Professional Documents

Culture Documents

V61342 Parker Piston Accumulators

V61342 Parker Piston Accumulators

Uploaded by

richard castañedaOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

V61342 Parker Piston Accumulators

V61342 Parker Piston Accumulators

Uploaded by

richard castañedaCopyright:

Available Formats

Catalog 1630-7/USA Hydraulic Accumulators

Piston Accumulators Maintenance Instructions

Hydraulic Piston

Accumulators

Installation

Most accumulators shipped from the factory will The accumulator can be mounted in any

not be pre-charged. However, in some cases they orientation. However, it should be rigidly mounted

will be shipped with some amount of nitrogen using any combination of the mounting holes

charge, the value of which will be stamped on the provided at the hydraulic cap or proper clamps.

nameplate. The hydraulic circuit, which contains a connection

Keep the hydraulic port covered to keep out to the accumulator should be designed so that it

foreign material until ready to make the hydraulic automatically discharges all hydraulic fluid from

connections. the accumulator when the equipment is turned off.

89 Parker Hannifin Corporation

Hydraulic Accumulator Division

Hydraulics Rockford, IL 61115

Catalog 1630-7/USA Hydraulic Accumulators

Piston Accumulators Maintenance Instructions

Pre-Charging (EE) Let the pre-charge set for 10 to 15 minutes. This

Use an inert gas such as nitrogen for pre-charging piston will allow the gas temperature to stabilize. If the

accumulators. desired pre-charge is exceeded, close nitrogen

bottle valve, slowly open bleed valve until

If water pumped nitrogen is not available, oil-pumped nitrogen desired pressure is reached (Figure 3).

may be used. (C.G.A. standards: Nitrogen gas bottles for water

pumped nitrogen has a right-hand valve thread which requires (FF) With a wrench, tighten hex nut at point “D” to

charging and gauging assembly 1445950000 for units up to close internal poppet (5-8 ft. lbs.) (5.7-9.2 cm kg).

3000 psi. Oil-pumped nitrogen requires a left-handed valve (GG) Hold gas valve at point “C” with wrench and

thread (use 1445960000). For accumulators rated over 3000 remove swivel nut assembly.

psi up to 5000 psi, use assembly #1449120000 (see Figure 3). (HH) When pre-charging has been completed, replace

If equipment other than the above listed is used, make sure it is gas cap and tighten (10-15 in. lb.) (11.5-17 cm kg),

compatible with the gas valve assembly. Nitrogen source and install gas valve guard.

all components must be rated for a pressure at least as high as

the nitrogen source. It is strongly recommended that the

nitrogen bottle used have a high pressure regulator.

Make sure nitrogen supply is shut off. Attach hose to nitrogen

bottle. If accumulator has a gas valve as shown in Figure 5

follow steps A through J and skip steps AA through HH. If

accumulator has a gas valve as shown in Figure 6, skip steps A

through J and follow steps AA through HH.

Accumulator having gas valve as per Figure 5.

(A) Remove gas valve guard and gas valve cap.

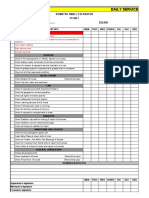

FIGURE 1 FIGURE 2

(B) Back gas chuck “T” handle all the way out PART #144595 0000 PART #085122 0000

(counter clockwise) before attaching charging

assembly to accumulator gas valve. 3000 PSI UNITS

(C) Close bleed valve. Part Number Charging and Gauging Assembly for 3000 PSI

(D) Making sure not to loop or twist the hose, attach 144595 0000 Charging and Gauging Assembly consists of 10' charging hose with

swivel nut to gas valve and tighten (10-15 in. lb.) (Std) standard right-hand thread nitrogen fittings adapter incorporating

(Right Hand) gas valve bleeder valve and gas chuck (less gauge). For left-hand

(11.5-17 cm kg). thread nitrogen bottle fitting, specify part number 144596 0000.

(E) Turn gas chuck “T” handle all the way down. This

will depress core in gas valve. Part Number Gauging Assembly for 3000 PSI

(F) Crack open nitrogen bottle valve and slowly fill 085122 0000 Gauging device consisting of adapter incorporating gas valve

accumulator. Shut off when gauge indicates bleeder valve and gas chuck (less gauge).

desired pre-charge.

(G) Let the pre-charge set for 10 to 15 minutes. This will

allow the gas temperature to stabilize. If the desired

pre-charge is exceeded, close nitrogen bottle valve, BLEED

then slowly open bleed valve (Figure 1). Do not reduce VALVE

pre-charge by depressing valve core with a foreign

object. Highpressure may rupture rubber valve seat.

SWIVEL

(H) When finished pre-charging accumulator, turn “T” NUT

handle all the way out on gas chuck (Figure 1), then PART #144912 0000

open bleed valve.

PART #144961 0000

(I) Hold gas valve to keep from turning, loosen swivel nut,

remove assembly. FIGURE 3 FIGURE 4

(J) Replace gas valve cap (10-15 in. lbs.) (11.5-17 cm

kg) and valve guard. (Gas valve cap serves as a 5000 PSI UNITS

secondary seal.) Part Number Charging and Gauging Assembly for 5000 PSI

144912 0000 Charging and Gauging Assembly consists of 10' charging

Accumulator having gas valve as per Figure 6. hose with standard right-hand thread nitrogen fittings

(AA) Remove gas valve guard and gas valve cap. (1.035-14 NGO female)adapter incorporating gas valve

bleeder valve and gas chuck (less gauge).

(BB) Close bleed valve and, making sure not to loop

or twist the hose, attach swivel nut to gas valve Part Number Gauging Assembly for 5000 PSI

and tighten (10-15 in. lb.) (11.5-17 cm kg). 144961 0000 Gaging device consisting of adapter incorporating gas

(CC) Hold gas valve at point “C” with one (1) wrench valve bleeder valve and gas chuck (less gauge).

while unscrewing hex nut at point “D” with a

second wrench. This will open the poppet inside

POINT “D”

the gas valve. Note: four (4) turns will fully open

the valve. CORE ACCUMULATOR POINT “C”

(DD) Crack open nitrogen bottle valve and slowly fill

ACCUMULATOR

accumulator. Close nitrogen bottle valve when

gauge indicates desired pre-charge.

PART #L07471000* (Buna) PART #612433 0000 Gas Valve with

Gas Valve with high pressure poppet for ASME units 7, 9, 12 bore

core for 3000 psi service and all 5000 psi units

FIGURE 5 FIGURE 6

90 Parker Hannifin Corporation

Hydraulic Accumulator Division

Hydraulics Rockford, IL 61115

Catalog 1630-7/USA Hydraulic Accumulators

Piston Accumulators Maintenance Instructions

Maintenance Remove from Hydraulic System

Repair Kits (see Parts List) are available for all Shut equipment down and make certain that hydraulic pressure

accumulator models. When ordering repair kits, state complete at the accumulator is at zero. At this point the piston will be

model number from nameplate. Also specify fluid and tempera- bottomed at the hydraulic end.

ture at which used.

For accumulators having gas valve as shown in Figure 5,

Occasional replacement of v-o-ring seal on the piston is attach gauging assembly as shown in Figure 2 following Steps

generally the only maintenance required. Replacement of other 1 through 5. Then, open bleed valve until all gas pre-charge is

seals on end caps and gas valve is recommended (see Kit relieved from accumulator. Then remove gauging assembly and

Numbers). gas valve.

Periodic checking of pre-charge pressure will detect whether v- For accumulators having gas valve as shown in Figure 6,

o-ring wear is sufficient to begin reducing sealing performance. remove gas valve guard and gas valve cap. Then hold valve at

If pre-charge is low, also check for gas valve and/or end seal point “C” with one (1) wrench while unscrewing hex nut at point

leakage. Allowing for temperature difference, if any, from time “D” with a second wrench. Wait until all gas pre-charge is

of its pressure checking, pre-charge pressure will rise if oil relieved from the accumulator and then remove gas valve.

gathers in the gas side and will fall if gas leaks into the oil side

or out past gas end seals. It is suggested that a check be made Remove accumulator from hydraulic system. Threaded holes in

a week after installation, and thereafter once a month. hydraulic cap may be used as a means of attachment for lifting,

or use a sling around the body.

Pre-charge Checking Procedure

Using appropriate valve in the hydraulic system,

Disassembly of Accumulator

discharge all oil from accumulator and allow piston to bottom Lay the accumulator horizontal and hold down with a strap

against hydraulic end cap. wrench or in a vise. Some accumulators may have both end

caps threaded into the body and some units may only have the

For accumulators rated for 3000 psi or less, use gauging gas cap threaded into the body. IN BOTH CASES ALWAYS

assembly as shown in Figure 2 (Part #0851220000). For REMOVE THE GAS CAP FIRST (end cap which contained gas

accumulators rated over 3000 psi up to 5000 psi, use assembly valve). To remove cap or caps, install three (3) pins into the

as shown in Figure 4 (Part #1449610000). holes in the cap, then, using a long bar working against the

Accumulators having gas valve as per Figure 5. pins, unthread the cap from the body. Remove o-rings and

back-up rings from end cap.

(1) Remove gas valve guard and gas valve cap.

Remove piston by pushing from hydraulic end with a bar.

(2) Back gas chuck “T” handle all the way out (counter

NEVER TRY TO REMOVE PISTON BY APPLYING COM-

clockwise) before attaching charging assembly to

PRESSED AIR AT OPPOSITE END. To remove v-o-ring from

accumulator gas valve.

piston, lift seal with small smooth screw driver or similar tool,

(3) Close bleed valve. moving the tool around the piston several times while using the

(4) Attach swivel nut to gas valve and tighten other hand to work ring off the piston.

(10-15 in. lb.) (11.5-17 cm kg).

(5) Turn gas chuck “T” handle all the way down. This Cleaning

will depress core in gas valve and check pressure.

Thoroughly clean metal parts in solvent and dry with com-

(6) To remove gauging assembly turn “T” handle all the pressed air. Clean bore of body with a clean, lint-free cloth

way out on gas chuck (Figure 1), then open bleed soaked in clean solvent. Bore must be clean of any visible

valve. particles or particles detectable to touch.

(7) Hold gas valve from turning, loosen swivel nut,

remove assembly.

(8) Replace gas valve cap (10-15 in. lbs.) (11.5-17 cm Inspection

kg) and valve guard. Inspect piston for cracks, burrs around o-ring grooves, or

Accumulators having gas valve as per Figure 6. damage. Examine body bore, using a light, for scratches or

scoring. Inspect end caps for damaged threads or burrs on o-

(9) Remove gas valve guard and gas valve cap. ring grooves.

(10) Close bleed valve.

(11) Attach swivel nut to gas valve and tighten

(10-15 in. lb.) (11.5-17 cm kg). Repair and Replacement

(12) Hold gas valve at point “C” with one (1) wrench Minor nicks, scratches or light scoring of the body bore can be

while unscrewing hex nut at point “D” with a removed by using crocus cloth. Dress bore until all apparent

second wrench. This will open the poppet inside imperfections have been removed. Replace teflon wear rings,

the gas valve. Turn 2-3 times and read pre-charge. v-o-rings, o-rings and their respective back up washers if the

original assembly contained them.

(13) With a wrench, tighten hex nut at point “D” to close

internal poppet (5-8 ft. lbs.) (5.7-9.2 cm kg).

(14) Hold gas valve at point “C” with wrench and

remove swivel nut assembly.

(15) Replace gas cap and tighten (10-15 in. lb.)

(11.5-17 cm kg), and install gas valve guard.

91 Parker Hannifin Corporation

Hydraulic Accumulator Division

Hydraulics Rockford, IL 61115

Catalog 1630-7/USA Hydraulic Accumulators

Piston Accumulators Maintenance Instructions

Reassembly

Coat all internal parts with clean hydraulic fluid before reas- Install new back-up ring first, then a new o-ring on threaded

sembly. end cap or caps and install into body bore. Care should be

exercised not to drag o-ring over threads. End cap will stop

With new v-o-ring and Teflon rings on piston, install piston, against chamfer leading into honed bore (extreme tightness not

hollow side toward gas end, in bore of body. Do not let v-o-ring required — o-ring sealing is not dependent upon cap tight-

drag on threads. Piston must go into bore exactly square and ness). Cap should be flush with or above the end of accumula-

very slowly. (V-o-ring will compress as it rides up the chamfer if tor body within 1/32" to 3/32".

done slowly, but may be damaged if forced quickly.) Piston will

fit snug. Use hammer and wood block to tap piston into place Install gas valve after replacing the o-ring.

until all of piston is 2 inches below beginning of honed bore. Remount accumulator and connect to hydraulic system. Pre-

Keep force against piston while tapping v-o-ring through the charge accumulator using procedure outlined on page 2 (where

bore chamfer, otherwise piston will bounce back, damaging the space is a problem it may be necessary to pre-charge accumu-

o-ring. Cover port opening to keep out dirt. lator before connecting it to the hydraulic system).

Parts List — Hydraulic Accumulators

Item Part Description

1* Body

2* Hydraulic Cap

3 Gas Cap

4 Piston

2 4 1 3 5 V-O-Ring

5A** V-O-Ring Back-Up Washers

6 Teflon Ring (Piston)

9A 7

7A

O-Ring

O-Ring Back-Up Washer

8▲ Gas Valve

8A Gas Valve O-Ring

9 Gas Valve Guard

8 9A Screw

* Some units may have these two

components welded together.

** Not used on 2" bore units

9 ▲ A.S.M.E. Units, 7", 9" and 12"

bore sizes, units rated above

3000 PSI will have valve per

Figure 6 on page 2 (Part No.

8A 6124330000). Other units will

have gas valve per Figure 5 on

page 2 (Part No. L07471000*)

which will contain gas valve core

5A 5 6 7 7A Part No. 5822220000.

Use tool (Part No. 5824410000) to

remove and replace new core.

Seal Kit Numbers (Includes items 5, 5A, 6, 7, 7A, 8A)

Bore Size

Material

2" 3" 4" 6" 7" 9" 12"

Buna-N (Std.) RK0200K000 RK0300K000 RK0400K000 RK0600K000 RK0700K000 RK0900K000 RK1200K000

Fluorocarbon RK0200E000 RK0300E000 RK0400E000 RK0600E000 RK0700E000 RK0900E000 RK1200E000

EPR RK0200D000 RK0300D000 RK0400D000 RK0600D000 RK0700D000 RK0900D000 RK1200D000

Hydrogenated Nitrile RK0200H000 RK0300H000 RK0400H000 RK0600H000 RK0700H000 RK0900H000 RK1200H000

Carboxylated Nitrile RK0200J000 RK0300J000 RK0400J000 RK0600J000 RK0700J000 RK0900J000 RK1200J000

Low Temp Nitrile RK0200Q000 RK0300Q000 RK0400Q000 RK0600Q000 RK0700Q000 RK0900Q000 RK1200Q000

92 Parker Hannifin Corporation

Hydraulic Accumulator Division

Hydraulics Rockford, IL 61115

You might also like

- 2AZ FE CoolingDocument35 pages2AZ FE CoolingLuks Fernandez50% (2)

- Plymouth and Chrysler-built cars Complete Owner's Handbook of Repair and MaintenanceFrom EverandPlymouth and Chrysler-built cars Complete Owner's Handbook of Repair and MaintenanceNo ratings yet

- API Plan 53-Accumulator Bladder ChargingDocument11 pagesAPI Plan 53-Accumulator Bladder Chargingsumantabal_uceNo ratings yet

- Ec (2jz-Gte) PDFDocument12 pagesEc (2jz-Gte) PDFAshokNo ratings yet

- Service Bulletin: Fuel Injection PumpDocument6 pagesService Bulletin: Fuel Injection PumpAnonymous wpUyixsj100% (2)

- Breaker Piping InstallationDocument11 pagesBreaker Piping InstallationZawminhtunNo ratings yet

- Engine Mechanical PDFDocument115 pagesEngine Mechanical PDFAndrey GladyshevNo ratings yet

- STC Oil Control Valve Mechanical 006 007 K38 K50Document18 pagesSTC Oil Control Valve Mechanical 006 007 K38 K50SpectrumRaijin100% (11)

- Pressure-Volume-Temperature For Oil: PVT Analysis - PVT RelationshipDocument21 pagesPressure-Volume-Temperature For Oil: PVT Analysis - PVT RelationshipyerkoNo ratings yet

- Mongo Burner For Gas ForgeDocument1 pageMongo Burner For Gas ForgeJacobParkerNo ratings yet

- Mining Lease AgreementDocument8 pagesMining Lease AgreementHebert SozinyuNo ratings yet

- STC Oil Control Valve (Mechanical) - 4Document2 pagesSTC Oil Control Valve (Mechanical) - 4Parveen KashyapNo ratings yet

- Diagrama Hidraulico m315d Renr9476renr9476-04 SisDocument2 pagesDiagrama Hidraulico m315d Renr9476renr9476-04 SisServimaquinaria Millan S.A.C100% (1)

- Line Sizing Criteria As Per Different International StandardsDocument4 pagesLine Sizing Criteria As Per Different International StandardsTiano BaLajadia100% (1)

- Brake Accumulator ChargingDocument10 pagesBrake Accumulator ChargingRajan Mullappilly100% (1)

- Maintenance - Piston'sDocument6 pagesMaintenance - Piston'smecambNo ratings yet

- Manual Tecnico Bomba StanadyneDocument3 pagesManual Tecnico Bomba StanadyneIvo Silva100% (4)

- CNG Compressors: Fueling Natural Gas VehiclesDocument9 pagesCNG Compressors: Fueling Natural Gas VehiclesKASIMNo ratings yet

- The Book of the Singer Junior - Written by an Owner-Driver for Owners and Prospective Owners of the Car - Including the 1931 SupplementFrom EverandThe Book of the Singer Junior - Written by an Owner-Driver for Owners and Prospective Owners of the Car - Including the 1931 SupplementNo ratings yet

- Recommended Installation of A Bop Control SystemDocument8 pagesRecommended Installation of A Bop Control SystemHamid Reza BabaeiNo ratings yet

- Fluid Mechanics 5th Edition, Chapter 2 Solutions (Douglas)Document15 pagesFluid Mechanics 5th Edition, Chapter 2 Solutions (Douglas)tarun100% (4)

- Wartsila Fuel Pump - MaintenanceDocument15 pagesWartsila Fuel Pump - MaintenanceAbhishek Singh Chauhan0% (1)

- CAMERON France S.A.S: Front SheetDocument24 pagesCAMERON France S.A.S: Front SheetkrishnsgkNo ratings yet

- Aga Z223-1 PDFDocument140 pagesAga Z223-1 PDFLuis EnriqueNo ratings yet

- Is 5844Document10 pagesIs 5844Ramakrishnan AmbiSubbiah100% (2)

- 5 - GEST 10 362 Edition 4 - Corrosion Behaviour of Carbon Steel in Wet and Dry ChlorineDocument41 pages5 - GEST 10 362 Edition 4 - Corrosion Behaviour of Carbon Steel in Wet and Dry ChlorineAdemilson JuniorNo ratings yet

- Hydraulic Piston AccumulatorsDocument24 pagesHydraulic Piston AccumulatorsEdu XaviNo ratings yet

- V61342 Parker Piston AccumulatorsDocument24 pagesV61342 Parker Piston AccumulatorsPaulPaucarCamposNo ratings yet

- Maintenance - BA'sDocument8 pagesMaintenance - BA'sEduardo CramerNo ratings yet

- Series "BA" Bladder AccumulatorsDocument8 pagesSeries "BA" Bladder AccumulatorsGustavo Aguilar y de RamírezNo ratings yet

- varco派克蓄能器气门芯与充氮工具varcoDocument6 pagesvarco派克蓄能器气门芯与充氮工具varcoHayLenLeeNo ratings yet

- F and G Series Hammer Gas Charge Service Kit InformationDocument5 pagesF and G Series Hammer Gas Charge Service Kit Information2222222222222-242735100% (1)

- Nitrogen Gas Charging InstructionsDocument5 pagesNitrogen Gas Charging InstructionsnelsonyNo ratings yet

- Especificaciones Acumulador de Direccion CAT789C Prueba y CargaDocument8 pagesEspecificaciones Acumulador de Direccion CAT789C Prueba y CargaRafael RodriguezNo ratings yet

- Coolant: InspectionDocument32 pagesCoolant: InspectionAiman NasirNo ratings yet

- SelectionDocument20 pagesSelectionJoséEnriqueSosaNo ratings yet

- Thermo Pot-Sse 10Document1 pageThermo Pot-Sse 10Bharat TailorNo ratings yet

- 3-070 TSBDocument5 pages3-070 TSBДжони Кейдж100% (1)

- 18SP607 - Series 60 Egr Ddec V Fuel Pump, Combination Pressure Regulator / Check Valve, and N3 Injector O-Ring and Washer KitDocument7 pages18SP607 - Series 60 Egr Ddec V Fuel Pump, Combination Pressure Regulator / Check Valve, and N3 Injector O-Ring and Washer KitaraceliluciojimenezNo ratings yet

- Instruction Bladder AccumulatorsDocument38 pagesInstruction Bladder AccumulatorsAdrian MicuNo ratings yet

- LC HDP 1100 D2数显喷油器13版说明书Document22 pagesLC HDP 1100 D2数显喷油器13版说明书DariusNo ratings yet

- On-Vehicle Inspection: Fuel Tube ConnectorDocument3 pagesOn-Vehicle Inspection: Fuel Tube ConnectordiemnganNo ratings yet

- Pressure Regulator Valve Kit: GM 6L45, 6L50, 6L80, 6L90Document2 pagesPressure Regulator Valve Kit: GM 6L45, 6L50, 6L80, 6L90Mohamed AhmedNo ratings yet

- Removal Refitting Variable Geometry Turbocharger GARETTDocument6 pagesRemoval Refitting Variable Geometry Turbocharger GARETTiliecNo ratings yet

- Pages From 87551885A - 921E Wheel Loader Repair ManualDocument3 pagesPages From 87551885A - 921E Wheel Loader Repair ManualЖеня СавченкоNo ratings yet

- Suspension 740Document14 pagesSuspension 740AndiNo ratings yet

- Patg Pamg Turbo PartsDocument12 pagesPatg Pamg Turbo Parts1luckywolf0% (1)

- 2AZ-FE Emission ControlDocument25 pages2AZ-FE Emission ControlLuks FernandezNo ratings yet

- Weber - 32 - 36 - DGV-32 36 DGV-fil - F0oouDocument2 pagesWeber - 32 - 36 - DGV-32 36 DGV-fil - F0oouelbarto0100% (1)

- Acomulador TENSOR AP555EDocument11 pagesAcomulador TENSOR AP555EAleixandre GomezNo ratings yet

- 28260-RPC-004 UsageDocument8 pages28260-RPC-004 Usagedouglas camposNo ratings yet

- Intake AndDocument16 pagesIntake AndGonzalez RubenNo ratings yet

- How To Recharge N2 Gas of HB BreakerDocument8 pagesHow To Recharge N2 Gas of HB BreakerTrevor BurnettNo ratings yet

- Engine Mechanical ECHO 2002Document85 pagesEngine Mechanical ECHO 2002Tomas Dominguez100% (1)

- Wheel Horse Hydraulic Lift Valve & Cylinder Repair ManualDocument12 pagesWheel Horse Hydraulic Lift Valve & Cylinder Repair ManualwordswainNo ratings yet

- Emission ControlDocument26 pagesEmission ControllogammicNo ratings yet

- SB388CDocument13 pagesSB388CBenjamin LeedsNo ratings yet

- Installation of Governor On 1U7326 Governor Calibration Bench... 3114, 3116 and 3126 MUI Engine Governors #I01154203 CaterpillarDocument8 pagesInstallation of Governor On 1U7326 Governor Calibration Bench... 3114, 3116 and 3126 MUI Engine Governors #I01154203 CaterpillargiovanebalzaniNo ratings yet

- Inspect Axial Play of Turbine Shaft - Toyota Hilux 1KZ TE RepairDocument2 pagesInspect Axial Play of Turbine Shaft - Toyota Hilux 1KZ TE RepairHassan KhattabNo ratings yet

- Kip KIPDocument28 pagesKip KIPAndrijana MajoNo ratings yet

- Pilot Oil Accumulator - Test and ChargeDocument6 pagesPilot Oil Accumulator - Test and Chargeالبراق للتوريدات وصيانة المعداتNo ratings yet

- PI - Fault Diagnosis CardsDocument11 pagesPI - Fault Diagnosis Cardsaakk75No ratings yet

- Perkins Boletin MotorDocument7 pagesPerkins Boletin MotorWilliams Araya100% (1)

- R065E2Document7 pagesR065E2Mk MakyNo ratings yet

- Ariston Genus 23 RepairDocument44 pagesAriston Genus 23 RepairDaniel PereiraNo ratings yet

- Operating and Maintenance Instructions On Tobul AccumulatorsDocument8 pagesOperating and Maintenance Instructions On Tobul AccumulatorsGuru VagaNo ratings yet

- Service Instruction For Servo Cylinder Type PBEDDocument2 pagesService Instruction For Servo Cylinder Type PBEDДжон Диллинджер100% (1)

- Marvel Carbureter and Heat Control As Used on Series 691 Nash Sixes Booklet SFrom EverandMarvel Carbureter and Heat Control As Used on Series 691 Nash Sixes Booklet SNo ratings yet

- Installation and Operation Instructions For Custom Mark III CP Series Oil Fired UnitFrom EverandInstallation and Operation Instructions For Custom Mark III CP Series Oil Fired UnitNo ratings yet

- The Petrol Engine: A Text-book dealing with the Principles of Design and Construction, with a Special Chapter on the Two-stroke EngineFrom EverandThe Petrol Engine: A Text-book dealing with the Principles of Design and Construction, with a Special Chapter on the Two-stroke EngineNo ratings yet

- Drill Quote PPC-quote Pumps Revised FEBDocument2 pagesDrill Quote PPC-quote Pumps Revised FEBHebert SozinyuNo ratings yet

- Drill Quote PPC-quote Pumps OGDocument2 pagesDrill Quote PPC-quote Pumps OGHebert SozinyuNo ratings yet

- PPC Attachment 2020Document2 pagesPPC Attachment 2020Hebert SozinyuNo ratings yet

- Drill Quote PPC-quote Pumps OGDocument2 pagesDrill Quote PPC-quote Pumps OGHebert SozinyuNo ratings yet

- Runeford Industries Fight Against Covid-19: - Visitors FormDocument1 pageRuneford Industries Fight Against Covid-19: - Visitors FormHebert SozinyuNo ratings yet

- V301139 - Copper - Core - MaintenanceCleaning Procedure102601Document2 pagesV301139 - Copper - Core - MaintenanceCleaning Procedure102601Hebert SozinyuNo ratings yet

- Electrical Drawing Package: LoadersDocument24 pagesElectrical Drawing Package: LoadersHebert Sozinyu100% (1)

- Trojan Nickel Mine Contract Engines 2019Document13 pagesTrojan Nickel Mine Contract Engines 2019Hebert SozinyuNo ratings yet

- TROJAN MINE C273 TORQUE CONVERTER REVISED 2020 MayDocument1 pageTROJAN MINE C273 TORQUE CONVERTER REVISED 2020 MayHebert SozinyuNo ratings yet

- V301090 - Donaldson - Air - Cleaner - E Series Service Guide & TipsDocument2 pagesV301090 - Donaldson - Air - Cleaner - E Series Service Guide & TipsHebert SozinyuNo ratings yet

- Air Cleaner Trouble Shooting: Short Filter LifeDocument2 pagesAir Cleaner Trouble Shooting: Short Filter LifeHebert SozinyuNo ratings yet

- Plant 27 StepsDocument120 pagesPlant 27 StepsHebert SozinyuNo ratings yet

- Runeford Industries (PVT) LTD: Tax Invoice No. RI001Document2 pagesRuneford Industries (PVT) LTD: Tax Invoice No. RI001Hebert SozinyuNo ratings yet

- Re: Diesel Plant Fitter / Site Supervisor - Professional Services in Bush Clearing, Land Preparation, General Earthworks and PLANT HIRE - 8942288Document3 pagesRe: Diesel Plant Fitter / Site Supervisor - Professional Services in Bush Clearing, Land Preparation, General Earthworks and PLANT HIRE - 8942288Hebert SozinyuNo ratings yet

- Daily Service: Komatsu Small ExcavatorDocument9 pagesDaily Service: Komatsu Small ExcavatorHebert SozinyuNo ratings yet

- Ashanti Volvo Tad1340ve EngineDocument2 pagesAshanti Volvo Tad1340ve EngineHebert SozinyuNo ratings yet

- Gyproc Loads January 2020Document59 pagesGyproc Loads January 2020Hebert SozinyuNo ratings yet

- (Revised Water Pump ProformaDocument2 pages(Revised Water Pump ProformaHebert SozinyuNo ratings yet

- FREDDA REBBECCA BF6L 914C ENGINE - 2020 - MayDocument1 pageFREDDA REBBECCA BF6L 914C ENGINE - 2020 - MayHebert SozinyuNo ratings yet

- NT 2178 GKDocument3 pagesNT 2178 GKAlla weerNo ratings yet

- D758-Et Minipurge ManualDocument39 pagesD758-Et Minipurge ManualNicholas marcolan (nmarcolan)No ratings yet

- Dissolved Gas Analysis of Thermal Faults in Transformer Liquids Simulated Using Immersed Heating MethodDocument10 pagesDissolved Gas Analysis of Thermal Faults in Transformer Liquids Simulated Using Immersed Heating MethodilhamNo ratings yet

- Adsorbents Solutions Refining Brochure PDFDocument2 pagesAdsorbents Solutions Refining Brochure PDFSALAM ALINo ratings yet

- Introduction To Fluid Mechanics - TocDocument3 pagesIntroduction To Fluid Mechanics - TocNguyễn Hồng Quân100% (2)

- Me231 Course ContentsDocument3 pagesMe231 Course ContentsBarry ANo ratings yet

- Detection of Sulfur Compounds in Natural GasDocument4 pagesDetection of Sulfur Compounds in Natural GasfarshidianNo ratings yet

- 2015 Spring HomeWorks P Only 04-27-2015Document12 pages2015 Spring HomeWorks P Only 04-27-2015Ali Jay J0% (1)

- 2013 GTC2013 Higman PresentationDocument9 pages2013 GTC2013 Higman PresentationAnonymous ceMqLbiNo ratings yet

- BCHT 10 Nov 21Document34 pagesBCHT 10 Nov 21Abir RahmanNo ratings yet

- El3000 Series: Easyline Continuous Gas Analyzers Models El3020, El3040Document26 pagesEl3000 Series: Easyline Continuous Gas Analyzers Models El3020, El3040Rajesh KumarNo ratings yet

- A Report On Demand & Supply Scenario of Natural Gas in INDIADocument26 pagesA Report On Demand & Supply Scenario of Natural Gas in INDIAUnnat ChauhanNo ratings yet

- HW1ADocument3 pagesHW1ANIRVANANo ratings yet

- Engine Fire Protection SystemDocument47 pagesEngine Fire Protection SystemSThaneasMur100% (2)

- Clase 2 MGarciaDocument67 pagesClase 2 MGarciaDiego Hernán Peláez ArangoNo ratings yet

- Week 04Document2 pagesWeek 04Balaji HimakarNo ratings yet

- Operating ManualDocument238 pagesOperating ManualEdson Walter Vereau RosasNo ratings yet

- RBD PltuDocument48 pagesRBD Pltusugeng wahyudiNo ratings yet

- AP Exp 3 Dumas Method Determination of The Molar Mass of A Volatile LiquidDocument4 pagesAP Exp 3 Dumas Method Determination of The Molar Mass of A Volatile LiquidHandugan Quinlog Noel100% (1)

- Me6301 Engineering Thermodynamics Nov Dec 2014.Document3 pagesMe6301 Engineering Thermodynamics Nov Dec 2014.BIBIN CHIDAMBARANATHANNo ratings yet