Professional Documents

Culture Documents

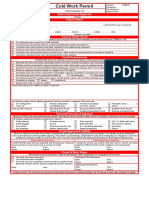

D.05 - Multi-Purpose Work Permit Form

Uploaded by

Benedito Cossa FelicianoOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

D.05 - Multi-Purpose Work Permit Form

Uploaded by

Benedito Cossa FelicianoCopyright:

Available Formats

Work Permit Version:

Permit No. :

07/2015

...........................................

Additional excavation work requirements

The location of all underground pipelines, electrical-, water- and other lines have thoroughly been examined

Status

Oiltanking Matola, SA

Permit Issuer: ........................................... If applicable, the contractor was briefed on the type and depth of present underground lines

Date & Time: ...........................................

The exact location of the excavation has been marked (attach plan with exact location marked)

Authorized Permit Applicant

A manual pre-excavation down to a depth of ....................... (m) is required for safety reasons

Department: Name:

…………………........................................................................ …………………..…………………….……………….………..................

A hot work permit is required as contaminated soil and/or groundwater is expected to be encountered

Planned Work Additional working at height requirements

Description of work: ................................................................................................. .................................................................................................................................................................................. Additional protection equipment:

Location of work: .................................................................................................................................................................................................... (add sheet for map, if required) Temporary handrail Mobile scaffolding Fixed scaffolding Cherry picker

Equipment to work on: .............................................................................................................................................................................................................................................................................. Raised platform Safety net Safety harness Others ..................................................

Equipment to be used: .............................................................................................................................................................................................................................................................................. All fall protection equipment is certified and checked to be used correctly

Vehicle types to be used: .............................................................................................................................................................................................................................................................................. Life jackets have to be worn when working over water

Expected period of work: From ............................................ (date) ............................. (hrs) to ............................................ (date) ............................ (hrs) No piles of material higher than 1.2 m are stored at workplaces above 2 m height

Performing company: ………………………………….…………………...……………….. Number of people: ............................................................................................................ Scaffolding has been adequately erected at proper location (attach respective scaffolding certificate)

This Permit is applicable for the following Additional radiation work requirements

Hot work Cold work Confined space entry Vehicle entry All radiation sources and equipment are approved and licensed by the applicable regulatory authorities

Electrical work Excavation work Working at height Radiation work The radiation work will be carried out by licensed radiation worker

General Safety Checks

The radiation outside the barricaded area will be below the maximum permissible levels

In case of an emergency the control room must be informed immediately by terminal telephone (???) or VHF. A field check has to be The work site has been marked with the applicable signs for radiation

carried out to fill in the status of the requirements. Special instructions (use additional sheets if required):

All contractors have received an HSSE induction and understood its content

Job-based risk assessment must be carried out (attached to permit), document no. : ……………………………………. The following safety and fire fighting equipment must be provided or activated at the work site:

Contractor have been briefed on the fluids contained in the neighbouring equipment Powder extinguisher CO2 extinguisher Firehose/ branchpipe Firewatch (name: …...……….…… )

Pressure relief valves have been vented to safe areas Foam car Fire fighting truck Fixed fire monitor Others ..................................................

Contractor have been provided with a terminal radio or other means of communication for emergency situations Personal Protective Equipment

Operations department has been informed about the works planned Minimum PPE in the restricted area are helmet, antistatic/product resistant safety shoes & antistatic clothing covering arms/legs.

Permit Requirements The following additional protective equipment is required:

A field check has to be carried out to fill in the status of the requirements. Status Safety glasses Protective gloves Dust respirator LEL / O2 meter with alarm

General cold and hot work requirements Safety goggles Overall Mask with filter Personal H2S detector

Work site has been barricaded, adequately marked and does not block emergency exits and equipment or escape routes Face shield Chemical protective suit S. C. breathing apparatus Life jacket

Welding must be conducted by approved welder who holds valid welder’s pass for welding process and joint type to be applied

Ear protection Rubber safety boots Safety harness / line Others ..................................................

Equipment must be de-pressurised/flushed/drained/purged, checked for leakage and is free of hazardous material

Gas-free Certificate

Electrical equipment must be locked out / tagged out, LOTO tag No.: …..……….............…… Regular gas tests considering the wind direction shall be carried out by an Authorised Gas Tester and recorded on this form.

Immediate work site must be cleared from combustible materials, spark/flash screens/barriers have to be placed Because of the more complex situation a separate Gas-free Certificate is required (attach to permit).

All related pipe work must be physically isolated by disconnecting blind-plating Time: ……………... h Signature ……………... h Signature ……………... h Signature The equipment/vessel/work site (15 m range) has been gas tested by

All nearby (at least 15 m range) vents, drains, sample points, sewers, pits and other openings have to be sealed Gas (% LEL) an Approved Gas Tester and certified gas-free.

Ventilation is needed natural mechanical O2 (%) No. of serial gas tester:............................................................

Equipment to work on must be earthed H2S (ppm) Date: ..................................................... Time: ......................................................................

Additional confined space entry requirements Name: ...................................................... Signed: ......................................................................

The confined space/vessel did contain the following hazardous material: ......................................................................................

Permit Aproval & Validity

A vessel entry control board has been provided to identify and monitor movement of vessel entry personnel Permit is valid (for one shift only) when complete by authorised Oiltanking personnel and signed. The validity must be extended if

work is allowed to be continued after expiring. The permit is automatically suspended due to an emergency or changes in work site

A rescue plan is available and a trained stand-by person (name …………………………. )has been assigned for the duration of the work conditions making it unsafe to continue the work. The work can only be resumed upon clearance from the approving authority.

Additional vehicle entry requirements Authorised Permit Issuer Authorised Permit Receiver

Driver (name:…………………………………………..…….) of vehicle (licence plate:……………………………..….………) has a valid driving licence I confirm that the work site was inspected and all necessary measures I accept the permit and confirm that work will be carried out safely

The vehicle must be fitted with a spark arrestor have been taken to ensure the work is carried out safely. subject to fulfilment of the permit conditions and requirements.

Roads have to be closed (attach plan with exact location marked and closure time indicated)

Date: ..................................................... Time: ….......................................................... Date: ..................................................... Time: …..........................................................

Name: ..................................................... Sign: Name: ..................................................... Sign:

The movement of heavy vehicles must be guided

….......................................................... …..........................................................

Permit & Work Status

The route and the surrounding area is free of product and product vapour

The permit must be returned for extension, in case of cancellation, after suspension or completion of the work.

The entry route to the work site/tank pit has been determined Permit Work

The driver is aware of the maximum height of the determined route

The work has been suspended.

Authorized Permit Receiver:

The driver is aware of the speed limit on the terminal The permit has been cancelled.

Name: ..................................................... Sign: …..........................................................

Date: ..................................................... Time:

…..........................................................

Additional electrical work requirements The work has been completed and the permit is herewith invalid.

Authorized Permit Issuer:

The electrical work will be carried out by licensed electricians (Work site has been cleared, cleaned, equipment has been returned.)

Date: ..................................................... Time: …..........................................................

The equipment to work on has been de-energised and electrically disconnected in the substation Date: ..................................................... Time: …..........................................................

Name: ..................................................... Sign: …..........................................................

All switches have been properly marked with warning signs All rights reserved. This document was prepared to control safety relevant work on Oiltanking facilities only. No warranty is made, either expressed or implied.

You might also like

- D.06 - Hot Work Permit FormDocument1 pageD.06 - Hot Work Permit FormBenedito Cossa FelicianoNo ratings yet

- D.07 - Cold Work Permit FormDocument1 pageD.07 - Cold Work Permit FormBenedito Cossa FelicianoNo ratings yet

- Oisd STD 109Document38 pagesOisd STD 109Swaraj PandaNo ratings yet

- Port Operations Manual 2002Document67 pagesPort Operations Manual 2002markie supieNo ratings yet

- Marquard Bahls Annual Report 2018 en WebDocument72 pagesMarquard Bahls Annual Report 2018 en WebMercury ManNo ratings yet

- Guidelines: OISD GDN-165 First Edition JULY-1999Document20 pagesGuidelines: OISD GDN-165 First Edition JULY-1999msb_75No ratings yet

- Oisd STD 127Document23 pagesOisd STD 127Priyank SutariyaNo ratings yet

- D.09 - Vehicle Entry Permit FormDocument1 pageD.09 - Vehicle Entry Permit FormBenedito Cossa FelicianoNo ratings yet

- Oisd STD 235Document129 pagesOisd STD 235tarun pandeyNo ratings yet

- Vopak Roadshow Presentation Q1 2014Document78 pagesVopak Roadshow Presentation Q1 2014ckyeakNo ratings yet

- OISD STD 2015 OISD STD 132 Pressure Relieving DevicesDocument60 pagesOISD STD 2015 OISD STD 132 Pressure Relieving DevicesÏÂm ÂvïRâjNo ratings yet

- Hsse and Pipe Check ListDocument6 pagesHsse and Pipe Check ListSandip PalNo ratings yet

- Oisd 161Document37 pagesOisd 161poojaupesNo ratings yet

- The Influence of Leadership and Organizational Commitment On Employee Performance Through Working Disciplines As Intervening VariablesDocument22 pagesThe Influence of Leadership and Organizational Commitment On Employee Performance Through Working Disciplines As Intervening VariablesHendra SaputraNo ratings yet

- Pol Tanklorry Design & Safety: OISD - RP-167 For Restricted CirculationDocument28 pagesPol Tanklorry Design & Safety: OISD - RP-167 For Restricted CirculationKiran KumarNo ratings yet

- Sign Sign 21213 1592915901392 PDFDocument2 pagesSign Sign 21213 1592915901392 PDFinsafaNo ratings yet

- Oisd 161Document20 pagesOisd 161Arvind BharadwajNo ratings yet

- Disclosure To Promote The Right To InformationDocument28 pagesDisclosure To Promote The Right To InformationKatie RamirezNo ratings yet

- Terminal Booklet Vopak Worldwide 2008Document102 pagesTerminal Booklet Vopak Worldwide 2008Fabu Lous CeeNo ratings yet

- 351-2 English Prose - UsagesDocument171 pages351-2 English Prose - UsagesKritika 12No ratings yet

- Oisd 203Document9 pagesOisd 203Rajesh Suthar100% (1)

- Truth Table For Common AnodeDocument3 pagesTruth Table For Common AnodeSisay ADNo ratings yet

- Fas 13Document6 pagesFas 13LPG Equipment Consulting and ServicesNo ratings yet

- OISD-GDN 199: Oil Industry Safety DirectorateDocument32 pagesOISD-GDN 199: Oil Industry Safety Directoratemasoud132No ratings yet

- Oisd GDN 168Document40 pagesOisd GDN 168sgh135550% (2)

- Oisd STD 170Document26 pagesOisd STD 170Nanu PatelNo ratings yet

- Oisd 234 DraftDocument32 pagesOisd 234 DraftThomas Snider100% (1)

- DOCDocument207 pagesDOCdhaktodesatyajitNo ratings yet

- Oisd 161Document20 pagesOisd 161Coimbatore DONo ratings yet

- Tank WagonDocument27 pagesTank Wagonrenger20150303No ratings yet

- Maintenance Schedules AnnexureDocument56 pagesMaintenance Schedules AnnexureJyoti Tecno PowerNo ratings yet

- Spill Prevention Control and Countermeasure PlanDocument56 pagesSpill Prevention Control and Countermeasure PlanPhilip ColeNo ratings yet

- GDN 224Document32 pagesGDN 224mkkamarajNo ratings yet

- Oiltanking Tank Overfill Protection Standard PDFDocument26 pagesOiltanking Tank Overfill Protection Standard PDFLEONARDO GARCIANo ratings yet

- STD 135Document26 pagesSTD 135Mathan Selva Kumar ANo ratings yet

- GDN 219Document23 pagesGDN 219Mitul PatelNo ratings yet

- Application Format For Seeking Certified CopiesDocument1 pageApplication Format For Seeking Certified CopiessinghcybercafeNo ratings yet

- Is 8451Document30 pagesIs 8451Ramakrishnan AmbiSubbiahNo ratings yet

- SOP-017-Testing of Specific Gravity of CondensateDocument9 pagesSOP-017-Testing of Specific Gravity of CondensateAmnaKamranNo ratings yet

- Oisd RP 167 PDFDocument28 pagesOisd RP 167 PDFgirishhodlur100% (1)

- Recommended Practices ON Static Electricity: OISD-110 OISD - 110 (Rev.1)Document35 pagesRecommended Practices ON Static Electricity: OISD-110 OISD - 110 (Rev.1)manuppm100% (1)

- How Many Questions Can Be Asked in One RTI ApplicationDocument6 pagesHow Many Questions Can Be Asked in One RTI ApplicationGANESH KUNJAPPA POOJARINo ratings yet

- Oisd STD 235Document110 pagesOisd STD 235Nanu PatelNo ratings yet

- Oisd STD 105Document27 pagesOisd STD 105akv9005100% (1)

- IQCM Final For Industry-12!06!2015Document142 pagesIQCM Final For Industry-12!06!2015raj dasNo ratings yet

- STD 159Document34 pagesSTD 159sparkarc4100% (2)

- 5158 00 PI SPC 0005 - 1 Specification For ValvesDocument38 pages5158 00 PI SPC 0005 - 1 Specification For Valvesأحمد عبدالنعيمNo ratings yet

- Oisd STD-225 PDFDocument42 pagesOisd STD-225 PDFGyan KumarNo ratings yet

- JIG Bulletin-115-EI1584-qualified-equipmentDocument3 pagesJIG Bulletin-115-EI1584-qualified-equipmentvaradarajck893No ratings yet

- Oisd RP 126Document17 pagesOisd RP 126ajayNo ratings yet

- Oisd STD 234 PDFDocument32 pagesOisd STD 234 PDFdinesh meenaNo ratings yet

- Guidelines For Issue of NOC For Constructions Around IAF Aerodromes - NOV2019 PDFDocument17 pagesGuidelines For Issue of NOC For Constructions Around IAF Aerodromes - NOV2019 PDFJaiNo ratings yet

- CV Daud SitorusDocument8 pagesCV Daud SitorusDaud SitorusNo ratings yet

- LPG Valves and Equipment 2022 23 Rev5.0 WebDocument88 pagesLPG Valves and Equipment 2022 23 Rev5.0 WebRadient MushfikNo ratings yet

- PV 20005 PCPL LP Mesh Bot - 01 (Rev B)Document1 pagePV 20005 PCPL LP Mesh Bot - 01 (Rev B)Dilinger ArkadisNo ratings yet

- PV Scada - Loc Ninh 5: Communication Switch PRS-7961BDocument3 pagesPV Scada - Loc Ninh 5: Communication Switch PRS-7961BThơi Hồ MinhNo ratings yet

- Unitech Limited: Speechbridge Technologies Pvt. LTDDocument1 pageUnitech Limited: Speechbridge Technologies Pvt. LTDKumar MNo ratings yet

- PV 20005 PCPL LP Mesh Top - 01 (Rev B)Document1 pagePV 20005 PCPL LP Mesh Top - 01 (Rev B)Dilinger ArkadisNo ratings yet

- Perhitungan Boq Sungai Teriti: Struktur Tanggul AtasDocument8 pagesPerhitungan Boq Sungai Teriti: Struktur Tanggul AtasRio AlviansyahNo ratings yet

- Consultoria Costructora Y&H Sac: LaminaDocument1 pageConsultoria Costructora Y&H Sac: Lamina01-IC-HU-HANS KENNEDY MIGUEL VIVANCONo ratings yet

- Physical & Chemical PropertiesDocument10 pagesPhysical & Chemical PropertiesJohnree A. Evangelista100% (1)

- TCDS E4ea PT6 PDFDocument22 pagesTCDS E4ea PT6 PDFGabriielLoopez100% (2)

- Antenna ConceptsDocument28 pagesAntenna Conceptssameerajamal100% (1)

- EG110 (Spring 2021) Exam #2 Pelayo MartinezDocument6 pagesEG110 (Spring 2021) Exam #2 Pelayo MartinezPelayo MartinezNo ratings yet

- FMC1278Document132 pagesFMC1278Herick Douglas PereiraNo ratings yet

- Solid Short Notes PDFDocument32 pagesSolid Short Notes PDFsanjeet singh kainturaNo ratings yet

- 3612Document6 pages3612Chandrashekar PatigeNo ratings yet

- Bending Effect On ExhaustDocument11 pagesBending Effect On Exhaustsayantan ghoshNo ratings yet

- 4grinding Polishing Flexible ToolsDocument113 pages4grinding Polishing Flexible ToolsGabriel DobrescuNo ratings yet

- Ugc Net: General Paper On Teaching & Research AptitudeDocument6 pagesUgc Net: General Paper On Teaching & Research AptitudeAkarshika pandeyNo ratings yet

- PPCE U 1 NotesDocument10 pagesPPCE U 1 NotesJeevanandam ShanmugasundaramNo ratings yet

- ReadMe NetDocument2 pagesReadMe NetMariano MartinezNo ratings yet

- BSC6900 GSM V900R012 DimensioningDocument88 pagesBSC6900 GSM V900R012 Dimensioningginiskid301086No ratings yet

- Removable Storage DevicesDocument10 pagesRemovable Storage DevicesEtty MarlynNo ratings yet

- Packet Tracer Skills Integration ChallengeDocument7 pagesPacket Tracer Skills Integration Challengekaloi0303No ratings yet

- DNV Rules For Woodenships 1970Document146 pagesDNV Rules For Woodenships 1970Manuel Cares FuentesNo ratings yet

- WeldingDocument752 pagesWeldingAndres_Pastor1987100% (3)

- PG Program in Paint & Coating Technology-April-2013Document10 pagesPG Program in Paint & Coating Technology-April-2013Uday Kumar GantiNo ratings yet

- Comparing The Mechanical Properties of Cyanate Ester Modified Epoxy /glass LaminatesDocument7 pagesComparing The Mechanical Properties of Cyanate Ester Modified Epoxy /glass LaminatesAndrew NallayanNo ratings yet

- Verificare Imbinare Cu Suruburi Grinda-StalpDocument2 pagesVerificare Imbinare Cu Suruburi Grinda-StalpVirginia Elena IordacheNo ratings yet

- Part Number Part Description Condition Quantity UOM Tag InfoDocument375 pagesPart Number Part Description Condition Quantity UOM Tag Info李聪No ratings yet

- 315 MVA Trafo PDFDocument12 pages315 MVA Trafo PDFzeeshanyg100% (2)

- Multi Core ProcessorsDocument7 pagesMulti Core ProcessorsBhavin Joshi100% (5)

- 1 s2.0 S2352012423002503 MainDocument14 pages1 s2.0 S2352012423002503 MainQuangNguyenVanNo ratings yet

- Hrvatski Registar Civilnih ZrakoplovaDocument22 pagesHrvatski Registar Civilnih ZrakoplovaIvo JosipNo ratings yet

- Dti Oil and Gas Industry White PaperDocument36 pagesDti Oil and Gas Industry White PaperSoniya AgnihotriNo ratings yet

- P1568Document9 pagesP1568Luis BarretoNo ratings yet

- Skip Cycle EngineDocument8 pagesSkip Cycle Enginekumar_yogesh223881No ratings yet

- Demountable Flares DatasheetDocument2 pagesDemountable Flares Datasheetmanojeil1No ratings yet

- 920-20601 GB Nk-9636a3Document0 pages920-20601 GB Nk-9636a3neeshakothari31No ratings yet