Professional Documents

Culture Documents

Tank Inspection As Per API 65 3and API 575

Uploaded by

Dr.Samir Saad0 ratings0% found this document useful (0 votes)

169 views41 pagesTank Inspection as per API 65 3and API 575 Prepared by Dr. Samir Saad

Original Title

Tank Inspection as per API 65 3and API 575

Copyright

© © All Rights Reserved

Available Formats

PDF or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentTank Inspection as per API 65 3and API 575 Prepared by Dr. Samir Saad

Copyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

0 ratings0% found this document useful (0 votes)

169 views41 pagesTank Inspection As Per API 65 3and API 575

Uploaded by

Dr.Samir SaadTank Inspection as per API 65 3and API 575 Prepared by Dr. Samir Saad

Copyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

You are on page 1of 41

AS PER

PCE ENE E A

BS [construction Standards

API STD 650, Welded Tanks for Oil Storag

* API 650 is a standard developed and published by the American Petroleum Institute (API) that

establishes minimum requirements for the design, fabrication, erection, and inspection of

welded storage tanks.

* This standard only applies to tanks with uniformly supported bottoms and to tanks in non-

refrigerated service that have a maximum design temperature of 93 °C (200 °F) oF less

4 5

* API 620s a standard developed and published by API that gives requirements for the design

and construction of large, welded storage tanks with pressures in their gas or vapor spaces of

not more than as Ibffin.2 gaug

APISTD 625, Tank Systems for Refrigerated Liquefied Gas Storage

* API 625 isa standard developed and published by AP! that covers low pressure, aboveground,

vertical, and cylindrical tank systems storing liquefied gases requiring refrigeration (min.

temperature as low as-398°C)

* API 653 is standard covers steel storage tanks built to API 650 and its predecessor A\

1s minimum requirements for maintaining the integrity of such tanks after they

Iteration, relocation, and

reconstruction.

* This document provides Ugefullinformnatie ecommended p Bfor the maintenance

and inspection of atmospheric and low-pres get

+ Whereas API 653is a little thin on actual tank inspection practice, ABI

informatior

APIRP 652, Linings of Aboveground Petroleum Storage Tank

Bottoms.

+ API 652 is recommended practice (RP) provides guidance on achieving effective corr

trol in aboveground storage tanks by application of tank bottom linings

* The purpose of this recommended practice (RP) is to present procedures and practices for

achieving ve corrosion control on aboveground storage tank bottoms through the use

Atmospheric

Pressure storage

tanks

ee yee

storage tanks

When referring to (vertical)

tanks, the term “atmospheric

| pressure” usually means tanks

designed to API 653.

API 653 also provides for rules

to design tanks for “higher

internal pressure” Up to 2.5

Ibffin.2 (28 kPa).

Low-pressure storage tanks are those

designed to operate with pressures in their

gas or vapor spaces exceeding the 2.5 Ibffin.

(8 kPa) gauge permissible in API 653, but not

exceeding the a5 Ibffin.? (103 kPa) gauge

maximum limitation of API 620.

s

ey

carbon steel, alloy steel, Crude oil, heavy oils, gas oils,

aluminum or other metals, furnace oils, naphtha, gasoline,

depending on service. and non-volatile chemicals.

carbon or alloy steel

hcisre easiest

Bi IR SAAD

3

Light crude oil, gasoline

blending stock, light naphtha,

pentane, volatile chemicals,

liquefied petroleum gas (LPG),

liquefied natural gas (LNG),

liquid oxygen, and liquid

nitrogen .

Noded Spherol

9

“

| Inspection Practices

@ Tank shell inspection

r Tank Floor inspections

Tank Roof Inspection

CPs

‘3s

4 i aT SAAD

The purpose of Peri

iH a 2 seasons shales rected by

Pit gauge:

roof and

rafters

Outside Calipers for

outside stiffeners and

wind girders thickness

measurements,

Plumb boband

line for shell and /q

columns

Air chisel to .

corrosion

MT Kit for crack

detection

= as

PT materials for

crack detection

Earth resistance meter

for Grounding

Connection

Hammer:

Stiffeners Wind

Girders &Anchor

Bolt

Ultrasonic

thickness (UT)

measurement

instruments

Thermography

Hot

& cold spots

Dumpy level

to check

settlement

=>__[aPis7s/aPiéss|| Tank inspection tools

@

Calibrated gauge

for leak testing

facuum Box

Tester for floor

welds

Remote UT/MFL.

crawlers for bottom

and shell

Internal scaffolding

for access

straight-beam UT for soil-side

corrosion

Acoustic emission

tests for detecting

leaks and cracking

‘Holiday’ spark tester

for linings

Watch for

pyrophoric

deposits

Working i

confined spaces

API22170,

Safe entry and

cleaning of tanks:

API2015

‘Tank Entry Supervisor

TES Certification + Permit to enter

‘Assurance of an

atmosphere that

contains sufficient

oxygen.

Clear of toxic

chemicals and gas

a

‘Communication with outside people

‘The BBRA}in of floating-roof tank shells may

corrode quickly, as both sides are exposed

Crevice corrosion

‘around wind girders! Tests on rivet

ligaments

Measure banding

at horizontal .) wm _checkitguid

eel aires using inate area for

accelerated

straight edge

Check for corrosion

ma _check for cracking

Cheek with torch for ™ (caustic SCC and

hydrogen blistering mechanical cracking)

= e =

a aris7s/APisss]|| Tank Floor inspections |

Walk on weld

seams: OK

2 rafters: OK

9

| Inspection Types and Frequency

Inspections from

internal Inspection

e Inspection Checklists

r Records

ie of the Tani

2_| aPiéss ||] Inspections from the Outside of the Tank

* Routine In-service

Inspections

¢ External Inspection

(Scheduled Inspection)

¢ Ultrasonic Thickness

Inspection

* Cathodic Protection

Surveys

>_| arisss || Routine In-service Inspections

(UoOcoO ko oan The [ice \jof such

portcii aire

inspections shall be

Tricsit iby close visual consistent with

pena ee CT ene scary

ground on a routine basis A (s

y Peat cae on

THis nspacion may Evidence of leaks; shell”

rent, but shall not ‘ortions; signs of

‘owner/operator } settlement; corrosion;

BBrsonnel and can be exceed one Sidiecadiioe trea

done by otherthan’ month. fot iidati int

authorized inspectors. : rouneanow pan

coatings, insulation

ieee systems, and

this inspection should be appurtenances should be

knowledgeable of the documented for follow-

storage facility

up action by an

Ghecadersder ofthe authorized inspector.

oduct stored

~—2_| aPlés3 || External Inspection -

All tanks shall be

givenav shall be called the

external inspection external inspection

by and must be

conducted at least

need to have

insulation removed

only to the extent

necessary to

determine

Tank grounding

system

components such

shall be

* visually checked.

External ultrasonic The ultrasonic thickness

thickness measurements measurements shall be

of the shell can bea made

means of

Determining a

rate of uniform

general corrosion

while the tank is

indication of the

integrity of the

shell.

The maximum i

interval shall be shall be the

FIGURE 12- CP ol Fi Ect

Where exterior tank bottom

corrosion is controlled by

of the system shall be conducted in

accordance with

2_| aPiéss ] Internal Inspection

Internal inspection

Bottom

Shell

Leak testing

Linings

Roof and structural members

Internal equipment

= 2_| aPiéss ] Internal Inspection =

2_| aPiéss ] Internal Inspection

Initial Internal Inspection Interval.

The interval from initial service date until the first internal inspection shall

unless a tank has one or more of

The initial inspection interval

1

| ‘An RBBiincludes steel bottoms, synthetic materials, clay liners, concrete pads, and all

other barriers or combinations of barriers é, which

have the function of:

The SUbsequent inspection interval shallot exceed

oleae} a (RPB) Release Prevention Barrier, or

‘CUTE E-LEARNING

AMIR. SAAD.

2_| aPiéss ] Inspection Checklists

provides ae checklists of items for consideration when

SF cure c-1caRNinc

pat ae ser npecion Chek

yo

9 tateeepeee oa

——————— an ee eee ep

napection Chacha

ee

————

Cama

2 EE a TT

AComplete record file consisting of three types of records,

namely:

1) Construction Records

* Construction records may include nameplate information, drawings,

specifications, construction completion report, and any results of

material tests and analyses.

2) Inspection History

+ The inspection history includes all measurements taken, the condition of

all parts inspected, and a record of all examinations and tests.

3)Repair/Alteration History

‘+ The repair/alteration history includes all data accumulated on a tank

from the time of its construction with regard to repairs, alterations,

replacements, and service changes (recorded with service conditions such

as stored product temperature and pressure).

tet) ofinspecton|

inspection methods and tests used (visual, MFL, UT, etc.) and results of each inspection method or test;

ttlement survey measurements and analysis if performed),

Reports

ae tk)

Dr. Samir Saad

General Manager

Cutech Arabia LLG

Experience: 18 Years (Oil and Gas)

Skills & Expertise

+ Welding and Welding Inspection

+ Non-Destructive Testing

Material Technology

In Service & On-stream Inspection

Corrosion and Management

Asset Integrity Management

Dr. Samir Saad

Professional Certification

Project Management Professional (PMP)®,: PMP@ Number: 3280417

'PMI Risk Management Professional (Pill-RMP)®:PWI-RMPO Number: 3223598,

PMI Agile Certified Practitioner (PIl-ACP)® :PMACP@ Number: 3230301

[ASME Authorized Inspector (Al), Boiler anc Pressure Vessel

‘ASNT NDT LEVEL II in 11 methods, ASNT ID: 190902

Vieual and Optical Testing (VT), "7. Magnetic fux leakage Testing (MFL),

Radiographic Testing (RT), 8. inferred ermal testing (IR),

Uttrasonic Testing (UT), 9. Acoustic Emission Testing (AE)

Liquid Penetrant Testing (PT), 10. Leak Testing (LT),

Magnetic Testing (MT), 11, Neutron Radiography (NR)

Electromagnetic Testing (ET),

‘AWS-CWEng.- Certled Weng Engineer, ID NO. 17010046,

‘AWS-CWE -Cortied Welting Educator ID NO. 1902001E.

‘AWS-CWM - Cerfieg Welding Inspector, ID NO. 19021324

‘AWS-CWS -Certied Welding Supervisor, ID NO. 20030008.

‘AWS-CWSR - Certfed Welding Sales Representative, ID NO.2003000R

{CSWIP 3.2.2 - Senior Weking inspector Personal, ID NO.74306,

[BGAS-CSWIP-Paining Inspector Grade 2-8GAS,ID:58970.

[API 610- Pressure Vessel Inspector ID NO. 35376,

[API B70- Process Piping Inspector ID NO. 38328.

[APL 683. aboveground storage tank inspector ID NO. 26171

‘API RP 680 Risk-Based inspection professional, ID NO. 52764

[APIRP 671. Corrosion and Matera Professional ID NO. 56359

‘APL 936 - Refractory Personnel, ID NO. 94784

'APL677 - Welding inspection and Metallurgy ID NO. 94785

{API SIFE-Source Inepector Fed Equipment, | NO. 95780

[API SIRE - Source inspector Rotating Equipment, ID NO. 99952

{API SIEE-Source Inspector Electrical Equipment, ID NO. 105108

[APL TES-Tank Entry Superior ID NO. 108678

[Lead auditor according to 180 8001:2018 trom IRC

You might also like

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (589)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (401)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (842)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (897)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5806)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (345)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1091)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- ASNT Basic Level III Notes - Part IDocument112 pagesASNT Basic Level III Notes - Part IDr.Samir SaadNo ratings yet

- ASNT Basic Level III Notes - Part IIDocument183 pagesASNT Basic Level III Notes - Part IIDr.Samir SaadNo ratings yet

- ASNT Radiographic Testing (RT) Level III NotesDocument183 pagesASNT Radiographic Testing (RT) Level III NotesDr.Samir SaadNo ratings yet

- ASNT Ultrasonic Testing (UT) Level III NotesDocument253 pagesASNT Ultrasonic Testing (UT) Level III NotesDr.Samir SaadNo ratings yet

- API 570 Piping Inspector - Volume 2Document297 pagesAPI 570 Piping Inspector - Volume 2Dr.Samir Saad100% (1)

- API 570 Piping Inspector - Volume 1Document617 pagesAPI 570 Piping Inspector - Volume 1Dr.Samir Saad100% (3)

- ASNT Electromagnetic Testing (ET) Level III NotesDocument250 pagesASNT Electromagnetic Testing (ET) Level III NotesDr.Samir SaadNo ratings yet

- ASNT Liquid Penetrant Testing (PT) Level III NotesDocument208 pagesASNT Liquid Penetrant Testing (PT) Level III NotesDr.Samir SaadNo ratings yet

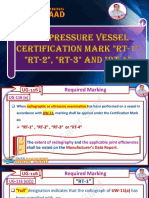

- The Pressure Vessel Certification Mark As Per ASME VIII Div.1Document11 pagesThe Pressure Vessel Certification Mark As Per ASME VIII Div.1Dr.Samir SaadNo ratings yet

- Welded Joint Category As Per ASME VIII Div.1Document13 pagesWelded Joint Category As Per ASME VIII Div.1Dr.Samir SaadNo ratings yet

- Minimum Distance Between Two Circumferential Pipe JointsDocument7 pagesMinimum Distance Between Two Circumferential Pipe JointsDr.Samir Saad100% (1)

- ASNT Neutron Radiography (NR) Level III NotesDocument63 pagesASNT Neutron Radiography (NR) Level III NotesDr.Samir SaadNo ratings yet

- ASNT Liquid Penetrant Testing (PT) Level IIDocument149 pagesASNT Liquid Penetrant Testing (PT) Level IIDr.Samir SaadNo ratings yet

- CWI & VT Level IIDocument287 pagesCWI & VT Level IIلوبيز إديسونNo ratings yet

- ASNT Radiographic Film Interpretation (RTFI) Level IIDocument266 pagesASNT Radiographic Film Interpretation (RTFI) Level IIDr.Samir Saad100% (2)

- ASNT Ultrasonic Testing (UT) Level IIDocument249 pagesASNT Ultrasonic Testing (UT) Level IIDr.Samir Saad100% (1)

- ASNT Acoustic Emission Testing (AE) Level III NotesDocument108 pagesASNT Acoustic Emission Testing (AE) Level III NotesDr.Samir SaadNo ratings yet

- ASNT Thermal/Infrared Testing (IR) Level III NotesDocument117 pagesASNT Thermal/Infrared Testing (IR) Level III NotesDr.Samir Saad100% (1)

- ASNT Magnetic Particle Testing (MT) Level IIDocument301 pagesASNT Magnetic Particle Testing (MT) Level IIDr.Samir SaadNo ratings yet

- ASNT Leak Testing (LT) Level III NotesDocument71 pagesASNT Leak Testing (LT) Level III NotesDr.Samir SaadNo ratings yet

- ASNT Magnetic Flux Leakage (MFL) Level III NotesDocument138 pagesASNT Magnetic Flux Leakage (MFL) Level III NotesDr.Samir Saad100% (1)

- ASNT Basic Level III Notes - Part IIIDocument163 pagesASNT Basic Level III Notes - Part IIIDr.Samir SaadNo ratings yet

- ASNT Magnetic Particle Testing (MT) Level III NotesDocument163 pagesASNT Magnetic Particle Testing (MT) Level III NotesDr.Samir SaadNo ratings yet