attachement—Longitudinal

Locations Waterwall

Boiler Type Power

Industry Pulp and Paper

Appearance Cracks close to attachments

Mechanism Corrosion Fatigue

Comments External attachments provide a restraint and high

operating stress. This, together with marginal water

chemistry particularly during startup, leads to corrosion-

fatigue cracks

Mechanical & Materials Engineering

www.mmengineering.com

M&M Engineering’s Boiler Tube Failure Handbook

Hole—Fireside

Locations Furnace Riser

Boiler Type Cyclone/Power

Industry Utility

Appearance Severe pock-marked corrosion on fireside

Mechanism Corrosion/Thermal Fatigue

Comments Damage caused direct impingement of waste chemical

cleaning solution on riser tube inside cyclone boiler. Tube

failure a combination of corrosion and thermal shock.

Mechanical & Materials Engineering

www.mmengineering.com

M&M Engineering’s Boiler Tube Failure Handbook

Crack—In or near weld or attachment—Longitudinal (random)

Locations Waterwall, Economizer

Boiler Type Recovery

Industry Pulp and Paper

Appearance Multiple cracks associated with attachment on outside of

tube

Mechanism Corrosion-fatigue

Comments External attachment provided a restraint and associated

high operating stress. This, together with marginal water

chemistry particularly during startup, leads to corrosion-

fatigue cracks

Mechanical & Materials Engineering

www.mmengineering.com

M&M Engineering’s Boiler Tube Failure Handbook

Cracks—In or near weld or attachment—Longitudinal

Locations Waterwall

Boiler Type Power

Industry Electric Utility

Appearance Longitudinal ID corrosion-fatigue cracks

Mechanism Corrosion-fatigue

Comments External attachment provided a restraint and associated

high operating stress. This, together with marginal water

chemistry particularly during startup, leads to corrosion-

fatigue cracks

Mechanical & Materials Engineering

www.mmengineering.com

M&M Engineering’s Boiler Tube Failure Handbook

Crack—Not in or near a weld—Longitudinal

Locations Superheater, Reheater

Boiler Type Power

Industry Electric Utility

Appearance Thick-lipped rupture and adjacent longitudinal fissuring

Mechanism Creep

Comments Prolonged exposure (over 40 years) to high-temperature

service.

Mechanical & Materials Engineering

www.mmengineering.com

M&M Engineering’s Boiler Tube Failure Handbook

Crack—Not in or near a weld—Longitudinal

Locations Superheater

Boiler Type Reformer

Industry Petrochemical

Appearance Irregular cracking

Mechanism Creep

Comments Indicative of end of service life

Mechanical & Materials Engineering

www.mmengineering.com

M&M Engineering’s Boiler Tube Failure Handbook

Crack—In or near weld or attachment—Transverse

Locations Superheater

Boiler Type Power

Industry Electric Utility

Appearance Complete weld separation

Mechanism Dissimilar metal weld failure (DMW)

Comments Dissimilar metals with different coefficients of expansion,

such as he stainless steel filler and the low-alloy base

material result in long-term creep damage accumulation

Mechanical & Materials Engineering

www.mmengineering.com

M&M Engineering’s Boiler Tube Failure Handbook

Deformation—Thinning

Locations Waterwall, Superheater

Boiler Type Power

Industry Common

Appearance External Wastage Beneath Adherent Slag Deposit

Mechanism Corrosion from Slag Attack

Comment Molten ash creates corrosive sulfur species. Alkalisulfates are

formed where metal temperatures are greater than 1000°F and

pyrosulfates where temperatures are greater than 700°F.

Mechanical & Materials Engineering

www.mmengineering.com

M&M Engineering’s Boiler Tube Failure Handbook

Hole—Waterside

Locations Economizer

Boiler Type Power

Industry Electric Utility

Appearance Thinning on inside of a u-bend or other change in direction

Mechanism Flow Accelerated Corrosion (FAC)

Comments FAC results from a combination of factors including

material limitations, design, and water chemistry. Failures

are typically catastrophic.

Mechanical & Materials Engineering

www.mmengineering.com

M&M Engineering’s Boiler Tube Failure Handbook

Deformation—Thinning

Locations Superheater, Reheater

Boiler Type Power

Industry Electric Utility

Appearance Smooth surface

Mechanism Fly Ash Erosion

Comments Wall thinning leads to stress rupture failure

Mechanical & Materials Engineering

www.mmengineering.com

M&M Engineering’s Boiler Tube Failure Handbook

Deformation—Thinning

Locations Reheater

Boiler Type Power

Industry Electric Utility

Appearance External thinning, smooth areas

Mechanism Fireside Corrosion/Erosion

Comments Abrasion from fly ash may cause erosion, corrosion may

also occur as sulfur deposits become acidic during

shutdown or cool gas temperatures. This type of

corrosion is more prevalent in oil-fired boilers and in the

back-end of the gas path i.e., economizers.

Mechanical & Materials Engineering

www.mmengineering.com

M&M Engineering’s Boiler Tube Failure Handbook

Hole—Fireside

Locations Waterwall

Boiler Type Power (oil and natural gas fired)

Industry Electric Utility

Appearance Thinning from the fireside, pockmarks on external surface

Mechanism Fireside corrosion

Comments Corrosion associated with acidic deposits from sulfur in the

fuel.

Mechanical & Materials Engineering

www.mmengineering.com

M&M Engineering’s Boiler Tube Failure Handbook

Hole—Fireside

Locations Waterwall

Boiler Type Reformer

Industry Petrochem

Appearance Metal wastage

Mechanism Fireside Corrosion

Comments Corrosion often due to sulfur in the fuel creating acidic deposits.

Mechanical & Materials Engineering

www.mmengineering.com

M&M Engineering’s Boiler Tube Failure Handbook

Crack—In or near weld attachment—Transverse (random)

Locations Superheater, Reheater

Boiler Type Power

Industry Electric Utility

Appearance Brittle fracture in heat affected zone of a weld

Mechanism Graphitization

Comments Occurs when a line of graphite nodules form in the heat

affected zone of the weld.

Mechanical & Materials Engineering

www.mmengineering.com

M&M Engineering’s Boiler Tube Failure Handbook

Crack—In or near weld or attachment—Transverse

Locations Waterwall

Boiler Type Power

Industry Electric Utility

Appearance Catastrophic failure associated with weld overlay

Mechanism Hydrogen damage

Comments Hydrogen damage is an under-deposit corrosion

mechanism. Weld overlay exacerbates hydrogen damage.

High probability that other tubes are similarly affected. All

affected tubes must be replaced.

Mechanical & Materials Engineering

www.mmengineering.com

M&M Engineering’s Boiler Tube Failure Handbook

Hole—Waterside

Locations Water wall

Boiler Type Power

Industry Electric Utility

Appearance Thick-lipped rupture, may be very large window missing or a

flap hanging by one edge or a long crack.

Mechanism Hydrogen damage

Comment Hydrogen damage is an under-deposit corrosion mechanism.

Damage occurs in high heat areas (e.g., above burners). Often

associated with one or more low pH excursions in the boiler

and/or long-term contamination (condenser tube leak). High

probability that other tubes are similarly affected. All affected

tubes must be replaced.

Mechanical & Materials Engineering

www.mmengineering.com

M&M Engineering’s Boiler Tube Failure Handbook

Deformation—Bulging

Locations Waterwall

Boiler Type Power

Industry Pulp and Paper

Appearance Bulging tube adjacent to field weld

Mechanism Long term overheat

Comments Boiler tube material has been deformed due to very heavy

deposits on the inside of the tube that insulate the tube

metal from the boiler water and cause overheating.

Mechanical & Materials Engineering

www.mmengineering.com

M&M Engineering’s Boiler Tube Failure Handbook

Deformation—Bulging

Locations Waterwall

Boiler Type Power

Industry Pulp and Paper

Appearance Bulging tube adjacent to field weld

Mechanism Long term overheat

Comments Boiler tube material has been deformed due to very heavy

deposits on the inside of the tube that insulate the tube

metal from the boiler water and cause overheating.

Mechanical & Materials Engineering

www.mmengineering.com

M&M Engineering’s Boiler Tube Failure Handbook

Crack—Not in or near weld or attachment—Longitudinal

Locations Superheater, Reheater, Waterwall

Boiler Type Power

Industry Electric Utility

Appearance Longitudinal crack at bend

Mechanism Long-term Overheat

Comment Excessive heat often caused hot spots in the boiler or from

flame impingement. Excessive internal deposits may also

contribute to overheating

Mechanical & Materials Engineering

www.mmengineering.com

M&M Engineering’s Boiler Tube Failure Handbook

Crack—Not in or near a weld—Longitudinal

Locations Superheater, Reheater

Boiler Type Power

Industry Electric Utility

Appearance Short longitudinal cracks with numerous parallel cracks

Mechanism Long Term Overheat/ Creep

Comment Caused when steam flow is blocked or partially restricted or

when the heating capacity of the tube exceeds the capacity of

the cooling media.

Mechanical & Materials Engineering

www.mmengineering.com

M&M Engineering’s Boiler Tube Failure Handbook

Crack—Not in or near a weld or attachment—Longitudinal

Locations Superheater

Boiler Type Industrial

Industry Process/Heating

Appearance Multitude of cracks parallel to tube

Mechanism Long Term Overheat/ Creep

Comments Deposits can accumulate in the bottom bend of

superheaters acting as insulation and contributing to a

long-term overheat condition. (Hole was created by

cutting torch and is not part of the failure)

Mechanical & Materials Engineering

www.mmengineering.com

M&M Engineering’s Boiler Tube Failure Handbook

Cracking—Not in or near a weld—Longitudinal

Locations Waterwall

Boiler Type Power

Industry Electric Utility

Appearance Forming lap at tube OD

Mechanism Material defect

Comments Manufacturing defect that was missed by tube mill

inspection

Mechanical & Materials Engineering

www.mmengineering.com

M&M Engineering’s Boiler Tube Failure Handbook

Hole—Waterside

Locations Waterwall, Superheater, Reheater

Boiler Type Power

Industry Electric Utility

Appearance ID pitting with corrosion tubercles

Mechanism Oxygen Pitting

Comments Improper lay-up, poor control of oxygen on

startup

Mechanical & Materials Engineering

www.mmengineering.com

M&M Engineering’s Boiler Tube Failure Handbook

Hole—Waterside

Locations Water wall

Boiler Type Power

Industry Electric Utility

Appearance Undercut corrosion, multi-color deposits (red, white, black).

This is a View of a tube ID following cleaning.

Mechanism Acid Phosphate Attack

Comment Under-deposit corrosion mechanism caused by reaction of

phosphate with magnetite for form maracite. Most often found

in high heat areas of the boiler. Typically associated with

boilers suffering phosphate hideout and using disodium

phosphate or sodium hexametaphosphate.

Mechanical & Materials Engineering

www.mmengineering.com

M&M Engineering’s Boiler Tube Failure Handbook

Crack—Not in or near a weld—Longitudinal

Locations Superheater

Boiler Type Industrial

Industry Process/Heat

Appearance Multiple tight fine cracks

Mechanism Stress Corrosion Cracking

Comments Residual stresses from tube forming combined with caustic

from the environment to cause the cracking.

Mechanical & Materials Engineering

www.mmengineering.com

M&M Engineering’s Boiler Tube Failure Handbook

Crack—Near or in weld or attachment

Locations Riser tube at rolled connection in drum

Boiler Type Industrial/Power

Industry Common

Appearance Transverse cracking in the rolled portion of tube where it

is inserted into the drum

Mechanism Caustic induced stress corrosion cracking

Comments Stresses are introduced into the tube by the rolling

operation. If these rolled connections leak-by, caustic

from the boiler treatment concentrates in the crevice and

leads to failure.

Mechanical & Materials Engineering

www.mmengineering.com

M&M Engineering’s Boiler Tube Failure Handbook

Hole—Fireside

Locations Reheater

Boiler Type Power

Industry Utility

Appearance Deformation and perforation from the outside in

Mechanism Mechanical damage

Comments Damage caused by shotgun slug used to deslag reheater

tubes. Similar failure can occur wherever mechanical

deslagging is performed.

Mechanical & Materials Engineering

www.mmengineering.com

M&M Engineering’s Boiler Tube Failure Handbook

Deformation—Thinning

Locations Waterwall, Superheater

Boiler Type Recovery

Industry Pulp and Paper

Appearance Metal thinning on fireside

Mechanism Smelt/Slag Attack

Comment Molten ash (Slag in a power boiler, smelt in a recovery boiler)

can be corrosive to the boiler tube.

Mechanical & Materials Engineering

www.mmengineering.com

M&M Engineering’s Boiler Tube Failure Handbook

Crack—not in or near a weld—Longitudinal

Locations Superheater, Reheater

Boiler Type Power

Industry Electric Utility

Appearance Fish-mouth rupture

Mechanism Short-term Overheat

Comment Caused when steam flow is blocked or severely restricted.

Lack of cooling leads to tensile rupture of tube.

Mechanical & Materials Engineering

www.mmengineering.com

M&M Engineering’s Boiler Tube Failure Handbook

Crack—Not in or near weld—Longitudinal

Locations Waterwall

Boiler Type Power

Industry Electric Utility

Appearance Fishmouth Opening

Mechanism Hot Tensile Overload

Comments Usually caused by starvation or severe wall loss due to

erosion or oxidation.

Mechanical & Materials Engineering

www.mmengineering.com

M&M Engineering’s Boiler Tube Failure Handbook

Crack—Not in or near a weld—Transverse

Locations Studded Waterwall

Boiler Type Recovery

Industry Pulp and Paper

Appearance Fine cracks around studs

Mechanism Thermal Fatigue

Comments Thermal cycling from intermittent wetting by slag/smelt

causes fatigue.

Mechanical & Materials Engineering

www.mmengineering.com

M&M Engineering’s Boiler Tube Failure Handbook

Crack—Not in or near a weld or attachment—Transverse

Locations Waterwall

Boiler Type Power

Industry Electric Utility

Appearance Circumferential cracking

Mechanism Thermal Fatigue

Comments Large thermal cycles caused by slagging/deslagging

Mechanical & Materials Engineering

www.mmengineering.com

M&M Engineering’s Boiler Tube Failure Handbook

Crack—In or near weld or attachment—Transverse

Locations Superheater

Boiler Type Power

Industry Electric Utility

Appearance Complete failure at weld

Mechanism Thermal Fatigue, DMW Creep

Comments Failure of Pressure Induction Weld

Mechanical & Materials Engineering

www.mmengineering.com

M&M Engineering’s Boiler Tube Failure Handbook

Crack—In or near weld or attachment—Transverse

Locations Evaporator

Boiler Type HRSG

Industry Co-Gen

Appearance Transverse crack near support

Mechanism Thermal Fatigue

Comments The fast cycling that occurs in HRSG units can put

tremendous strains on restrained tubing creating thermal

fatigue.

Mechanical & Materials Engineering

www.mmengineering.com

M&M Engineering’s Boiler Tube Failure Handbook

Hole—Waterside

Locations Evaporator Section

Boiler Type HRSG

Industry Co-Gen

Appearance Severe corrosion on side of tube facing gas turbine/duct

burners

Mechanism Multiple underdeposit corrosion mechanisms including

caustic gouging, phosphate attack, and hydrogen damage

Comments Corrosion caused by a combination of pre-construction

deposits, poor chemistry control, and high heat flux from

duct burners.

Mechanical & Materials Engineering

www.mmengineering.com

M&M Engineering’s Boiler Tube Failure Handbook

Hole—Material Defect

Locations Superheater

Boiler Type Power

Industry Pulp and Paper

Appearance Porosity in weld

Mechanism Weld Defect

Comments Weld porosity may be due to inadequate shield gas flow or

contamination on the surface of the material.

Mechanical & Materials Engineering

www.mmengineering.com

M&M Engineering’s Boiler Tube Failure Handbook

Hole—Fireside/Material Flaw

Locations Waterwall, Superheater, Reheater

Boiler Type Power

Industry Electric Utility

Appearance Defect at wear bar attachment

Mechanism Weld/Materials defect

Comments Poor shop welding practice

Mechanical & Materials Engineering

www.mmengineering.com

M&M Engineering’s Boiler Tube Failure Handbook

Crack—In or near weld or attachment—Longitudinal or random

Locations Superheater

Boiler Type Power

Industry Electric Utility

Appearance Longitudinal cracks adjacent to weld

Mechanism Wrong material/Creep

Comments Cracks are in oxide scale and may or may not extend into

tube wall. Tube wall is deformed.

Mechanical & Materials Engineering

www.mmengineering.com

You might also like

- Welding for Challenging Environments: Proceedings of the International Conference on Welding for Challenging Environments, Toronto, Ontario, Canada, 15–17 October 1985From EverandWelding for Challenging Environments: Proceedings of the International Conference on Welding for Challenging Environments, Toronto, Ontario, Canada, 15–17 October 1985No ratings yet

- Corrosion BasicsDocument208 pagesCorrosion BasicsVINOTHINI R B.Ed100% (2)

- Kalmar DRF 450 TranmissionDocument24 pagesKalmar DRF 450 Tranmissiontuấn anh nguyễnNo ratings yet

- Handbook of Structural Welding: Processes, Materials and Methods Used in the Welding of Major Structures, Pipelines and Process PlantFrom EverandHandbook of Structural Welding: Processes, Materials and Methods Used in the Welding of Major Structures, Pipelines and Process PlantRating: 3.5 out of 5 stars3.5/5 (3)

- Tds 11hd FlyerDocument2 pagesTds 11hd Flyerعلي اثمار ناهي سباهيNo ratings yet

- 571 SummaryDocument3 pages571 SummarySimbu Arasan100% (1)

- High Temperature Effects On Vessel IntegrityDocument33 pagesHigh Temperature Effects On Vessel IntegrityImthiyaz H100% (1)

- Mercedez ConfiguracionDocument7 pagesMercedez ConfiguracionCarlos HernandezNo ratings yet

- Seismic Specific Functionality in Midas Gen - EurocodeDocument33 pagesSeismic Specific Functionality in Midas Gen - Eurocodekdb92uce100% (1)

- Boiler RLADocument4 pagesBoiler RLAGaneshNo ratings yet

- Water Side Corrosion in BoilersDocument10 pagesWater Side Corrosion in BoilerselgawadhaNo ratings yet

- Pipeline and Energy Plant Piping: Design and TechnologyFrom EverandPipeline and Energy Plant Piping: Design and TechnologyRating: 5 out of 5 stars5/5 (2)

- 2 Welding On Rotors Welding On Rotors For Power Plant Turbo Sets Dr.-Ing. Wolfgang Janssen, Siemens AG, Power Generation, GermanyDocument13 pages2 Welding On Rotors Welding On Rotors For Power Plant Turbo Sets Dr.-Ing. Wolfgang Janssen, Siemens AG, Power Generation, GermanySumit RaiNo ratings yet

- Puddle Arc Vs Thermite WeldingDocument8 pagesPuddle Arc Vs Thermite WeldingBemo RelNo ratings yet

- Boiler (Steam Generation) KSDocument25 pagesBoiler (Steam Generation) KSBangun WijayantoNo ratings yet

- RCA of Boiler Tube Failure in 210 MW PlantDocument5 pagesRCA of Boiler Tube Failure in 210 MW PlantAnsuman Sen Sharma50% (2)

- SA210 A1 Engg - Failure Analysis - Rajat PDFDocument8 pagesSA210 A1 Engg - Failure Analysis - Rajat PDFShoaib AhmedNo ratings yet

- CBB 2024 Chapter 4-Second Law of Thermo V2Document90 pagesCBB 2024 Chapter 4-Second Law of Thermo V2Ameer Muhammad100% (1)

- NETRA Corrosion Control Dec 2016Document132 pagesNETRA Corrosion Control Dec 2016ankitgarg13100% (1)

- Analysis and Optimization of Reheater Tube Failures: J. HenryDocument4 pagesAnalysis and Optimization of Reheater Tube Failures: J. Henryravi singhNo ratings yet

- Analysis of Boiler Tube FailureDocument6 pagesAnalysis of Boiler Tube FailureInternational Journal of Innovative Science and Research Technology100% (1)

- EPRI Sootblower PPDocument21 pagesEPRI Sootblower PPJackSparrow86No ratings yet

- Residual Life Assessment and Failure of The BoilerDocument21 pagesResidual Life Assessment and Failure of The BoilernagasureshNo ratings yet

- Boilers Efficiency & Boiler Heat BalanceDocument13 pagesBoilers Efficiency & Boiler Heat BalanceNipun Sabharwal100% (1)

- Report On The Procedures/practices To Minimize The Boiler Tube Leaks in The Thermal Power StationsDocument10 pagesReport On The Procedures/practices To Minimize The Boiler Tube Leaks in The Thermal Power Stationshari gopala charyNo ratings yet

- Failure Analysis of A Superheater Tube Ruptured in A Power PlantDocument10 pagesFailure Analysis of A Superheater Tube Ruptured in A Power Plantadventius S.S100% (1)

- Flexible ConnectionsDocument118 pagesFlexible ConnectionsMuzaffarNo ratings yet

- 1 - Boiler Tube FailuresDocument54 pages1 - Boiler Tube FailuresMohamad EshraNo ratings yet

- Residual Life Assessment and Failure of The BoilerDocument21 pagesResidual Life Assessment and Failure of The BoilernagasureshNo ratings yet

- Level II - Ata 28 Fuel SystemsDocument40 pagesLevel II - Ata 28 Fuel SystemswagdiNo ratings yet

- Boiler Tube InvestigationDocument6 pagesBoiler Tube InvestigationWaleed EmaraNo ratings yet

- 1 - Boiler Tube FailuresDocument55 pages1 - Boiler Tube FailuresLakshminarayan100% (1)

- 2020-SATVENDRA-Refractory Lining of The Electric Arc Furnace - IspatGuruDocument12 pages2020-SATVENDRA-Refractory Lining of The Electric Arc Furnace - IspatGurugutierrezcamposd20No ratings yet

- Repair PipelineDocument10 pagesRepair Pipelinesolrac4371No ratings yet

- Deutz 2011Document5 pagesDeutz 2011Lukman Exmes67% (3)

- Tube LeakageDocument38 pagesTube LeakageSantanu DuttaNo ratings yet

- MR2006 Wed 64JCostaDocument68 pagesMR2006 Wed 64JCostaseagull70No ratings yet

- Va21031 Damage MechanismDocument14 pagesVa21031 Damage MechanismwidadNo ratings yet

- 61.ABSTRACT Water Tube BoillerDocument1 page61.ABSTRACT Water Tube BoillerJayaseelanNo ratings yet

- Failure Case StudiesDocument28 pagesFailure Case StudiesBharat KhandekarNo ratings yet

- 1.economics of Corrosion.Document36 pages1.economics of Corrosion.Takudzwa MbengoNo ratings yet

- 38 - Liquid Metal Assisted Cracking of Galvanized Structural Steel SectionsDocument7 pages38 - Liquid Metal Assisted Cracking of Galvanized Structural Steel SectionsMarjan SubanNo ratings yet

- 02 VI STEEL INDUSTRIES (Autosaved)Document10 pages02 VI STEEL INDUSTRIES (Autosaved)raj patelNo ratings yet

- E.O.Paton Electric Welding Institute Activity in The FieldDocument10 pagesE.O.Paton Electric Welding Institute Activity in The FieldMaksimovNo ratings yet

- Special ElectivesDocument31 pagesSpecial ElectivesSagarias AlbusNo ratings yet

- Welding Lectures 1-2 PDFDocument33 pagesWelding Lectures 1-2 PDFKshitijGauravVermaNo ratings yet

- BRO-0007.7 Arc Solutions Brochure ENDocument16 pagesBRO-0007.7 Arc Solutions Brochure ENBhayu Senoaji Dwi PrimasanjoyoNo ratings yet

- Evaluation of Microstructure of High Pressure TurbineDocument8 pagesEvaluation of Microstructure of High Pressure TurbineAndrea CalderaNo ratings yet

- Thermal SprayDocument32 pagesThermal SprayMayur Patel100% (3)

- Geometrical Degradation of Electrode and Liquid Metal Embrittlement Cracking in Resistance Spot WeldingDocument15 pagesGeometrical Degradation of Electrode and Liquid Metal Embrittlement Cracking in Resistance Spot WeldingMathews LimaNo ratings yet

- Water Chemistry WorkshopAKSinhaDocument212 pagesWater Chemistry WorkshopAKSinhaSameer Kimmatkar100% (2)

- Role of Welding Defects On The Failure of Sub-Sea Carbon Steel Gas PipelineDocument5 pagesRole of Welding Defects On The Failure of Sub-Sea Carbon Steel Gas Pipelinemaian sajaNo ratings yet

- Phos Attack HW5aDocument1 pagePhos Attack HW5amustafaNo ratings yet

- De Aqui Vas A Sacar El Caso de Estudio de SoldaduraDocument16 pagesDe Aqui Vas A Sacar El Caso de Estudio de Soldadurakaren villalobo sierraNo ratings yet

- BRO-0007.8 Arc Solutions Brochure enDocument16 pagesBRO-0007.8 Arc Solutions Brochure enravisankarariyanNo ratings yet

- Welding Technology SignedDocument96 pagesWelding Technology SignedAamer MohammedNo ratings yet

- Magnetic Pulse Welding, Crimping and Forming: Cold - Clean - Strong - Cost-EffectiveDocument12 pagesMagnetic Pulse Welding, Crimping and Forming: Cold - Clean - Strong - Cost-EffectiveAli MoghiNo ratings yet

- Vdocuments - MX Thermal SprayDocument32 pagesVdocuments - MX Thermal SprayUlviyye ElesgerovaNo ratings yet

- Microarc Oxidation - KeroniteDocument23 pagesMicroarc Oxidation - Keronitefeni4kaNo ratings yet

- The Effect of Groove Welding On Mechanical PropertDocument8 pagesThe Effect of Groove Welding On Mechanical PropertMuhammad Zuhairy jabarNo ratings yet

- Aluminum Bronze PDFDocument37 pagesAluminum Bronze PDFTi AnnelNo ratings yet

- Pourmohammad 2019Document11 pagesPourmohammad 2019CHONKARN CHIABLAMNo ratings yet

- Hook Crack in ERWDocument11 pagesHook Crack in ERWN TanejaNo ratings yet

- Sinta 5Document7 pagesSinta 5Amelia AzzuraNo ratings yet

- Unit I Introduction: EEE 521 A Course Material On Electrical Machines DesignDocument166 pagesUnit I Introduction: EEE 521 A Course Material On Electrical Machines DesignHimanshu RaiNo ratings yet

- Msa 2022060115090222Document16 pagesMsa 2022060115090222Hany KhalifaNo ratings yet

- Fatigue Performance of Thermally Cut Bolt Holes in Structural Steel S460MDocument13 pagesFatigue Performance of Thermally Cut Bolt Holes in Structural Steel S460Mcarlos aquinoNo ratings yet

- 410 Types PDFDocument18 pages410 Types PDFGökhan ÇiçekNo ratings yet

- Tig Welding in AluminiumDocument11 pagesTig Welding in AluminiumMohnishNo ratings yet

- Mat Defect CNL8aDocument1 pageMat Defect CNL8amustafaNo ratings yet

- Wrong Material Creep CYL5aDocument1 pageWrong Material Creep CYL5amustafaNo ratings yet

- ST OVHT CNL11aDocument1 pageST OVHT CNL11amustafaNo ratings yet

- Phos Attack HW5aDocument1 pagePhos Attack HW5amustafaNo ratings yet

- Graph CYT6aDocument1 pageGraph CYT6amustafaNo ratings yet

- Analysis of The Reasons For The Leakage of A Boiler Water-Wall Tube in A Power PlantDocument6 pagesAnalysis of The Reasons For The Leakage of A Boiler Water-Wall Tube in A Power PlantmustafaNo ratings yet

- Creep CNL2a1Document1 pageCreep CNL2a1mustafaNo ratings yet

- Cor Fatigue CYL3a1Document1 pageCor Fatigue CYL3a1mustafaNo ratings yet

- 2018 - Dlsud - Esd Diagram - Logic Diagram - GRP 5Document1 page2018 - Dlsud - Esd Diagram - Logic Diagram - GRP 5Jake Polo SantiagoNo ratings yet

- EXA453209 AssDocument1 pageEXA453209 AssPraveen Kumar pkNo ratings yet

- M.Tech Seminar ReportDocument33 pagesM.Tech Seminar ReportKalyaniNo ratings yet

- Training Report GaganDocument18 pagesTraining Report GaganYaman VermaNo ratings yet

- Shimano EV-FD-C101-E, C102 Altus Top Swing Front DerailleurDocument1 pageShimano EV-FD-C101-E, C102 Altus Top Swing Front DerailleurxjcaiNo ratings yet

- HW App2 105(s)Document14 pagesHW App2 105(s)Hiền TrầnNo ratings yet

- Ball Valve (Maxflow)Document16 pagesBall Valve (Maxflow)vishnuNo ratings yet

- (LLOYD) Law of Conservation of Linear MomentumDocument9 pages(LLOYD) Law of Conservation of Linear MomentumHideous PikaNo ratings yet

- Boe (Boiler Operation Engineer) Short Type Question Answer For Examination - AskpowerplantDocument15 pagesBoe (Boiler Operation Engineer) Short Type Question Answer For Examination - AskpowerplantRaju MaityNo ratings yet

- Diesel Electric Trolley Mounted Portable CompressorDocument5 pagesDiesel Electric Trolley Mounted Portable CompressorHisham HamdiNo ratings yet

- SDP NLM 02 Newton Laws of MotionDocument7 pagesSDP NLM 02 Newton Laws of MotionMukul KayalNo ratings yet

- ME631A-Viscous Flow Theory-FCH-SYSDocument3 pagesME631A-Viscous Flow Theory-FCH-SYSVivek SinghNo ratings yet

- Rob Notes VrsceDocument121 pagesRob Notes VrsceNEELIMA100% (1)

- Study of DynamometerDocument5 pagesStudy of DynamometerMohanraj Kulandasamy100% (1)

- V Ec210 240 211 1123 9909 PDFDocument9 pagesV Ec210 240 211 1123 9909 PDFАлександр АндреевNo ratings yet

- Dr. Somashekhar S. HiremathDocument18 pagesDr. Somashekhar S. HiremathdkannanapkNo ratings yet

- FIRE3700 - 7600 - Tutorial 3 (Solution) - 2022Document8 pagesFIRE3700 - 7600 - Tutorial 3 (Solution) - 2022Leticia AyalaNo ratings yet

- New Lifestyle Catalogue VRV Home SeriesDocument64 pagesNew Lifestyle Catalogue VRV Home SeriesDara daikin TJSNo ratings yet

- Tripartech: Progressive Dies & Progressive Die StampingDocument2 pagesTripartech: Progressive Dies & Progressive Die StampingJOHN WICKNo ratings yet

- Methods of Analysis of Prestressed Continuous Beam: /contdDocument26 pagesMethods of Analysis of Prestressed Continuous Beam: /contdAdam SalimiNo ratings yet