Professional Documents

Culture Documents

Screenshot 2023-03-17 at 9.58.13 PM

Uploaded by

elon muskCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Screenshot 2023-03-17 at 9.58.13 PM

Uploaded by

elon muskCopyright:

Available Formats

Download now $

Underground Cable

Fault Detection: A

Minor Project Report…

On

Show full title

Uploaded by Lukesh Kumar

! 100% (3) · 3K views · 30 pages

Document Information "

Original Title

Download now

324864(24)_301302416030.docx $

Copyright

© © All Rights Reserved

Available Formats A Minor Project Report

DOCX, PDF, TXT or read online from

On Scribd

UNDERGROUND CABLE FAULT

Share this document DETECTION

Project Report submitted to

Chhattisgarh Swami Vivekanand Technical University Bhilai (India)

In partial fulfilment for award of the degree of

Facebook Twitter

BACHELOR OF ENGINEERING

#

In

Electrical Engineering

By

EmailLukesh Kumar Shubham Bani

Gaurav Tiwari Mahima Singh

Did you find this document useful?

Under the Guidance of

Prof. Rejo Roy

Is this content inappropriate? Report Engineering

Department of Electrical this Document

RCET- Rungta College of Engineering and Technology, Bhilai (CG)

Session 2019-20

DECLARATION

We the undersigned solemnly declare that the report of the project work en9tled

“Underground Cable Fault Detector”, is based on my/our own work carried out during the

course of our study under the supervision of Prof. Rejo Roy.

we assert that the statements made and conclusions drawn are an outcome of the

project work. I/we further declare that to the best of our knowledge and belief that the report

does not contain any part of any work which has been submiHed for the award of any other

degree/diploma/cer9Icate in this University or any other University.

_______________ ________________ _______________ ________________

Lukesh Kumar Shubham Bani Gaurav Tiwari Mahima Singh

Roll No. : Roll No. : Roll No. : Roll No.:

301302416030 301302416080 301302416078 301302416031

Enrollment No.: Enrollment No.: Enrollment No.: Enrollment No.:

BA5538 BB5681 BB5593 BA5666

DEPARTMENT OF ELECTRICAL ENGINEERING

Rungta college of Engineering & Technology, Bhilai (India)

CERTIFICATE

Cer9Ied that the contents of the project report en9tled, “ Underground Cable

Fault Detector” is a bonaIde work carried out under my guidance by

(1) Lukesh Kumar , (2) Shubham Bani, (3) Gaurav Tiwari ,

(4) Mahima Singh in par9al fulIlment of the requirements for the degree of

Bachelor of Engineering in Electrical Engineering.

Date:

(Prof. S. BharT) ( ) (Prof. Rejo Roy)

HOD External Project Guide

Advertisement

ACKNOWLEDGEMENT

It is a maHer of profound privilege and pleasure to extend my sense of respect and

deepest gra9tude to our project guide Prof. Rejo Roy Department of Electrical Engineering

under whose precise guidance and gracious encouragement we had the privilege to work.

We would like to avail this opportunity to thank Prof. S. BharT, Head of Department,

Electrical Engineering, for facilita9ng such a congenial environment in our department and also

his unending encouragement throughout.

We owe the greatest debt and special respec[ul thanks to Shri Santosh Rungta,

Chairman, Dr. Sourabh Rungta, Director (Tech.), Shri Sonal Rungta, Director (F&A), and Dr. S. M.

Prasanna Kumar, Director, Rungta College of Engineering and Technology, Bhilai, for their

inspira9onal and constant encouragement that enabled us to present our work in this form.

We would also like to thank the many people in my college, faculty members and

suppor9ng stac, for always being helpful over the years.

Last but not the least; we would like to express deepest gratefulness to our parents for

their con9nuous moral support and encouragement. Their love accompanies us wherever we

go.

Lukesh Kumar

Shubham Bani

Gaurav Tiwari

Mahima Singh

ABSTRACT

4

God giged sense of vision to the human being is an important aspect of our life. But there are

some unfortunate people who lack the ability of visualizing things. The visually impaired have to

face many challenges in their daily life. The problem gets worse when there is an obstacle in

front of them. Blind s9ck is an innova9ve s9ck designed for visually disabled people for

improved naviga9on. The paper presents a theore9cal system concept to provide a smart

ultrasonic aid for blind people. The system is intended to provide overall measures – Ar9Icial

vision and object detec9on. The aim of the overall system is to provide a low cost and ejcient

naviga9on aid for a visually impaired person who gets a sense of ar9Icial vision by providing

informa9on about the environmental scenario of sta9c and dynamic objects around them.

Ultrasonic sensors are used to calculate distance of the obstacles around the blind person to

guide the user towards the available path. Output is in the form of sequence of beep sound

which the blind person can hear.

Advertisement

TABLE OF CONTENTS

Abstract………………………………………………………………………………..v

1. Introduction……………………………………………………………………......1

1.1 Overview………………………………………………………………….....1

1.2 Objective of the Project……………………………………………………...1

1.3 Detailed Problem Definition…………………………………………….......1

1.4 Economic Feasibility and Commercial Use of the Proposed Project………..2

1.5 Use of Computational Tool……………………………………………….....2

1.6 Future Prospects of the Project……………………………………………...2

1.7 Organization of the Project Report……………………………………….....2

2. Literature Survey……………………………………………………………...….3

2.1 Overview………………………………………………………………........3

2.2 Detailed Literature Review………………………………………………....3

2.3 Summary…………………………………………………………………....3

3. Methodology……………………………………………………………………..5

3.1 Overview…………………………………………………………………...5

3.2 Explanation……………………………………………………………...…5

3.3 Hardware Requirements…………………………………………………....7

3.4 Software Implementation……………………………………………….…13

3.5 Working…………………………………………………………………...14

3.6 Summary………………………………………………………………….14

4. Results and Discussion………………………………………………………….…15

5. Conclusion and future scope………………………………………………...……16

5.1 Conclusion……………………………………………………………….…16

5.2 Future Scope…………………………………………………………….….16

6. Bibliography………………………………………………………………………17

Advertisement

1. INTRODUCTION

1.1 Overview

Till last decades cables were made to lay overhead& currently it is lay to underground cable

which is superior to earlier method. Because the underground cable are not affected by any

adverse weather condition such as storm, snow, heavy rainfall as well as pollution. But when any

fault occur in cable, then it is difficult to locate fault. So we will move to find the exact location

of fault. Now the world is become digitalized so the project is intended to detect the location of

fault in digital way. The underground cable system is more common practice followed in many

urban areas. While fault occurs for some reason, at that time the repairing process related to that

particular cable is difficult due to not knowing the exact location of cable fault.

Fault in cable is represented as:

• Any defect,

• Inconsistency,

• Weakness or non-homogeneity that affect performance of cable.

• Current is diverted from the intended path

• Caused by breaking of conductor& failure of insulation

1.2 Objective of the project

The objective of this project is to determine the distance of underground cable fault from base

station in kilometers. While a fault occurs for some reason, at that time the repairing process

related to that particular cable is difficult due to not knowing the exact location of the cable

fault.The proposed system is to find the exact location of the fault. The project uses the standard

concept of Ohms law i.e., when a low DC voltage is applied at the feeder end through a Cable

lines, then current would vary depending upon the location of fault in the cable. In case there is a

short circuit (Line to Ground), the voltage across series resistors changes accordingly, which is

then fed to inbuilt ADC of Arduino board to develop precise digital data for display in

kilometers.

1.3 Detailed problem Definition

The main problem is that the underground cables have higher initial cost and insulation problems at high

voltages. Another main drawback is that, if a fault does occur, it is difficult to locate and repair the fault

because the fault is invisible. Fault in cable can be classified in two groups:

1) Open circuit fault: Open circuit faults are better than short circuit fault, because when these fault

occurs current flows through cable becomes zero. This type of fault is caused by break in conducting

path. Such faults occur when one or more phase conductors break.

2) Short circuit fault: Further short circuit fault can be categorized in two types:

a) Symmetrical fault: Three-phase fault is called symmetrical fault. In this all three phases are short

circuited.

b) Unsymmetrical fault: In this fault magnitude of current is not equal & not displaced by 120 degree.

1.4 Economic Feasibility and Commercial Use of Proposed project

Its main application is to detect the fault of underground cable which is very hard to detect as it is not

possible to see such faults which are quite possible in the case of overhead transmission line. So for

such cases this project is very helpful as the distance at which the fault has occurred can be

calculated and then further action regarding the fault can be taken to overcome them.

1.5 Future prospects of the project

The proposed system in this paper detect only the location of Short Circuit fault in underground cable

line, and also detect the location of open circuit fault, to detect the open circuit fault capacitor is used in

circuit which measure the change in resistance & calculate the distance of fault. For future research, the

system would proceed with similar neural networks structure for different types fault and fault location

estimation. Fault location methods can be classified as:

1) Online method: This method utilize & process the sampled voltages& current to determine the fault

points. Online method for underground cable are less than overhead lines.

2) Offline method: In this method special instrument is used to test out service of cable in the field. There

are two offline methods as following

Advertisement

A) Racer method: In this method fault point is detected by walking on the cable lines. Fault point is

indicated from audible signal or electromagnetic signal. It is used to pinpoint fault location very

accurately.

Example: 1) Tracing current method

2) Sheath coil method

B) Terminal method: It is a technique used to detect fault location of cable from one or both ends

without tracing. This method use to locate general area of fault, to expedite tracing on buried cable.

Example: 1) Murray loop method

2) Impulse current method

1.6 Organization of the Project Report

The organization of the project report is basis on the fault detection of the underground cable .As the use

of underground cables goes increasing due to their advantages and having beneficial in day to day life.

The project consist of the methodology of the proposed project. Some result and conclusion arrives

during these session of project work.

[CHAPTER 1] deals with Literature survey, In these section we discussed about the Introduction and

evaluation of the model

We discussed concept of the underground fault in the cable and the implementation of the fault occur and

also about the detailed problem.

[CHAPTER 2] deals with the analysis on the underground fault detection. The main methodology of the

fault detection is discussed here, consisting the main body of the project. Overview of the project process

of the project connection of the circuit, hardware used and the implemented software in the ATmega328

[CHAPTER3] consist the main snapshot of the program and discussed about the result of the project

making. For the future scope result arrives how the fault detection can done how they are solved.

[CHAPTER4] conclusion and the future scope of main project is discussed here. we also discussed is this

project are economical on not and the customer service

10

2. LITERATURE SURVEY

2.1 Overview

For the real worldwide operated voltage distribution lines underground cables have been used

from many years. In order to reduce the sensitivity of distribution networks to environmental

influences underground voltage cables are highly used. Underground cables have been widely

used in power distribution networks due to the advantages of underground connection, more

enhanced security than overhead lines in adverse weather condition, less liable to damage by

storms or lightning. It is less costly for larger distance, eco- friendly and low maintenance cost.

But if any fault occur in cable, then it is difficult to its type. So this system is use to detect the

location and type of fault in digital way. The requirement of locating the faulty point in an

underground cable in order is to facilitate quicker repair, improve the system reliability and

reduced outage period

.2.2 Detailed Literature Review

Underground cables are the electric power transmission cables. Because of their reliability on

transmitting, they used in urban areas and in thick population areas, where overhead transmission

is dangerous. Underground cables have low maintenance cost, less chances of faults, smaller

voltage drop. In recent improvements in the design and manufacture have led to development of

cables suitable for use at high voltage. The design and construction of underground transmission

lines differ from overhead lines. The first underground transmission line was a 132 kV line

constructed in 1927. The cable was fluid-filled and paper insulated. The fluid was necessary to

dissipate the heat. For decades, reliability problems continued to be associated with constructing

longer cables at higher voltages. The most significant issue was maintenance difficulties. Not

until mid-1960s did the technology advance sufficiently so that a high-voltage 345 kV line could

be constructed underground. The lines though were still fluid filled. In the 1990s the first solid

cable transmission line was constructed more than one mile in length and greater than 230 kV.

Cables are generally laid directly in the ground or in ducts in the underground distribution

system. For this reason, there are little chances of faults in underground cables. However, if a

11

Trusted by over 1 million members

Try Scribd FREE for 30 days to access over 125

million titles without ads or interruptions!

Start Free Trial

Cancel Anytime.

fault does occur, it is difficult to locate and repair the fault because conductors are not visible.

Nevertheless, the following are the faults most likely to occur in underground cables.

Underground cables are the electric power transmission cables. Because of their reliability on

transmitting, they used in congested urban areas and in thick population areas, where overhead

transmission is dangerous. Underground cables have low maintenance cost, less chances of

faults, smaller voltage drop. In recent improvements in the design and manufacture have led to

development of cables suitable for use at high voltage

2.3 Summary

The aim of this project to detect the fault and work with them or deal with them easily. The

project has an extended to the fault location in underground cables can be easily found by using

Effective Global Positioning System, Global System for Mobile Communication, which thereby

directly indicates the distance of fault from the nearby substation along with sending an SMS or

Voice to the registered mobile number. This helps the repairing team to clear the fault within less

time. This can be implemented for 3-Phase System also.

12

3. METHODOLOGY

3.1 Overview

The main concept of this project is to find the distance of underground cable fault from the base

station in kilometers. In many urban areas, cable fault is a common problem. When a fault occurs

due to some reason, the process of fault tracking without knowing the location related to that

particular cable is very difficult. The proposed system is designed to track the exact location of

the fault occurred in the cable.

3.2 Explanation

While fault occurs for some reason, at that time the repairing process related to that particular

cable is difficult due to not knowing the exact location of cable fault.

Fault in cable is represented as:

• Any defect,

• Inconsistency,

• Weakness or non-homogeneity that affect performance of cable.

• Current is diverted from the intended path

• Caused by breaking of conductor& failure of insulation

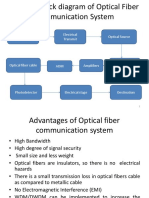

BLOCK DIAGRAM:

The project uses the simple concept of OHMs law where a low DC voltage is applied at the

feeder end through a series resistor. The current would vary depending upon the length of fault

of the cable in case there is a short circuit of LL or 3L or LG etc.

The series resistor voltage drop changes accordingly which is then fed to an ADC to develop

precise digital data which the programmed microcontroller would display the same in Kilo

meters. The project is assembled with a set of resistors representing c able length in KMs and

13

Advertisement

fault creation is made by a set of switches at every known KM to cross check the accuracy of the

same.

This is proposed model of underground cable fault distance locator using microcontroller. It is

classified in four parts –DC power supply part, cable part, controlling part, display part.

DC power supply part consist of ac supply of 230v is step down using transformer, bridge

rectifier converts ac signal to dc & regulator is used to produce constant dc voltage.

The cable part is denoted by set of resistors along with switches Current sensing part of cable

represented as set of resistors &switches are used as fault creators to indicate the fault at each

location. This part senses the change in current by sensing the voltage drop.

Next is controlling part which consist of analog to digital convertor which receives input from

the current sensing circuit, converts this voltage into digital signal and feeds the microcontroller

with the signal.

The microcontroller also forms part of the controlling unit and makes necessary calculations

regarding the distance of the fault.

The microcontroller also drives a relay driver which in turn controls the switching of a set of

relays for proper connection of the cable at each phase.

The display part consists of the LCD display interfaced to the microcontroller which shows the

status of the cable of each phase and the distance of the cable at the particular phase, in case of

any fault.

14

POWER SUPPLY

The power supply circuit consists of step down transformer which is 230v step down to 12v.In

this circuit 4diodes are used to form bridge rectifier which delivers pulsating dc voltage & then

fed to capacitor filter the output voltage from rectifier is fed to filter to eliminate any ac.

components present even after rectification. The filtered DC voltage is given to regulator to

produce 12v constant DC voltage.

15

Advertisement

You might also like

- Underground Cable Fault Detection: A Minor Project Report OnDocument30 pagesUnderground Cable Fault Detection: A Minor Project Report OnLukesh Kumar100% (5)

- 422 423 4P2 Report (p1)Document38 pages422 423 4P2 Report (p1)Tharun KumarNo ratings yet

- Certificate: Department of Electrical and Electronics Engineering SRMGPCDocument11 pagesCertificate: Department of Electrical and Electronics Engineering SRMGPCsaurabh_awasthi19No ratings yet

- Online Banking SystemDocument5 pagesOnline Banking SystemShashwat KanhaiyaNo ratings yet

- Table of ContentsDocument6 pagesTable of ContentssknagarNo ratings yet

- Group - 2 - Design of RC T Girder BridgeDocument229 pagesGroup - 2 - Design of RC T Girder BridgesubodhstudymaterialsNo ratings yet

- Taha Ashraf Reg - No 220101161044Document6 pagesTaha Ashraf Reg - No 220101161044tahaashraf160No ratings yet

- Bluetooth Final - MergedDocument73 pagesBluetooth Final - MergedJyoti RanjanNo ratings yet

- Final Merge - 1 PDFDocument44 pagesFinal Merge - 1 PDFsriNo ratings yet

- "Soil Nailing Technique" A Project: Bachelor of TechnologyDocument137 pages"Soil Nailing Technique" A Project: Bachelor of Technologyp. vamsikrishnaNo ratings yet

- Periocular Biometrics Under Relaxed Constraints: Project Report OnDocument61 pagesPeriocular Biometrics Under Relaxed Constraints: Project Report OnMohit SinghNo ratings yet

- Development of Master Board and Robotic Arm For UGVDocument40 pagesDevelopment of Master Board and Robotic Arm For UGVksbasdaNo ratings yet

- Internship Report of THLDocument76 pagesInternship Report of THLAnish PokharelNo ratings yet

- MergedDocument13 pagesMergedtahaashraf160No ratings yet

- Final - Report TUDocument96 pagesFinal - Report TUrabeen tajNo ratings yet

- Line Following Robot Without Using MicrocontrollerDocument17 pagesLine Following Robot Without Using Microcontroller21EE026 Anushka SrivastavaNo ratings yet

- VedPrakashTiwari 4Document47 pagesVedPrakashTiwari 4s.t. entertainmentNo ratings yet

- A Project Report ON: Student Fees Management SystemDocument19 pagesA Project Report ON: Student Fees Management SystemJámès KõstãNo ratings yet

- REMS Final Project Thesis ReportDocument75 pagesREMS Final Project Thesis ReportSuraj SinghNo ratings yet

- "Routing Algorithm": Chhattisgarh Swami Vivekanand Technical University Bhilai (India)Document37 pages"Routing Algorithm": Chhattisgarh Swami Vivekanand Technical University Bhilai (India)Akshay AgrawalNo ratings yet

- Metal DetectorDocument53 pagesMetal DetectorTauseef AhmadNo ratings yet

- 1 Nidhi Group ReportDocument27 pages1 Nidhi Group ReportBARUN SINGHNo ratings yet

- Competitive Exam Preparation Application: in Partial Fulfillment of Requirement For The Award of DegreeDocument41 pagesCompetitive Exam Preparation Application: in Partial Fulfillment of Requirement For The Award of Degreelalit raoNo ratings yet

- CipherBayFinal REportDocument28 pagesCipherBayFinal REportrohitchotarajan786No ratings yet

- Networking GuidesDocument118 pagesNetworking Guidesganeshkhanal946No ratings yet

- Social Network Analysis ReportDocument51 pagesSocial Network Analysis ReportRATNESH SHAHNo ratings yet

- Image FusionDocument86 pagesImage FusionAbhishek Reddy GarlapatiNo ratings yet

- Project ThesisDocument62 pagesProject ThesisPriyanshu MangalNo ratings yet

- Traffic Sign Recognition Using Yolov3 Based Detector: Bachelor of TechnologyDocument40 pagesTraffic Sign Recognition Using Yolov3 Based Detector: Bachelor of TechnologyNaresh DamaNo ratings yet

- Group 11 Mini Project PDFDocument36 pagesGroup 11 Mini Project PDFAnjul MNo ratings yet

- P C M RC-M (C & B) S B L: Katchalla Bala KishoreDocument63 pagesP C M RC-M (C & B) S B L: Katchalla Bala KishoreAnonymous w8tjcvmymNo ratings yet

- Project ReportDocument88 pagesProject ReportShubham RaktateNo ratings yet

- Project Front PagesDocument8 pagesProject Front PagesJyothi KsNo ratings yet

- Project Report Draft FInalDocument39 pagesProject Report Draft FInalAshish KumarNo ratings yet

- Major ProjectDocument37 pagesMajor Projecthimanshu malviyaNo ratings yet

- Major Final DocumentDocument62 pagesMajor Final DocumentN. Akhila GoudNo ratings yet

- Decentralized E-Voting SystemDocument39 pagesDecentralized E-Voting SystemAmit KumarNo ratings yet

- Front Pages-1Document6 pagesFront Pages-1zwdfeagrshNo ratings yet

- Minor Project ReportDocument28 pagesMinor Project ReportMohit SoniNo ratings yet

- Rent Nepal ProjectDocument32 pagesRent Nepal ProjectNabeen ParajuliNo ratings yet

- ASVM CompltedDocument70 pagesASVM CompltedØsöme Bôy HarishNo ratings yet

- Speed Control of BLDC MotorDocument68 pagesSpeed Control of BLDC MotorMukund Joshi93% (15)

- Minor Project Fiii - MergedDocument62 pagesMinor Project Fiii - Mergedshrimayi2102No ratings yet

- Group 24 ReportDocument48 pagesGroup 24 ReportVishwanath GroupsNo ratings yet

- Hand Written ProjectDocument40 pagesHand Written ProjecthayatNo ratings yet

- 1807 Pratik LogkeeperDocument36 pages1807 Pratik LogkeeperProject 21-22No ratings yet

- Distributed Learning System B.Tech in Department of Computer Science and Engineering University Institute of Technology, RGPV, BhopalDocument46 pagesDistributed Learning System B.Tech in Department of Computer Science and Engineering University Institute of Technology, RGPV, Bhopalankuprajapati0525No ratings yet

- BlackBook FinalDocument46 pagesBlackBook FinalHimay MewadaNo ratings yet

- Amitsinghproject Modified WWDocument28 pagesAmitsinghproject Modified WWamit singhNo ratings yet

- Final Year Internship Project Report by Satyajeet (1) (1) 6 Copy With Color 7 Copy +colorDocument57 pagesFinal Year Internship Project Report by Satyajeet (1) (1) 6 Copy With Color 7 Copy +colorAliNo ratings yet

- Taha Ashraf Reg - No 220101161044Document6 pagesTaha Ashraf Reg - No 220101161044tahaashraf160No ratings yet

- AbhishekDocument22 pagesAbhishekrajatkchauhan8077No ratings yet

- Image Watermarking: MR - Abhishek Chaube MR - Bharat Chauhan MR - Deepak ChandrasekharanDocument37 pagesImage Watermarking: MR - Abhishek Chaube MR - Bharat Chauhan MR - Deepak ChandrasekharanDeepak ChandrasekharanNo ratings yet

- Mini ProjectDocument40 pagesMini ProjectPakki Akhil KumarNo ratings yet

- Final Print RTDocument36 pagesFinal Print RTTapesh DadhichNo ratings yet

- Toxic Comment Analyser: Indian Institute of Information Technology, KalyaniDocument37 pagesToxic Comment Analyser: Indian Institute of Information Technology, KalyaniAshish KumarNo ratings yet

- Voice Controlled Robot CarDocument28 pagesVoice Controlled Robot CarRajeev SinghaniyaNo ratings yet

- Sensor Network System For Residential Gas Leak Detection, Monitoring and ControllingDocument8 pagesSensor Network System For Residential Gas Leak Detection, Monitoring and ControllingAvd KishoreNo ratings yet

- Cloud-Based Microservices: Techniques, Challenges, and SolutionsFrom EverandCloud-Based Microservices: Techniques, Challenges, and SolutionsNo ratings yet

- Sw. Pt. Nawal Kishore Sharma Government P.G. College, Dausa: Applica On IDDocument6 pagesSw. Pt. Nawal Kishore Sharma Government P.G. College, Dausa: Applica On IDSumer SainiNo ratings yet

- Report Group 1Document67 pagesReport Group 11706112No ratings yet

- A23.3-04 CorbelsDocument3 pagesA23.3-04 CorbelsDivyesh MistryNo ratings yet

- Sony DVR-VX2000 ManualDocument92 pagesSony DVR-VX2000 ManualHenryNo ratings yet

- Declaration KitDocument4 pagesDeclaration KitJITANSHUCHAMPNo ratings yet

- Source of Information Electrical Transmit Optical SourceDocument37 pagesSource of Information Electrical Transmit Optical SourcesubashNo ratings yet

- Short CV RJCDocument3 pagesShort CV RJCShivani KhannaNo ratings yet

- ISO 14031 Environmental Performance EvaluationDocument65 pagesISO 14031 Environmental Performance EvaluationSanjayaNo ratings yet

- TRANS Finals NSTPDocument6 pagesTRANS Finals NSTPStephanieNo ratings yet

- Why Are Engineers Considered An Important Segment of The Society?Document2 pagesWhy Are Engineers Considered An Important Segment of The Society?Angellete D. GacayanNo ratings yet

- Aliquat-336 As A Novel Collector For Quartz FlotationDocument8 pagesAliquat-336 As A Novel Collector For Quartz FlotationMaicol PérezNo ratings yet

- Heinemann English Language Teaching A Division of Heinemann Publishers (Oxford)Document192 pagesHeinemann English Language Teaching A Division of Heinemann Publishers (Oxford)Tina100% (6)

- Operation and Control Philosophy: PROJ Kurdistan Pumping Station (KPS2)Document21 pagesOperation and Control Philosophy: PROJ Kurdistan Pumping Station (KPS2)Nobar GulajanNo ratings yet

- U6 CWDocument17 pagesU6 CWyoussef.hussein.se7sNo ratings yet

- Math InterventionDocument2 pagesMath InterventionEmerita TrasesNo ratings yet

- Quantum: PhysicsDocument11 pagesQuantum: PhysicsVinodNo ratings yet

- PSSR Pre-Commissioning SafetyDocument6 pagesPSSR Pre-Commissioning SafetymanuNo ratings yet

- Spectral and Amplification Characteristics in San Salvador City (El Salvador) For Upper-Crustal and Subduction EarthquakesDocument9 pagesSpectral and Amplification Characteristics in San Salvador City (El Salvador) For Upper-Crustal and Subduction EarthquakesSergio Ito SunleyNo ratings yet

- Models of Cultural Heritage Management: Transformations in Business and Economics January 2014Document23 pagesModels of Cultural Heritage Management: Transformations in Business and Economics January 2014aaziNo ratings yet

- Top Renewable Energy Trends of 2018: Madeleine HoweDocument4 pagesTop Renewable Energy Trends of 2018: Madeleine HowedubryNo ratings yet

- 11.22 Elastic Settlement of Group Piles: RumusDocument1 page11.22 Elastic Settlement of Group Piles: RumusHilda MaulizaNo ratings yet

- Exercise Phase 4 - Team LeadershipDocument13 pagesExercise Phase 4 - Team LeadershipLUZ AMPARO MARTINEZNo ratings yet

- Grammar: Frequency AdverbsDocument2 pagesGrammar: Frequency AdverbsRedamanNo ratings yet

- Do Global Economic and Political Integrations Bring More Harm To The Philippines and The Filipinos or Not? Articulate Your StanceDocument3 pagesDo Global Economic and Political Integrations Bring More Harm To The Philippines and The Filipinos or Not? Articulate Your StancenonononowayNo ratings yet

- September 2017 Part 1 Standardised Competence-Oriented Written School-Leaving ExaminationDocument32 pagesSeptember 2017 Part 1 Standardised Competence-Oriented Written School-Leaving Examinationbestgamer100% (1)

- Eng Pcdmis 2022.1 CMM ManualDocument453 pagesEng Pcdmis 2022.1 CMM ManualRahulNo ratings yet

- Seminar ReportDocument23 pagesSeminar ReportMamta MishraNo ratings yet

- Vignettes: I. Lesson PlanDocument27 pagesVignettes: I. Lesson PlanAcademic ServicesNo ratings yet

- A Study On Five International Scientists: Micro Project ReportDocument18 pagesA Study On Five International Scientists: Micro Project ReportAishwarya MohanNo ratings yet

- Manufacturing Commercial Phosphate FertilizerDocument2 pagesManufacturing Commercial Phosphate FertilizerGhulam Mohy UddinNo ratings yet