Professional Documents

Culture Documents

Wear Ring Replacement For A Series Pumps

Uploaded by

HesOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Wear Ring Replacement For A Series Pumps

Uploaded by

HesCopyright:

Available Formats

Wear Ring Replacement for A-Series Pumps

Technical Pages

ABSTRACT

HOMA provides a bronze volute wear ring and integral cast iron impeller wear ring as

standard construction. This document will provide the procedure for replacing a wear

ring in an A-series pump. The impeller wear surface is over sized and can be machined

true and renewed with a new wear ring heat shrink fitted over the newly machined

surface; this will require removal of the impeller. Refer to HOMA document “A Series

Impeller Change: 88FN2020” on homapump.com for instructions on impeller removal.

Removal of optional stainless steel wear rings will require removal of the impeller from

the shaft. Wear rings should be ordered and replaced in sets.

PROCEDURE

Removing Volute Wear-Ring

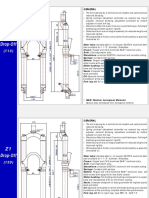

To remove the wear ring from the volute use a pry bar or crow foot and evenly pull

the wear-ring up at opposing sides.

If a pry bar will not fit between the casting and the ring, or the wear ring will not come

out, the best option is to remove the volute, set it suction-side down, and drill two

holes through the wear ring on opposite points (Figure 1). Then use a sturdy chisel

and break the wear ring at these two points so it will easily come out (Figure 2).

Figure 1 Figure 2

88FN2050A Published: Mar-19 Page 1 of 2

Removing Impeller Wear-Ring

If the pump is installed with a pair of stainless steel wear rings, then it is necessary

to remove the wear ring from the nose of the impeller. If the integral impeller wear

surface will continue to be used, skip to the “Installing Wear Ring” step

Remove the impeller according to HOMA document “A Series Impeller Change:

88FN2020” (available on homapump.com).

Using a torch, heat the wear ring evenly and pry the ring off using a pry bar

Installing Wear-Ring

Place a new wear ring into the bottom of the volute over the suction inlet.

HOMA recommends the use of a press and appropriate tools when installing bronze

wear rings. As an alternative, drive the wear ring with a brass drift pin gently and

evenly at opposing sides until fully seated. Take care not to distort the wear ring as

binding with the impeller will occur.

If you are installing an impeller wear ring, heat shrink fit the wear ring over the nose

of the impeller

Install the impeller to the motor if it was removed.

Install the motor with impeller into the volute squarely.

Do not use bolts to draw the motor to the volute. Damage to the wear rings, shaft

and impeller will occur.

Once the volute is fully seated the bolts can be put into place making sure that the

volute is in proper location as marked during disassembly. HOMA recommends the

use of blue # 242 locking compound on the bolts before installing.

Routinely rotate the impeller as the bolts are being tightened to check for binding of

the impeller and wear rings.

Torque all bolts as specified. Check by hand that the impeller spins freely without

rubbing or binding.

Bolt torques: 16MM: 108 ft-lb, 12MM: 45 ft-lb, 10MM: 26 ft-lb

88FN2050A Published: Mar-19 Page 2 of 2

You might also like

- Manual Mantenimiento Mission 40Document8 pagesManual Mantenimiento Mission 40Daygor Martinez SabucoNo ratings yet

- 001-054 Piston and Connecting Rod AssemblyDocument8 pages001-054 Piston and Connecting Rod AssemblyYè WințNo ratings yet

- GS150&200 Engine Service GuideDocument51 pagesGS150&200 Engine Service GuideMiguel LemosNo ratings yet

- Manitou Hyd Pump Repair ManualDocument48 pagesManitou Hyd Pump Repair ManualArdian Makhmud100% (2)

- Mecanica MotoareDocument45 pagesMecanica MotoareAutogrederNo ratings yet

- Motor3 Suzuki VL800Document20 pagesMotor3 Suzuki VL800Crisan SorinNo ratings yet

- Manitou MT940-MT1740 HydraulicDocument234 pagesManitou MT940-MT1740 HydraulicVeselina Gaidarska91% (22)

- Connecting Rod ReplacementDocument11 pagesConnecting Rod Replacementfjafarvand100% (1)

- BD Governor Spring Kit Installation Instructions: Vehicles Which May Never Be Used Upon A HighwayDocument9 pagesBD Governor Spring Kit Installation Instructions: Vehicles Which May Never Be Used Upon A HighwayLina Delgado OsorioNo ratings yet

- Blackmer 807b and 828b Manual - BLACKMERDocument6 pagesBlackmer 807b and 828b Manual - BLACKMERGerencia Rigar Colombia SASNo ratings yet

- YD25 Engine MechDocument35 pagesYD25 Engine MechAlex Hernandez100% (2)

- Remove RockerDocument16 pagesRemove RockerjeremyNo ratings yet

- Sistema de TransmisionDocument239 pagesSistema de TransmisionCez Lopez BañezNo ratings yet

- Clutch Echo 2002Document17 pagesClutch Echo 2002Tomas DominguezNo ratings yet

- C014 Assembly-Disassembly ManualDocument21 pagesC014 Assembly-Disassembly Manualwillyan100% (2)

- Bushing & Thrust Washer Kit: Bushing Installation & Removal ToolsDocument2 pagesBushing & Thrust Washer Kit: Bushing Installation & Removal ToolsakkoladaNo ratings yet

- Motor M14 ControlDocument6 pagesMotor M14 ControlROBERSON ROMERÒNo ratings yet

- Range Rover Manual Suspension PDFDocument14 pagesRange Rover Manual Suspension PDFsleepyninjitsuNo ratings yet

- Soosan Servicemanual SB GBDocument10 pagesSoosan Servicemanual SB GBvanNo ratings yet

- IS233Document2 pagesIS233Carlos Lara CastroNo ratings yet

- Marzocchi 01 Z1 - Dropoff ManualDocument18 pagesMarzocchi 01 Z1 - Dropoff ManualHarry James BoundenNo ratings yet

- TTR125 150BigBore Update2Document4 pagesTTR125 150BigBore Update2eddielindermannNo ratings yet

- Ac Compressor ServicingDocument25 pagesAc Compressor Servicingsonny1234100% (1)

- BHW Balance Shaft Module ReplacementDocument32 pagesBHW Balance Shaft Module Replacementszasz100% (1)

- 6.38 10M EH Single Shear Seal BOPDocument19 pages6.38 10M EH Single Shear Seal BOPpramodptvpm_65797156No ratings yet

- IOM Actuator AutomaxSupernovaDocument4 pagesIOM Actuator AutomaxSupernovaNaser JahangiriNo ratings yet

- T Able of ContentsDocument8 pagesT Able of Contentshugo_bikerNo ratings yet

- Fork Gold Valve Installation: DisassemblyDocument4 pagesFork Gold Valve Installation: DisassemblyTiyok HidrolikNo ratings yet

- Toyota Tundra (2UZ FE) 2002Document16 pagesToyota Tundra (2UZ FE) 2002Isaac Castillo100% (1)

- Toyota Camry LE Sedan V6-3.0L (1MZ-FE) 2001: Timing Belt: Service and RepairDocument14 pagesToyota Camry LE Sedan V6-3.0L (1MZ-FE) 2001: Timing Belt: Service and RepairEutério SilvaNo ratings yet

- Toyota Truck RAV4 2WD L4-2.0L (1AZ-FE) 2002: Timing Chain: Service and RepairDocument15 pagesToyota Truck RAV4 2WD L4-2.0L (1AZ-FE) 2002: Timing Chain: Service and RepairyosnielNo ratings yet

- Differential Carrier: ComponentsDocument16 pagesDifferential Carrier: Componentspriyankar007No ratings yet

- 4L80E Build Tips and TricksDocument5 pages4L80E Build Tips and TricksSjoling8211No ratings yet

- Camry Solara SLEV6Document13 pagesCamry Solara SLEV6arturmikieNo ratings yet

- Tightening of Tie BoltsDocument4 pagesTightening of Tie BoltsAnik Das 8040No ratings yet

- Toyota Avalon XL V6-3.0L (1MZ-FE) 2001: Timing Belt: Service and RepairDocument15 pagesToyota Avalon XL V6-3.0L (1MZ-FE) 2001: Timing Belt: Service and RepairFrancisco Guillen-DorantesNo ratings yet

- Suspension FrontDocument8 pagesSuspension FrontTiago BertuolNo ratings yet

- Sturmey Archer S RF3 Hub InstructionsDocument4 pagesSturmey Archer S RF3 Hub Instructionsdupazbita11No ratings yet

- Toyota Camry CE Sedan L4-2.2L DOHC (5S-FE) MFI 2001: Timing Belt: Service and RepairDocument17 pagesToyota Camry CE Sedan L4-2.2L DOHC (5S-FE) MFI 2001: Timing Belt: Service and RepairWenceslao Francisco Mejía EspinozaNo ratings yet

- Camry Solara SEV6Document13 pagesCamry Solara SEV6arturmikieNo ratings yet

- OWI 1000 DrawworksDocument54 pagesOWI 1000 DrawworksÖnder Büyükişcan100% (1)

- 7 - Lubrification and RepairsDocument5 pages7 - Lubrification and RepairsGabriel vieiraNo ratings yet

- QuickServe Online - (4310591) N14 Base Engine (STC, Celect™, Celect Plus™) Service ManualDocument10 pagesQuickServe Online - (4310591) N14 Base Engine (STC, Celect™, Celect Plus™) Service Manualcarlosar1477No ratings yet

- 4HP14 Manual 50-97Document50 pages4HP14 Manual 50-97Azmi MushoffaNo ratings yet

- Suspension Front 4wdDocument12 pagesSuspension Front 4wdAnimemanuel MuñozNo ratings yet

- BF20 Belt Drive Kit Installation InstructionsDocument51 pagesBF20 Belt Drive Kit Installation InstructionsBryan DixNo ratings yet

- Toyota Truck SequoiaDocument16 pagesToyota Truck SequoiaD3NYNo ratings yet

- KPS03 Installation InstructionsDocument12 pagesKPS03 Installation InstructionsHybrid RacingNo ratings yet

- Generic Install Instructions 1 Innovators West 3v DamperDocument2 pagesGeneric Install Instructions 1 Innovators West 3v DamperAlejandro Da CostaNo ratings yet

- Sci Mop Bombas Espuma Cgp80 - ChemguardDocument13 pagesSci Mop Bombas Espuma Cgp80 - Chemguarddiuska13No ratings yet

- RP2Document24 pagesRP2Vennia PapadipoulouNo ratings yet

- Maico-MC 250 400 501 Square Barrel-68 71-Service Manual EngineDocument29 pagesMaico-MC 250 400 501 Square Barrel-68 71-Service Manual EngineducmansNo ratings yet

- Toyota Celica GT L4 1.8L 1ZZ FEDocument21 pagesToyota Celica GT L4 1.8L 1ZZ FEWolfgang WilliamsNo ratings yet

- CBR250R-Set Up InstructionsDocument15 pagesCBR250R-Set Up InstructionsRicardo XlvNo ratings yet

- Plymouth and Chrysler-built cars Complete Owner's Handbook of Repair and MaintenanceFrom EverandPlymouth and Chrysler-built cars Complete Owner's Handbook of Repair and MaintenanceNo ratings yet

- The Book of the Singer Junior - Written by an Owner-Driver for Owners and Prospective Owners of the Car - Including the 1931 SupplementFrom EverandThe Book of the Singer Junior - Written by an Owner-Driver for Owners and Prospective Owners of the Car - Including the 1931 SupplementNo ratings yet

- A Book of Helpful Tips on Overhauling a Vintage Engine - Including Car, Motorbike and Lawn Mower EnginesFrom EverandA Book of Helpful Tips on Overhauling a Vintage Engine - Including Car, Motorbike and Lawn Mower EnginesRating: 5 out of 5 stars5/5 (1)

- Gun Digest American Arms ATI GSG-5 Assembly/Disassembly InstructionsFrom EverandGun Digest American Arms ATI GSG-5 Assembly/Disassembly InstructionsNo ratings yet

- PS SWS 50 Spec SheetDocument2 pagesPS SWS 50 Spec SheetpowersoakNo ratings yet

- Feedback Control SystemDocument40 pagesFeedback Control SystemMuhammad SaeedNo ratings yet

- Calculate Size of Circuit Breaker or Fuse For Transformer (As Per NEC)Document4 pagesCalculate Size of Circuit Breaker or Fuse For Transformer (As Per NEC)erson1981No ratings yet

- Low Power Out Mack mp10 mp8 mp7Document5 pagesLow Power Out Mack mp10 mp8 mp7hamilton mirandaNo ratings yet

- Summative Test: Computer Hardware ServicingDocument30 pagesSummative Test: Computer Hardware ServicingROMARIE QUIJANONo ratings yet

- Comparing The Mechanical Properties of Cyanate Ester Modified Epoxy /glass LaminatesDocument7 pagesComparing The Mechanical Properties of Cyanate Ester Modified Epoxy /glass LaminatesAndrew NallayanNo ratings yet

- Box Pushing Paper - 1Document5 pagesBox Pushing Paper - 1Naresh KumarNo ratings yet

- Bhavin Desai ResumeDocument5 pagesBhavin Desai Resumegabbu_No ratings yet

- Toyota WayDocument6 pagesToyota WayMeth RonoNo ratings yet

- Chapter-I Part TwoDocument6 pagesChapter-I Part TwoTigst Tigst YzachewNo ratings yet

- R-L-C Circuit Analysis: ProcedureDocument2 pagesR-L-C Circuit Analysis: ProcedureAbhyuday ChauhanNo ratings yet

- Concurrent Programming in Java - LeaDocument2 pagesConcurrent Programming in Java - LeaSeanNo ratings yet

- EG110 (Spring 2021) Exam #2 Pelayo MartinezDocument6 pagesEG110 (Spring 2021) Exam #2 Pelayo MartinezPelayo MartinezNo ratings yet

- The Intelligent Choice in Comfort: Split & Window Type Air ConditionersDocument32 pagesThe Intelligent Choice in Comfort: Split & Window Type Air Conditionersfrancesco camporealeNo ratings yet

- Real Time Embedded Systems E 626 ADocument2 pagesReal Time Embedded Systems E 626 Aeta100% (1)

- Zagi 60wDocument24 pagesZagi 60wAlexandre P. CruzNo ratings yet

- JBPM TutorialDocument56 pagesJBPM Tutorialc_prateeshNo ratings yet

- BS en 12668-3 2000Document15 pagesBS en 12668-3 2000lamhuu quangNo ratings yet

- UpsDocument22 pagesUpsroshani007No ratings yet

- Lgrplgso PDF 1615650993Document9 pagesLgrplgso PDF 1615650993Emerald GrNo ratings yet

- 1662 SMC Ds tcm228-701431635Document12 pages1662 SMC Ds tcm228-701431635cersanedNo ratings yet

- Hiwin Linear Guideway Catalog - G99TE13-0809Document0 pagesHiwin Linear Guideway Catalog - G99TE13-0809frahedlerNo ratings yet

- Singingrock Leaflet Arbo 2014 150dpiDocument9 pagesSingingrock Leaflet Arbo 2014 150dpiElvis Leo Dady Trank EchevarriaNo ratings yet

- TigerPMS CM63Document19 pagesTigerPMS CM63Mohamed BahaaNo ratings yet

- Module 5 AtcDocument12 pagesModule 5 AtcRakshith AcchuNo ratings yet

- Select Hollow Blade TurbineDocument10 pagesSelect Hollow Blade TurbinescranderiNo ratings yet

- Atlas Copco Tech Tip - Resetting Service TimersDocument9 pagesAtlas Copco Tech Tip - Resetting Service TimersEnio0% (1)

- Dti Oil and Gas Industry White PaperDocument36 pagesDti Oil and Gas Industry White PaperSoniya AgnihotriNo ratings yet

- Plantation Tree ProjectsDocument15 pagesPlantation Tree Projectsmahnoor cheemaNo ratings yet

- MVP507Document1 pageMVP507Joseph TingNo ratings yet