Professional Documents

Culture Documents

Closure To  Œbridge Planning Using GIS and Expert System Approachâ by Amin Hammad, Yoshito Itoh, and Takayuki Nishido

Uploaded by

Alberto Astorayme ValenzuelaOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Closure To  Œbridge Planning Using GIS and Expert System Approachâ by Amin Hammad, Yoshito Itoh, and Takayuki Nishido

Uploaded by

Alberto Astorayme ValenzuelaCopyright:

Available Formats

SHEAR AND REACTION DISTRIBUTIONS single bearings in the analysis.

The location of the bearings

are shown in Fig. 10. Reactions due to dead load were deter-

IN CONTINUOUS SKEW mined using concrete and bituminous concrete densities spec-

B

COMPOSITE BRIDGES ified in design drawings. Reactions due to prestressing were

determined from the tendon profile using losses consistent

with the AUSTROADS Bridge Design Code (AUSTROADS

1992). To determine the most severe reactions due to live load

Discussion by Bruce W. Golley3 at the various bearings, influence surfaces were drawn using

the Mtiller-Breslau principle by imposing a unit displacement

The authors have made an excellent contribution to the un- at the bearing location and plotting displacement contours.

derstanding of the behavior of continuous skew bridges, and These influence surfaces enabled the current AUSTROADS

have presented valuable empirical formulas to enable bridge design vehicles to be positioned to cause maximum reactions

due to live load. The surfaces for the reactions near an acute

Downloaded from ascelibrary.org by Universidad Nacional De Ingenieria on 10/19/18. Copyright ASCE. For personal use only; all rights reserved.

designers to more accurately predict reaction and shear distri-

butions under dead and live loads. The authors have demon- corner (bearing 1) and near an obtuse corner (bearing 5) are

strated through model tests and finite element analysis the crit- shown in Figs. 11 and 12, respectively, which demonstrate the

ical nature of obtuse corners in both single-span and significant influence of skew on the reactions. A dynamic load

multiple-span bridges. The discusser was particularly inter- allowance of 0.4 was applied to the live loads. and maximum

ested in the comparison of support reactions under simulated reactions at all bearings due to dead, live, impact, and pre-

truck loading measured during tests and verified by finite el- stressing loads were determined. The maximum estimated re-

ement modelling. As the authors observed, "The maximum actions under working loads are summarized in Table 4.

reaction at the simply supported end of the loaded long span The obtuse corner was found to satisfy the shear provisions

increased from 10.4 kN in the case of bridge model 1 with of the AUSTROADS Bridge Design Code under a force of

skew angle e = 0° to 14.1 kN in the case of bridge model 2 756 kN' However, based on a number of simplifying assump-

with skew angle e = 45°. This represents an increase of about tions and using a capacity reduction factor of 0.8, it was de-

36%." It should be noted that with the rectangular bridge termined that an upward force of 776 kN applied at bearing 5

model, 1, the maximum reaction occurred at an interior beam, would cause a yield line to develop at the corner. The crack

whereas with the skewed bridge model, 2, the maximum re- pattern corresponding to the yield line agreed approximately

action was at the outside beam at an obtuse corner. The max- with the observed crack pattern, although the crack directions

imum reaction measured on an outer beam in bridge model 1 were influenced by the prestressing forces. Thus, the maximum

was 7.7 kN (Fig. 4); hence, if the outer beam reactions are working reaction consistent with current design loads was al-

compared, the increase is about 83%, which demonstrates even most the same as the ultimate capacity of the corner. Of

more the critical nature of the obtuse corners of this type of course, a yield line did not develop, because following crack-

bridge. ing, the reaction was redistributed to other bearings. It is of

The discusser was recently involved with an investigation interest to note that, had the transverse reinforcement been laid

into the cause of cracking of a continuous 45° skew curved normal to the bridge centerline, the ultimate corner reaction to

bridge (Golley et al. 1994). Though the bridge was a pre- cause a yield line would have increased to 1368 kN, well in

stressed concrete voided slab bridge, and thus of a different excess of the working reaction of 756 kN. Based on this ob-

type from the steel-concrete composite bridges investigated by servation, the cracks were filled with epoxy. and external

the authors, the effects of skew are similar. The cracking oc-

curred at the obtuse corners; therefore, the investigation con- 10

centrated on the reactions in those locations. Brief details of 9

the investigation are summarized below to reinforce the au- 3

8

thors' conclusion that "increasing the skew increases signifi- 2

cantly the reaction of the exterior girder and decreases it for ...-: 7

the interior girder." ....-~6

The bridge is a two-span continuous prestressed concrete • BEARING

voided slab bridge, with a plan view as shown in Fig. 10. The FIG. 10. Plan of Bridge. Showing Crack Pattern on Soffit

general form of cracking on the bridge soffit is also shown in

the figure. The spans were each 22.86 m measured along the 0.0

0.0

centerline, which had a radius of 550 m. Because the bridge

was curved, there was a 3% cross fall. The deck thickness was

760 mm, increasing to 1220 mm at the central pier. The voids

were 460 mm in diameter and were discontinuous to permit

reinforcement of transverse end beams, diaphragms, and a cen-

tral headstock, all of which were skew. The transverse rein-

forcement in the top and bottom slabs was also skew. The 1.0 0.5

bridge was supported by five pairs of elastomeric bearings at FIG. 11. Influence Surface for Reaction at Acute Corner Bear-

each end, and by five Pot Stay bearings at the central pier. ing

The general form of the cracking on the bridge soffit is also

shown in Fig. JO. 1.0 0.5 0.0

An elastic analysis was carried out using the finite element

program LUSAS (LUSAS 1994). The bridge deck was mod-

elled as an equivalent thick orthotropic plate. using 504 8-node

curved quadrilateral elements. Bearing pairs were replaced by

"November 1996, Vol. I, No.4. by Tarek Ebeido and John B. Kennedy

(Paper 11028).

'Sr. Lect., School of Civ. Engrg., University College, Australian De- FIG. 12. Influence Surface for Reaction at Obtuse Corner

fence Force Academy. Canberra ACT 2600, Australia. Bearing

JOURNAL OF BRIDGE ENGINEERING / MAY 1998/91

J. Comput. Civ. Eng., 1995, 9(1): 91-92

TABLE 4. Maximum Reactions at End Bearings

Closure by Tarek Ebeido4 and

Maximum reactIon

Bearing number (kN)

John B. KennedY'

(1 ) (2)

I 325 We would like to thank the discusser for his interest in the

2 602 paper. His comments on the analysis and repair of the contin-

3 837 uous 45° skew voided-slab bridge in Australia contribute sig-

4 887

5 756 nificantly to the value of our paper. The failure at the obtuse

corners of that bridge is not surprising. Very likely it is due

to the direction of the transverse reinforcement in the top and

plates were glued to the soffit nonnal to the centerline. Con- bottom of the slab. The transverse reinforcement was placed

stant monitoring since the repair work was carried out in 1993 in the skew direction. Several investigations by Kennedy

Downloaded from ascelibrary.org by Universidad Nacional De Ingenieria on 10/19/18. Copyright ASCE. For personal use only; all rights reserved.

indicates further cracking has been prevented. (1983) have shown that when transverse reinforcement is

From Table 4, it can be seen that the maximum reaction at placed nonnal to the bridge centerline, not only does it sig-

the obtuse corner is 2.3 times the maximum reaction at the nificantly increase the bridge stiffness, but it also prevents or

acute corner. In the authors' tests, summarized in Fig. 4, this reduces considerably the possibility of cracking at the obtuse

ratio is between about 5 and 7, but the bridge type and the corners. The repair job on the bridge suggested by the dis-

loading pattern were different. An important point to empha-

cusser with external plates glued to the soffit at the obtuse

size continually is that high reactions occur at obtuse comers

of single- and multiple-span skew bridges, and the authors' corners and nonnal to the centerline is certainly the correct

extensive parametric study enables designers to conservatively approach.

estimate the forces.

APPENDIX. REFERENCES APPENDIX. REFERENCE

AUSTROADS bridge design code. (1992). AUSTROADS, Sydney, Aus-

tralia. Kennedy, J. B. (1983). "Orientation of ribs in waffle-slab skew bridges."

Golley, B. w., Jovanovic, M. P.• and Bylo, R. J. (1994). "The cause and J. Struct. Engrg., ASCE, 109(3), Sll-816.

repair of the partial failure of a skew prestressed concrete bridge."

Proc. Australasian Structural Engineering Conference, Sydney, Aus- 'Leet., Struct. Engrg. Dept., Alexandria Univ., Egypt.

tralia, 859 - 862. 'Univ. Distinguished Prof., Dept. of Civ. and Envir. Engrg., Univ. of

LUSAS user manual. (1994). FEA Ltd., Surrey, U.K. Windsor, Windsor, Ont., Canada N9B 3P4.

92/ JOURNAL OF BRIDGE ENGINEERING I MAY 1998

J. Comput. Civ. Eng., 1995, 9(1): 91-92

You might also like

- Chester HouseDocument6 pagesChester Housesymon kiplelgo100% (4)

- Table C3-1 Asce 7-10 PDFDocument8 pagesTable C3-1 Asce 7-10 PDFamalia noorlailyNo ratings yet

- Eyewitness Companions Architecture (Eyewitness Companion Guides) by Jonathan GlanceyDocument514 pagesEyewitness Companions Architecture (Eyewitness Companion Guides) by Jonathan GlanceyOsiris97% (30)

- (Asce) ST 1943-541X 0002294Document14 pages(Asce) ST 1943-541X 0002294Sergio Alejandro barreiroNo ratings yet

- 06-Nonlinear Analysis of Integral Abutment Bridges Finite Element ModelDocument8 pages06-Nonlinear Analysis of Integral Abutment Bridges Finite Element ModelEduardo Reyes NegreteNo ratings yet

- (Asce) 0733 9445 (2001) 127 11 (1266)Document10 pages(Asce) 0733 9445 (2001) 127 11 (1266)Seyed Mohamad Mehdi SajediNo ratings yet

- ASCEJGGE2001 Nonlinear Analysis Integral Bridges Faraji Ting Crovo Ernst ASCE1090-02412001127 5454Document8 pagesASCEJGGE2001 Nonlinear Analysis Integral Bridges Faraji Ting Crovo Ernst ASCE1090-02412001127 5454Nicholas FeatherstonNo ratings yet

- (Building Code 1983), For Instance, Which Treats The Problem of ComputationDocument11 pages(Building Code 1983), For Instance, Which Treats The Problem of ComputationabadittadesseNo ratings yet

- Cracking of RC Beam Column Joints Implications For Practical Structural Analysis and DesignDocument7 pagesCracking of RC Beam Column Joints Implications For Practical Structural Analysis and DesignMartin CibulkaNo ratings yet

- Bond-Slip Model For Detailed Finite-Element AnalysisDocument10 pagesBond-Slip Model For Detailed Finite-Element AnalysisSilver rayleighNo ratings yet

- Analysis of Piles Subject To Embankment Induced Lateral Soil Moviments - MUST READDocument10 pagesAnalysis of Piles Subject To Embankment Induced Lateral Soil Moviments - MUST READThiago GisbertNo ratings yet

- Ten Years of Experiments On Bridges Using Resilient Damage Resistant Systems and Accelerated Construction Techniques PDFDocument9 pagesTen Years of Experiments On Bridges Using Resilient Damage Resistant Systems and Accelerated Construction Techniques PDFtungch46No ratings yet

- Seismic Behavior of Steel Structure With Buckling-Restrained BracesDocument9 pagesSeismic Behavior of Steel Structure With Buckling-Restrained BracesMarce Carrasquilla SolisNo ratings yet

- Direct Strength Method To The Design of Castellated Steel BeamDocument16 pagesDirect Strength Method To The Design of Castellated Steel BeamAdnan NajemNo ratings yet

- 2002 Fantilli Et Al.Document9 pages2002 Fantilli Et Al.fsimaNo ratings yet

- Stability of Beams With Tapered I-Sections: Journal of Engineering Mechanics September 1987Document22 pagesStability of Beams With Tapered I-Sections: Journal of Engineering Mechanics September 1987Johann BarcelosNo ratings yet

- Seismic Behavior of Steel Structure With Buckling Restrained BracesDocument9 pagesSeismic Behavior of Steel Structure With Buckling Restrained BracesZhi Ming CheahNo ratings yet

- Analytical Calculation Model For Predicting Cracking Behavior of Reinforced Concrete TiesDocument17 pagesAnalytical Calculation Model For Predicting Cracking Behavior of Reinforced Concrete TiesSalim AwadNo ratings yet

- 18part1 010Document22 pages18part1 010nima sarNo ratings yet

- Wick Drain - Smear ZoneDocument5 pagesWick Drain - Smear ZonehamidkarimpourNo ratings yet

- The Response of Surface Structures To Tunnel Construction: J. N. Franzius, D. M. Potts and J. B. BurlandDocument15 pagesThe Response of Surface Structures To Tunnel Construction: J. N. Franzius, D. M. Potts and J. B. BurlandNISHANT ROYNo ratings yet

- Deformation Analysis of Prestressed Continuous Steel-Concrete Composite BeamsDocument13 pagesDeformation Analysis of Prestressed Continuous Steel-Concrete Composite BeamsSaul Max Huayta AguilarNo ratings yet

- 1 s2.0 S014102961600119X MainDocument19 pages1 s2.0 S014102961600119X MainTheyCalledMe ZafNo ratings yet

- 1986 Dowel Action Math ModelsDocument11 pages1986 Dowel Action Math ModelsLuiz Fernando ColussoNo ratings yet

- 2001 - Interaction Surfaces of Reinforced-Concrete Sections in Biaxial BendingDocument7 pages2001 - Interaction Surfaces of Reinforced-Concrete Sections in Biaxial Bendingryan rakhmatNo ratings yet

- Biaxialflexureand Axial Load Interaction in Short Rectangular Reinforced Concrete ColumnsDocument12 pagesBiaxialflexureand Axial Load Interaction in Short Rectangular Reinforced Concrete ColumnscarlosfernandoNo ratings yet

- Simplified Equations For Rigidity and Lateral Deflection For Reinforced Concrete Cantilever Shear WallsDocument5 pagesSimplified Equations For Rigidity and Lateral Deflection For Reinforced Concrete Cantilever Shear WallsB KAUSHIKNo ratings yet

- Thin-Walled Structures: Son Tung Vy, Mahen Mahendran, Thananjayan SivaprakasamDocument18 pagesThin-Walled Structures: Son Tung Vy, Mahen Mahendran, Thananjayan SivaprakasamLidya DewiNo ratings yet

- DGS 2010 RMOTC TensleepDocument5 pagesDGS 2010 RMOTC TensleepaliNo ratings yet

- 5 - 2021 - Behavior and Design of Steel Delta Girders For Flexure and Shear - OmarDocument13 pages5 - 2021 - Behavior and Design of Steel Delta Girders For Flexure and Shear - OmarwesleynjNo ratings yet

- Rodrigues 2016Document8 pagesRodrigues 2016BaNếpNo ratings yet

- (Asce) GM 1943-5622 0002079Document14 pages(Asce) GM 1943-5622 0002079AmanNo ratings yet

- Modelling Beam-Column Joints For Progressive Collapse AnalysisDocument9 pagesModelling Beam-Column Joints For Progressive Collapse AnalysismusitefaNo ratings yet

- Homogenizationof Masonry Using Numerical SimulationsDocument12 pagesHomogenizationof Masonry Using Numerical SimulationsvadaleNo ratings yet

- Seismic Resistance of R/C Exterior Connections With Floor SlabDocument15 pagesSeismic Resistance of R/C Exterior Connections With Floor SlabMarimuthu KaliyamoorthyNo ratings yet

- ContentDocument116 pagesContentsakthistructNo ratings yet

- Effects of Confinement in Circular Hollow Concrete Columns: Xiao Liang, Ph.D. and Sri Sritharan, PH.D., M.ASCEDocument13 pagesEffects of Confinement in Circular Hollow Concrete Columns: Xiao Liang, Ph.D. and Sri Sritharan, PH.D., M.ASCEmusitefaNo ratings yet

- IRC 6-2017 Ammendment (Jul-17)Document2 pagesIRC 6-2017 Ammendment (Jul-17)avisek_basuNo ratings yet

- By C. V. Girija Vallabhan, Member, ASCE, and Y. C. Das: J. Eng. Mech. 1988.114:2072-2082Document11 pagesBy C. V. Girija Vallabhan, Member, ASCE, and Y. C. Das: J. Eng. Mech. 1988.114:2072-2082nhan nguyenNo ratings yet

- Leon - 1989 - Interior Joints With Variable Anchorage LengthsDocument15 pagesLeon - 1989 - Interior Joints With Variable Anchorage LengthsMarimuthu KaliyamoorthyNo ratings yet

- Accidental Design Eccentricity Is It Important For The Inelastic Response of Buildings To Strong EarthquakesDocument16 pagesAccidental Design Eccentricity Is It Important For The Inelastic Response of Buildings To Strong EarthquakesmohamedNo ratings yet

- Effect of Seismic Load History On Deformation Limit States For Longitudinal Bar Buckling in RC Circular ColumnsDocument13 pagesEffect of Seismic Load History On Deformation Limit States For Longitudinal Bar Buckling in RC Circular ColumnsAristotle MedinaNo ratings yet

- Excavation Induced Building Response by Laminate Beam MethodDocument6 pagesExcavation Induced Building Response by Laminate Beam MethodvttrlcNo ratings yet

- OPSD3101.150 Rev#0 Nov2005Document6 pagesOPSD3101.150 Rev#0 Nov2005Safwat El RoubyNo ratings yet

- 2-Guidelines and Methods On Segmental Tunnel Lining Analysis and DesignDocument10 pages2-Guidelines and Methods On Segmental Tunnel Lining Analysis and Designsbaia amineNo ratings yet

- Osgoui Et Al. 2017 - WTCDocument10 pagesOsgoui Et Al. 2017 - WTCReza OsgouiNo ratings yet

- Model Prediction of Rutting in Asphalt Concrete by D. V. Ramsamooj P.E., J. Ramadan/ and G. S. Lin, 3 P.EDocument9 pagesModel Prediction of Rutting in Asphalt Concrete by D. V. Ramsamooj P.E., J. Ramadan/ and G. S. Lin, 3 P.EdedyNo ratings yet

- Modeling of Steel - Concrete Composite Beams by RfemDocument6 pagesModeling of Steel - Concrete Composite Beams by RfemTomasz WróblewskiNo ratings yet

- A New Model To Simulate Joint Shear Behavior of Poorly Detailed Beam-Column Connections in RC Structures Under Seismic Loads Part I-Exterior JointsDocument18 pagesA New Model To Simulate Joint Shear Behavior of Poorly Detailed Beam-Column Connections in RC Structures Under Seismic Loads Part I-Exterior JointsRosNo ratings yet

- El-Ariss - 2006Document5 pagesEl-Ariss - 2006Jackeline SantosNo ratings yet

- The Effect of Discontinuity Persistence An Rock Slope StabilityDocument11 pagesThe Effect of Discontinuity Persistence An Rock Slope StabilityTendi SulaksoNo ratings yet

- A Macro-Modelling Continuum Approach With Embedded Discontinuities For The Assessment of Masonry Arch Bridges Under Earthquake Loading - Panto - 2022Document21 pagesA Macro-Modelling Continuum Approach With Embedded Discontinuities For The Assessment of Masonry Arch Bridges Under Earthquake Loading - Panto - 2022labursNo ratings yet

- Stress Transfer Across Interfaces in Reinforced Concrete Due To Aggregate Interlock and Dowel Action - Maekawa&qureshi PDFDocument14 pagesStress Transfer Across Interfaces in Reinforced Concrete Due To Aggregate Interlock and Dowel Action - Maekawa&qureshi PDFRômulo Menck Romanichen100% (1)

- Sustainability 15 00036 v3Document23 pagesSustainability 15 00036 v3Brayan Damiro Zavala LuyoNo ratings yet

- Tension Chord Model For Structural Concrete: Structural Engineering International November 1998Document13 pagesTension Chord Model For Structural Concrete: Structural Engineering International November 1998AmenNo ratings yet

- 2012-Singh Bhagat-Agrawal-Vibration AttenuationDocument10 pages2012-Singh Bhagat-Agrawal-Vibration AttenuationKamal Kumar AgrawalNo ratings yet

- 01 Banushi2018Document20 pages01 Banushi2018Mecon LtdNo ratings yet

- One Engineer's Opinion - Bolted SplicesDocument2 pagesOne Engineer's Opinion - Bolted SplicesDoctoreNo ratings yet

- Effects of Seismically Induced Pounding at Expansion Joints of Concrete BridgesDocument10 pagesEffects of Seismically Induced Pounding at Expansion Joints of Concrete BridgesJuan BravoNo ratings yet

- Behavioral Study of Reinforced Concrete Beams Designed For Shear Using Compressive Force Path and ACI Code ModelsDocument5 pagesBehavioral Study of Reinforced Concrete Beams Designed For Shear Using Compressive Force Path and ACI Code ModelsStefania RinaldiNo ratings yet

- Analysis of Structure Supported On Elastic FoundationDocument6 pagesAnalysis of Structure Supported On Elastic FoundationKami SosaNo ratings yet

- Modelling of RC Columns in BridgesDocument24 pagesModelling of RC Columns in BridgesAjithNo ratings yet

- Dislocations and Plastic Deformation: International Series of Monographs in Natural PhilosophyFrom EverandDislocations and Plastic Deformation: International Series of Monographs in Natural PhilosophyNo ratings yet

- Abstracting Lessons Learned From Design ReviewsDocument9 pagesAbstracting Lessons Learned From Design ReviewsAlberto Astorayme ValenzuelaNo ratings yet

- In Memoriam - Professor Fang Zhao - The Computing in Civil Engineering Community Loses A Great FriendDocument1 pageIn Memoriam - Professor Fang Zhao - The Computing in Civil Engineering Community Loses A Great FriendAlberto Astorayme ValenzuelaNo ratings yet

- Automated Geo-Spatial Hazard Warning System GEOWARNS - Italian Case StudyDocument18 pagesAutomated Geo-Spatial Hazard Warning System GEOWARNS - Italian Case StudyAlberto Astorayme ValenzuelaNo ratings yet

- Modeling of Temperatureâ "Frequency Correlation Using Combined Principal Component Analysis and Support Vector Regression TechniqueDocument14 pagesModeling of Temperatureâ "Frequency Correlation Using Combined Principal Component Analysis and Support Vector Regression TechniqueAlberto Astorayme ValenzuelaNo ratings yet

- Structural Deterioration Modeling Using Variational InferenceDocument9 pagesStructural Deterioration Modeling Using Variational InferenceAlberto Astorayme ValenzuelaNo ratings yet

- Automated Recovery of Structural Drawing Images Collected From Postdisaster ReconnaissanceDocument11 pagesAutomated Recovery of Structural Drawing Images Collected From Postdisaster ReconnaissanceAlberto Astorayme ValenzuelaNo ratings yet

- Intelligent Approach Based On Random Forest For Safety Risk Prediction of Deep Foundation Pit in Subway StationsDocument14 pagesIntelligent Approach Based On Random Forest For Safety Risk Prediction of Deep Foundation Pit in Subway StationsAlberto Astorayme ValenzuelaNo ratings yet

- Improved Similarity Measure in Case-Based Reasoning With Global Sensitivity Analysis - An Example of Construction Quantity EstimatingDocument18 pagesImproved Similarity Measure in Case-Based Reasoning With Global Sensitivity Analysis - An Example of Construction Quantity EstimatingAlberto Astorayme ValenzuelaNo ratings yet

- Neural Networks For River Flow PredictionDocument1 pageNeural Networks For River Flow PredictionAlberto Astorayme ValenzuelaNo ratings yet

- Ensemble Methods For Binary Classifications of Airborne LIDAR DataDocument11 pagesEnsemble Methods For Binary Classifications of Airborne LIDAR DataAlberto Astorayme ValenzuelaNo ratings yet

- Closure To  Œperformance of Shuffled Frog-Leaping Algorithm in Finance-Based Schedulingâ by Anas Alghazi, Shokri Z. Selim, and Ashraf ElazouniDocument3 pagesClosure To  Œperformance of Shuffled Frog-Leaping Algorithm in Finance-Based Schedulingâ by Anas Alghazi, Shokri Z. Selim, and Ashraf ElazouniAlberto Astorayme ValenzuelaNo ratings yet

- Combining BIM and Ontology To Facilitate Intelligent Green Building EvaluationDocument15 pagesCombining BIM and Ontology To Facilitate Intelligent Green Building EvaluationAlberto Astorayme ValenzuelaNo ratings yet

- Tools: Building Design by Angelika Drach, Sandro Heitz Z and Markus Langenegger 3 AbstractDocument18 pagesTools: Building Design by Angelika Drach, Sandro Heitz Z and Markus Langenegger 3 AbstractAlberto Astorayme ValenzuelaNo ratings yet

- Discussion - Constructability Analysis - Machine Learning ApproachDocument4 pagesDiscussion - Constructability Analysis - Machine Learning ApproachAlberto Astorayme ValenzuelaNo ratings yet

- Closure To  Œneural Networks For River Flow Predictionâ by William J. GrenneyDocument2 pagesClosure To  Œneural Networks For River Flow Predictionâ by William J. GrenneyAlberto Astorayme ValenzuelaNo ratings yet

- EditorialDocument2 pagesEditorialAlberto Astorayme ValenzuelaNo ratings yet

- 020 - 001 General Notes 01Document1 page020 - 001 General Notes 01YH YihaoNo ratings yet

- 5th Yr. Sports Complex - Design Brief With Site Plan - Jun 2023Document7 pages5th Yr. Sports Complex - Design Brief With Site Plan - Jun 2023Vishal SheteNo ratings yet

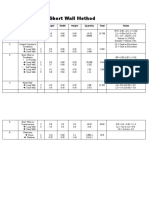

- Long Wall and Short Wall MethodDocument2 pagesLong Wall and Short Wall MethodRafayMalikNo ratings yet

- P1 2 Storey Res 7 20 23Document1 pageP1 2 Storey Res 7 20 23Jehrome CruzNo ratings yet

- ComparisonDocument3 pagesComparisonPrashant VermaNo ratings yet

- Airconditioning System ComparisonDocument14 pagesAirconditioning System Comparisonahmad aboulsoudNo ratings yet

- Farnsworth House SummaryDocument6 pagesFarnsworth House SummaryAshtonNo ratings yet

- Boq For Interior FurnishingDocument50 pagesBoq For Interior FurnishingMaulik ShahNo ratings yet

- Hotel Space Allocations PDFDocument2 pagesHotel Space Allocations PDFAshwin KumarNo ratings yet

- c1f1 c1f1 WFDocument4 pagesc1f1 c1f1 WFsicnarfoyamat1977100% (1)

- Elemental Cost Analysis-Form 1: Job Title: Client: Location: Tender DateDocument1 pageElemental Cost Analysis-Form 1: Job Title: Client: Location: Tender DateninaamirahmNo ratings yet

- Sloping Roof Top of A Residential BuildingDocument34 pagesSloping Roof Top of A Residential BuildingAnjaliNo ratings yet

- Lecture 6 Circulation Within Spatial UnitsDocument24 pagesLecture 6 Circulation Within Spatial UnitsArun Ahlawat100% (1)

- Vastu GyanDocument9 pagesVastu GyanPath FinderzNo ratings yet

- Ccip Worked Examples Ec2Document224 pagesCcip Worked Examples Ec2HerrMeier4221100% (20)

- 4 Double Tee Design PDFDocument19 pages4 Double Tee Design PDFnfaayedNo ratings yet

- Design 8 - Research No.1 - de Luxe Hotel - Navarro - Navarro, Tricia Marvi - PrelimDocument50 pagesDesign 8 - Research No.1 - de Luxe Hotel - Navarro - Navarro, Tricia Marvi - PrelimTricia Marvi P. NavarroNo ratings yet

- DWG - Edrafor - 170814 - STR - Tse28801-R0 - Dwe28801r00 B - FaDocument1 pageDWG - Edrafor - 170814 - STR - Tse28801-R0 - Dwe28801r00 B - FaMuddather SurourNo ratings yet

- Big R Steel BridgesDocument4 pagesBig R Steel Bridgesstratus02No ratings yet

- Swa Oct 15 22KJ0068Document6 pagesSwa Oct 15 22KJ0068Jed CobongNo ratings yet

- Kansas City Red Book: January 2010, Volume: 2, Issue 3Document52 pagesKansas City Red Book: January 2010, Volume: 2, Issue 3kcredbookNo ratings yet

- Modern Architecture in The Philippines and The Quest For Filipino StyleDocument6 pagesModern Architecture in The Philippines and The Quest For Filipino Styledonna benitoNo ratings yet

- General Objectives of Phase: Schematic DesignDocument6 pagesGeneral Objectives of Phase: Schematic DesignRashad AbdelhyNo ratings yet

- Architecture in Spain and Portugal in Renaissance PeriodDocument11 pagesArchitecture in Spain and Portugal in Renaissance PeriodGels GenovaNo ratings yet

- Multideck 60-V2 Features and ApplicationsDocument18 pagesMultideck 60-V2 Features and ApplicationsKha PhucNo ratings yet

- Budhist ArchitectureDocument57 pagesBudhist Architecturemeghaann0% (1)

- 1.1 House Design Guide PDFDocument30 pages1.1 House Design Guide PDFscribdbugmenot1919No ratings yet