Hazard Identification Pro-forma for NOSCO

Uploaded by

mohamed Abo-EwishaHazard Identification Pro-forma for NOSCO

Uploaded by

mohamed Abo-Ewisha- Loading, Transportation & Discharging: Covers various hazards associated with loading, transportation, and discharging operations, including risks, controls, and actions to be taken.

- Lifting & Skidding: Details hazards related to lifting and skidding activities with associated risks, controls, and recommended actions.

- Risk Level Assessment: Provides a table to prioritize risk levels based on likelihood and severity for effective hazard management.

National Transport & Overseas Services Co.

ﺣﺼﺮ ﻣﺼﺎدر اﳋﻄﺮ وﺗﻘﻴﻴﻤﻬﺎ الشركة الوطنية لخدمات النقل وأعالي البحـــار

NOSCO ﻧــﻮﺳﻜــﻮ

Hazard Identification pro-forma

Company: NOSCO Site / location: SG Power Plant Date: 1/9/2016

ACTIVITY RISK Residual

HAZARD RISK AT RISK CONTROLS FREQUANCY SEVERITY ACTION TO BE TAKEN

LEVEL Risk

(1) (2) F S

(1*2) level

DRIVER,

NO JOB NOT OPERATION CORRECT PRE-

Loading ,Transportation & discharging

Customer 2 3 6 1 3 3

AVAILABILITY COMPLETED DEPT. STAFF PLANNING OF

satisfactio

TRAINNING AVAILABILITY

LATE START PLANNING:

Customer

OR WRONG DELAYS OPERATION DEPT. 1 3 3 NONE 1 3 3

satisfactio

RELEASE TIME + CUSTOMER SER.

n

Customer

NOT READY DELAYS CUSTOMER SERVICE 1 3 3 REVIEWING INSTRUCTIONS 1 3 3

satisfactio

UNSUITABLE

SITE SUPERVISION: DRIVER

EQ. & DROPPE STAFF , PUBLIC PROCEDURE

1 4 4 TO PRE-CHECK 1 4 4

OPERATOR D & OBJECT CHECKS AT OPERATORS

LOW-SKILLS OBJECTS LOADING SITE & TOOLS(EQ.)

Operation areas will

be cordoned off with

tape or physical

barriers, sign and

unauthorized persons

will be kept away by

Unauthorized Fatality, STAFF , PUBLIC observer. Continued One person in crew will

persons within Serious & OBJECT reminders to loading 1 4 4 be responsible for 1 4 4

operating injury. Bodily staff and Port monitoring adherence to

areas harm Operators the barriers

supervision of the

requirements at TBT.

Constant monitoring

for breach of

Check worksite is clear

before starting work,

Injury to Training,TBT, remove all trip hazards.

Trips and falls STAFF 1 4 4 Orderliness and tidiness 1 4 4

Personne Housekeeping

l . Supervision and

coaching of workforce

Issue Index: 1.1 HSF-01 Issuance Date: 01-08-2007

National Transport & Overseas Services Co. ﺣﺼﺮ ﻣﺼﺎدر اﳋﻄﺮ وﺗﻘﻴﻴﻤﻬﺎ الشركة الوطنية لخدمات النقل وأعالي البحـــار

NOSCO ﻧــﻮﺳﻜــﻮ

Hazard Identification pro-forma

Operational Personnel

versed in basics of

manual handling/lifting.

Trapping, Lifting equipment to be

Manual

strain Staff Training, TBT, PPE 1 4 4 utilized wherever 1 3 3

handling

injuries, possible. All personnel to

Loading ,Transportation & discharging

Bodily harm wear appropriate

Personal Protective

Lifting Fatality, Pre-job instruction. Pre lift

STAFF , PUBLIC Inspection,

accessories Serious inspections will be

,OBJECT Observation, 1 4 4 1 4 4

not attached injury, undertaken. Only certified

property Work guidelines

correctly damage to equipment to be used.

Only properly trained

Rigging staff involved in

Fatality, attaching cargo. Crane

Serious Maintenance, Work and lifting tackle to be

STAFF , PUBLIC

Droppe injury, guidelines All lifting well maintained and

, OBJECT& 1 4 4 1 4 4

d damage to equipment checked daily prior to

property

Objects property, certification verified. operations.

Bodily harm. Pre lift inspections

undertaken.

Fatality,

Pre-announcement will be

Other work Serious

STAFF ,OBJECT& TBT, Jetty cargo plans. made; all other activities

activities in the injury, 2 4 8 1 4 4

property in the immediate vicinity

vicinity damage to

will be monitored.

property,

Experienced personnel

will attend the operation.

Serious Sufficient supervision and

Knowledge guidance will be supplied

injury, STAFF ,OBJECT& TBT,

based 2 3 6 Berth operator. Operation 1 3 3

damage to property Awareness,

human will be applied as per the

property, Supervision

factors method statement.

Bodily harm.

Toolbox Talks.

Experienced personnel.

Serious Personnel will be

Work Guidelines, instructed as to their

injury,

Error based STAFF ,OBJECT& TBT, and Supervision duties and be informed

damage to 2 3 6 1 3 3

human property by Competent staff. about the operation in a

property,

factors Bodily harm. pre-job tool- box meeting.

Driver fatigue Realistic time

frame to perform job.

Issue Index: 1.1 HSF-01 Issuance Date: 01-08-2007

National Transport & Overseas Services Co. ﺣﺼﺮ ﻣﺼﺎدر اﳋﻄﺮ وﺗﻘﻴﻴﻤﻬﺎ الشركة الوطنية لخدمات النقل وأعالي البحـــار

NOSCO ﻧــﻮﺳﻜــﻮ

Hazard Identification pro-forma

Staff to be properly

instructed in working at

heights, Fall arresters to

Personnel PPE, ERP be worn when and where

Falling Serious (Enterprise applicable, anti-slip boots

STAFF 2 3 6 1 3 3

Loading ,Transportation & discharging

From injury, resource planning), to be worn, Adherence to

Height Bodily harm TBT this rule must be

emphasized to all staff

during toolbox talks

Crew

staff is ranked.

member

Customer Substitutes are continues verbal and

fatigue, confusion 2 2 4 1 2 2

satisfactio nominated for visual check of staff

illness each rank.

n

or injury

Prim mover checkup at

Prim mover Time delay Customer Trained staff for 2 2 4 1 2 2

workshop before

Malfunctioning satisfactio quick arriving to site

n maintenance

"Procedure checks

"Inspection,

Fatality, at loading site.

STAFF, Observation,

Unsuitable Serious Lashing is not permitted

PUBLIC,OBJECT Work guidelines 1 4 4 1 4 4

Loading injury, unless loading is

& Site

damage to approved upon by

property supervision

property Supervisor & Driver"

(Toolbox

DRIVER &

LESS THAN DROPPE TOOLBOX TALKS:

PUBLIC& OBJECT STEVEDORES 1 4 4 1 4 4

STANDARD D REVIEWING

TRAINING

S OBJECTS INSTRUCTIONS

Pre-job instruction. Pre

loading inspections will be

undertaken. Only certified

equipment to be used.

Not (The vessel is lashed to the

CARGO STAFF , PUBLIC EQUIPMENT &

SUITABLE 2 3 6 low- bed by 2 lashing 1 3 3

DAMAGE(S & OBJECT CARGO

FOR CARGO chains separately and

) STANDARDS

SPECS. rubber strings are used

under the chains to avoid

scratching the vessel)

CARGO AUTHORITIE As Low As

PUBLIC & OBJECT ROAD PERMIT 2 2 4 1 2 2

over- S Reasonably

Issue Index: 1.1 HSF-01 Issuance Date: 01-08-2007

National Transport & Overseas Services Co. ﺣﺼﺮ ﻣﺼﺎدر اﳋﻄﺮ وﺗﻘﻴﻴﻤﻬﺎ الشركة الوطنية لخدمات النقل وأعالي البحـــار

NOSCO ﻧــﻮﺳﻜــﻮ

Hazard Identification pro-forma

Electrical flashing lights

surround the cargo piece,

DRIVER TRAINNING to warn other drivers and

BY COMPETENT surrounding traffic of the

CARGO DRIVER , OTHERS PERSONNEL cargo to avoid hitting it.

ACCIDENTS 2 2 4 1 2 2

over- & OBJECT Complete Escort fitted

Loading ,Transportation & discharging

THROUGH

size TOOLBOX TALKS with servicing trucks and

traffic police accompany

the transportation

"hydraulic system is

equipped with self-

Hydraulic Time Customer locking valve in Hydraulic system is

connection delay, satisfaction& case of pressure 1 1 1 checked and tested at 1 1 1

Damage damage to property drop. workshop before

property New connections arriving to site

with quick coupling

are available"

Pre-journey

inspection &Change Inspection during all

DROPPE DRIVER , OTHERS

Flat tire after securing the low 2 4 8 stops&2 spare tires 1 4 4

D & OBJECT bed/the truck and are available

OBJECTS the cargo

If needed cut off

Proper route and work

the electric current

DRIVER , OTHERS location planning &

High voltage electric shock & raise the wires 2 3 6 1 3 3

& OBJECT inspection. Not

with isolated

exceeding the max. load

stands until

height

Reflectors lights and

traffic cones

Standby at surround the vessel All equipments are

rest or check ACCIDENTS STAFF & PUBLIC and low bed along 2 3 6 available and safely rest 1 3 3

points with the servicing points are neatly

truck and cars to chosen.

Allsecure

bridgesit.are

Road permits are issued

CARGO approved to pass

Bridge Crossing STAFF & PUBLIC 4 2 8 by means of the ministry 2 2 4

DAMAGE(S over by the ministry

of transportation

) of transportation

Drives do not exceed Toolbox Talks: Reviewing

Sliding on Vehicle Driver, vehicle max allowable instruction(defensive

2 3 6 1 3 3

the road Crushin and the driving time and take driving)

g objects sufficient breaks.

Issue Index: 1.1 HSF-01 Issuance Date: 01-08-2007

National Transport & Overseas Services Co. ﺣﺼﺮ ﻣﺼﺎدر اﳋﻄﺮ وﺗﻘﻴﻴﻤﻬﺎ الشركة الوطنية لخدمات النقل وأعالي البحـــار

NOSCO ﻧــﻮﺳﻜــﻮ

Hazard Identification pro-forma

Calling the operating

Mechanica Vehicle Driver, vehicle pre-journey

2 2 4 supervisor for 1 2 2

l Crushin and the truck

guidance and help

breakdown g objects check

Loading ,Transportation & discharging

Inform drivers about areas

of difficult / abnormal

Absence of road conditions before

road Vehicle Driver, vehicle Planning according the trip

3 3 9 1 3 3

guiding Crushin and the to road SURVEY &Drives do not exceed

signs. g objects max allowable driving

time and take sufficient

Drives do not exceed max

Vehicle Driver, vehicle

Wrong turn Training the driver 1 4 4 allowable driving time 1 4 4

Crushin and the

and take sufficient

g objects

breaks.

Toolbox Talks: Reviewing

instruction and stick to

Wrong Vehicle Driver, vehicle speed limits (Drives do

exceedin Crushin and the Training the driver 1 4 4 not exceed max allowable 1 4 4

g g objects driving time and take

sufficient breaks)

Inform drivers about areas

of difficult / abnormal

road conditions before

Improper Vehicle Driver, vehicle Planning according the trip

1 4 4 1 4 4

road Crushin and the to road survey &Drives do not exceed

condition g objects max allowable driving

time and take sufficient

breaks.

Absence Vehicle Driver, vehicle pre-journey Toolbox Talks: Reviewing

1 3 3 1 3 3

of Crushin and the truck instruction

lights g objects check

Losing Vehicle Driver, vehicle pre-journey

1 4 4 Inspection during all stops 1 4 4

the Crushin and the truck

trailer g objects check

Issue Index: 1.1 HSF-01 Issuance Date: 01-08-2007

National Transport & Overseas Services Co. ﺣﺼﺮ ﻣﺼﺎدر اﳋﻄﺮ وﺗﻘﻴﻴﻤﻬﺎ الشركة الوطنية لخدمات النقل وأعالي البحـــار

NOSCO ﻧــﻮﺳﻜــﻮ

Hazard Identification pro-forma

Accident on Delaying Driver, vehicle Slowing down and Calling the operating

Loading ,Transportation & discharging

the way or and the avoiding the 4 1 4 supervisor for 2 1 2

crushing objects accident place guidance

traffic Customer Stopping and Calling the operating

congestio Delaying satisfactio turning on 4 1 4 supervisor for 2 1 2

n n waiting lights guidance

Driver, vehicle Mooring on the

Delaying , the objects & side of the road Calling the operating

Mist 4 1 4 2 1 2

or Customer and turning on supervisor for

crushing satisfaction waiting lights guidance

Delaying or Driver, vehicle Mooring on the

Rains crushing , the objects & side of the road 4 1 4 Calling the operating 2 1 2

due to Customer and turning on supervisor for

sliding satisfaction waiting lights guidance

Slowing down and

Delaying , Driver, vehicle avoiding the fire

crushing , the objects & place if it is necessary Calling the operating

Fire on the road 4 1 4 2 1 2

or fire Customer to stop the mooring supervisor for

satisfaction place must be away guidance

enough of the fire

Supervising the

Driver, vehicle Supervising loading process & 4

Fall of the cargo Load loss 1 4 4 1 4

and the flat the loading Securing the load by

rack process good lashing

Issue Index: 1.1 HSF-01 Issuance Date: 01-08-2007

National Transport & Overseas Services Co. ﺣﺼﺮ ﻣﺼﺎدر اﳋﻄﺮ وﺗﻘﻴﻴﻤﻬﺎ الشركة الوطنية لخدمات النقل وأعالي البحـــار

NOSCO ﻧــﻮﺳﻜــﻮ

Hazard Identification pro-forma

ACTIVITY RISK Residual

HAZARD RISK AT RISK CONTROLS FREQUANCY SEVERITY ACTION TO BE

LEVEL Risk

(1) (2) TAKEN F S

(1*2) level

STAFF &

Power

DELAYS customer Pump is equipped with diesel motor 1 3 3 Using diesel motor 1 3 3

source

satisfactio

failure

Weakness CARGO

Landslide Level and compact ground 1 3 3 NONE 1 3 3

the DAMAGE(S

ground )

Electricity

Lifting & Skidding

Customer Get rid of

connections DELAYS Closing safety circle 1 5 5 1 3 3

satisfactio damaged

failure

n connection

Hydraulic

connections DELAYS Customer Closing safety valve 1 5 5 Replacing with new 1 4 4

failure satisfactio quick-fixed

n connection

STAFF ,

Hydraulic Delaying PUBLIC Adding wooden layers to stools 1 4 4 Replacing host 1 3 3

host or & with height difference 15 cm

damage crushing OBJECT maximum

Check worksite is

clear before starting

work, remove all trip

Trips Injury to hazards. Orderliness

STAFF Training,TBT, Housekeeping. 1 4 4 1 3 3

and Personne and tidiness

falls l Supervision and

coaching of workforce

Cargo &

Delaying

staff& All equipment are experimented at Alternative

Equipment or cargo 1 4 4 1 3 3

customer company workshop before execution equipment are

damage

satisfaction insured

rollers crush cargo Inspection and testing 1 4 4 None 1 3 3

before execution

Issue Index: 1.1 HSF-01 Issuance Date: 01-08-2007

National Transport & Overseas Services Co. ﺣﺼﺮ ﻣﺼﺎدر اﳋﻄﺮ وﺗﻘﻴﻴﻤﻬﺎ الشركة الوطنية لخدمات النقل وأعالي البحـــار

NOSCO ﻧــﻮﺳﻜــﻮ

Hazard Identification pro-forma

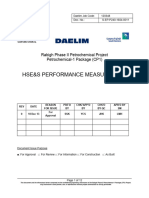

Use the following table to prioritize risk Level:

likelihood معدل تكرار المخاطر مستوى المخاطر

غير وارد الحدوث قد يحدث محتمل الحدوث دائم الحدوث Risk level

1 2 3 4

/ الكلى الوفاة

5 10 15 20 العجز

5

حالة عظمى

4 8 12 16

4

شدة المخاطر

حالة صغرى

3 6 9 12

3

حالة بسيطة

2 4 6 8

2

إسعاف أولى

1 2 3 4

1

Prepared by:

HSE Manager

Name Eng . Ahmed Zaky

Signature ........................................................................................

Issue Index: 1.1 HSF-01 Issuance Date: 01-08-2007

You might also like

- Container Inspection Checklist: 17-Point Truck & Trailer InspectionNo ratings yetContainer Inspection Checklist: 17-Point Truck & Trailer Inspection1 page

- Container Checklist: CHECKLIST (At Shipper's Premises)No ratings yetContainer Checklist: CHECKLIST (At Shipper's Premises)3 pages

- Emergency Evacuation Procedure From Overhead CraneNo ratings yetEmergency Evacuation Procedure From Overhead Crane9 pages

- Livestock Transportation Emergency Response Plan: With TheNo ratings yetLivestock Transportation Emergency Response Plan: With The4 pages

- Weighbridge Usage SOP - PDF - Displayname Weighbridge Usage SOPNo ratings yetWeighbridge Usage SOP - PDF - Displayname Weighbridge Usage SOP12 pages

- Industrial Action Contingency Plan Guide - GrindrodNo ratings yetIndustrial Action Contingency Plan Guide - Grindrod9 pages

- SOP 001.WI-3.Transfer Passenger ActivityNo ratings yetSOP 001.WI-3.Transfer Passenger Activity3 pages

- Finished Goods Transport Delivery Procedure 2021No ratings yetFinished Goods Transport Delivery Procedure 20211 page

- EHS Monitoring Integrated Management SystemNo ratings yetEHS Monitoring Integrated Management System4 pages

- QLD Route Assessment for Heavy VehiclesNo ratings yetQLD Route Assessment for Heavy Vehicles73 pages

- Safety Guidelines for Warehousing OperationsNo ratings yetSafety Guidelines for Warehousing Operations18 pages

- Main Gate Vehicle Movement Control SheetNo ratings yetMain Gate Vehicle Movement Control Sheet1 page

- Job Safety Analysis for Material UnloadingNo ratings yetJob Safety Analysis for Material Unloading6 pages

- Non Conformance Report: Reg. Number DateNo ratings yetNon Conformance Report: Reg. Number Date1 page

- LSR Bypassing Safety Controls Toolbox Talk100% (3)LSR Bypassing Safety Controls Toolbox Talk12 pages

- LSR Safe Mechanical Lifting Toolbox TalkNo ratings yetLSR Safe Mechanical Lifting Toolbox Talk13 pages

- Aga Psms Workshop Pge Andre Da Costa-3-1-16 Rev For WebNo ratings yetAga Psms Workshop Pge Andre Da Costa-3-1-16 Rev For Web16 pages

- Site-Specific Safety Orientation ChecklistNo ratings yetSite-Specific Safety Orientation Checklist3 pages

- HSE Section Head Resume of Ismail HassanNo ratings yetHSE Section Head Resume of Ismail Hassan2 pages

- Meha S-NewCV-August 2017-2017-12-9 - 11-51-06No ratings yetMeha S-NewCV-August 2017-2017-12-9 - 11-51-063 pages

- English Guide for Eco-Friendly PracticesNo ratings yetEnglish Guide for Eco-Friendly Practices5 pages

- Motor Vehicle Hypothecation Registration GuideNo ratings yetMotor Vehicle Hypothecation Registration Guide5 pages

- Nigeria 2040 Agriculture & Food Security Plan (2026-2030)No ratings yetNigeria 2040 Agriculture & Food Security Plan (2026-2030)8 pages

- LPG Production Imports Data For January 2024No ratings yetLPG Production Imports Data For January 20241 page

- 01jan24 The Steam Has Gone Out of Globalisation - Slowbalisation DirectNo ratings yet01jan24 The Steam Has Gone Out of Globalisation - Slowbalisation Direct6 pages

- Certificate of Origin for PharmaceuticalsNo ratings yetCertificate of Origin for Pharmaceuticals1 page

- Nia - Response To AOM HCAAP 2013-008 - Illegal Contract TerminationNo ratings yetNia - Response To AOM HCAAP 2013-008 - Illegal Contract Termination128 pages

- FedEx Strategic Management Analysis 2012No ratings yetFedEx Strategic Management Analysis 201230 pages

- Managerial Economics: Key Principles ExplainedNo ratings yetManagerial Economics: Key Principles Explained2 pages

- Knowing The Score:: New Data, Underwriting, and Marketing in The Consumer Credit MarketplaceNo ratings yetKnowing The Score:: New Data, Underwriting, and Marketing in The Consumer Credit Marketplace34 pages

- General Provisions of RA 9184 and Its IRRNo ratings yetGeneral Provisions of RA 9184 and Its IRR79 pages