Professional Documents

Culture Documents

Mantencion Sistema A - C

Uploaded by

Fernando Pérez SarriaOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Mantencion Sistema A - C

Uploaded by

Fernando Pérez SarriaCopyright:

Available Formats

PLACING THE FIRE DETECTION AND SUPPRESSION SYSTEM IN SERVICE

Daily Inspections – Control Module – Check LED indication. See ANSUL Manual

-CHECKFIRE SC-N ELECTRIC DETECTION &

ACTUATION SYSTEM-

Every 50 Operating – Pneumatic actuation – Check for damage, loose or missing mounting

hours or weekly (which- lines, linear fire detec- parts. If any irregularities are found, corrective

ever comes first) tion wire, extinguishing action must be taken. Contact your local

nozzles and mounting ANSUL Service.

brackets

Every 3000 Operating – Fire Detection and Actu- – Check the complete system according to the

hours or every 6 month ation System instructions in the ANSUL Manual. -CHECK-

(whichever comes first) FIRE SC-N ELECTRIC DETECTION & ACTUA-

TION SYSTEM-

– Expellant gas cartridges – Check weight. Weight is stamped on the car-

(LT-10-R) tridge. Replace the cartridge if the weight is

1/4 oz. (7.1 g) or more below the weight

stamped on the cartridge.

– LT-A-101 and LVS Fire – Check the complete systems for mechanical

Suppression Systems damage or corrosion. Check that all compo-

nents are securely fastened and all hose fittings

are tight. Check filling level of extinguishing

agent tanks. See ANSUL Manuals LT-A-101

and LVS for detailed description of the checking

procedures. If any irregularities are found, cor-

rective action must be taken. Contact your local

ANSUL Service.

Every 6000 Operating – Control Module – Replace Lithium Battery, see ANSUL Manual

hours or yearly (which- -CHECKFIRE SC-N ELECTRIC DETECTION &

ever comes first) ACTUATION SYSTEM-

Every 5 Years – Actuation System – Replace Protracting Actuation Device (PAD).

This Device replaces also the Squib Assembly

used on former systems. Check fire detection

wire and end of line resistance

See ANSUL Manual -CHECKFIRE SC-N ELEC-

TRIC DETECTION & ACTUATION SYSTEM-

10-Year Maintenance – LVS System – Pressure test of expellant gas cartridges.

Examination See ANSUL Manual -LVS SYSTEM-

12-Year Maintenance – LT-A-101 and LVS – Pressure test of all extinguishing agent tanks

Examination System and all actuating hoses. Replacement of all

expellant gas cartridges.

See ANSUL Manuals LT-A-101 System and

LVS SYSTEM.

Final Checks and Adjustments 5 - 331

COMMISSIONING OF THE AIR CONDITIONING

– Refrigerant must be handled with care to avoid serious personal injury.

– Wear safety goggles to prevent refrigerant from contacting your eyes. Refrigerant can cause serious frost bite

or blindness because of its low boiling temperature. In case of eye contact, flush with plenty of water for at

least 15 minutes. Call a Physician. Wash skin with soap and water.

– Do not overheat the refrigerant container. Temperatures above 40°C will cause excessive container pressures

which can cause the container to burst.

– When it is necessary to heat service cans for charging in cold weather, use warm water at a temperature

below 40°C.

– Do not smoke or discharge refrigerant near an open flame. When refrigerant vapor contacts an open flame,

poisonous gas is produced.

– When removing refrigerant from the system, use a recovery process that minimizes refrigerant loss to the

atmosphere.

– Use caution with a refrigeration system in a closed or confined area with a limited air supply. Refrigerant dis-

places air and can cause oxygen depletion, resulting in suffocation and possible death.

– If refrigerant was inhaled, move victim to fresh air and use cardiopulmonary resuscitation or mouth to mouth

ventilation, if necessary. Stay with victim until arrival of emergency medical personnel.

– All work on the air conditioning should be carried out by well trained refrigeration specialists only.

– General Instructions regarding Commissioning of the Air Conditioning

Absolute cleanliness must be ensured when working on the air conditioning system, as practically all the faults that

arise can be traced back to the presence of dirt. As a refrigeration system is a closed system, any foreign bodies

remain in the system until they cause a problem or even serious damage, which can then usually only be repaired

at a great deal of trouble and expense. The system may nevertheless appear to start up and work perfectly nor-

mally. Damage caused by foreign bodies and dirt may not manifest itself for many month.

The continued proper functioning of the system depends on thorough and professional standards of work right

from the outset. This entails proper storage and keeping all components closed and/or covered, through profes-

sional installation and assembly. In repair situations as well, right up to the scrupulous checking for leaks, cleaning,

filling and commissioning of the system.

Professional and careful handling of tools, vacuum pumps, gauge manifold, etc. will provide many years of reliable

system operation.

Following commissioning every air conditioning system must be checked for leaks. Leaks not only means loss of

refrigerant and hence reduced cooling capacity, they can also result in the ingress of moisture, which will eventu-

ally cause problems in the system. A pressure test must first be performed when a new system has been installed.

Dry nitrogen 4.6 or 5.0 at 20 to max. 25 bar is used for the pressure test. This has the advantage that serious leaks

or loose connections can be detected without the loss of any expensive refrigerant. In addition, the use of nitrogen

purges (and hence cleans) the system as part of the pressure test. Do not add any kind of additives or contrast

substances to the refrigerant oil and/or refrigerant. If the pressure in a closed system does not fall, it can be

assumed that there is no leakage in the system.

5 - 332 Final Checks and Adjustments

COMMISSIONING OF THE AIR CONDITIONING

The air conditioning system will be delivered ex works completely filled with refrigerant and oil.

R 134a

l

Compressor oil POE

Carrier Sütrak SE 55

Fuchs Reniso E 68

ICI RL 68 S

Mobil EAL Arctic 68

Operator’s Cab: 6.000 gram

at an ambient temperature of 22° Celsius

Working pressure (Gauge reading)

High pressure switch:

Cut-off point 23.5 bar

Switch-on point 16.6 bar

Low pressure switch:

Cut-off point 0.35 bar

Switch-on point 2.10 bar

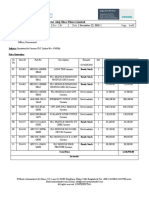

25 10.6 - 13.9

30 12.2 - 15.8

35 13.9 - 17.9

40 15.8 - 20.2

45 17.9 - 22.6

On the high – pressure side should be a pressure (gauge reading) of 12.2 to 20.2 bar under normal conditions.

20 1.0 - 1.9

25 1.4 - 2.5

30 1.9 - 3.1

35 2.5 - 3.9

On the low – pressure side should be a pressure (gauge reading) of 1.9 bar under normal conditions.

Final Checks and Adjustments 5 - 333

COMMISSIONING OF THE AIR CONDITIONING

Fig. 5-198

5 - 334 Final Checks and Adjustments

COMMISSIONING OF THE AIR CONDITIONING

(1) Air conditioner unit

(2) Refrigerant compressor. The Maintenance Manual for the compressor is part of the

Operation and Maintenance Manual Volume 2 Binder.

(3) Sight glass for checking refrigerant filling

(4) Shut-off valve on dryer cartridge

(5) Dryer cartridge

(6) Refrigerant collector reservoir

(7) Condenser

(8) Condenser blower

(9) Low pressure switch

(10) High pressure switch

(11) Expansion valves

(12) Evaporator blower

(13) Evaporator

(14) Cool air outlets

(15) High pressure service valve

(16) Low pressure service valve

(17) Magnetic clutch

(18) Cable plug for the magnetic clutch

Connect the high and low pressure refrigerant lines from compressor (2) to the air conditioner unit (1) and open

service valves (15 and 16) Fig. 5-198. Reconnect cable plug (18) for the magnetic clutch (17).

Check refrigerant level.

Switch on air conditioning equipment and run at maximum capacity for approx. 5 minutes. Observe inspection

glass (3). A refrigerant flow loaded with bubbles or foam indicates a lack of refrigerant. In this case add the missing

quantity of refrigerant.

Final Checks and Adjustments 5 - 335

You might also like

- Advanced Temperature Measurement and Control, Second EditionFrom EverandAdvanced Temperature Measurement and Control, Second EditionNo ratings yet

- Blake Mouton Managerial GridDocument3 pagesBlake Mouton Managerial GridRashwanth Tc100% (1)

- Powapak Air Ultra Operating ManualDocument45 pagesPowapak Air Ultra Operating ManualBenrub Flores75% (4)

- RTHC Svn02c enDocument16 pagesRTHC Svn02c enRicardo100% (1)

- P3 Past Papers Model AnswersDocument211 pagesP3 Past Papers Model AnswersEyad UsamaNo ratings yet

- Valvegyr®: Siemens Building TechnologiesDocument16 pagesValvegyr®: Siemens Building TechnologiesAbdul LatheefNo ratings yet

- Valvegyr®: Building Technologies DivisionDocument21 pagesValvegyr®: Building Technologies DivisionIshfaqAhmedMayoNo ratings yet

- Ldu 11 Eun 7696 en 25042005Document16 pagesLdu 11 Eun 7696 en 25042005Thiago FernandesNo ratings yet

- Ycrl0064-0156 Start-Up Checklist CommissioningDocument8 pagesYcrl0064-0156 Start-Up Checklist Commissioninggabo andresNo ratings yet

- Best Control ManualDocument16 pagesBest Control ManualVictor BecerraNo ratings yet

- Ldu 11Document17 pagesLdu 11tvbm100No ratings yet

- Troubleshooting Intermittent Ignition Systems For Gas Furnaces and BoilersDocument27 pagesTroubleshooting Intermittent Ignition Systems For Gas Furnaces and BoilerswarthogwillieNo ratings yet

- Fire Sprinkler Flow SwitchDocument8 pagesFire Sprinkler Flow Switchm.sofiqur rahmanNo ratings yet

- Maintenance and TroubleshootingDocument3 pagesMaintenance and TroubleshootingOkta AdityaNo ratings yet

- Operation and MaintenanceDocument76 pagesOperation and Maintenancesaie_1No ratings yet

- Norriseal Cantilever Level ControllerDocument6 pagesNorriseal Cantilever Level ControllerMertNo ratings yet

- Tyco Alarm Check Valve AV-1 300 PDFDocument26 pagesTyco Alarm Check Valve AV-1 300 PDFRomyrNo ratings yet

- Catalog Functional Safety Solutions Asco en 5084612Document16 pagesCatalog Functional Safety Solutions Asco en 5084612alejomariana03No ratings yet

- 05-MAR Ammonia PurgerDocument2 pages05-MAR Ammonia PurgerlhotapNo ratings yet

- Fire Alarm ValveDocument2 pagesFire Alarm ValveasdthuNo ratings yet

- 1 System Description LP3-RLU - 13.02.2006 New NHP5Document9 pages1 System Description LP3-RLU - 13.02.2006 New NHP5Andrei ZahaNo ratings yet

- Drain ValveDocument1 pageDrain ValveJose MontielNo ratings yet

- 1.4 Layer of ProtectionDocument41 pages1.4 Layer of ProtectionSrinivas BobbyNo ratings yet

- Em217030 PDFDocument141 pagesEm217030 PDFOskar Giancarlo Sifuentes EcheNo ratings yet

- JAK2.1 - Sequence of Operation: 1. General DescriptionDocument10 pagesJAK2.1 - Sequence of Operation: 1. General Descriptionrifky maulanaNo ratings yet

- Manual Técnico Hydraulic Power Unit EM217030 PDFDocument141 pagesManual Técnico Hydraulic Power Unit EM217030 PDFAlexander Cordova RosalesNo ratings yet

- Method Statement For Testing & Commissioning of Vacuum SystemDocument5 pagesMethod Statement For Testing & Commissioning of Vacuum SystemDong VanraNo ratings yet

- Relief Valves - 3 & 4 Inch - Operating & MaintenanceDocument6 pagesRelief Valves - 3 & 4 Inch - Operating & MaintenanceGenard Sabenacio GarciaNo ratings yet

- Thermocompressors Preventative Maintenance PDFDocument3 pagesThermocompressors Preventative Maintenance PDFalicardozoNo ratings yet

- Valvegyr®: Siemens Building TechnologiesDocument15 pagesValvegyr®: Siemens Building TechnologiesUlziitumur BatzorigNo ratings yet

- Owner'S Service Manual NO. 13259 Inspection, Maintenance and RechargeDocument4 pagesOwner'S Service Manual NO. 13259 Inspection, Maintenance and Rechargeespartako2008No ratings yet

- 02 PDFDocument11 pages02 PDFSerban LucianNo ratings yet

- Ammonia Systems: Testing, Charging and SafetyDocument3 pagesAmmonia Systems: Testing, Charging and SafetyCorrosion FactoryNo ratings yet

- Hydraulic System Trainer AS-10Document13 pagesHydraulic System Trainer AS-10Tanlets Gery100% (1)

- KGT ManualDocument25 pagesKGT ManualLeo MoltoNo ratings yet

- Turbine Interlocks and ProtectionDocument31 pagesTurbine Interlocks and ProtectionShambhu Mehta100% (1)

- 69 2012Document20 pages69 2012vaglohrdNo ratings yet

- 98 Dodge Ram Truck SM SCSDocument1 page98 Dodge Ram Truck SM SCSEduardo MacMasterNo ratings yet

- Tm-90-21-Ul (R-03/30/22)Document20 pagesTm-90-21-Ul (R-03/30/22)Mohamed Abou El hassanNo ratings yet

- Service Manual: 311D LRR ExcavatorDocument46 pagesService Manual: 311D LRR ExcavatorBuku Digital50% (2)

- ARCA Fly ReglerInstr GBDocument6 pagesARCA Fly ReglerInstr GBChanNo ratings yet

- Manipulator Elements Sergejs BoikoDocument14 pagesManipulator Elements Sergejs BoikoСергей БойкоNo ratings yet

- Vaicar KatalogDocument67 pagesVaicar KatalogSami Enis ArıoğluNo ratings yet

- Acttech Act Gstat TDocument3 pagesActtech Act Gstat TSony CNo ratings yet

- Powerex - Bombas de Vacio - Vane - Montado en Skid - ManualDocument56 pagesPowerex - Bombas de Vacio - Vane - Montado en Skid - ManualHugovillarruelNo ratings yet

- Valvula Unitrol CalentadorDocument4 pagesValvula Unitrol CalentadorJose MarcanoNo ratings yet

- Ballast TreatmentDocument5 pagesBallast TreatmentApetroae Ana-MariaNo ratings yet

- Gascon Systems Auto Change-Over Manifold Maintenance InstructionsDocument11 pagesGascon Systems Auto Change-Over Manifold Maintenance InstructionsNasro JuvNo ratings yet

- K & T Style Hydraulic System Test Analysers - ManualDocument16 pagesK & T Style Hydraulic System Test Analysers - Manualpravesh bhartiNo ratings yet

- Hyundai Excel X2 1989-1998 Air Conditioning PDFDocument53 pagesHyundai Excel X2 1989-1998 Air Conditioning PDFAamir Nasir KhanNo ratings yet

- Plastech Manual LTU6000 enDocument34 pagesPlastech Manual LTU6000 enCesar PomposoNo ratings yet

- Ta-Fus1On-C: Combined Control and Balancing Valves With Independent EQM CharacteristicsDocument16 pagesTa-Fus1On-C: Combined Control and Balancing Valves With Independent EQM CharacteristicsCatalin DinuNo ratings yet

- Fallos en Electrovalvulas PDFDocument4 pagesFallos en Electrovalvulas PDFJesus Humberto Tejero ArceoNo ratings yet

- Pressure Independent Control ValveDocument16 pagesPressure Independent Control ValverakamechNo ratings yet

- ENM-10 Level SensorsDocument6 pagesENM-10 Level SensorsAnteUkićNo ratings yet

- PSVDocument38 pagesPSVSajid Raza100% (1)

- KGL ManualDocument47 pagesKGL ManualAaron Shane IrvinNo ratings yet

- Iom Ylae-2Document32 pagesIom Ylae-2lam100% (1)

- Calibration and Leak-By Test ProceduresDocument2 pagesCalibration and Leak-By Test Proceduresromi_hamdaniNo ratings yet

- PNEUMATICS AND AIR CIRCUITS UNDERSTANDING THE CASCADE VALVE AND PLC UNDERSTANDINGFrom EverandPNEUMATICS AND AIR CIRCUITS UNDERSTANDING THE CASCADE VALVE AND PLC UNDERSTANDINGNo ratings yet

- Contemporary Anaesthetic Equipments.: An Aid for Healthcare ProfessionalsFrom EverandContemporary Anaesthetic Equipments.: An Aid for Healthcare ProfessionalsNo ratings yet

- Compresor TMDocument62 pagesCompresor TMFernando Pérez SarriaNo ratings yet

- System Pressure - ReleaseDocument2 pagesSystem Pressure - ReleaseFernando Pérez SarriaNo ratings yet

- Automatic Lubrication System TroubleshootingDocument2 pagesAutomatic Lubrication System TroubleshootingFernando Pérez SarriaNo ratings yet

- Automatic Lubrication System Air - PurgeDocument2 pagesAutomatic Lubrication System Air - PurgeFernando Pérez SarriaNo ratings yet

- Printed in Sweden 0103Document361 pagesPrinted in Sweden 0103Fernando Pérez SarriaNo ratings yet

- Operation System A - CDocument96 pagesOperation System A - CFernando Pérez Sarria100% (1)

- Display and KeypadDocument2 pagesDisplay and KeypadFernando Pérez SarriaNo ratings yet

- Parameter ViewingDocument1 pageParameter ViewingFernando Pérez SarriaNo ratings yet

- Initialization Procedures From Start To Finish - 54839Document16 pagesInitialization Procedures From Start To Finish - 54839Fernando Pérez SarriaNo ratings yet

- AH18856 Respirador HidraulicoDocument11 pagesAH18856 Respirador HidraulicoFernando Pérez SarriaNo ratings yet

- Automatic Lubrication System - AdjustDocument4 pagesAutomatic Lubrication System - AdjustFernando Pérez SarriaNo ratings yet

- Parts & Service NewsDocument4 pagesParts & Service NewsFernando Pérez SarriaNo ratings yet

- Rops Transmission Service Center Implement Valve Bumper: Electrical System 993K Wheel LoaderDocument6 pagesRops Transmission Service Center Implement Valve Bumper: Electrical System 993K Wheel LoaderFernando Pérez SarriaNo ratings yet

- Parts & Service News: 0. Assignment of The Software To The HardwareDocument1 pageParts & Service News: 0. Assignment of The Software To The HardwareFernando Pérez SarriaNo ratings yet

- Parts Manual: D10T2 Track-Type TractorDocument823 pagesParts Manual: D10T2 Track-Type TractorHaytham Maged100% (1)

- Parts & Service News: Major Code: 55 NO.: Date: AH18855 August 3, 2017Document4 pagesParts & Service News: Major Code: 55 NO.: Date: AH18855 August 3, 2017Fernando Pérez SarriaNo ratings yet

- Hoja de Inspeccion (Ingles)Document13 pagesHoja de Inspeccion (Ingles)Fernando Pérez SarriaNo ratings yet

- Flexiroc D60 and D65: Atlas Copco Surface Drill RigsDocument4 pagesFlexiroc D60 and D65: Atlas Copco Surface Drill RigsFernando Pérez SarriaNo ratings yet

- Kac 730eDocument4 pagesKac 730eQrwer SffNo ratings yet

- Parts & Service News: This PARTS & SERVICE NEWS Supersedes The Previous Issue AH00510 Which Should Be DiscardedDocument3 pagesParts & Service News: This PARTS & SERVICE NEWS Supersedes The Previous Issue AH00510 Which Should Be DiscardedFernando Pérez SarriaNo ratings yet

- HB 4700, 4700 DP: Spare Parts ListDocument52 pagesHB 4700, 4700 DP: Spare Parts ListFernando Pérez SarriaNo ratings yet

- Parts Manual: D10T2 Track-Type TractorDocument913 pagesParts Manual: D10T2 Track-Type TractorHaytham Maged0% (1)

- Excabadora 390d Plano HYDRAULICODocument10 pagesExcabadora 390d Plano HYDRAULICOhitler morales gavidiaNo ratings yet

- Qdoc - Tips - Manual Fallas TerexDocument184 pagesQdoc - Tips - Manual Fallas TerexFernando Pérez SarriaNo ratings yet

- Pm-Clinic Service: Inspection Procedure ManualDocument18 pagesPm-Clinic Service: Inspection Procedure ManualFernando Pérez SarriaNo ratings yet

- PC5500 SN 15032 Operation and Maintenance ManualDocument527 pagesPC5500 SN 15032 Operation and Maintenance ManualFernando Pérez Sarria100% (1)

- Procedimiento de Armado PC5500E-6Document106 pagesProcedimiento de Armado PC5500E-6Fernando Pérez SarriaNo ratings yet

- AH17897 Reinicio SistemaDocument3 pagesAH17897 Reinicio SistemaFernando Pérez SarriaNo ratings yet

- Excabadora 390d Plano HYDRAULICODocument10 pagesExcabadora 390d Plano HYDRAULICOhitler morales gavidiaNo ratings yet

- Functions of Theory in ResearchDocument2 pagesFunctions of Theory in ResearchJomariMolejonNo ratings yet

- VOTOL EMController Manual V2.0Document18 pagesVOTOL EMController Manual V2.0Nandi F. ReyhanNo ratings yet

- Moral GPS: A Positive Ethic For Our Multicultural WorldDocument279 pagesMoral GPS: A Positive Ethic For Our Multicultural WorldLeonard Bowman75% (4)

- Cash Flow July 2021Document25 pagesCash Flow July 2021pratima jadhavNo ratings yet

- ChatGPT & EducationDocument47 pagesChatGPT & EducationAn Lê Trường88% (8)

- Philo Q2 Lesson 5Document4 pagesPhilo Q2 Lesson 5Julliana Patrice Angeles STEM 11 RUBYNo ratings yet

- Construction Project - Life Cycle PhasesDocument4 pagesConstruction Project - Life Cycle Phasesaymanmomani2111No ratings yet

- TTDM - JithinDocument24 pagesTTDM - JithinAditya jainNo ratings yet

- Kübler 5800-5820 - enDocument5 pagesKübler 5800-5820 - enpomsarexnbNo ratings yet

- Cap1 - Engineering in TimeDocument12 pagesCap1 - Engineering in TimeHair Lopez100% (1)

- Stability Analysis of Geocell Reinforced Slopes by Considering Bending EffectDocument13 pagesStability Analysis of Geocell Reinforced Slopes by Considering Bending EffectRakesh KapoorNo ratings yet

- Swelab Alfa Plus User Manual V12Document100 pagesSwelab Alfa Plus User Manual V12ERICKNo ratings yet

- I. Choose The Best Option (From A, B, C or D) To Complete Each Sentence: (3.0pts)Document5 pagesI. Choose The Best Option (From A, B, C or D) To Complete Each Sentence: (3.0pts)thmeiz.17sNo ratings yet

- Etag 002 PT 2 PDFDocument13 pagesEtag 002 PT 2 PDFRui RibeiroNo ratings yet

- Dec 2-7 Week 4 Physics DLLDocument3 pagesDec 2-7 Week 4 Physics DLLRicardo Acosta Subad100% (1)

- 'Causative' English Quiz & Worksheet UsingEnglish ComDocument2 pages'Causative' English Quiz & Worksheet UsingEnglish ComINAWATI BINTI AMING MoeNo ratings yet

- Approvals Management Responsibilities and Setups in AME.B PDFDocument20 pagesApprovals Management Responsibilities and Setups in AME.B PDFAli LoganNo ratings yet

- Anker Soundcore Mini, Super-Portable Bluetooth SpeakerDocument4 pagesAnker Soundcore Mini, Super-Portable Bluetooth SpeakerM.SaadNo ratings yet

- Template Budget ProposalDocument4 pagesTemplate Budget ProposalimamNo ratings yet

- Superlab Manual PDFDocument76 pagesSuperlab Manual PDFGabriela Soares100% (1)

- MPI Unit 4Document155 pagesMPI Unit 4Dishant RathiNo ratings yet

- Intelligent Status Monitoring System For Port Machinery: RMGC/RTGCDocument2 pagesIntelligent Status Monitoring System For Port Machinery: RMGC/RTGCfatsahNo ratings yet

- LC For Akij Biax Films Limited: CO2012102 0 December 22, 2020Document2 pagesLC For Akij Biax Films Limited: CO2012102 0 December 22, 2020Mahadi Hassan ShemulNo ratings yet

- Ficha Tecnica Bomba Inyeccion MiniFlex EDocument1 pageFicha Tecnica Bomba Inyeccion MiniFlex Ejohn frader arrubla50% (2)

- Aristotle - OCR - AS Revision NotesDocument3 pagesAristotle - OCR - AS Revision NotesAmelia Dovelle0% (1)

- 5steps To Finding Your Workflow: by Nathan LozeronDocument35 pages5steps To Finding Your Workflow: by Nathan Lozeronrehabbed100% (2)

- Rsi r2 Super Rsi FaqDocument14 pagesRsi r2 Super Rsi FaqChandrasekar Chandramohan100% (1)

- MATH CIDAM - PRECALCULUS (Midterm)Document4 pagesMATH CIDAM - PRECALCULUS (Midterm)Amy MendiolaNo ratings yet