Professional Documents

Culture Documents

Minimum Distance Between Two Circumferential Pipe Joints

Uploaded by

Dr.Samir Saad100%(1)100% found this document useful (1 vote)

77 views7 pagesMinimum Distance Between Two Circumferential Pipe Joints as per codes and standard- Prepared by Dr. Samir Saad

Copyright

© © All Rights Reserved

Available Formats

PDF or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentMinimum Distance Between Two Circumferential Pipe Joints as per codes and standard- Prepared by Dr. Samir Saad

Copyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

100%(1)100% found this document useful (1 vote)

77 views7 pagesMinimum Distance Between Two Circumferential Pipe Joints

Uploaded by

Dr.Samir SaadMinimum Distance Between Two Circumferential Pipe Joints as per codes and standard- Prepared by Dr. Samir Saad

Copyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

You are on page 1of 7

€ [eyed e. ¥

CATT ASV) “Le

MINIMUM DISTANCE _—

BETWEEN TWO

oat ce NUP U PIPE i

ASME B31.3, 341-4.1

(B)(2)

ASME VIII.DIV.1, UW-g (d)

When a circumferential weld with

an intersecting longitudinal

weld(s) is examined, at least the

adjacent 38 mm (1.1/ in.) of each

intersecting weld shall be

examined.

Except when the longitudinal joints are

radiographed 4 in. (100 mm) each side of

each circumferential welded intersection,

vessels made up of two or more courses

shall have the centers of the welded

longitudinal joints of adjacent courses

staggered or separated by a distance of at

least five times the thickness of the

thicker plate

>[2 | BSstandard

Standards (BS) are specified the minimum distance between welds.

Sai nos

welding of steel pipelines on

PIC EU ere eee

Fey

lass | arc welding of

Pee e Terrace

Cea Caste)

* States that "the toes of * States that "the

adjacent butt welds proximity of weld toe-

shall, whenever to-toe distance Shall)

possible, beno closer| not be less than four

than four times the times the pipe

nominal thickness of thickness"

the pipe.

lesagra(e acy]

ee roscis

carrying of fluids (Section 10)

* States that (if design

factors are such that

the meeting of more

than two welded seams

cannot be avoided,

‘then appropriate

precautions shall be

taken which shall be|

agreed between the

contracting parties."

BS standard

Minimum distance??

\

PIPE Wall Thickness —|

L

ea | TT

| ‘BS 2633 {Ferritic Steel Pipework} | ‘4 xnominal thickness of the pipe

| BS 4515 {C-Mn Pipeline} i 4x pipe wall thickness

BS 2971 {Carbon Stee! Pipework} \ ae

1 {Carbon jipework}

D

“LEAR!

R f

EAMIR-SAAD

>t 3 | From other specifications, standards and common practice:

Branch connections (with or

without r¢

forcing pads or The larger of

OLETS) and Circumferential

50mm (or) 4xT

welds

The Larger of

50mm (or) 4xT

Two circumferential welds

<6" Pipes

100mm (or) 4xT 8” to 12” Pipes

150mm (or) 4xT 14”and above

Two adjacent fillet welds

Smaller of 40mm (or) 3xT

AllSizes

Profile

Dr. Samir Saad

General Manager

Cutech Arabia LLC

Experience: 18 Years (Oil and Gas)

Skills & Expertise

+ Welding and Welding inspection

Non-Destructive Testing

Material Technology

In Service & On-stream Inspection

Corrosion and Management

Asset Integrity Management

Dr, Samirsaad

Professional Certification

Project Management Professional (PMP)®,: PMP@ Number: 3230417

PMI Risk Management Professional (PMLRMP)®:PMI-RMPO Numbor. 3223508,

PMI Agie Certified Practitioner (PMIAACP)® :PIVI-ACP@ Number’ 1230001

ASME Authorized Inspector (Al), Boler and Pressure Vessel

‘ASNT NDT LEVEL Min 14 methods, ASNT 10: 190902

1. Visual and Optical Testing (VT), "7. Magnetic ux leakage Testing (AFL),

2 Radiographic Testing (RT), inferred thermal testing (IR),

3. Utrasonie Tesing (UT), ‘98. Acoustic Emission Testing (AE)

4 Liquid Penetrant Testing (PD), 10. Leak Testing (LD).

‘5. Magnetic Testing (MN), 411. Neutron Radiography (NAY)

6. Electromagnetic Tesing (EM)

‘AWS-CWEng, -Cattfed Welding Engineer ID NO. 17010046,

‘AWS-CWE - Cetfied Weng Educa, 1 NO. 1902004E.

‘ANS-CWT - Ceriied Welding Inspector. 1D NO. 19021321

[AWS.CWS - Certified Weting Superisor, D NO. 20030005,

‘AWS.CWSR - Ceted Welding Sales Represertatve, IO NO. 2003000R

‘CS¥MP 3.22 - Senior Woking nspector Personal ID WO.7A30

[BGAS-CSWMP-Paining Inspector Grace 25GAS, 589730,

‘API 810. Pressure Vessel inspector ID NO. 35376,

‘API 870. Process Ppingnspecor ID NO. 38328

‘API 653. aboveground storage tank inspector © NO. 36171

‘APIRP 680 -ick Based Inspection professional 1D NO. 52784

‘APIRP 671- Corosion and Matanale Proessional i NO. 56359

‘API 996 Retaciry Personnel, ID NO. 24784

‘APIBT7- Welling nspecton and Metalugy, 1 NO. 04785

‘API BIFE-Source Ispecor Fed Equpment (© NO. 98780

[API SIRE Source speciot Rotaing Equipment, I NO. 99652

‘API SIEE-Source Ispector Electical Equipmert, D NO. 105108

‘API TES- Tan Eriry Superisct, 1D NO, 106079

‘Lead ausitor according 1 180 9001:2018 nom IRC

You might also like

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (589)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5796)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (400)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (345)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1091)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- ASNT Radiographic Testing (RT) Level III NotesDocument183 pagesASNT Radiographic Testing (RT) Level III NotesDr.Samir SaadNo ratings yet

- ASNT Basic Level III Notes - Part IIDocument183 pagesASNT Basic Level III Notes - Part IIDr.Samir SaadNo ratings yet

- API 570 Piping Inspector - Volume 2Document297 pagesAPI 570 Piping Inspector - Volume 2Dr.Samir Saad100% (1)

- ASNT Basic Level III Notes - Part IDocument112 pagesASNT Basic Level III Notes - Part IDr.Samir SaadNo ratings yet

- ASNT Ultrasonic Testing (UT) Level III NotesDocument253 pagesASNT Ultrasonic Testing (UT) Level III NotesDr.Samir SaadNo ratings yet

- API 570 Piping Inspector - Volume 1Document617 pagesAPI 570 Piping Inspector - Volume 1Dr.Samir Saad100% (3)

- ASNT Electromagnetic Testing (ET) Level III NotesDocument250 pagesASNT Electromagnetic Testing (ET) Level III NotesDr.Samir SaadNo ratings yet

- ASNT Liquid Penetrant Testing (PT) Level III NotesDocument208 pagesASNT Liquid Penetrant Testing (PT) Level III NotesDr.Samir SaadNo ratings yet

- Tank Inspection As Per API 65 3and API 575Document41 pagesTank Inspection As Per API 65 3and API 575Dr.Samir SaadNo ratings yet

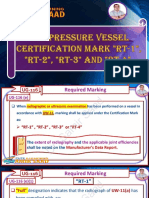

- The Pressure Vessel Certification Mark As Per ASME VIII Div.1Document11 pagesThe Pressure Vessel Certification Mark As Per ASME VIII Div.1Dr.Samir SaadNo ratings yet

- Welded Joint Category As Per ASME VIII Div.1Document13 pagesWelded Joint Category As Per ASME VIII Div.1Dr.Samir SaadNo ratings yet

- ASNT Radiographic Film Interpretation (RTFI) Level IIDocument266 pagesASNT Radiographic Film Interpretation (RTFI) Level IIDr.Samir Saad100% (2)

- ASNT Thermal/Infrared Testing (IR) Level III NotesDocument117 pagesASNT Thermal/Infrared Testing (IR) Level III NotesDr.Samir Saad100% (1)

- ASNT Ultrasonic Testing (UT) Level IIDocument249 pagesASNT Ultrasonic Testing (UT) Level IIDr.Samir Saad100% (1)

- ASNT Neutron Radiography (NR) Level III NotesDocument63 pagesASNT Neutron Radiography (NR) Level III NotesDr.Samir SaadNo ratings yet

- ASNT Magnetic Particle Testing (MT) Level IIDocument301 pagesASNT Magnetic Particle Testing (MT) Level IIDr.Samir SaadNo ratings yet

- ASNT Liquid Penetrant Testing (PT) Level IIDocument149 pagesASNT Liquid Penetrant Testing (PT) Level IIDr.Samir SaadNo ratings yet

- ASNT Acoustic Emission Testing (AE) Level III NotesDocument108 pagesASNT Acoustic Emission Testing (AE) Level III NotesDr.Samir SaadNo ratings yet

- CWI & VT Level IIDocument287 pagesCWI & VT Level IIلوبيز إديسونNo ratings yet

- ASNT Leak Testing (LT) Level III NotesDocument71 pagesASNT Leak Testing (LT) Level III NotesDr.Samir SaadNo ratings yet

- ASNT Magnetic Flux Leakage (MFL) Level III NotesDocument138 pagesASNT Magnetic Flux Leakage (MFL) Level III NotesDr.Samir Saad100% (1)

- ASNT Basic Level III Notes - Part IIIDocument163 pagesASNT Basic Level III Notes - Part IIIDr.Samir SaadNo ratings yet

- ASNT Magnetic Particle Testing (MT) Level III NotesDocument163 pagesASNT Magnetic Particle Testing (MT) Level III NotesDr.Samir SaadNo ratings yet