Professional Documents

Culture Documents

PCB Design Notes

PCB Design Notes

Uploaded by

tyler bretes0 ratings0% found this document useful (0 votes)

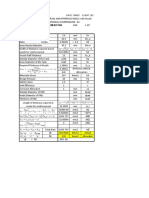

12 views1 pageThe document provides guidelines for PCB design including through hole clearance sizes, pad diameters, temperature rise, trace width and clearance based on IPC standards. Minimum hole sizes are specified as the maximum lead diameter plus a tolerance ranging from 0.15mm to 0.25mm depending on the required production level. Pad diameter is calculated as the minimum hole size plus an annular ring and fabrication allowance where the required tolerances decrease from level A to C production. Designs should allow for a maximum 10 degree Celsius temperature rise at an ambient of 25 degrees Celsius. Trace width for a 1 amp capacity board is recommended at 15 mils and clearances of 0.1mm for low voltage and 0.25mm for power devices.

Original Description:

Basic set of design notes needed for PCB design

Copyright

© © All Rights Reserved

Available Formats

TXT, PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentThe document provides guidelines for PCB design including through hole clearance sizes, pad diameters, temperature rise, trace width and clearance based on IPC standards. Minimum hole sizes are specified as the maximum lead diameter plus a tolerance ranging from 0.15mm to 0.25mm depending on the required production level. Pad diameter is calculated as the minimum hole size plus an annular ring and fabrication allowance where the required tolerances decrease from level A to C production. Designs should allow for a maximum 10 degree Celsius temperature rise at an ambient of 25 degrees Celsius. Trace width for a 1 amp capacity board is recommended at 15 mils and clearances of 0.1mm for low voltage and 0.25mm for power devices.

Copyright:

© All Rights Reserved

Available Formats

Download as TXT, PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

12 views1 pagePCB Design Notes

PCB Design Notes

Uploaded by

tyler bretesThe document provides guidelines for PCB design including through hole clearance sizes, pad diameters, temperature rise, trace width and clearance based on IPC standards. Minimum hole sizes are specified as the maximum lead diameter plus a tolerance ranging from 0.15mm to 0.25mm depending on the required production level. Pad diameter is calculated as the minimum hole size plus an annular ring and fabrication allowance where the required tolerances decrease from level A to C production. Designs should allow for a maximum 10 degree Celsius temperature rise at an ambient of 25 degrees Celsius. Trace width for a 1 amp capacity board is recommended at 15 mils and clearances of 0.1mm for low voltage and 0.25mm for power devices.

Copyright:

© All Rights Reserved

Available Formats

Download as TXT, PDF, TXT or read online from Scribd

You are on page 1of 1

PCB DESIGN NOTES

Through Hole Clearance

Minimum Hole Size = Maximum Lead Diameter + 0.25mm (for Level A of IPC-2222)

Minimum Hole Size = Maximum Lead Diameter + 0.20mm (for Level B of IPC-2222)

Minimum Hole Size = Maximum Lead Diameter + 0.15mm (for Level C of IPC-2222)

Larger Holes = Easier to Produce and Assemble

Pad Diameter = Minimum Hole Size + Minimum Annular Ring X 2 + Minimum Fabrication

Allowance

Pad Diameter = Minimum Hole Size + 0.1mm + 0.60mm (for Level A of IPC-2221)

Pad Diameter = Minimum Hole Size + 0.1mm + 0.50mm (for Level B of IPC-2221)

Pad Diameter = Minimum Hole Size + 0.1mm + 0.40mm (for Level C of IPC-2221)

Level A: General Design Producibility — Preferred

Level B: Moderate Design Producibility — Standard

Level C: High Design Producibility — Reduced

Larger Pads = Easier to Produce and Assemble

Design for 10C T rise at ambient temperature (25C)

1A capacity, 2oz copper, trace width = 15 mils

For Low Voltage, Use .1mm trace clearance generally (per IPC 2221 standards), .25mm

for power conversion devices (per IPC 9592 standards)

You might also like

- Hydrotest Pressure CalculationDocument26 pagesHydrotest Pressure CalculationChetan B Kapadia100% (13)

- Design Data: 2" Threadolet CalculationDocument2 pagesDesign Data: 2" Threadolet Calculationgrabetty50% (2)

- IBR Design Calculations - FinalDocument6 pagesIBR Design Calculations - Finalshazan100% (1)

- ACI 318-08 Development and Splices of ReinforcementDocument6 pagesACI 318-08 Development and Splices of ReinforcementElie MenassaNo ratings yet

- Asme Viii Shell & Se HeadDocument5 pagesAsme Viii Shell & Se HeadSnr George RaczNo ratings yet

- 23C5366A-SA1A.02-Inquiry list-MINDA INFRASTRUCTURE LLP - Case-01 - DLP 5% For 60 Months - PC Rates - SDocument8 pages23C5366A-SA1A.02-Inquiry list-MINDA INFRASTRUCTURE LLP - Case-01 - DLP 5% For 60 Months - PC Rates - SswapnilNo ratings yet

- How To Calculate PTH Hole and Pad Diameter Sizes According To IPC-7251, IPC-2222 and IPC-2221 StandardsDocument3 pagesHow To Calculate PTH Hole and Pad Diameter Sizes According To IPC-7251, IPC-2222 and IPC-2221 StandardsmryalamrbNo ratings yet

- Structural MembersDocument37 pagesStructural Membersmario gadianoNo ratings yet

- Labor Housing in The Kingdom of Saudi ArabiaDocument7 pagesLabor Housing in The Kingdom of Saudi Arabianamita.sultania26No ratings yet

- Rectangular TankDocument38 pagesRectangular TankSam LowNo ratings yet

- ACI 318-Development and SplicesDocument4 pagesACI 318-Development and SplicesRafeeq WazirNo ratings yet

- Aci 318-08 Development and Splices of ReinforcementDocument2 pagesAci 318-08 Development and Splices of ReinforcementAjay SastryNo ratings yet

- Aci 318-08 Development and Splices of Reinforcement - Editing ProtectedDocument6 pagesAci 318-08 Development and Splices of Reinforcement - Editing Protectedbryamdv23No ratings yet

- Clean Water Tank - Id - 7200x10900 HDocument208 pagesClean Water Tank - Id - 7200x10900 HWilly SastraleksanaNo ratings yet

- T-0622 4T Dosing Vessel 2: Project: Iocl Kolkata Lobp Design Check ForDocument11 pagesT-0622 4T Dosing Vessel 2: Project: Iocl Kolkata Lobp Design Check ForAnant KumbhejkarNo ratings yet

- Hydrotest Pressure CalculationDocument26 pagesHydrotest Pressure Calculationrudrakr0% (1)

- Calculations Per ABS Code Along With ASME Sec. VIII Div.1 XXXXDocument17 pagesCalculations Per ABS Code Along With ASME Sec. VIII Div.1 XXXXordenador90No ratings yet

- Dish End Diameter Calculator - 18C7Document1 pageDish End Diameter Calculator - 18C7Raymond BalladNo ratings yet

- DB Reg SK GBDocument2 pagesDB Reg SK GBABDELLAHABDELLAH2010No ratings yet

- App 1 Cylindrical Shells - ASMEDocument2 pagesApp 1 Cylindrical Shells - ASMEwassim2014No ratings yet

- Tugas 1 Workbook5 Putu Widhi A 04211540000017Document5 pagesTugas 1 Workbook5 Putu Widhi A 04211540000017Putu Widhi ApriliaNo ratings yet

- Sample3 APVDocument40 pagesSample3 APVlaleye_olumideNo ratings yet

- Project Information: Basic Design ParametersDocument14 pagesProject Information: Basic Design Parameterssilveer12No ratings yet

- API 650 Water Storage TankDocument6 pagesAPI 650 Water Storage TankJoeNo ratings yet

- Glass FINALDocument43 pagesGlass FINALkishore pmNo ratings yet

- Interference Fits and PressureDocument21 pagesInterference Fits and PressurerwmingisNo ratings yet

- LCD Modul Ds-c2004Document17 pagesLCD Modul Ds-c2004Aleksandar LomovicNo ratings yet

- PB101424 0Document9 pagesPB101424 0emilio mendez olveraNo ratings yet

- Design Procedure For Aes He PDFDocument30 pagesDesign Procedure For Aes He PDFRyan Goh Chuang HongNo ratings yet

- Aci 318-08 Development and Splices of Reinforcement - Editing ProtectedDocument4 pagesAci 318-08 Development and Splices of Reinforcement - Editing Protectedpaarth93No ratings yet

- Btd965La3: Cystech Electronics CorpDocument5 pagesBtd965La3: Cystech Electronics Corpciencias9966No ratings yet

- 16.0 M Dia X 18.0 HT Fire Water Tank Rev 0Document30 pages16.0 M Dia X 18.0 HT Fire Water Tank Rev 0kpsahuNo ratings yet

- PB101266 0Document10 pagesPB101266 0emilio mendez olveraNo ratings yet

- Design CalculationDocument3 pagesDesign CalculationRavi AgarwalNo ratings yet

- Layout Design: 18-322 Fall 2003Document40 pagesLayout Design: 18-322 Fall 2003Sai SadiqNo ratings yet

- Design Calculation For Dirty Brackish Water Tank (129-0T2540)Document9 pagesDesign Calculation For Dirty Brackish Water Tank (129-0T2540)Dhakshina KNo ratings yet

- L 8 IhjnmklgfDocument27 pagesL 8 IhjnmklgfbrintopvNo ratings yet

- Design Calculation of 2 KL Lin Storage Manf Si. No.: Vs/Asme/03 DOC NO.: PVL/VAL/2021 REV. NO.: 0 DATE: 24 SEPTEMBER, 2021Document1 pageDesign Calculation of 2 KL Lin Storage Manf Si. No.: Vs/Asme/03 DOC NO.: PVL/VAL/2021 REV. NO.: 0 DATE: 24 SEPTEMBER, 2021pratyaNo ratings yet

- Nozzle With Reinforcement Pad: Date: 13/6/21 Client: IecDocument1 pageNozzle With Reinforcement Pad: Date: 13/6/21 Client: Iecגרבר פליקסNo ratings yet

- AD 2000 HesapDocument11 pagesAD 2000 HesapBaşarŞenNo ratings yet

- 2N2219A 2N2222A: High Speed SwitchesDocument1 page2N2219A 2N2222A: High Speed SwitchesxufooNo ratings yet

- Helsingin - Painesailio: Design Data & Process InformationDocument31 pagesHelsingin - Painesailio: Design Data & Process InformationUdoy Hossen KhanNo ratings yet

- 06745JS2 (7) - Strength Calculations of Module4 (IBR)Document23 pages06745JS2 (7) - Strength Calculations of Module4 (IBR)Pratik Ray Chaudhury100% (3)

- Document Frontsheet: Project: 3930 - 9 - Olefin Complex Ethane Cracking PlantDocument49 pagesDocument Frontsheet: Project: 3930 - 9 - Olefin Complex Ethane Cracking Plantsusa2536No ratings yet

- Pipeline Coatings PDFDocument29 pagesPipeline Coatings PDFAsimNo ratings yet

- BuildingsDocument105 pagesBuildingsSreekantha RNo ratings yet

- Manual Calc. Welded Storage Tank API-650Document1 pageManual Calc. Welded Storage Tank API-650safar bahariNo ratings yet

- Note PCB Fab Chandra Debugger EnglishDocument4 pagesNote PCB Fab Chandra Debugger EnglishSreedhar Naidu KNo ratings yet

- WT Calculation - Pipelines With CRA CladDocument6 pagesWT Calculation - Pipelines With CRA CladShankar VadivelNo ratings yet

- API 650 Storage Tank 2400Document34 pagesAPI 650 Storage Tank 2400PANOLI PROJECTNo ratings yet

- Design Guidelines for Surface Mount TechnologyFrom EverandDesign Guidelines for Surface Mount TechnologyRating: 5 out of 5 stars5/5 (1)

- Beginning Digital Electronics through ProjectsFrom EverandBeginning Digital Electronics through ProjectsRating: 5 out of 5 stars5/5 (1)

- Audio IC Projects: A Collection of Useful Circuits Based on Readily Available ChipsFrom EverandAudio IC Projects: A Collection of Useful Circuits Based on Readily Available ChipsNo ratings yet