Professional Documents

Culture Documents

Work Instruction Type RII IK-FBI-PROJ-PR-14-006 Rev.01. Englis...

Uploaded by

Hudzaifah AbdussalamOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Work Instruction Type RII IK-FBI-PROJ-PR-14-006 Rev.01. Englis...

Uploaded by

Hudzaifah AbdussalamCopyright:

Available Formats

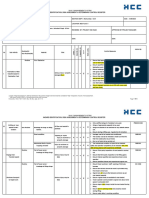

Model Process WORK INSTRUCTION Prepare Reyhan Respati No.

Doc IK-FBI-PROJ/PR/14-006

Title : Checked Y.Kurita Revisi 01

-

CLAMPING PROCESS OF CLAMPING TYPE RII MACHINE Aproved K. Nakazaki Date of issue 18-Dec-19

TYPE RII

Dept Project Page 1 to 1

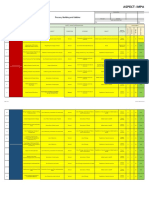

PROCESS FLOW ACTIVITIES DONE □ ENVIRONMENTAL ASPECTS AND IMPACTS

Prepare rebar Marking on rebar Dies Setting

Clamping Machine Preparation

ASPECT IMPACT HANDLING

- Check hydraulic pump. 1 2 3

- Check the clamping machine. ~ Used gloves ~ aesthetics Discard in its place

~ environmental

- Check 220V electricity ~ Oil Leaks

contamination

Repair the engine

use travo.

- Check die set size.

Implementation of the Clamping Process

1. Prepare Coupler, Rebar, Dies, and Measuring tool in

1 Materials and Tools Preparation

accordance with the specified size/diameter. □ New 5S

(Rebar-end shall be straight, or grind it if needed)

Make sure the dies in Operate the buttons

1. Make sure work equipment including PPE is available and ready

2. Spray rebar-end (=insertion side) using a marking tool. accordance with the size worked on the machine for use.

2 Marking

2. After finishing work, put the work equipment that has been used

3. Set dies and check the specified size. 4 5 Forward↑ back to its original place available.

3. Clean the work area after every work.

4. Make sure the electrical equipment is in the "OFF" condition during

3 Setting Dies

4. Insert rebar into coupler. recess and after work(ENERGY SAVING).

Insertion length shall satisfy the minimum insertion length. Be careful when working, prioritizing work safety.

5. Proceed clamping from coupler-end by pressing "Forward" 6 Back↓

4 Setting Coupler

button until the cylinder stops automatically. □ Personal Protective Equipment

Repeat the clamping process that is not yet perfect Mask Rubber Glove / Cloth Glove

6. Press "Back" button to have cylinder back to the original

5 Clamping / Pressing

position. Remaining parts in Glasses Safety Vest

Lunpy surface Minimum Insertion Length

perfect clamped

Helm Ear Plug

7. All areas of coupler shall be clamped.

7

6 Clamping / Releasing

Apply D-gauge whether clamping is performed properly. Arm Cover Safety Shoes

Re-clamp if D-gauge does not fit to coupler.

Safety Back

If Failed 8. Operator performs QC inspection by measuring clamped

7 Re-clamping

coupler, such as appearance, length, and diameter etc. Stock Opaname Barang Jadi

Operator shall inform Supervisor for further decision if failures

are found.

□ Matters of concern.

1) Prepare (Fire extinguisher and dust cloth)

8 Not Ok Report 9. Fill out QC report. complete and ready to use.

Quality Control

SPV 1. Coupler length after clamping 2) Contact No. Tel. Emergency if needed :

2. Coupler diameter after clamping with Caliper. Quality

Tersisa bagian yang check

belumbased on QC check sheets

di clamping Sales Engineering (Ibrahim) : 0878-2310-6133

3. Marking by visual judgement using D Gauge, Caliper & meter QC Report Site Supervisor (Holil) : 0857-7543-1167

Note: 5pcs of clamped couler shall be checked per day.

9 QC Report Preparation >2pcs: Morning Check D Gauge Caliper Length

>2pcs: Afternoon

Related document

8 9

>1pc : Clamping completion of the day. 1. Surat Laporan Hasil Jepitan Tipe RII (Sama Diameter) FR/QC/CL/013 Rev.04

RII Type Clamping Inspection Report (Same Diameter)

10 Clamping process can continue

10. If the clamping inspection process has passed all, then the

clamping process can continue.

Finish

You might also like

- Aspect-Impact Rating Sheet (Airs) : Department/ Section/ Unit: Process, Building and UtilitiesDocument4 pagesAspect-Impact Rating Sheet (Airs) : Department/ Section/ Unit: Process, Building and UtilitiesSir ZenNo ratings yet

- Task Risk Assessment For Sandblasting and Painting of Sheets SpoolsDocument3 pagesTask Risk Assessment For Sandblasting and Painting of Sheets SpoolsAftab Qadir100% (1)

- Impa 5th EditionDocument1,547 pagesImpa 5th EditionGaurav Maithil100% (3)

- 4M Change Tracking SheetDocument1 page4M Change Tracking SheetKanaiya Jha100% (5)

- QAP StructureDocument2 pagesQAP Structureayoki100% (1)

- Colorful Chalkboard Classroom Labels and OrganizersFrom EverandColorful Chalkboard Classroom Labels and OrganizersNo ratings yet

- IMPA 5 TH EDITION - CompressedDocument1,547 pagesIMPA 5 TH EDITION - CompressedManuel GuerreroNo ratings yet

- Equipment Schematic - For P5 DualDocument4 pagesEquipment Schematic - For P5 DualrahulNo ratings yet

- Piping Class PDFDocument4 pagesPiping Class PDFanil pkNo ratings yet

- 2539-00-ITP-012 - 0 - ITP For Plastic Piping PDFDocument17 pages2539-00-ITP-012 - 0 - ITP For Plastic Piping PDFdang2172014100% (1)

- EPB2.4 + V3f20 Installation - Start-Up ProcDocument30 pagesEPB2.4 + V3f20 Installation - Start-Up ProcBeltran Héctor75% (4)

- Brand Loyalty & Competitive Analysis of Pankaj NamkeenDocument59 pagesBrand Loyalty & Competitive Analysis of Pankaj NamkeenBipin Bansal Agarwal100% (1)

- Hiradc ProduksiDocument156 pagesHiradc ProduksiNur AisyahNo ratings yet

- The Eminence in Shadow, Vol. 4Document255 pagesThe Eminence in Shadow, Vol. 4Ezra Salvame83% (6)

- GC11 Pipe Thickness CalcDocument1 pageGC11 Pipe Thickness CalcsrinivasanNo ratings yet

- 10 Tanker Version 11 AmmendedDocument46 pages10 Tanker Version 11 AmmendedHarbinder SinghNo ratings yet

- Daily Report 7 April 2023 Sent PDFDocument2 pagesDaily Report 7 April 2023 Sent PDFBambang ArdiansyahNo ratings yet

- PPE MATRIX Hazard MappingDocument1 pagePPE MATRIX Hazard MappingSaurabh SinghNo ratings yet

- Gear Data For 71400418Document2 pagesGear Data For 71400418Pratap ThakurNo ratings yet

- Add Work RappDocument4 pagesAdd Work Rappsumantri NCNo ratings yet

- Annexure 3 - Vendor ComparisonDocument1 pageAnnexure 3 - Vendor ComparisonNikhil KarkeraNo ratings yet

- MBV - Products - List V-Belt VNDocument1 pageMBV - Products - List V-Belt VNSteven PhamNo ratings yet

- Daily Report 6 April 2023 Sent PDFDocument2 pagesDaily Report 6 April 2023 Sent PDFBambang ArdiansyahNo ratings yet

- RA Routing Fueling ProcessesDocument1 pageRA Routing Fueling Processesmohamed atefNo ratings yet

- Actuve Raileay Pulling PipebookDocument2 pagesActuve Raileay Pulling Pipebookatulpatil99No ratings yet

- Task Risk Assessment Enter Company Name AMG: Risk Evaluation (Refer To Evaluation Form)Document3 pagesTask Risk Assessment Enter Company Name AMG: Risk Evaluation (Refer To Evaluation Form)Faizan ShabbirNo ratings yet

- SKH Metals LTD.: Process Control StanderdDocument2 pagesSKH Metals LTD.: Process Control StanderdshinuNo ratings yet

- 12282A - Expansion Joints DatasheetDocument1 page12282A - Expansion Joints DatasheetGaurav TripathiNo ratings yet

- Feasiblity Review 1 1 HD BucketDocument3 pagesFeasiblity Review 1 1 HD BucketSandeep KumarNo ratings yet

- TK-103-FGL-34 Holiday InspectionDocument1 pageTK-103-FGL-34 Holiday InspectionjoseNo ratings yet

- A Nálisis Del M Odo y E Fecto de La F AllaDocument43 pagesA Nálisis Del M Odo y E Fecto de La F AllaAlfredoNo ratings yet

- BLDG - Revised Inspection and Test PlanDocument23 pagesBLDG - Revised Inspection and Test Plan124th EAGLECOM KimJaveroNo ratings yet

- TSMH4MD1 H4 01 TG T 31 TG0 002003213391Document39 pagesTSMH4MD1 H4 01 TG T 31 TG0 002003213391hamidrezaNo ratings yet

- Line 2 WJDocument1 pageLine 2 WJMahmoud A. HafeezNo ratings yet

- Line 1 WJDocument1 pageLine 1 WJMahmoud A. HafeezNo ratings yet

- Trouble HistoryDocument7 pagesTrouble HistoryShahzaibUsmanNo ratings yet

- TK-103-FGL-26-matt Inspection Prior To Tissue ApplicationDocument1 pageTK-103-FGL-26-matt Inspection Prior To Tissue ApplicationjoseNo ratings yet

- Daily Report 8 April 2023 PDFDocument2 pagesDaily Report 8 April 2023 PDFBambang ArdiansyahNo ratings yet

- Tpl-Yiapl-Ph1&2-An-15 R1Document1 pageTpl-Yiapl-Ph1&2-An-15 R1Ramesh BabuNo ratings yet

- Equipment ListDocument7 pagesEquipment Listyadav yadavNo ratings yet

- CT - PT MQPDocument12 pagesCT - PT MQPGnanavel GNo ratings yet

- Daily Report 10 April 2023Document3 pagesDaily Report 10 April 2023Bambang ArdiansyahNo ratings yet

- Hirac Man Trasnfer BasketDocument4 pagesHirac Man Trasnfer BasketPinaki BhattacharjeeNo ratings yet

- Machine Condition Report: BintangDocument15 pagesMachine Condition Report: BintanglilikNo ratings yet

- Latest ILC 4 Year PlanDocument5 pagesLatest ILC 4 Year PlanARNAB GHOSHNo ratings yet

- Facility Requirement & Evaluation Sheet: For Production IncreaseDocument1 pageFacility Requirement & Evaluation Sheet: For Production IncreaseAlfi BachtiarNo ratings yet

- Name of The Project: Avigna Industrial Park, Nagondapalli Village, Hosur, Tamil NaduDocument4 pagesName of The Project: Avigna Industrial Park, Nagondapalli Village, Hosur, Tamil Nadua paul jayakumarNo ratings yet

- Inspection Standard: Daily Inprocess Inspection/Prod./Rejection ReportDocument5 pagesInspection Standard: Daily Inprocess Inspection/Prod./Rejection ReportPrakash kumarTripathiNo ratings yet

- KD 125Document6 pagesKD 125Ibrahim HamdyNo ratings yet

- MFL67218276 Rumanian 09 09Document33 pagesMFL67218276 Rumanian 09 09RemodaNo ratings yet

- Daily Report Activity: Senin, 11 Januari 22 14 Mechanical Extruder 2Document2 pagesDaily Report Activity: Senin, 11 Januari 22 14 Mechanical Extruder 2Rosid Ridwan Nur IchsanNo ratings yet

- NBC Jaf GQC RT A 150,151,152,153Document4 pagesNBC Jaf GQC RT A 150,151,152,153Akansha SharmaNo ratings yet

- 1778-4711-WD-DWG-006I - Line 4711-105-WCS-15-Q235A - CommentDocument6 pages1778-4711-WD-DWG-006I - Line 4711-105-WCS-15-Q235A - CommentAsyifa AldanaNo ratings yet

- Plant and Machinery (1) - 2Document1 pagePlant and Machinery (1) - 2SM AreaNo ratings yet

- Roughness Inspection ReportDocument1 pageRoughness Inspection ReportwahyuNo ratings yet

- Remot Seafty PanelDocument15 pagesRemot Seafty PanelابويحيىالمراديNo ratings yet

- Final Enquiry List For ValvesDocument12 pagesFinal Enquiry List For ValvesnikhilNo ratings yet

- Piping DetailsDocument16 pagesPiping DetailsSasi MesthiriNo ratings yet

- 1778 4601 TH DWG 003J 1Document1 page1778 4601 TH DWG 003J 1Asyifa AldanaNo ratings yet

- JG Summit Stage 1 Expansion Project Battery Limit Interface Table - NCPX A3-JGS1EP-IT-25-001Document2 pagesJG Summit Stage 1 Expansion Project Battery Limit Interface Table - NCPX A3-JGS1EP-IT-25-001mengelito almonteNo ratings yet

- Welder Test 18 December 2018Document1 pageWelder Test 18 December 2018NEMO MEMBUATNo ratings yet

- Pt. Multi Karya Engineering: Pt. Riau Andalan Pulp & PapperDocument1 pagePt. Multi Karya Engineering: Pt. Riau Andalan Pulp & PapperImade Subagianta100% (1)

- Imb SH Hse 0028Document9 pagesImb SH Hse 002801095902062ahmedNo ratings yet

- Output D4Document34 pagesOutput D4Angel MingaNo ratings yet

- Prakhar Gupta Epics and Empires-Game of Thrones Make Up EssayDocument5 pagesPrakhar Gupta Epics and Empires-Game of Thrones Make Up EssayGat DanNo ratings yet

- Activate My Win 7 Pro Product KeyDocument4 pagesActivate My Win 7 Pro Product KeydoktauNo ratings yet

- UntitledDocument4 pagesUntitledapi-223522684No ratings yet

- Upfc PlacementDocument0 pagesUpfc PlacementVamsi KumarNo ratings yet

- Polyethylene PolyamineDocument6 pagesPolyethylene PolyamineAV kayanNo ratings yet

- Tahmina Ferdousy Jhumu: HND Btec Unit 15 Psychology For Health and Social CareDocument29 pagesTahmina Ferdousy Jhumu: HND Btec Unit 15 Psychology For Health and Social CareNabi BoxNo ratings yet

- h4 History of India Ad 1526 - Ad 1707Document2 pagesh4 History of India Ad 1526 - Ad 1707Baddela ReddyNo ratings yet

- Docs Grails Org 4 0 0 Guide Single HTMLDocument296 pagesDocs Grails Org 4 0 0 Guide Single HTMLlicface13No ratings yet

- A 268 - A 268M - 01 Qti2oc0wmq - PDFDocument6 pagesA 268 - A 268M - 01 Qti2oc0wmq - PDFMan98No ratings yet

- James Bruce, One of Russian Tsar Peter The Great's Key Advisors (1669-1735)Document2 pagesJames Bruce, One of Russian Tsar Peter The Great's Key Advisors (1669-1735)Johanna Granville100% (1)

- Research Propsal v1.2Document3 pagesResearch Propsal v1.2john7904No ratings yet

- MikroC PRO For DsPIC30Document9 pagesMikroC PRO For DsPIC30ivcal20No ratings yet

- Research ProposalDocument2 pagesResearch Proposalsmh9662No ratings yet

- QBM101Document37 pagesQBM101Shang BinNo ratings yet

- Reflective EssayDocument4 pagesReflective Essayapi-385380366No ratings yet

- Ahmed 2022. Ergonomic Work From Home and Occupational Health Problems Amid COVID-19Document17 pagesAhmed 2022. Ergonomic Work From Home and Occupational Health Problems Amid COVID-19FioriAmeliaHathawayNo ratings yet

- ADCD LowDocument8 pagesADCD LowrahulmultivisionNo ratings yet

- Suricata User Guide: Release 4.1.0-DevDocument272 pagesSuricata User Guide: Release 4.1.0-DevDavid Simon Hoyos GonzalezNo ratings yet

- BC Caribou Recovery Program Stakeholders Teleconference MinutesDocument5 pagesBC Caribou Recovery Program Stakeholders Teleconference MinutesRevelstoke MountaineerNo ratings yet

- New Criticism Hills Like White Elephants FinalDocument4 pagesNew Criticism Hills Like White Elephants Finalapi-313631761No ratings yet

- A Priori and A Posteriori Knowledge: A Priori Knowledge Is Knowledge That Is Known Independently of Experience (That IsDocument7 pagesA Priori and A Posteriori Knowledge: A Priori Knowledge Is Knowledge That Is Known Independently of Experience (That Ispiyush_maheshwari22No ratings yet

- Predicates and ArgumentsDocument4 pagesPredicates and ArgumentsOanh NguyễnNo ratings yet

- Sociology Internal AssessmentDocument21 pagesSociology Internal AssessmentjavoughnNo ratings yet

- Department of Labor: BC Bond ListDocument67 pagesDepartment of Labor: BC Bond ListUSA_DepartmentOfLabor100% (1)

- Factors Affecting Pakistani English Language LearnersDocument19 pagesFactors Affecting Pakistani English Language LearnersSaima Bint e KarimNo ratings yet

- HRM ModelDocument6 pagesHRM ModelsakshiNo ratings yet