Professional Documents

Culture Documents

API 5l-Oct2004 - psl1-2

Uploaded by

ravikumar singhOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

API 5l-Oct2004 - psl1-2

Uploaded by

ravikumar singhCopyright:

Available Formats

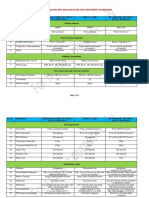

APPENDIX J— SUMMARY OF DIFFERENCES BETWEEN PSL 1 AND PSL 2 (INFORMATIVE)

Parameter PSL 1 PSL 2 Reference

Grade range A25 through X70 B through X80 Table 1

Size range 0.405 through 80 41/2 through 80 Table 1

Type of Pipe Ends Plain-end, threaded-end; Plain-end Table 1

belled-end; special coupling pipe

Seam welding All methods; continuous welding All methods except continuous Table 1

limited to Grade A25 and laser welding

Electric welds: welder frequency No minimum 100 kHz minimum 5.1.3.3.2

Heat treatment of electric welds Required for grades > X42 Required for all grades 5.1.3.3.1; 5.1.3.3.2; 6.2.6

(B through X80) 04

Chemistry: max C for seamless 0.28% for grades ³ B 0.24% Tables 2A, 2B

pipe

Chemistry: max C for welded 0.26% for grades ³ B 0.22% Tables 2A, 2B

pipe

Chemistry: max P 0.030% for grades ³ A 0.025% Tables 2A, 2B

Chemistry: max S 0.030% 0.015% Tables 2A, 2B

Carbon Equivalent: Only when purchaser speciÞes Maximum required for each grade 4.2; 4.3; 6.1.3; SR15.1

SR18

Yield Strength, Maximum None Maximum for each grade Tables 3A, 3B

UTS, Maximum None Maximum for each grade Tables 3A, 3B

Fracture Toughness None required Required for all grades 6.2.5; 9.3.5; 9.10.4; 9.12.6;

Table 14 04

Repair by welding of pipe body, Permitted Prohibited 5.3.2; 9.9; B.1; B.2

plate, and skelp

Repair by welding of weld seams Permitted by agreement Prohibited 4.3; 9.8.5.6; 9.9; B.1.2; B.4

without Þller metal

04

CertiÞcation CertiÞcates when speciÞed per CertiÞcates (SR15.1) mandatory 12.1

SR15

Traceability Traceable only until all tests are Traceable after completion of 5.6

passed, unless SR 15 is speciÞed tests (SR15.2) mandatory

--`,`,`,`,`,`````,,`,`,,`,`-`-`,,`,,`,`,,`---

149

Copyright American Petroleum Institute

Reproduced by IHS under license with API Licensee=RELIANCE PETROLEUM LTD/5950466001

No reproduction or networking permitted without license from IHS Not for Resale, 04/26/2005 00:13:48 MDT

You might also like

- DAVID - Strategic Management - Concepts and Cases - A Competitive Advantage ApproachDocument12 pagesDAVID - Strategic Management - Concepts and Cases - A Competitive Advantage ApproachKhoerul NasyikinNo ratings yet

- Summary of Differences PSL 1 and PSL 2 (Based On API 5L Edition 43)Document1 pageSummary of Differences PSL 1 and PSL 2 (Based On API 5L Edition 43)Buddy EkoNo ratings yet

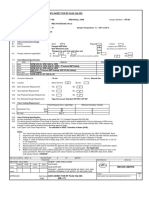

- Welder Qualification Form for Rana Pratap ChouhanDocument1 pageWelder Qualification Form for Rana Pratap ChouhanMahendra singhNo ratings yet

- CAT Level 2 QuestionnairesDocument16 pagesCAT Level 2 QuestionnairesRona Amor MundaNo ratings yet

- PSL1 PSL2 PDFDocument1 pagePSL1 PSL2 PDFArmandoZacariasAcostaNo ratings yet

- Difference Between PSL1 and PSL2Document1 pageDifference Between PSL1 and PSL2samkarthik47100% (1)

- Well Heads According To Api 6aDocument5 pagesWell Heads According To Api 6aEDWIN M.PNo ratings yet

- SANS 1431:2007 Welded Structural Steel StandardDocument30 pagesSANS 1431:2007 Welded Structural Steel StandardjohndupNo ratings yet

- Motor Protection Relay Test ReportDocument8 pagesMotor Protection Relay Test ReportAnonymous dH3DIEtzNo ratings yet

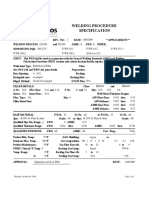

- Form Wps JBL09-2011Document2 pagesForm Wps JBL09-2011fawad aliNo ratings yet

- DGCL-IBFPL-WPS-05 Station Piping (2 Inch & Below)Document4 pagesDGCL-IBFPL-WPS-05 Station Piping (2 Inch & Below)সীমান্ত ছাড়িয়ে - Shemanto ChariyeNo ratings yet

- Differences between psi1 and psi2 pipe standardsDocument1 pageDifferences between psi1 and psi2 pipe standardsclyde shugartNo ratings yet

- PQR FC-19-23.1Document2 pagesPQR FC-19-23.1cycsi02No ratings yet

- PQR FC-19-23Document2 pagesPQR FC-19-23cycsi02No ratings yet

- Welder Qualification Procedure PDFDocument13 pagesWelder Qualification Procedure PDFEngineersEDGE Coimbatore0% (1)

- Procedure For WQTDocument13 pagesProcedure For WQTdevikar8umNo ratings yet

- Special Notes On ValvesDocument101 pagesSpecial Notes On ValvesamithcivilNo ratings yet

- A 946 - 95 R00 QTK0NGDocument2 pagesA 946 - 95 R00 QTK0NGPRASANTH PRASANTHNo ratings yet

- Avq Asd 2023 735 2023Document12 pagesAvq Asd 2023 735 2023asbar salesNo ratings yet

- WQR V01 PLT 012-ComDocument3 pagesWQR V01 PLT 012-Comhaim timorNo ratings yet

- Specification For T&Y Strainer: 0 27.08.2015 First Issue NV US SVKDocument20 pagesSpecification For T&Y Strainer: 0 27.08.2015 First Issue NV US SVKvishal bhamreNo ratings yet

- BHEL steel casting technical delivery conditionsDocument6 pagesBHEL steel casting technical delivery conditionsalex hutaurukNo ratings yet

- HT VCB Fire SSDocument8 pagesHT VCB Fire SSjalaj bisenNo ratings yet

- 404 Bus 2 CVT 181021030334Document6 pages404 Bus 2 CVT 181021030334SARAVANAN ANo ratings yet

- 2.02 D [DS] [Type 1381, 1381V] [Pressure Switch] [LPCB, CE]Document3 pages2.02 D [DS] [Type 1381, 1381V] [Pressure Switch] [LPCB, CE]michal.musollariNo ratings yet

- A 283a 283m-03-Standard Specification for Low & Intermediate Strength Carbon Steel PlatesDocument2 pagesA 283a 283m-03-Standard Specification for Low & Intermediate Strength Carbon Steel PlatesAgni MalekuNo ratings yet

- WPS for GTAW Welding of Aluminum Butt JointsDocument2 pagesWPS for GTAW Welding of Aluminum Butt Jointsmahmoud_allam3No ratings yet

- BHEL steel casting technical delivery conditionsDocument7 pagesBHEL steel casting technical delivery conditionspl_arunachalam79No ratings yet

- BHEL, Tiruchirapalli-620014. Quality Assurance TECHNICAL DELIVERY CONDITION Product: Steel Castings. (Valves)Document7 pagesBHEL, Tiruchirapalli-620014. Quality Assurance TECHNICAL DELIVERY CONDITION Product: Steel Castings. (Valves)abdulNo ratings yet

- Psl1 Vs Psl2Document10 pagesPsl1 Vs Psl2Varun PatelNo ratings yet

- TEST PLAN IS 2062Document2 pagesTEST PLAN IS 2062GOPAL MaityNo ratings yet

- Brass Plate, Sheet, Strip, and Rolled Bar: Standard Specification ForDocument9 pagesBrass Plate, Sheet, Strip, and Rolled Bar: Standard Specification ForarunjacobnNo ratings yet

- Comparison For Wps QualificationDocument2 pagesComparison For Wps QualificationHalimNo ratings yet

- SAE J429 - Portland BoltDocument2 pagesSAE J429 - Portland BoltDileepa WarnakulasooriyaNo ratings yet

- A 808 - A 808M - 00 Qtgwoc9boda4ts1sruqDocument3 pagesA 808 - A 808M - 00 Qtgwoc9boda4ts1sruqdelta lab sangliNo ratings yet

- High-Strength, Low-Alloy Carbon, Manganese, Columbium, Vanadium Steel of Structural Quality With Improved Notch ToughnessDocument2 pagesHigh-Strength, Low-Alloy Carbon, Manganese, Columbium, Vanadium Steel of Structural Quality With Improved Notch ToughnessMytzy Godoy TapiaNo ratings yet

- Procedure For Welder QualificationDocument28 pagesProcedure For Welder Qualificationjagannath100% (1)

- CKD V3301seriesDocument3 pagesCKD V3301seriesAbdulNo ratings yet

- APL HEC: Hearoon Engineering Company Welding Procedure Specification Asme Sec - IxDocument2 pagesAPL HEC: Hearoon Engineering Company Welding Procedure Specification Asme Sec - Ixmc160403810 Usman AliNo ratings yet

- R900564519 Valvula Retencion Rexroth Z2SRK6Document4 pagesR900564519 Valvula Retencion Rexroth Z2SRK6soniamargarita22021995No ratings yet

- Data Sheet 2 More 300# PV - RF - NT-79 PDFDocument1 pageData Sheet 2 More 300# PV - RF - NT-79 PDFSachin KumarNo ratings yet

- Adr01 02 03 06Document21 pagesAdr01 02 03 06Satyagit VirgoNo ratings yet

- ASTM A53 Type E Grade B ERW Submittal SheetDocument1 pageASTM A53 Type E Grade B ERW Submittal SheetElian Olivares MatusNo ratings yet

- PQR FC-12-22Document2 pagesPQR FC-12-22cycsi02No ratings yet

- 33kV HT Panel SpecificationDocument2 pages33kV HT Panel SpecificationSAEL SOLAR100% (1)

- Pressure Vessel Plates, Carbon-Manganese-Silicon Steel, Quenched and Tempered, For Welded Layered Pressure VesselsDocument2 pagesPressure Vessel Plates, Carbon-Manganese-Silicon Steel, Quenched and Tempered, For Welded Layered Pressure VesselsDiegoNo ratings yet

- API6A Trim Material RatingsDocument5 pagesAPI6A Trim Material RatingsRicardo Paz SoldanNo ratings yet

- ASTM A283 GR C PDFDocument3 pagesASTM A283 GR C PDFDiego Alonso100% (2)

- AddPak Chemical Injector Technical DataDocument4 pagesAddPak Chemical Injector Technical Dataeka pramudia santosoNo ratings yet

- Brass Plate, Sheet, Strip, and Rolled Bar: Standard Specification ForDocument8 pagesBrass Plate, Sheet, Strip, and Rolled Bar: Standard Specification ForTony VazquezNo ratings yet

- 1206 2Document2 pages1206 2nemabobNo ratings yet

- RCE Series: Digital Pressure TransducersDocument6 pagesRCE Series: Digital Pressure Transducerszakaria alhosinyNo ratings yet

- Tech B-3722 SF-80AM PDFDocument5 pagesTech B-3722 SF-80AM PDFEduard Gonzalo Rojas CervantesNo ratings yet

- Microwave Devices, Circuits and Subsystems for Communications EngineeringFrom EverandMicrowave Devices, Circuits and Subsystems for Communications EngineeringRating: 4 out of 5 stars4/5 (1)

- Newnes Circuit Calculations Pocket Book: with Computer ProgramsFrom EverandNewnes Circuit Calculations Pocket Book: with Computer ProgramsNo ratings yet

- Flow Measurement: By Square-Edged Orifice Plate Using Corner TappingsFrom EverandFlow Measurement: By Square-Edged Orifice Plate Using Corner TappingsRating: 5 out of 5 stars5/5 (1)

- Natural Diamond Grading and Origin Reports from $30Document3 pagesNatural Diamond Grading and Origin Reports from $30adzim zakariyaNo ratings yet

- Cebu Institute of Technology University College of Engineering and Architecture Department of Industrial Engineering COURSEWARE ES034 ENGINEERING MANAGEMENT Week 8 Leading and ControllingDocument9 pagesCebu Institute of Technology University College of Engineering and Architecture Department of Industrial Engineering COURSEWARE ES034 ENGINEERING MANAGEMENT Week 8 Leading and ControllingMariaEzzaSyUyNo ratings yet

- Microsoft Cloud Partner Program Walking DeckDocument18 pagesMicrosoft Cloud Partner Program Walking DeckTech On Demand Solution ProvidersNo ratings yet

- D365 Business Central Implementation PackageDocument17 pagesD365 Business Central Implementation PackageAnh Bao Tran DuongNo ratings yet

- Unlock Hidden Revenue Potential with Botify SEODocument22 pagesUnlock Hidden Revenue Potential with Botify SEOTrue NorthNo ratings yet

- The Way of The SamuraiDocument131 pagesThe Way of The SamuraiSign InNo ratings yet

- Law Commission of Bangladesh.Document6 pagesLaw Commission of Bangladesh.Nishat Chowdhury DolonNo ratings yet

- Best Street High Street MasterplanDocument64 pagesBest Street High Street MasterplanGreyson LawrenceNo ratings yet

- UPI Compliance ChecklistDocument15 pagesUPI Compliance ChecklistKaran PanchalNo ratings yet

- Airtel NavratnaDocument29 pagesAirtel Navratnariteshgoyal0380% (5)

- Sun PharmaDocument8 pagesSun PharmaDeepak WadhwaNo ratings yet

- Axis Bluechip Fund Attribution Analysis PDFDocument7 pagesAxis Bluechip Fund Attribution Analysis PDFYasahNo ratings yet

- Model Draft of - Notice Under Section 80 CPC Against State GovernmentDocument4 pagesModel Draft of - Notice Under Section 80 CPC Against State Governmentshivam5singh-25No ratings yet

- PDF 20230705 232946 0000Document10 pagesPDF 20230705 232946 0000Umaisa MustafaNo ratings yet

- Tsupreme Ourt: 31/epuhlic of TbeDocument16 pagesTsupreme Ourt: 31/epuhlic of TbeMonocrete Construction Philippines, Inc.No ratings yet

- Linear Programming Applications Chapter 8Document8 pagesLinear Programming Applications Chapter 8Aftab KhanNo ratings yet

- Data Skills Report 2020Document41 pagesData Skills Report 2020Wee WeeNo ratings yet

- Combinepdf PDFDocument256 pagesCombinepdf PDFMaridasrajanNo ratings yet

- Salesforce Assignment 2 - Abdur-Rehman QureshiDocument4 pagesSalesforce Assignment 2 - Abdur-Rehman QureshiAbdur-Rehman QureshiNo ratings yet

- Customer Journey Maps & InfographicsDocument28 pagesCustomer Journey Maps & InfographicsSolange Letícia dos Santos MeloNo ratings yet

- A Comparative Study of Bancassurance Products in Banks - SynopsisDocument8 pagesA Comparative Study of Bancassurance Products in Banks - Synopsisammukhan khan100% (1)

- Understanding Capital and CapitalizationDocument17 pagesUnderstanding Capital and Capitalizationashfaq shaikhNo ratings yet

- 0806 04 Corrective & Preventive Action - Doc Warranty ClaimsDocument10 pages0806 04 Corrective & Preventive Action - Doc Warranty ClaimsSundara Rajan RamakrishnanNo ratings yet

- Going Rate PricingDocument3 pagesGoing Rate PricingHarshitha RNo ratings yet

- Cookies Haven: Have every bite without guiltDocument8 pagesCookies Haven: Have every bite without guiltjeanneNo ratings yet

- CMSNR Sale Tax v. K. KelukuttyDocument2 pagesCMSNR Sale Tax v. K. KelukuttyjaishreeNo ratings yet

- Financial AccountingDocument71 pagesFinancial AccountingHoàng My Trần100% (1)

- Chapter 15Document34 pagesChapter 15IstikharohNo ratings yet

![2.02 D [DS] [Type 1381, 1381V] [Pressure Switch] [LPCB, CE]](https://imgv2-1-f.scribdassets.com/img/document/719579414/149x198/2cb59567f6/1712130212?v=1)