Professional Documents

Culture Documents

Controlling Project Schedules with PEPs

Uploaded by

Yousef Adel HassanenOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Controlling Project Schedules with PEPs

Uploaded by

Yousef Adel HassanenCopyright:

Available Formats

Engineering Encyclopedia

Saudi Aramco DeskTop Standards

Controlling The Project Schedule

Note: The source of the technical material in this volume is the Professional

Engineering Development Program (PEDP) of Engineering Services.

Warning: The material contained in this document was developed for Saudi

Aramco and is intended for the exclusive use of Saudi Aramco’s employees.

Any material contained in this document which is not already in the public

domain may not be copied, reproduced, sold, given, or disclosed to third

parties, or otherwise used in whole, or in part, without the written permission

of the Vice President, Engineering Services, Saudi Aramco.

Chapter : Project Management For additional information on this subject, contact

File Reference: PMT30103

Engineering Encyclopedia Project Management

Controlling The Project Schedule

Content Page

PURPOSE OF PROJECT PLANNING AND SCHEDULING.............................................. 1

Effective Management Control Through Planning..................................................... 2

Evaluate Performance Against Project Baseline............................................. 3

Establish Trends ............................................................................................ 4

Actions to Enhance Planning Performance..................................................... 4

Schedule Control During Engineering and Procurement............................................ 5

Project Milestone Schedule............................................................................ 5

Drawing Control............................................................................................ 6

Purchase Requisition / Purchase Order Control.............................................. 6

Schedule Control During Construction...................................................................... 6

Project Milestone Schedule............................................................................ 6

Detailed Logic Network Diagrams................................................................. 7

Summary Level Network Diagram ................................................................ 7

The Master Contracting Plan..................................................................................... 7

CONTROLLING THE PROJECT SCHEDULE USING THE.............................................. 8

PROJECT EXECUTION PLAN........................................................................................... 8

Description of Project Execution Plan Contents ........................................................ 9

Approval Sheet.............................................................................................. 9

Project Summary ........................................................................................... 9

Contracting Plan ............................................................................................ 9

Material Procurement Plan ...........................................................................10

Project Cost and Funding..............................................................................10

Project Execution Sequence..........................................................................11

Project Milestone Schedule...........................................................................11

Project Organization and Interfaces ..............................................................11

Areas of Concern..........................................................................................11

Others...........................................................................................................11

Applying the Project Execution Plan as a Control Tool ............................................12

TRACKING SCHEDULE PERFORMANCE USING THE PROJECT ...............................13

Saudi Aramco DeskTop Standards

Engineering Encyclopedia Project Management

Controlling The Project Schedule

COMPLETION SCHEDULE ..............................................................................................13

Introduction to the Project Completion Schedule Report ..........................................13

Projects to be Reported ............................................................................................13

Frequency & Report Period......................................................................................13

Approvals and Responsibilities ................................................................................14

Project Completion Schedule Information ................................................................14

Detailed Engineering ....................................................................................14

DC Material Procurement.............................................................................15

Construction Progress...................................................................................16

Major Project Milestones..............................................................................16

WORK AID: GUIDELINES FOR PREPARING A PROJECT MILESTONE

SCHEDULE........................................................................................................................18

GLOSSARY........................................................................................................................19

ADDENDUM......................................................................................................................21

Saudi Aramco DeskTop Standards

Engineering Encyclopedia Project Management

Controlling The Project Schedule

PURPOSE OF PROJECT PLANNING AND SCHEDULING

Project scheduling, and project planning in general, is an integral part of project management and

controls. The planning process entails:

• Establishing a plan that is specific to the project goals and objectives

• Executing the plan to achieve the objectives

• Monitoring progress against the plan

• Taking corrective action when necessary

The essentials of planning and schedule control are outlined in the following paragraphs:

• The principal element of the project planning function is the Project Execution

Plan (PEP), which is based on the intended project execution sequence. The

PEP, which is prepared at the beginning of the project, provides the guidelines

that are used in the development and implementation of other detailed plans.

• The second level of planning and scheduling control is the production of

detailed CPM networks, project milestone schedules, materials arrival

schedules, etc. These items give recognition to the PEP and the

interrelationships among project activities by the contractors, equipment

manufacturers, material suppliers, subcontractors, the proponent, and others.

By relating all the activities in a logical sequence, the work is scheduled so that

the best overall completion plan is obtained. This schedule is the single most

important tool that Saudi Aramco has for providing visibility and exercising

control. The schedule should be:

– Detailed to provide a clear understanding of the critical and subcritical

paths covering all project elements

– A detailed step-by-step prediction of how the project will be executed

consistent with the abilities to track all functions and to measure

performance

– Consistent with the project budget, reflecting productivity forecasts,

manpower requirements, and realistic durations

Fundamentally, there are two categories of planning and scheduling:

1. Requirements that establish the content of the schedules based on job

specifications, division of responsibility, administration, procurement, tracking,

cost control, and monitoring.

Saudi Aramco DeskTop Standards 1

Engineering Encyclopedia Project Management

Controlling The Project Schedule

2. Techniques that include the instruments that are used to provide scheduling

outputs such as CPM networks, time-scaled summary level networks, computer

or manual analysis reports, manpower loading charts, and planned progress

curves.

Ultimately, the Saudi Aramco Project Manager (PM) has the responsibility to make sure that

planning and schedule control is fully implemented on large complex projects. The SAPMT

usually includes a Planning/Scheduling Engineer (PSE) devoted full time to schedule control and

appraisal. For projects that have no PSE, these duties should be assigned to one of the Project

Engineers. In either case, the Project Support Services Division can provide qualified personnel

for consultation on schedule related matters through periodic visits to the contractor's

engineering and/or field offices.

Effective Management Control Through Planning

Although the words “planning” and “scheduling” have been used interchangeably, they have

different meanings in project management applications. Planning is the process of breaking a

project down into specific work elements and of defining the sequence in which these work

elements should be performed for optimum cost and time performance. Scheduling is the

process of defining the time frames in which each work element should be performed, thus

determining the start and completion dates of a project.

Effective planning and scheduling, along with cost control and progress reporting are four major

elements that are used to ensure optimum performance in the execution of a project. The

planning and scheduling functions are disciplined approaches to project management. Without

planning and scheduling implementation, there can be no effective controls. The proper

implementation involves establishing a PEP and detailed schedules with specific objectives,

working the plans to achieve them, and taking corrective actions if deviations from the plan

jeopardize the schedule.

The application of planning and scheduling techniques on a project ensures that the project work

is properly scoped, that the sequence of activities is established, and that the required resources

are assigned. The application of planning and scheduling techniques would make the project

proceed in an orderly fashion without experimentation and constant changes in the work

sequence.

There are four basic requirements that are necessary in implementing an effective planning

function:

1. An experienced organization with appropriate support services

2. A well-defined planning and control system

Saudi Aramco DeskTop Standards 2

Engineering Encyclopedia Project Management

Controlling The Project Schedule

3. The implementation of integrated cost and schedule functions

4. Management support and "buy-in" from all participants

During the conceptual phase of a project, approximate project duration and completion dates are

developed by the Operations Proponent, Facilities Planning Department, and the Project

Management Departments. At Project Proposal completion, a reliable and definitive PEP should

be available. The Project Manager should satisfy himself that all of the milestone dates and

predicted completion dates are realistic, achievable, and consistent with the cost/schedule criteria

that were established for the project.

Due to the implementation of detailed logic networks, resource loading, and the calculation of

start and finish dates, the planning function helps to validate project completion dates. The

scheduling function helps to identify any unrealistic durations or dates for individual activities,

major milestones, and/or project completion dates.

Evaluate Performance Against Project Baseline

Once the detailed plans are developed, the evaluation of actual performance against the project

baseline can be initiated. This process includes the following tasks:

• Tracking actual performance against the baseline

• Identifying actual and potential problems

• Evaluating the impacts of the problems

• Recommending and implementing corrective solutions

• Identifying opportunities to enhance performance

The project's planning staff is generally regarded as an information-gathering and dissemination

service. They are responsible for collecting and analyzing actual performance data in order to

identify any actual or potential deviations from the project baselines. The Project Engineer

should continually use planning documents and the actual status to assess the impacts on project

performance and to make timely decisions that keep the project on track.

There are a variety of ways to show the actual project status, the culmination of which is the

development of project status reports from which project control strategies can be implemented

by the management. The actual project performance is constantly compared with the project

baselines. The exceptions are identified and analyzed. Corrective actions are implemented to

ensure project objectives are achieved.

Saudi Aramco DeskTop Standards 3

Engineering Encyclopedia Project Management

Controlling The Project Schedule

Establish Trends

The implementation of an effective planning function on a capital project helps to establish

performance trends during the execution phase. By instituting systems that accurately assess the

project status and monitor the schedule performance, the Project Engineer can identify the

project trends. When the actual project data is compared with the project baselines, any

deviations will become evident. By analyzing these deviations and identifying their causes, the

Project Engineer can determine the underlying trends. Once the trends are identified, the Project

Engineer can implement corrective actions to keep the project on track. The trends on a typical

project can be:

• Poor productivity

• Delays in receipt of vendor drawings

• Shortages of qualified personnel

• Rework and misfit problems

• Schedule delays and missed milestones

• Schedule conflicts among contractors

• Excessive work scope changes

A good planning function should be able to identify these trends early enough so that the

SAPMT can institute necessary actions prior to any major impact on the project's overall

performance.

Actions to Enhance Planning Performance

The SAPMT, working with the contractors, should strive to improve the planning performance

on a Saudi Aramco project. The improvement of the planning performance has two major

benefits:

1. Improved planning and control information

2. Improved forecasting of performance

As the project progresses from the Project Preliminary Engineering Phase to more definitive

execution phases, the need for an effective planning function increases. By improving the

planning function, project management is assured of accurate project data for prudent decision

making.

Saudi Aramco DeskTop Standards 4

Engineering Encyclopedia Project Management

Controlling The Project Schedule

To achieve enhanced planning performance, it is essential that the contractors have strong

planning capabilities which are supported by an effective planning and control system. The

contractor's project control staff should be experienced and knowledgeable in modern planning

and scheduling techniques. The SAPMT and the contractors should take the following actions in

order to enhance the planning performance on Saudi Aramco projects:

• Early and complete definition of the project scope

• Compliance with the PEP

• Development of a Work Breakdown Structure

• Implementation of resource loading and leveling techniques

• Close monitoring of critical and near-critical path activities

• The receipt of "buy-ins" from all project participants

• The establishment of accurate progress reporting techniques

• Making the planning system responsive to changes

• Constantly seeking areas to enhance project performance

Schedule Control During Engineering and Procurement

During engineering—whether it is detailed or preliminary/project proposal development — the

steps necessary to control the project schedule are the same.

Project Milestone Schedule

The Project Milestone Schedule is used for the entire duration of a project. The Project

Milestone Schedule includes milestones for each phase of the project; therefore, it is one of the

schedule control documents that are used during the engineering phase. The Project Completion

Schedule is the control schedule and it is discussed later.

The Project Milestone Schedule identifies each major activity within the overall project time

frame. The format for preparing the Project Milestone Schedule (Addendum 1) is that of a bar

chart. The project activities that are shown on the Project Milestone Schedule include project

development and design milestones, major equipment procurement, and the construction phase.

It is normally developed by Saudi Aramco's Project Scheduling Engineer.

Saudi Aramco DeskTop Standards 5

Engineering Encyclopedia Project Management

Controlling The Project Schedule

Drawing Control

The Drawing Control is the primary document that is used during the engineering phase to

understand schedule and engineering progress. The Drawing Control (Addendum 2) must define

every drawing and specification that needs to be produced to complete the scope of work. Many

contractor’s Drawing Controls may also define the other deliverables, which gives the Project

Engineer a complete understanding of the deliverables within one document.

As a result, the Drawing Control is a powerful control tool that should be studied by the Project

Engineer. The Project Engineer should insist that the contractor accurately and consciously

update the Drawing Control on a regular basis.

It is important for the Project Engineer to insist that the contractor identifies the man-hours that

are required to complete each of the deliverables when the updates are completed. With this

information, the Project Engineer can assess the man-hours that are required to complete the

work. He can compare the required man-hours with the remaining service order man-hours.

Obviously, this is a great control tool.

Purchase Requisition / Purchase Order Control

During detailed engineering, the Project Engineer has the added responsibility of ordering

materials. In order to control the schedule of materials during detailed engineering, the

contractor prepares a purchase requisition control log. He also prepares a purchase order control

log. Refer to Module 5 for more details on these control tools. The purpose of these control

tools is to assure that every activity during the procurement process is scheduled for a specific

date . The actual date is tracked and compared to the plan. This comparison is extremely

important because the delivery of the materials at the site will be determined by the Project

Engineer’s actions at the early stages of the project. If the project team and contractor

consistently miss the planned dates, the Project Engineer should take a closer look at the plan

and he should take the appropriate action. It may be absolutely essential that the dates as

planned must be kept and personnel adjustments may be necessary.

It is not necessary to prepare a detailed logic network for engineering. Engineering does not lend

itself to this type of control document. The two documents discussed above are completely

adequate for the proper control of engineering activates .

Schedule Control During Construction

Project Milestone Schedule

The Project Milestone Schedule also identifies project milestones for the construction phase;

therefore, it is a control tool for the construction phase.

Saudi Aramco DeskTop Standards 6

Engineering Encyclopedia Project Management

Controlling The Project Schedule

Detailed Logic Network Diagrams

In order to properly control schedule for the construction phase, the Project Engineer should

insist that a Detailed Logic Network Diagram is prepared by the Construction Contractor. The

Detailed Logic Network Diagram should be a Critical Path Method (CPM) diagram. The level

of detail that is needed for the CPM depends on the complexity of the project. The Project

Engineer should prevent the contractor from preparing a CPM that is too complex to be analyzed

or understood. A CPM that is too complex is useless and it is a waste of money to prepare. The

CPM can always be expanded later when additional details become available. Another useful

technique is to expand certain activities outside the CPM if additional details would be helpful to

understand a particular set of activities. This technique allows better control the schedule.

Detailed Logic Network Diagrams are constructed to show the order in which the contractor

proposes to carry out the work and to indicate the restrictions of access and availability of work

areas, and the availability and use of manpower, material and scheduling, coordinating and

performing the work under contract (including all activities of subcontractors, equipment

vendors and suppliers).

Summary Level Network Diagram

The Detailed Logic Network Diagram is summarized in a Summary Level Network Diagram.

Usually, the Summary Level Network Diagram is prepared first; however, it usually requires

some adjustments after the Detailed diagram is prepared. The Summary Level Network Diagram

is in the form of a time-scaled summary CPM. The network consists of the major project

development, engineering, procurement and construction activities to be performed (usually 50 -

200 activities), including durations, major constraints, and inter-dependencies. The Summary

Level Network Diagram establishes the control points that are reflected in the Project Milestone

Schedule. The Summary Level Network Diagram also provides overall schedule visibility with

regard to the Detailed Logic Network Diagram.

The Master Contracting Plan

The Master Contracting Plan defines all of the contracts that are required to accomplish a

particular project or ER. The Master Contracting Plan is approved by the Services Review

Committee (SRC). As each contract in the Master Contracting Plan is ready to be awarded, the

SRC is advised of the recommended successful bidder and it is asked to approve the

recommendation in reference to the approved Master Contracting Plan. In this manner, the SRC

has the ability to oversee the consistency of the company contracting strategy and policy.

The Master Contracting Plan preparation should be coordinated with the Contracting

Representative during the development of the PEP.

Saudi Aramco DeskTop Standards 7

Engineering Encyclopedia Project Management

Controlling The Project Schedule

CONTROLLING THE PROJECT SCHEDULE USING THE

PROJECT EXECUTION PLAN

The Project Execution Plan defines the SAPMT’s plans to execute the project. A PEP on a Saudi

Aramco Project must have the following contents as described in SAEP-12 (Addendum 3):

1. Project Summary

2. Contracting Plan

3. Material Procurement Plan

4. Project Cost and Funding

5. Project Execution Sequence

6. Project Milestone Schedule

7. Project Responsibility Matrix

8. Project Interface/SAPMT Personnel

9. Areas of Concern

10. Exhibits

In addition to the above contents, the PEP must have two additional sheets in the front, namely:

1. Approval Sheet

2. Revision Control

Depending upon the size, complexity, and execution strategy, additional sections can be added to

a PEP. If the Project Manager adds other sections to a PEP, he must demonstrate that the

additional sections are unique and that they are as important as the other sections. The Project

Managers may consider any of the following additional sections depending upon the unique

characteristics of the project:

• Environmental Plan

• Quality Plan

• Safety Plan

• Technology and Process Licenser Information

• Project Construction Execution Strategy

• Project Controls Plan

Saudi Aramco DeskTop Standards 8

Engineering Encyclopedia Project Management

Controlling The Project Schedule

Description of Project Execution Plan Contents

Approval Sheet

Each PEP must have an approval sheet with signatures from the Project Manager to the final

approval of the Vice President, Project Management. This document is intended to get

commitment and approval from various management levels of the Saudi Aramco Project

Management Organization and the project Proponent.

Project Summary

The Project Summary provides a brief synopsis and the objectives of the Project. The following

items are incorporated into the Project Summary:

Project Overview - It summarizes the purpose of the work and explains why it is being done

(e.g., to increase production capacity of a plant by 100,000 barrels/day).

Design Basis - It provides a synopsis of how the work is to be accomplished by summarizing the

project's basis of design as described in the current scoping paper (e.g., to increase production by

expanding existing facilities or by constructing a new plant).

Project Scope - It briefly describes what is to be accomplished by the project and the physical

facilities that are being built, demolished, revamped, etc. This information summarizes the work

as described in the current Design Basis Scoping Paper and/or in the Project Proposal scope of

work.

Contracting Plan

A contracting plan is a set of interrelated contracts or amendments that are prepared for each

proposed contractor. The contracting plan is the result of an analysis and evaluation of the

various contracting alternatives for the work or the interrelated work to be contracted. The

contracting plan is tailored to the specific work needs of each contract or amendment. The

contracting plan takes into account the economics of various contracting alternatives and it

assesses scheduling, operating costs, influences of location, type of work, and size of the work in

order to develop a recommended course of action. Alternative contracting routes, which could be

used if market conditions or other factors preclude using the preferred route, should also be

considered.

The basic contracting plan should accomplish the following:

• Provide a concise description of work to be contracted.

• Provide an analysis of each contract request for each interrelated series of

contract requests, including alternatives.

Saudi Aramco DeskTop Standards 9

Engineering Encyclopedia Project Management

Controlling The Project Schedule

• Provide the justification for the proposed method of contract procurement,

including an explanation of the method of contractor screening to develop a

slate of bidders.

• Present a contract procurement schedule, which sets forth all contracting

activities through award.

• Appropriate contracting milestones in procuring services of various contractors:

- Expenditure Request Approval (ERA)

- Preparation and Issuance of Bid Packages

- Contract Award

- Mechanical Completion

- On-Stream

• Determine the type of contract to be used and whether the contractor will be

permitted to subcontract portions of the work.

• Provide written documentation that supports all of the above. If applicable, an

overall economic analysis in support of the proposed contract type, schedule,

and cost estimate should be included.

The actual amount of data that is obtained, analyzed, and evaluated for each contracting plan

depends on the size, schedule, and complexity of the work to be contracted. For large contracts,

the amount of detailed information required is usually extensive.

Material Procurement Plan

The Material Procurement Plan discusses major considerations concerning project materials and

their procurement and movement. It should state the proposed procurement and traffic

responsibilities of Saudi Aramco and the contractor. Details of the items are included in Module

5.

The materials plan should prepare a listing of materials identified as "long lead items" and what

actions will be taken to ensure that their field-need dates will be met.

Project Cost and Funding

The PEP describes preliminary cost estimates and how they will be monitored and updated until

the time of Expenditure Request Approval (ERA). In addition, the PEP defines what procedures

will be implemented to ensure proper reporting and control of the Project Budget throughout the

life of the project.

Saudi Aramco DeskTop Standards 10

Engineering Encyclopedia Project Management

Controlling The Project Schedule

The PEP provides an estimated timing and the amount of Preliminary Engineering Funds (TC-

68) that are required for items such as studies, specifications, soil investigations, and the Project

Proposal.

Project Execution Sequence

The Project Execution Sequence will be in the form of a time-scaled logic diagram depicting the

major activities and milestones required to successfully complete a project. Emphasis shall be

placed on the front-end engineering, materials, and Contracting Development Activities.

Project Milestone Schedule

The Project Milestone Schedule will be in the form of a bar chart summarizing the major project

activities and project milestones including Contracting Development Activities.

Project Organization and Interfaces

This section addresses the responsibilities of SAPMT personnel and their interaction with others

involved in the project.

Areas of Concern

This section identifies project concerns where corresponding plans of action or solutions have

not been completely defined. Any unusual efforts or procedures that are required for successful

project completion should be included in this section. Also, any anticipated problems that may

affect operability, cost or schedule should be highlighted in this section.

Engineering Design - This section focuses on factors that can influence the project design (e.g.,

operations manning philosophy, operating reliability, capital versus operating costs, material

sourcing premiums, labor premiums, location constraints, etc.). Engineering Design also

provides action plans that address these concerns.

Construction - This section is used to promote factors that can influence the project construction

(e.g., site location, security, other projects, etc.). It provides action plans that address these

concerns.

Company Interface - This section summarizes other Saudi Aramco activities that will be

affected by the project (e.g., maintaining minimum production rates at existing facilities).

Others

This section addresses any other known factors that may impact efficient execution of the project

and provide plans that address the concerns (e.g., SAPMT staffing restraints).

Saudi Aramco DeskTop Standards 11

Engineering Encyclopedia Project Management

Controlling The Project Schedule

Applying the Project Execution Plan as a Control Tool

The PEP is the primary planning document that is prepared by the SAPMT to execute the

project. As such, it represents the best thinking of the SAPMT about the project. The Project

Engineer should use the PEP to define the control tools that are needed to effectively control the

project schedule.

The PEP reflects the SAPMT's schedule plan to execute the project. The PEP becomes the

guideline document for all of the other detailed planning by the SAPMT. The SAPMT can apply

the project milestone schedule dates as control points when it measures the project performance.

As the project progresses, the project's actual performance is compared with the information that

is included in the PEP. Any significant deviations that may effect any of the major milestones or

the project on-stream dates are quickly identified and reported BY the SAPMT. Based on the

magnitude of any deviation, the SAPMT may initiate necessary corrective actions to correct the

problems and get the project back on schedule.

The PEP identifies the issues that are important to the project so that the Project Engineer can

define the quality of control required for each phase of the project.

Saudi Aramco DeskTop Standards 12

Engineering Encyclopedia Project Management

Controlling The Project Schedule

TRACKING SCHEDULE PERFORMANCE USING THE PROJECT

COMPLETION SCHEDULE

Introduction to the Project Completion Schedule Report

A Project Completion Schedule (PCS) is the monthly progress plan for detail engineering,

material procurement, and construction. The PCS is prepared on Saudi Aramco Form 6974

(Addendum 4). The PCS is prepared immediately after approval of Prior Approval Expenditure

Request (PAER) funds or full ERA because the milestone dates are required for Monthly

Progress Update (MPU) and Budget Item Summary Report (BISR) reporting.

Projects to be Reported

The SAPMT prepares a PCS for all projects that are under the control of Engineering & Project

Management that have approved PAER or full ER funding. The Job Orders (JOs) within a BI

that fall under a single Project Manager normally constitute the scope of work, which is covered

by one PCS.

When the JO is assigned to another department or Project Manager, a separate PCS is prepared

and updated by the assigned Project Manager. These PCSs are submitted to the Project Manager

who is responsible for the BI and they are to be incorporated into the total project PCS. The

overall progress plan for total BI scope is reflected on one PCS and it is approved by the

responsible Manager.

Frequency & Report Period

The initial PCS (revision 0) should be submitted with the first MPU. If the original PCS

completion dates for detail engineering, material procurement, or construction experience a slip

but do not change the BI on-stream date, a revised PCS may be prepared at the discretion of the

Project Manager who is responsible for the BI.

A revised PCS must be prepared and submitted as soon as it becomes apparent that the BI on-

stream date will be impacted by one month or more. The revised PCS should be prepared in

support of the Project Change Request (PCR). Upon approval of the PCR by Project

Management and the Proponent, the responsible Project Manager should submit the revised PCS

along with the approved PCR to his Department Manager for approval.

Saudi Aramco DeskTop Standards 13

Engineering Encyclopedia Project Management

Controlling The Project Schedule

Approvals and Responsibilities

All PCSs that are submitted should be approved at the appropriate level. Approvals are required

as follows:

• The Executive Director must approve the original PCS and revisions to the PCS

that affect the BI on-stream date of dependent BI/JO on-stream dates by one

month.

• The Department Manager must approve any revisions to the PCS that does not

affect a BI on-stream date or dependent BI/JO on-stream dates.

Project Completion Schedule Information

After the approval of ER funds, the PCS report is developed by the SAPMT to establish project

milestone dates. It is imperative that the information that is contained in the PCS is accurate

and realistic because the PCS establishes the project schedule baseline. The project status

reports, such as MPU reports, compare the actual performance to the information that was

established in the original PCS (unless it has been revised). The PCS revisions have to be

approved by the Project Management Executive Director and the Vice President.

The PCS contains projected percent completions in the following three major work categories of

a project:

• Detailed Engineering

• Direct Charge (DC) Material Procurement

• Construction

Detailed Engineering

The PCS report is a useful document for establishing the project's schedule baseline. Based on

the SAPMT approved engineering schedule, the planned detail engineering progress percent

completion's are shown on the PCS and the MPU. Every month, the actual progress is tracked

against the established progress baselines.

After the award of the engineering contract, the contractor is expected to develop detailed

engineering schedules. Based on the SAPMT-approved engineering schedules and the

associated progress curves, information that is related to detailed engineering planned percent

completion's can be listed in the PCS. To complete the detailed engineering plan section of the

PCS, the Project Engineer should enter the planned cumulative monthly progress for detail

engineering, i.e., all engineering accomplished under TC-60 funds. Both original and current

progress percentages must be shown on a revised PCS.

Saudi Aramco DeskTop Standards 14

Engineering Encyclopedia Project Management

Controlling The Project Schedule

Detailed Engineering Progress - Engineering that is accomplished with TC-68 funds will not

be included as part of the detailed engineering in the PCS. The PCS starting point for progress

measurement of detailed engineering will be zero and it will begin the month following ER

approval. Detailed engineering includes all design office activities to be accomplished with TC-

60 funds that are required to achieve mechanical completion. Detailed engineering progress of

95% should be achieved no later than mechanical completion and will include completion of all

drawings, bid packages, requisitions, start-up and operating manuals, purchase orders, Saudi

Aramco Material System Specification (SAMSS) allocations, and other miscellaneous

engineering and related activities. The final 5% progress consists of design office activities that

are not easily measured and that do not impact mechanical completion, e.g., technical support to

construction and commissioning, preparation of as-built drawings (if done in the design office),

and the final design and procurement close-out activities, including demobilization of the

contractor engineering office. The activities that are performed during the last 5% of detailed

engineering are expected to not require more than 5% of the total engineering man-hour budget.

DC Material Procurement

The contractor's detailed engineering schedule is also used to identify information that is related

to procurement percent completions for DC materials. The cumulative monthly progress for DC

material procurement is indicated in terms of cumulative percentage complete.

For an initial PCS, the planned cumulative monthly progress percentages are entered in the

Original line in the appropriate month. Revised cumulative progress percentages are entered in

the Current line when updating the PCS.

Both original and current cumulative progress percentages are shown on the revised PCS. When

a revised PCS is issued, actual cumulative percentages complete are shown with an "(A)"

notation. In both the Original and Current Lines, the planned cumulative monthly progress

percentages are entered as calculated amounts. Those amounts are calculated as:

[(The percent of purchase requisitions that are released to purchasing) X 20%] +

[(The percent of purchase orders that are placed) X 40%] + [(The percent of Materials

"at site" in US dollars) X 40%]

The term "at site" means the material and equipment has arrived at the site in Saudi Arabia. The

formula shows that weighting is 20% for the purchase requisitions released, 40% for the number

of purchase orders placed, and 40% for the materials that are at the site.

DC material procurement activity begins with the SAMPT’s technical approval of the purchase

requisition and procurement is complete when the material is received at the site. Note that

technical bid evaluation and vendor drawing review/approval are engineering functions;

therefore, man-hours that are associated with these tasks are considered an engineering function

rather than a DC material-procurement function.

Saudi Aramco DeskTop Standards 15

Engineering Encyclopedia Project Management

Controlling The Project Schedule

DC material procurement activities that are performed in an engineering office and are

considered as DC material functions include buying, expediting, and inspection. Traffic, which is

responsible for the transportation of material from a vendor/shop/harbor to the In-Kingdom port,

is also included if it is performed by the contractor.

The SAPMT tracks the actual schedule performance against the plan and identifies any

deviations so that it can implement actions to correct any delays.

Construction Progress

During the initial stages of the project, the construction schedule information is relatively scarce.

Although the major construction milestones have been established, the Project Engineer

completes the construction section of the PCS by using the Overall Project Schedule to develop

construction percent completions. The monthly progress for construction activity is indicated in

terms of cumulative percentage complete. In a PCS, all percentages are stated in whole numbers

and all dates are stated in numeric month and year.

For the initial PCS, the cumulative monthly progress percentages are entered in the Original line

in the appropriate month. When the PCS is updated, revised cumulative monthly progress

percentages are entered in the Current line. Both original and current cumulative progress

percentages are shown in the revised PCS. When a revised PCS is issued, actual cumulative

percentages complete are shown with an "(A)" notation.

The construction percent complete is a weighted physical measurement of construction progress.

The method of measuring progress varies depending on the type of project and the construction

discipline. Nevertheless, the percent complete must be accurate and quantified, i.e., based on the

quantify of equipment and/or material that is actually installed at the construction jobsite.

Major Project Milestones

The SAPMT must identify major project milestones to track the project schedule performance.

The major project milestones, which are listed below, are common to most capital projects.

Some projects may differ in the order that these milestones occur. The acronyms that are

shown are used to facilitate input into the PCS report. If additional milestones are added on the

PCS form, the SAPMT should assign an acronym to them.

Saudi Aramco DeskTop Standards 16

Engineering Encyclopedia Project Management

Controlling The Project Schedule

ERA Expenditure Request Approval

DE-CA Design Engineering-Contract Award

LSTK-BPC Lump Sum Turnkey-Bid Package Complete

PB-BPC Procure Build-Bid Package Complete

PB-CA Procure Build-Contract Award

LSTK-CA Lump Sum Turnkey-Contract Award

CONST-BPC Construction Bid Package Complete

CONST-CA Construction Contract Award

CS Construction Start

MC Mechanical Completion

OS On-stream Date

Once these milestones dates are established, the SAPMT can track the actual schedule

performance. Any slippages from these milestones should be carefully monitored, and their

impact on the on-stream date must be analyzed and reported to the Project Engineer.

Saudi Aramco DeskTop Standards 17

Engineering Encyclopedia Project Management

Controlling The Project Schedule

WORK AID: GUIDELINES FOR PREPARING A PROJECT MILESTONE

SCHEDULE

The Work Aid provides guidelines in preparing a PMS.

Guidelines:

1. Review the PMS for reasonableness of duration's for each project phase.

2. Review the PMS to assure that the critical milestones are identified.

3. Examine the materials lead times to assure that they support the contracting plan.

4. Examine the materials delivery times to assure that they support the construction

schedule.

5. Identify any critical path activities which require out of policy procedures to be used.

6. Examine the overall schedule to assure that it supports the project funding requirements.

Saudi Aramco DeskTop Standards 18

Engineering Encyclopedia Project Management

Controlling The Project Schedule

GLOSSARY

AFE, Form 6035-A Authorization for Expenditure. An AFE provides approval to a

SAPMT to commit and expend TC-60 funds for funded projects.

BI Budget item. It is applicable to projects prior to TC-60 funding.

CONST-BPC Construction Bid Package Complete

CONST-CA Construction Contract Award

CS Construction Start

DE-CA Design Engineering-Contract Award

Drawing Control The primary document that is used during the engineering phase

to understand schedule and engineering progress.

ERA Expenditure Request Approval. It is used in connection with the

month and year in which approval is given by EXCOM or the

board of directors. An approved ER and AFE are the authority to

commit and expend Company resources for the purchase and/or

construction of a facility.

ERA Expenditure Request Approval

Form 56D An expenditure request form (Saudi Aramco Form 56D) that

details the capital costs by cost element and job order/phase.

JO Job Order. A specific part of a budget item.

LSTK-BPC Lump Sum Turnkey-Bid Package Complete

LSTK-CA Lump Sum Turnkey-Contract Award

MC Mechanical Completion

OS On-stream Date

PAER Prior Approval Expenditure Request.

PB-BPC Procure Build-Bid Package Complete

PB-CA Procure Build-Contract Award

PCR A Project Change Request is a document that is issued to reflect

changes to scope, cost, and/or schedule.

PEP Project Execution Plan

Saudi Aramco DeskTop Standards 19

Engineering Encyclopedia Project Management

Controlling The Project Schedule

PSE Planning/Scheduling Engineer

Project Proposal It provides the final design basis from which an ER is developed

and from which all approved scope changes are measured.

TC-60 An account code that is used in connection with PAER or fully-

funded ER capital projects.

TC-68 An account code that is used in connection with project proposal

activities prior to partial or full funding.

Saudi Aramco DeskTop Standards 20

Engineering Encyclopedia Project Management

Controlling The Project Schedule

ADDENDUM

1. Project Milestone Schedule

2. Drawing Control

3. SAEP-12

4. Project Completion Schedule

Saudi Aramco DeskTop Standards 21

Engineering Encyclopedia Project Management

Controlling The Project Schedule

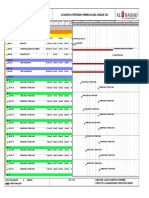

ADDENDUM 1: Project Milestone Schedule

Saudi Aramco DeskTop Standards 22

Engineering Encyclopedia Project Management

Controlling The Project Schedule

ADDENDUM 2: Drawing Control

Saudi Aramco DeskTop Standards 23

Engineering Encyclopedia Project Management

Controlling The Project Schedule

ADDENDUM 3: SAEP-12

Saudi Aramco DeskTop Standards 24

Engineering Encyclopedia Project Management

Controlling The Project Schedule

ADDENDUM 3: SAEP-12

Saudi Aramco DeskTop Standards 25

Engineering Encyclopedia Project Management

Controlling The Project Schedule

ADDENDUM 3: SAEP-12

Saudi Aramco DeskTop Standards 26

Engineering Encyclopedia Project Management

Controlling The Project Schedule

ADDENDUM 3: SAEP-12

Saudi Aramco DeskTop Standards 27

Engineering Encyclopedia Project Management

Controlling The Project Schedule

ADDENDUM 3: SAEP-12

Saudi Aramco DeskTop Standards 28

Engineering Encyclopedia Project Management

Controlling The Project Schedule

ADDENDUM 3: SAEP-12

Saudi Aramco DeskTop Standards 29

Engineering Encyclopedia Project Management

Controlling The Project Schedule

ADDENDUM 3: SAEP-12

Saudi Aramco DeskTop Standards 30

Engineering Encyclopedia Project Management

Controlling The Project Schedule

ADDENDUM 3: SAEP-12

Saudi Aramco DeskTop Standards 31

Engineering Encyclopedia Project Management

Controlling The Project Schedule

ADDENDUM 3: SAEP-12

Saudi Aramco DeskTop Standards 32

Engineering Encyclopedia Project Management

Controlling The Project Schedule

ADDENDUM 3: SAEP-12

Saudi Aramco DeskTop Standards 33

Engineering Encyclopedia Project Management

Controlling The Project Schedule

ADDENDUM 3: SAEP-12

Saudi Aramco DeskTop Standards 34

Engineering Encyclopedia Project Management

Controlling The Project Schedule

ADDENDUM 3: SAEP-12

Saudi Aramco DeskTop Standards 35

Engineering Encyclopedia Project Management

Controlling The Project Schedule

ADDENDUM 3: SAEP-12

Saudi Aramco DeskTop Standards 36

Engineering Encyclopedia Project Management

Controlling The Project Schedule

ADDENDUM 3: SAEP-12

Saudi Aramco DeskTop Standards 37

Engineering Encyclopedia Project Management

Controlling The Project Schedule

ADDENDUM 4: Project completion schedule

Saudi Aramco DeskTop Standards 38

You might also like

- Project Cost Estimating Manual: Third Edition December 2007Document83 pagesProject Cost Estimating Manual: Third Edition December 2007Osama El-ShafieyNo ratings yet

- Earned Value MethodDocument69 pagesEarned Value MethodNasser AsainNo ratings yet

- S 000 1630 0004 - A Procedure For Subcontractor ReportingDocument10 pagesS 000 1630 0004 - A Procedure For Subcontractor ReportinghunghoanglongNo ratings yet

- Verifications and Validations in Finite Element Analysis (FEA)Document23 pagesVerifications and Validations in Finite Element Analysis (FEA)raasisNo ratings yet

- PMT 20108Document52 pagesPMT 20108Yousef Adel HassanenNo ratings yet

- Global SCANDocument187 pagesGlobal SCANLuis GonzalezNo ratings yet

- COVER Building ServiceDocument12 pagesCOVER Building ServiceMaizan SofiaNo ratings yet

- Saudi Aramco Contracting Process GuideDocument17 pagesSaudi Aramco Contracting Process GuideYousef Adel HassanenNo ratings yet

- PMT 30105Document29 pagesPMT 30105Yousef Adel HassanenNo ratings yet

- PMT 30101Document37 pagesPMT 30101Yousef Adel HassanenNo ratings yet

- MaxBulk Mailer™ MAXMAILER USER GUIDEDocument19 pagesMaxBulk Mailer™ MAXMAILER USER GUIDEhbmarufuNo ratings yet

- PMT 30108Document30 pagesPMT 30108Yousef Adel HassanenNo ratings yet

- How To Get Costing of Labor?: Preparing Detailed EstimateDocument21 pagesHow To Get Costing of Labor?: Preparing Detailed Estimatecass0608No ratings yet

- Tkp-A SD Piping ScaffDocument54 pagesTkp-A SD Piping Scaffanjangandak2932100% (1)

- PMT 30104Document22 pagesPMT 30104Yousef Adel HassanenNo ratings yet

- Sample WeightageDocument3 pagesSample WeightageAbdul Nafeeq AliNo ratings yet

- Laporan Project Irsyad 20230712 1734hrs With SignDocument76 pagesLaporan Project Irsyad 20230712 1734hrs With SignAbdul FatahNo ratings yet

- Field Schedule Control ProcedureDocument37 pagesField Schedule Control Procedureคุณพ่อน้อง บิ๊กบอสNo ratings yet

- Construction Planning: Choosing Tech and Defining TasksDocument198 pagesConstruction Planning: Choosing Tech and Defining TasksHajarath Prasad AbburuNo ratings yet

- NTPC Project MonitoringDocument38 pagesNTPC Project MonitoringadehriyaNo ratings yet

- Guidelines For The Preparation of Project Plans: orDocument27 pagesGuidelines For The Preparation of Project Plans: orIqbal BaigNo ratings yet

- Productivity Claims: Contracts and Claims DepartmentDocument98 pagesProductivity Claims: Contracts and Claims DepartmentFatmah Ashraf ElwardagyNo ratings yet

- S08 - Cash Flow StatementDocument55 pagesS08 - Cash Flow StatementYassin DyabNo ratings yet

- CM PE 305 Project Monthly ReportDocument15 pagesCM PE 305 Project Monthly ReportVinh Do ThanhNo ratings yet

- 10 Estimation Function PT Q2Document61 pages10 Estimation Function PT Q2Varundeep SinghalNo ratings yet

- Unit Rates & Cost Establishment For SSIP AGPDocument65 pagesUnit Rates & Cost Establishment For SSIP AGPketemaNo ratings yet

- Cost BudgetingDocument16 pagesCost Budgetinghappy tubeNo ratings yet

- KBR Infrastructure Controls Planning & SchedulingDocument4 pagesKBR Infrastructure Controls Planning & SchedulingkamlNo ratings yet

- Construction Delays: Understanding Project Delays and How to Analyze Their ImpactDocument2 pagesConstruction Delays: Understanding Project Delays and How to Analyze Their ImpactAllen JDanielNo ratings yet

- Chapter 3 Determine BudgetDocument26 pagesChapter 3 Determine BudgettewodrosNo ratings yet

- PM 6Document33 pagesPM 6Ahmed SaeedNo ratings yet

- Project Controls Major Requirements-RevisedDocument7 pagesProject Controls Major Requirements-RevisedjigsawibNo ratings yet

- MPR Month YearDocument58 pagesMPR Month YearSanthosh PalaniappanNo ratings yet

- Cost Estimation of Reactor - 060Document36 pagesCost Estimation of Reactor - 060Muhammad UsamaNo ratings yet

- SPEED Update - PACEDocument1 pageSPEED Update - PACEANEESH KAVILNo ratings yet

- MD-451-0000-OM-CO-SPC-00007 Rev 0Document8 pagesMD-451-0000-OM-CO-SPC-00007 Rev 0Ruel BuntogNo ratings yet

- Project WBS EstimateDocument6 pagesProject WBS EstimateSatria PinanditaNo ratings yet

- Benefit To Compensation Ratio CalculationsDocument6 pagesBenefit To Compensation Ratio CalculationsRamkishor PandeyNo ratings yet

- Project Control and Quality MonitoringDocument17 pagesProject Control and Quality MonitoringF2043 AMMAR AZ-ZHAFRI BIN ABDUL HALIMNo ratings yet

- Construction Project Administration: Dr. Abubakar SharafatDocument100 pagesConstruction Project Administration: Dr. Abubakar Sharafatmalik awansNo ratings yet

- Projacs Training PDFDocument715 pagesProjacs Training PDFsayr0sNo ratings yet

- 06 - Project Schedule Management-2019!06!13 13-20-52Document105 pages06 - Project Schedule Management-2019!06!13 13-20-52Sherif MansourNo ratings yet

- Engineering ProcedureDocument34 pagesEngineering ProcedureAnthony YunNo ratings yet

- Estimating MethodsDocument10 pagesEstimating MethodsAer AsedoNo ratings yet

- Al Mamsha Baseline Programme - Rev 3.1Document343 pagesAl Mamsha Baseline Programme - Rev 3.1Mohab ZahranNo ratings yet

- Presentation 1Document45 pagesPresentation 1koky123456789No ratings yet

- تحليل المخاطر بمشروع المنارة للاتصالاتDocument23 pagesتحليل المخاطر بمشروع المنارة للاتصالاتSuleiman BaruniNo ratings yet

- Project Cost Reporting GuideDocument24 pagesProject Cost Reporting GuideShaneene Berlyn AgulayNo ratings yet

- Big Picture in Focus: Ulob Metalanguage: Develop Work Breakdown StructureDocument7 pagesBig Picture in Focus: Ulob Metalanguage: Develop Work Breakdown StructureArthur LeywinNo ratings yet

- Lecture 6fDocument30 pagesLecture 6fhiteshNo ratings yet

- Project RecordsDocument103 pagesProject Recordslebanese2711No ratings yet

- 4 Cost ControlDocument30 pages4 Cost ControlAmeyuNo ratings yet

- Primavera Cost LoadingDocument5 pagesPrimavera Cost LoadingGerry TriazNo ratings yet

- PT Borneo Mitra Sinergi: Project Close Out PlanDocument4 pagesPT Borneo Mitra Sinergi: Project Close Out PlanaswarNo ratings yet

- Project Controls RequirementsDocument8 pagesProject Controls RequirementsJuan Dela CruzNo ratings yet

- S-TR-GEN-PSTS (Planning & Scheduling TechSpec) (Rev 0-2009)Document10 pagesS-TR-GEN-PSTS (Planning & Scheduling TechSpec) (Rev 0-2009)Abhinav SinhaNo ratings yet

- PECI5405 EstimationDocument96 pagesPECI5405 EstimationGobardhanNo ratings yet

- F-02 Project Delivery Plan AgendaDocument9 pagesF-02 Project Delivery Plan AgendaAhmed MohamedNo ratings yet

- Job Description: Project EngineerDocument2 pagesJob Description: Project EngineerRichard GacitúaNo ratings yet

- Schedule B PDFDocument122 pagesSchedule B PDFHarun RashidNo ratings yet

- Presentasi EPCDocument34 pagesPresentasi EPCtiantaufikNo ratings yet

- Economic ReportDocument9 pagesEconomic ReportYeeXuan TenNo ratings yet

- Project Management Plan TemplateDocument9 pagesProject Management Plan TemplateAsmaaNo ratings yet

- Set-S-3 (Ipc) - 09 06 12Document2 pagesSet-S-3 (Ipc) - 09 06 12Yousef Adel HassanenNo ratings yet

- PT SEV - YE III +ûRNEK SORULAR - NG - L - ZCEDocument18 pagesPT SEV - YE III +ûRNEK SORULAR - NG - L - ZCEYousef Adel HassanenNo ratings yet

- PT Level II Test PaperDocument7 pagesPT Level II Test PaperYousef Adel HassanenNo ratings yet

- M/s. Smart Technocrats & Consultancy Services (I) PVT. LTDDocument7 pagesM/s. Smart Technocrats & Consultancy Services (I) PVT. LTDYousef Adel HassanenNo ratings yet

- Set-Cr - Ipc - 07.07.12Document8 pagesSet-Cr - Ipc - 07.07.12Yousef Adel HassanenNo ratings yet

- msr3 5aprDocument3 pagesmsr3 5aprYousef Adel HassanenNo ratings yet

- PT Sev - Ye Ii Deneme Test - NG - L - ZceDocument10 pagesPT Sev - Ye Ii Deneme Test - NG - L - ZceYousef Adel HassanenNo ratings yet

- PT Theory FromDocument75 pagesPT Theory FromYousef Adel HassanenNo ratings yet

- PT Theory FromDocument75 pagesPT Theory FromYousef Adel HassanenNo ratings yet

- Liquid Penetrant Examination of Non-Porous Materials: 1. StatusDocument24 pagesLiquid Penetrant Examination of Non-Porous Materials: 1. StatusYousef Adel HassanenNo ratings yet

- PT03 PDFDocument15 pagesPT03 PDFKhaled BouhlelNo ratings yet

- PT04 PDFDocument25 pagesPT04 PDFKhaled BouhlelNo ratings yet

- PTINDocument0 pagesPTINSihem BenNo ratings yet

- PT16Document19 pagesPT16Pradeep Kumar BowmarajuNo ratings yet

- PT General 2Document4 pagesPT General 2Yousef Adel HassanenNo ratings yet

- PT2SDocument4 pagesPT2SYousef Adel HassanenNo ratings yet

- Electric Power Applications of Liquid Penetrant Testing: HapterDocument18 pagesElectric Power Applications of Liquid Penetrant Testing: HaptertariqNo ratings yet

- PT2 Specific - MasterDocument4 pagesPT2 Specific - MasterYousef Adel HassanenNo ratings yet

- PT Specfic 2Document2 pagesPT Specfic 2Yousef Adel HassanenNo ratings yet

- PT2 Specific - EsconDocument3 pagesPT2 Specific - EsconMangalraj MadasamyNo ratings yet

- PT2 Specific-Article 6Document3 pagesPT2 Specific-Article 6Yousef Adel HassanenNo ratings yet

- Liquid Penetrant Testing: Level-II GeneralDocument8 pagesLiquid Penetrant Testing: Level-II GeneralYousef Adel HassanenNo ratings yet

- CBIP Examination PTL1 GeneralDocument4 pagesCBIP Examination PTL1 GeneralHeather SullivanNo ratings yet

- PT Specfic 1Document2 pagesPT Specfic 1Mangalraj MadasamyNo ratings yet

- PMT 30106Document36 pagesPMT 30106Yousef Adel HassanenNo ratings yet

- Harcourt - Solutions - Advanced Functions and Introductory CalculusDocument299 pagesHarcourt - Solutions - Advanced Functions and Introductory CalculusEthan BlackNo ratings yet

- CHX - Theta RodStar SoftwareDocument2 pagesCHX - Theta RodStar Softwaretomas.a.sierraNo ratings yet

- Maze Ransomware Attack Prevention GuideDocument7 pagesMaze Ransomware Attack Prevention GuideprakashrjsekarNo ratings yet

- Artificial Intelligence - Course OutlineDocument3 pagesArtificial Intelligence - Course Outlinehafiza javeriaNo ratings yet

- Computer AssignmentDocument8 pagesComputer AssignmentSHOBHIT GUPTA 211319No ratings yet

- Unit Plan TemplateDocument4 pagesUnit Plan TemplateAoi KitsuneNo ratings yet

- Atp Assv1 Pl72888213 LetterDocument1 pageAtp Assv1 Pl72888213 LetterNarin SangrungNo ratings yet

- Configuration Management in Drupal 8 - DDD2016 PDFDocument57 pagesConfiguration Management in Drupal 8 - DDD2016 PDFUzielNo ratings yet

- MIT SBL Booklet2Document13 pagesMIT SBL Booklet2Luis Alberto Zapata OjedaNo ratings yet

- Crafting Game-Based Learning: An Analysis of Lessons For Minecraft Education EditionDocument4 pagesCrafting Game-Based Learning: An Analysis of Lessons For Minecraft Education EditionRayner TangkuiNo ratings yet

- Question Bank-JavaDocument3 pagesQuestion Bank-Javarachana saiNo ratings yet

- Solve Trig Equations Worksheet 12.15 Pp4yf1 PDFDocument3 pagesSolve Trig Equations Worksheet 12.15 Pp4yf1 PDFYee MeiNo ratings yet

- Human Coding & Interrater Reliability in Content AnalysisDocument9 pagesHuman Coding & Interrater Reliability in Content AnalysisTerry College of BusinessNo ratings yet

- LVP615 User ManualDocument98 pagesLVP615 User ManualOleg KuzminskyNo ratings yet

- FminconDocument3 pagesFminconБогдан КулиничNo ratings yet

- MOD-14-1735 - V10.14 Feature Description - Issue 1.1Document11 pagesMOD-14-1735 - V10.14 Feature Description - Issue 1.11012268087No ratings yet

- Metropolis Metropolis: AM/ AMSDocument224 pagesMetropolis Metropolis: AM/ AMSAlexeyNo ratings yet

- E&M T05 Option For MX800Document3 pagesE&M T05 Option For MX800Денис ХлопцевNo ratings yet

- Research Article: A Comparative Analysis of The Top Ott Platforms in India Liya RajeshDocument18 pagesResearch Article: A Comparative Analysis of The Top Ott Platforms in India Liya RajeshPrathamesh DivekarNo ratings yet

- Global Master's in Blockchain Technologies: Master's Degree by The IL3-Universitat de BarcelonaDocument4 pagesGlobal Master's in Blockchain Technologies: Master's Degree by The IL3-Universitat de BarcelonaAungsinghla MarmaNo ratings yet

- Auction Script User View RegisterDocument9 pagesAuction Script User View RegisterEric PetersonNo ratings yet

- Airbus Pleiades Imagery User Guide 15042021Document114 pagesAirbus Pleiades Imagery User Guide 15042021Fernando Dávila AguirreNo ratings yet

- Applied Productivity Tools With Advanced Application TechniquesDocument21 pagesApplied Productivity Tools With Advanced Application TechniquesRyan Rojas RicablancaNo ratings yet

- 998-20934418 Capabilities-BrochureDocument59 pages998-20934418 Capabilities-BrochureTeddy PahlewiNo ratings yet

- Dainese Andrea CVDocument2 pagesDainese Andrea CVSultan AliNo ratings yet

- Cisco Catalyst 2950 Series SwitchesDocument12 pagesCisco Catalyst 2950 Series SwitchesEDUARDONo ratings yet

- Nexford University CatalogDocument127 pagesNexford University CatalogSola Adesanya-AtirokoNo ratings yet

- Test Accredited Configuration Engineer ACE Exam PANOS 8 0 VersionDocument12 pagesTest Accredited Configuration Engineer ACE Exam PANOS 8 0 VersionMunfed Rana83% (23)