Professional Documents

Culture Documents

m3 Divider Bar Reinforcement

m3 Divider Bar Reinforcement

Uploaded by

William SouzaOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

m3 Divider Bar Reinforcement

m3 Divider Bar Reinforcement

Uploaded by

William SouzaCopyright:

Available Formats

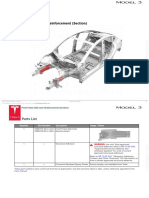

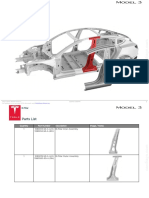

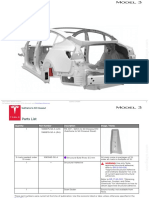

Divider Bar Reinforcement

TESLA BODY REPAIR MANUAL Updated: 02OCT17 1

For feedback on the accuracy of this document, email BodyRepair@tesla.com.

Divider Bar Reinforcement

Parts List

Quantity Part Number Description Image / Notes

1 1082599-S0-A (LH) Divider Bar Reinforcement

1082600-S0-A (RH)

3 rivets needed; 1063943-00-A Structural Bulb Rivet, 6.5 mm All rivets come in packages of 10; order all rivets

order 10 rivets in multiples of 10.

1 — Structural Adhesive WARNING: Use only Tesla-approved

structural adhesive; refer to BR-15-92-008,

"Approved Structural Adhesive and

Urethane Sealants" for a list of current

approved structural adhesives.

Refer to BR-17-92-002, "Obtaining Adhesives,

Coolant, and Other Chemicals" for information on

how to obtain approved structural adhesive.

1 — Weld-Through Primer CAUTION: Only use zinc weld-through

primers. Other primers might cause

corrosion and compromise the integrity of

the repair.

Source locally; not available from Tesla.

TESLA BODY REPAIR MANUAL Updated: 02OCT17 2

For feedback on the accuracy of this document, email BodyRepair@tesla.com.

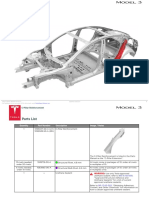

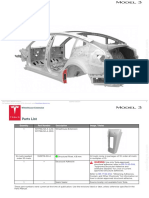

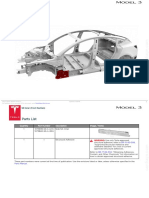

Divider Bar Reinforcement

Parts List

Quantity Part Number Description Image / Notes

1 — Urethane Sealant Refer to BR-17-92-002, "Obtaining Adhesives,

Coolant, and Other Chemicals" for information on

how to obtain approved urethane sealant.

These part numbers were current at the time of publication. Use the revisions listed or later, unless otherwise specified in the

Parts Manual.

TESLA BODY REPAIR MANUAL Updated: 02OCT17 3

For feedback on the accuracy of this document, email BodyRepair@tesla.com.

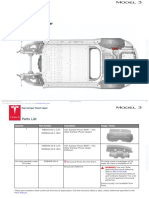

Divider Bar Reinforcement

Repair Information

Repair Information Warnings and Cautions Special Tools

This procedure is for the left-hand WARNING: Wear the appropriate The special tool listed below is required

component; the procedure is identical for personal protective equipment to perform this procedure:

the right-hand component. (PPE) when performing this • Resistance Spot Welder

procedure.

Use only an approved resistance spot

CAUTION: This procedure involves welder. Refer to BR-16-92-007,

both steel and aluminum "Approved Welders" for a list of

components. Use the appropriate current approved resistance spot

tools at each step to avoid cross- welders.

contamination.

TESLA BODY REPAIR MANUAL Updated: 02OCT17 4

For feedback on the accuracy of this document, email BodyRepair@tesla.com.

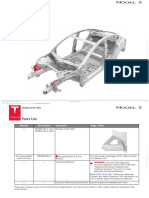

Divider Bar Reinforcement

Prerequisites

Remove the Quarter Outer Skin.

TESLA BODY REPAIR MANUAL Updated: 02OCT17 5

For feedback on the accuracy of this document, email BodyRepair@tesla.com.

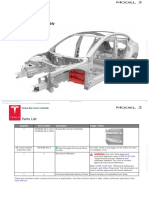

Divider Bar Reinforcement

Removal

1

Remove the original component.

A

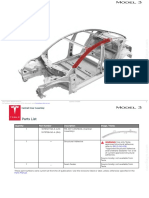

Identify the component materials in the repair area.

Aluminum

High-Strength Steel

Ultra High-Strength Steel

B

Remove the foam dam.

NOTE: Save the foam dam for installation in a later step.

TESLA BODY REPAIR MANUAL Updated: 02OCT17 6

For feedback on the accuracy of this document, email BodyRepair@tesla.com.

Divider Bar Reinforcement

Removal

1

Remove the original component (continued).

C

Use an SPR removal tool or a drill with a high-strength steel bit to

remove the factory self-piercing rivets. Use a belt sander for any

factory self-piercing rivets that cannot be removed with an SPR

removal tool or a drill.

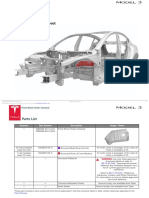

Factory SPR (x4)

NOTE: The 2 factory SPRs toward the front of the vehicle might have

been removed during the removal of the Quarter Outer Skin.

TESLA BODY REPAIR MANUAL Updated: 02OCT17 7

For feedback on the accuracy of this document, email BodyRepair@tesla.com.

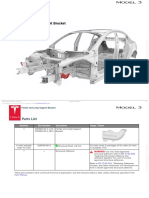

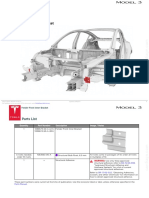

Divider Bar Reinforcement

Removal

1

Remove the original component (continued).

D

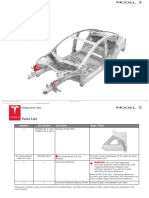

Use a drill with a spot weld bit to drill out the factory spot welds.

Factory Spot Weld (x7)

NOTE: Factory spot weld locations shown are approximate. Exact

spot weld locations and number vary from vehicle to vehicle.

NOTE: Remove the spot welds from inside of the vehicle.

TESLA BODY REPAIR MANUAL Updated: 02OCT17 8

For feedback on the accuracy of this document, email BodyRepair@tesla.com.

Divider Bar Reinforcement

Removal

1

Remove the original component (continued).

E

Use a heat gun to heat the adhesive joints, and then use a hammer

and chisel to remove the original component.

WARNING: Do not heat the adhesive joints above 100°C (212°F).

Heating the adhesive joints above 100°C (212°F) can weaken the

aluminum and compromise vehicle crash integrity.

WARNING: Do not heat any adhesive joints of components that are

not being removed. Heating adhesive joints weakens the adhesive

bond and could compromise vehicle crash integrity.

TESLA BODY REPAIR MANUAL Updated: 02OCT17 9

For feedback on the accuracy of this document, email BodyRepair@tesla.com.

Divider Bar Reinforcement

Removal

2

Use a disc sander with a medium-abrasive surface conditioning disc to

remove any remaining materials from the bond paths. Use a belt sander

with a medium-abrasive belt for any areas that cannot be reached with

a disc sander. Vacuum any adhesive dust.

WARNING: Remove the epoxy adhesive in a well-ventilated area. Wear

suitable personal protective equipment.

WARNING: Use only sanding wheels and belts that are 80 grit or finer

on aluminum components. Using sanding wheels or belts that are

coarser than 80 grit can cause fractures in the aluminum.

TESLA BODY REPAIR MANUAL Updated: 02OCT17 10

For feedback on the accuracy of this document, email BodyRepair@tesla.com.

Divider Bar Reinforcement

Replacement

1

Prepare for installation.

A

If necessary, grind down any remaining pieces of the factory spot

weld that would interfere with the placement of the new component.

B

If necessary, use a hammer and dolly to straighten the portion of the

original Rear Roof Rail that contacts the Divider Bar Reinforcement.

TESLA BODY REPAIR MANUAL Updated: 02OCT17 11

For feedback on the accuracy of this document, email BodyRepair@tesla.com.

Divider Bar Reinforcement

Replacement

1

Prepare for installation (continued).

C

Put the new component into position and clamp it into place.

TESLA BODY REPAIR MANUAL Updated: 02OCT17 12

For feedback on the accuracy of this document, email BodyRepair@tesla.com.

Divider Bar Reinforcement

Replacement

1

Prepare for installation (continued).

D

Mark the fastener locations on the new component.

Structural Bulb Rivet, 6.5 mm (x3)

TESLA BODY REPAIR MANUAL Updated: 02OCT17 13

For feedback on the accuracy of this document, email BodyRepair@tesla.com.

Divider Bar Reinforcement

Replacement

1

Prepare for installation (continued).

D

Mark the fastener locations on the new component (continued).

TESLA BODY REPAIR MANUAL Updated: 02OCT17 14

For feedback on the accuracy of this document, email BodyRepair@tesla.com.

Divider Bar Reinforcement

Replacement

1

Prepare for installation (continued).

E

Use a drill with a 6.8 mm (17/64 in) bit to drill holes for structural

bulb rivets.

NOTE: Install a grip screw after drilling each hole to keep the panel

aligned while drilling the remaining holes.

TESLA BODY REPAIR MANUAL Updated: 02OCT17 15

For feedback on the accuracy of this document, email BodyRepair@tesla.com.

Divider Bar Reinforcement

Replacement

1

Prepare for installation (continued).

F

Mark the bond path areas on the new component and on the vehicle.

These areas will be prepared for bonding in a later step.

G

Remove the new component.

TESLA BODY REPAIR MANUAL Updated: 02OCT17 16

For feedback on the accuracy of this document, email BodyRepair@tesla.com.

Divider Bar Reinforcement

Replacement

2

Prepare the surfaces.

A

Use a red Scotch-Brite pad or equivalent to scuff the new

component in the steel-to-aluminum bond path areas.

Steel-to-Aluminum Bond Path

TESLA BODY REPAIR MANUAL Updated: 02OCT17 17

For feedback on the accuracy of this document, email BodyRepair@tesla.com.

Divider Bar Reinforcement

Replacement

2

Prepare the surfaces (continued).

B

Use a disc sander with a medium-abrasive surface conditioning disc

to remove the e-coat on the new component and on the vehicle in

the both path areas and weld areas.

Steel-to-Steel Bond Path

Steel-to-Aluminum Bond Path

Installation Spot Weld Areas

WARNING: Remove the e-coat in a well-ventilated area. Wear

suitable personal protective equipment.

WARNING: Use only sanding wheels and belts that are 80 grit or

finer on aluminum components. Using sanding wheels or belts that

are coarser than 80 grit can cause fractures in the aluminum.

CAUTION: Within two hours of removing the e-coat or paint, cover

the abraded aluminum areas in the bond path with a thin primer layer

of structural adhesive. If the abraded aluminum areas are not primed

within two hours, they must be abraded again to remove any

oxidation.

NOTE: Use a belt sander with a medium-abrasive belt for any areas

that cannot be reached with a disc sander.

TESLA BODY REPAIR MANUAL Updated: 02OCT17 18

For feedback on the accuracy of this document, email BodyRepair@tesla.com.

Divider Bar Reinforcement

Replacement

2

Prepare the surfaces (continued).

B

Use a disc sander with a medium-abrasive surface conditioning disc

to remove the e-coat on the new component and on the vehicle in

the both path areas and weld areas (continued).

TESLA BODY REPAIR MANUAL Updated: 02OCT17 19

For feedback on the accuracy of this document, email BodyRepair@tesla.com.

Divider Bar Reinforcement

Replacement

2

Prepare the surfaces (continued).

B

Use a disc sander with a medium-abrasive surface conditioning disc

to remove the e-coat on the new component and on the vehicle in

the both path areas and weld areas (continued).

TESLA BODY REPAIR MANUAL Updated: 02OCT17 20

For feedback on the accuracy of this document, email BodyRepair@tesla.com.

Divider Bar Reinforcement

Replacement

2

Prepare the surfaces (continued).

C

Use tape to mask off the structural adhesive bond path areas on the

new component and on the vehicle.

Steel-to-Steel Bond Path

NOTE: This prevents these areas from being sprayed with weld-

through primer in a later substep.

TESLA BODY REPAIR MANUAL Updated: 02OCT17 21

For feedback on the accuracy of this document, email BodyRepair@tesla.com.

Divider Bar Reinforcement

Replacement

2

Prepare the surfaces (continued).

C

Use tape to mask off the structural adhesive bond path areas on the

new component and on the vehicle (continued).

D

Clean all the weld areas on the new component or components and

on the vehicle with isopropyl alcohol (IPA).

WARNING: Wipe off the remaining isopropyl alcohol with a clean, dry

towel immediately after application. Do not let the remaining

isopropyl alcohol air dry. Allowing the remaining isopropyl alcohol to

air dry can compromise the adhesive bond.

TESLA BODY REPAIR MANUAL Updated: 02OCT17 22

For feedback on the accuracy of this document, email BodyRepair@tesla.com.

Divider Bar Reinforcement

Replacement

2

Prepare the surfaces (continued).

E

Apply weld-through primer to the installation spot weld areas on the

new component and on the vehicle.

Installation Spot Weld Areas

TESLA BODY REPAIR MANUAL Updated: 02OCT17 23

For feedback on the accuracy of this document, email BodyRepair@tesla.com.

Divider Bar Reinforcement

Replacement

2

Prepare the surfaces (continued).

E

Apply weld-through primer to the installation spot weld areas on the

new component and on the vehicle (continued).

TESLA BODY REPAIR MANUAL Updated: 02OCT17 24

For feedback on the accuracy of this document, email BodyRepair@tesla.com.

Divider Bar Reinforcement

Replacement

2

Prepare the surfaces (continued).

E

Apply weld-through primer to the installation spot weld areas on the

new component and on the vehicle (continued).

F

Remove the tape.

TESLA BODY REPAIR MANUAL Updated: 02OCT17 25

For feedback on the accuracy of this document, email BodyRepair@tesla.com.

Divider Bar Reinforcement

Replacement

2

Prepare the surfaces (continued).

G

Clean the areas that were taped in the previous substeps with

isopropyl alcohol (IPA).

WARNING: Wipe off the remaining isopropyl alcohol with a clean, dry

towel immediately after application. Do not let the remaining

isopropyl alcohol air dry. Allowing the remaining isopropyl alcohol to

air dry can compromise the adhesive bond.

3

Apply structural adhesive.

A

Spread a thin coating of structural adhesive as a primer layer on the

bond paths on the vehicle and the new component.

Steel-to-Steel Bond Path

Steel-to-Aluminum Bond Path

NOTE: Assembly must be performed while the primer layer is still

wet. The drying time of the adhesive varies depending on

temperature and humidity.

TESLA BODY REPAIR MANUAL Updated: 02OCT17 26

For feedback on the accuracy of this document, email BodyRepair@tesla.com.

Divider Bar Reinforcement

Replacement

3

Apply structural adhesive (continued).

A

Spread a thin coating of structural adhesive as a primer layer on the

bond paths on the vehicle and the new component (continued).

TESLA BODY REPAIR MANUAL Updated: 02OCT17 27

For feedback on the accuracy of this document, email BodyRepair@tesla.com.

Divider Bar Reinforcement

Replacement

3

Apply structural adhesive (continued).

A

Spread a thin coating of structural adhesive as a primer layer on the

bond paths on the vehicle and the new component (continued).

TESLA BODY REPAIR MANUAL Updated: 02OCT17 28

For feedback on the accuracy of this document, email BodyRepair@tesla.com.

Divider Bar Reinforcement

Replacement

3

Apply structural adhesive (continued).

B

While the primer layer is still wet, apply a bead of structural adhesive

on top of the primer layer on the new component.

4

Install the new component.

A

Put the new component into position and clamp it into place.

TESLA BODY REPAIR MANUAL Updated: 02OCT17 29

For feedback on the accuracy of this document, email BodyRepair@tesla.com.

Divider Bar Reinforcement

Replacement

4

Install the new component (continued).

A

Put the new component into position and clamp it into place

(continued).

B

Insert the structural bulb rivets.

Structural Bulb Rivet, 6.5 mm (x3)

TESLA BODY REPAIR MANUAL Updated: 02OCT17 30

For feedback on the accuracy of this document, email BodyRepair@tesla.com.

Divider Bar Reinforcement

Replacement

4

Install the new component (continued).

B

Insert the structural bulb rivets (continued).

C

Install the structural bulb rivets.

TESLA BODY REPAIR MANUAL Updated: 02OCT17 31

For feedback on the accuracy of this document, email BodyRepair@tesla.com.

Divider Bar Reinforcement

Replacement

4

Install the new component (continued).

D

Wipe off any excess adhesive.

E

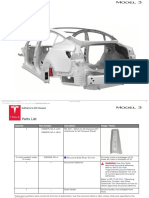

Mark the spot weld locations.

Installation Spot Weld (x5)

TESLA BODY REPAIR MANUAL Updated: 02OCT17 32

For feedback on the accuracy of this document, email BodyRepair@tesla.com.

Divider Bar Reinforcement

Replacement

4

Install the new component (continued).

E

Mark the spot weld locations (continued).

F

Perform resistance spot welding.

WARNING: Failure to follow all welding safety precautions, including

the use of personal protective equipment, could result in serious

injury or property damage. Only technicians who have successfully

met Tesla’s requirements for welding training are authorized to weld

structural components on Tesla vehicles.

CAUTION: Do not weld on a Tesla vehicle with an energized high

voltage or 12V system. Welding on a Tesla vehicle with an energized

high voltage or 12V system might damage vehicle components.

TESLA BODY REPAIR MANUAL Updated: 02OCT17 33

For feedback on the accuracy of this document, email BodyRepair@tesla.com.

Divider Bar Reinforcement

Replacement

4

Install the new component (continued).

G

Apply urethane sealant to the edge of the foam dam that was

removed in an earlier step.

H

Install the foam dam.

TESLA BODY REPAIR MANUAL Updated: 02OCT17 34

For feedback on the accuracy of this document, email BodyRepair@tesla.com.

Divider Bar Reinforcement

Replacement

4

Install the new component (continued).

I

Bake the structural adhesive so that the bonded panels reach a

temperature of 60°C–80°C (140°F–176°F) for at least 30 minutes to

achieve full strength.

WARNING: Do not allow the High Voltage Battery to reach a

temperature above 74°C (165°F). Heating the High Voltage Battery

above 74°C (165°F) for an extended period could result in injury to

personnel and/or damage to the battery.

TESLA BODY REPAIR MANUAL Updated: 02OCT17 35

For feedback on the accuracy of this document, email BodyRepair@tesla.com.

You might also like

- Sill Inner (Complete) : Tesla Body Repair Manual For Feedback On The Accuracy of This Document, Email - Updated: 13APR18Document40 pagesSill Inner (Complete) : Tesla Body Repair Manual For Feedback On The Accuracy of This Document, Email - Updated: 13APR18Đông NguyễnNo ratings yet

- Sill Inner (Complete) : Tesla Body Repair Manual For Feedback On The Accuracy of This Document, Email - Updated: 13APR18Document40 pagesSill Inner (Complete) : Tesla Body Repair Manual For Feedback On The Accuracy of This Document, Email - Updated: 13APR18Đông NguyễnNo ratings yet

- RT 149 PDFDocument10 pagesRT 149 PDFRaul Diaz100% (1)

- M3 Sill Outer (Complete)Document182 pagesM3 Sill Outer (Complete)Đông NguyễnNo ratings yet

- Product Introduction for C&C Truck: C&C Trucks Automotive Engineering Research Institute 2014 年 7 月 July, 2014Document45 pagesProduct Introduction for C&C Truck: C&C Trucks Automotive Engineering Research Institute 2014 年 7 月 July, 2014Đông NguyễnNo ratings yet

- M3 Front Frame Rail Inner Reinforcement (Section)Document24 pagesM3 Front Frame Rail Inner Reinforcement (Section)Hieu DvNo ratings yet

- Shotgun Outer: Tesla Body Repair Manual For Feedback On The Accuracy of This Document, Email - Updated: 27JUL17Document26 pagesShotgun Outer: Tesla Body Repair Manual For Feedback On The Accuracy of This Document, Email - Updated: 27JUL17Đông Nguyễn100% (1)

- BS 4873 2004 Aluminum Alloy WindowsDocument18 pagesBS 4873 2004 Aluminum Alloy WindowsJoseph Allan TolentinoNo ratings yet

- m3 C-Pillar ReinforcementDocument29 pagesm3 C-Pillar ReinforcementWilliam SouzaNo ratings yet

- M3 Torque Box Cover AssemblyDocument20 pagesM3 Torque Box Cover AssemblyHieu DvNo ratings yet

- Shotgun Inner: Tesla Body Repair Manual For Feedback On The Accuracy of This Document, Email - Updated: 30AUG18 1Document21 pagesShotgun Inner: Tesla Body Repair Manual For Feedback On The Accuracy of This Document, Email - Updated: 30AUG18 1Đông NguyễnNo ratings yet

- Dash Crossmember: Tesla Body Repair Manual For Feedback On The Accuracy of This Document, Email - Updated: 08FEB19 1Document13 pagesDash Crossmember: Tesla Body Repair Manual For Feedback On The Accuracy of This Document, Email - Updated: 08FEB19 1Đông NguyễnNo ratings yet

- M3 Fender and Lamp Support BracketDocument17 pagesM3 Fender and Lamp Support BracketĐông NguyễnNo ratings yet

- M3 Cantrail Extension InnerDocument22 pagesM3 Cantrail Extension InnerDongTaNo ratings yet

- A-Pillar Outer Reinforcement (Complete)Document24 pagesA-Pillar Outer Reinforcement (Complete)DongTaNo ratings yet

- B-Pillar: Tesla Body Repair Manual For Feedback On The Accuracy of This Document, Email - Updated: 26SEP18 1Document64 pagesB-Pillar: Tesla Body Repair Manual For Feedback On The Accuracy of This Document, Email - Updated: 26SEP18 1DongTaNo ratings yet

- Wheelhouse Extension: Tesla Body Repair Manual For Feedback On The Accuracy of This Document, Email - Updated: 28JUL17Document28 pagesWheelhouse Extension: Tesla Body Repair Manual For Feedback On The Accuracy of This Document, Email - Updated: 28JUL17Hieu DvNo ratings yet

- 02-M3 Shotgun Outer PDFDocument26 pages02-M3 Shotgun Outer PDFLinh VoNo ratings yet

- Trunk Floor Extension: Tesla Body Repair Manual For Feedback On The Accuracy of This Document, Email - Updated: 01AUG17Document20 pagesTrunk Floor Extension: Tesla Body Repair Manual For Feedback On The Accuracy of This Document, Email - Updated: 01AUG17Hieu DvNo ratings yet

- Shotgun Shear Wall: Tesla Body Repair Manual For Feedback On The Accuracy of This Document, Email - Updated: 15JAN18Document25 pagesShotgun Shear Wall: Tesla Body Repair Manual For Feedback On The Accuracy of This Document, Email - Updated: 15JAN18Đông NguyễnNo ratings yet

- Front Frame Rail Inner (Large Front Section)Document38 pagesFront Frame Rail Inner (Large Front Section)Dong NguyenNo ratings yet

- Front Frame Rail Inner Reinforcement (Complete)Document29 pagesFront Frame Rail Inner Reinforcement (Complete)Dong NguyenNo ratings yet

- M3 Fender Attachment BracketsDocument14 pagesM3 Fender Attachment BracketsĐông NguyễnNo ratings yet

- M3 Fender Front Inner BracketDocument19 pagesM3 Fender Front Inner BracketĐông NguyễnNo ratings yet

- M3 Cantrail Inner AssemblyDocument16 pagesM3 Cantrail Inner AssemblyDongTaNo ratings yet

- 02-M3 Shock Tower CloseoutDocument21 pages02-M3 Shock Tower CloseoutLinh VoNo ratings yet

- Shotgun Tower: Tesla Body Repair Manual For Feedback On The Accuracy of This Document, Email - Updated: 25JAN18Document35 pagesShotgun Tower: Tesla Body Repair Manual For Feedback On The Accuracy of This Document, Email - Updated: 25JAN18Đông NguyễnNo ratings yet

- M3 - Rear Wheelhouse Rear StiffenerDocument17 pagesM3 - Rear Wheelhouse Rear StiffenerDongTaNo ratings yet

- 02-M3 Shotgun Shear Wall PDFDocument25 pages02-M3 Shotgun Shear Wall PDFLinh VoNo ratings yet

- 02-M3 Frunk BracketDocument15 pages02-M3 Frunk BracketLinh VoNo ratings yet

- M3 - Rear Wheelhouse Front StiffenerDocument17 pagesM3 - Rear Wheelhouse Front StiffenerDongTaNo ratings yet

- m3 Subframe To Sill CloseoutDocument16 pagesm3 Subframe To Sill CloseoutWilliam SouzaNo ratings yet

- Front Frame Rail Inner (Small Front Section)Document40 pagesFront Frame Rail Inner (Small Front Section)Dong NguyenNo ratings yet

- 02-M3 Shotgun Tower PDFDocument35 pages02-M3 Shotgun Tower PDFLinh VoNo ratings yet

- Toeboard Outer: Tesla Body Repair Manual For Feedback On The Accuracy of This Document, Email - Updated: 18APR19 1Document16 pagesToeboard Outer: Tesla Body Repair Manual For Feedback On The Accuracy of This Document, Email - Updated: 18APR19 1Hieu DvNo ratings yet

- Fender Support BracketDocument13 pagesFender Support BracketDong NguyenNo ratings yet

- Subframe To Sill CloseoutDocument16 pagesSubframe To Sill CloseoutĐông NguyễnNo ratings yet

- Trunk Floor Assembly (Side Panel)Document23 pagesTrunk Floor Assembly (Side Panel)Hieu DvNo ratings yet

- Sill Inner (Front Section)Document20 pagesSill Inner (Front Section)Đông NguyễnNo ratings yet

- M3 - Rear Damper Mount UpperDocument29 pagesM3 - Rear Damper Mount UpperDongTaNo ratings yet

- Sill Insert (Front Section)Document39 pagesSill Insert (Front Section)Đông NguyễnNo ratings yet

- m3 Charge Port Housing AssemblyDocument20 pagesm3 Charge Port Housing AssemblyWilliam SouzaNo ratings yet

- M3 Sill Outer (Front Section)Document120 pagesM3 Sill Outer (Front Section)Đông NguyễnNo ratings yet

- Body-M3 Symbols Used in The Body Repair ManualDocument8 pagesBody-M3 Symbols Used in The Body Repair ManualLinh VoNo ratings yet

- RT-127 Crank Angle Sensor ReplacementDocument12 pagesRT-127 Crank Angle Sensor ReplacementGeorgios MariolisNo ratings yet

- A Size 10 × 4-5 Smooth-Tread Friction Test Tire: Standard Specification ForDocument5 pagesA Size 10 × 4-5 Smooth-Tread Friction Test Tire: Standard Specification ForEric GozzerNo ratings yet

- Astm E1136Document3 pagesAstm E1136Carlos Gallardo LagosNo ratings yet

- Blowout Resistance of Room-Temperature Vulcanized ElastomersDocument5 pagesBlowout Resistance of Room-Temperature Vulcanized ElastomersAMUL VEKARIANo ratings yet

- PDS - NA - PRP Repair Data SheetDocument2 pagesPDS - NA - PRP Repair Data SheetHendra AwanNo ratings yet

- RT-127 - Issue3 Crank Angle Sensor Tooth Belt ReplacementDocument12 pagesRT-127 - Issue3 Crank Angle Sensor Tooth Belt ReplacementGeorgios MariolisNo ratings yet

- Standard Tire For Pavement Frictional Property TestsDocument3 pagesStandard Tire For Pavement Frictional Property TestsFRANZ RICHARD SARDINAS MALLCONo ratings yet

- E501 1113239-1Document4 pagesE501 1113239-1Sum BeautyNo ratings yet

- D4317 4434Document6 pagesD4317 4434JEISON ESTEBAN YUCUMA MARTINEZNo ratings yet

- Six Steps To Successful Repair of GT ComponentsDocument13 pagesSix Steps To Successful Repair of GT ComponentsThanapaet RittirutNo ratings yet

- Secondary Seal For Sealed Insulating Glass Units For Structural Sealant Glazing ApplicationsDocument12 pagesSecondary Seal For Sealed Insulating Glass Units For Structural Sealant Glazing ApplicationsAbdullah NajjarNo ratings yet

- Ipc1998-2028 - Repairing Pipe Defects Without Operational Outages With PetrosleeveDocument9 pagesIpc1998-2028 - Repairing Pipe Defects Without Operational Outages With PetrosleeveDietmar WengerNo ratings yet

- Adhesives: Standard Terminology ofDocument13 pagesAdhesives: Standard Terminology ofgt toniNo ratings yet

- Evaluation of Load-Carrying Capacity of Lubricants Used in Hypoid Final-Drive Axles Operated Under Low-Speed and High-Torque ConditionsDocument18 pagesEvaluation of Load-Carrying Capacity of Lubricants Used in Hypoid Final-Drive Axles Operated Under Low-Speed and High-Torque Conditionsomar TahaNo ratings yet

- Assembly Fluid 1 TDSDocument1 pageAssembly Fluid 1 TDSpokleNo ratings yet

- Steps 1 and 2Document5 pagesSteps 1 and 2mohammad293No ratings yet

- ManualDocument3 pagesManualRodrigo AbbaNo ratings yet

- Application of Repairs To Turbomachinery EquipmentDocument12 pagesApplication of Repairs To Turbomachinery Equipmentalhumaid28No ratings yet

- 05 Tyco TJRDocument6 pages05 Tyco TJRsamNo ratings yet

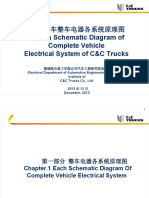

- Each Schematic Diagram of Complete Vehicle Electrical System of C&C TrucksDocument20 pagesEach Schematic Diagram of Complete Vehicle Electrical System of C&C TrucksĐông Nguyễn100% (2)

- Basic Knowledge About Automotive Air Conditioning: ConfidentialDocument22 pagesBasic Knowledge About Automotive Air Conditioning: ConfidentialĐông NguyễnNo ratings yet

- Structure and Principle Introduction of Complete Vehicle Electrical System of C&C TrucksDocument17 pagesStructure and Principle Introduction of Complete Vehicle Electrical System of C&C TrucksĐông NguyễnNo ratings yet

- Subframe To Sill CloseoutDocument16 pagesSubframe To Sill CloseoutĐông NguyễnNo ratings yet

- Introduction and Actual Operation of Front Wheel Alignment: Research Institute Chassis DepartmentDocument15 pagesIntroduction and Actual Operation of Front Wheel Alignment: Research Institute Chassis DepartmentĐông NguyễnNo ratings yet

- M3 Sill Outer (Rear)Document17 pagesM3 Sill Outer (Rear)Đông NguyễnNo ratings yet

- Shotgun Tower: Tesla Body Repair Manual For Feedback On The Accuracy of This Document, Email - Updated: 25JAN18Document35 pagesShotgun Tower: Tesla Body Repair Manual For Feedback On The Accuracy of This Document, Email - Updated: 25JAN18Đông NguyễnNo ratings yet

- Sill Insert (Front Section)Document39 pagesSill Insert (Front Section)Đông NguyễnNo ratings yet

- Sill Inner (Front Section)Document20 pagesSill Inner (Front Section)Đông NguyễnNo ratings yet

- Shotgun Shear Wall: Tesla Body Repair Manual For Feedback On The Accuracy of This Document, Email - Updated: 15JAN18Document25 pagesShotgun Shear Wall: Tesla Body Repair Manual For Feedback On The Accuracy of This Document, Email - Updated: 15JAN18Đông NguyễnNo ratings yet

- M3 Fender and Lamp Support BracketDocument17 pagesM3 Fender and Lamp Support BracketĐông NguyễnNo ratings yet

- M3 Fender Front Inner BracketDocument19 pagesM3 Fender Front Inner BracketĐông NguyễnNo ratings yet

- M3 Fender Attachment BracketsDocument14 pagesM3 Fender Attachment BracketsĐông NguyễnNo ratings yet

- Decorative Concrete SeminarDocument8 pagesDecorative Concrete SeminarMahaManthra100% (2)

- CHT81 Ni 1Document1 pageCHT81 Ni 1ImmalatulhusnaNo ratings yet

- Lecture 1 - Reinforced Concrete - IntroductionDocument62 pagesLecture 1 - Reinforced Concrete - IntroductionChristopher PaladioNo ratings yet

- Production of Automotive Components (Oat751) : Presented byDocument11 pagesProduction of Automotive Components (Oat751) : Presented bytsrNo ratings yet

- TDS Byk-333 en PDFDocument4 pagesTDS Byk-333 en PDFManoj Lalita GoswamiNo ratings yet

- BS6622/BS7835 Three Core Armoured 6.6kV XLPE Stranded Copper ConductorsDocument3 pagesBS6622/BS7835 Three Core Armoured 6.6kV XLPE Stranded Copper ConductorsBhagoo HatheyNo ratings yet

- Specification For SealantsDocument17 pagesSpecification For SealantsMalak HindiNo ratings yet

- Mechanical Design of Transmission LinesDocument33 pagesMechanical Design of Transmission LinesKashif Hussain ShahNo ratings yet

- Item Canvassed Report: Category Item Description UnitDocument9 pagesItem Canvassed Report: Category Item Description UnitNino Joycelee TuboNo ratings yet

- PVC Suspension K-70Document1 pagePVC Suspension K-70ÜNAL AYDINNo ratings yet

- 02-Annexure A - Civil & Finishing Works-Super Structure, Senegal-090723Document26 pages02-Annexure A - Civil & Finishing Works-Super Structure, Senegal-090723Ablaye GueyeNo ratings yet

- A 48 CP, Ap, FPDocument1 pageA 48 CP, Ap, FPMuhammad HannanNo ratings yet

- BT Bu RevDocument26 pagesBT Bu RevArriane CausingNo ratings yet

- BME (Steel)Document8 pagesBME (Steel)Mohil JainNo ratings yet

- Chapter4 - Imperfections in SolidsDocument35 pagesChapter4 - Imperfections in SolidsSibakanta SahuNo ratings yet

- WCB FireRated U905Document1 pageWCB FireRated U905mahendraNo ratings yet

- Brosur PentensDocument2 pagesBrosur PentensKaldon DarwisNo ratings yet

- Chemistry For Engineers 3Document34 pagesChemistry For Engineers 3Audrey VicenteNo ratings yet

- Physical & Chemical Properties Common Sizes and API Standard/Not ScheduledDocument2 pagesPhysical & Chemical Properties Common Sizes and API Standard/Not ScheduledMidhun K Chandrabose100% (1)

- Ultra High Molecular Weight PolyethyleneDocument7 pagesUltra High Molecular Weight PolyethyleneAliceAlormenuNo ratings yet

- Company Profile Power PointDocument12 pagesCompany Profile Power PointAzzus BkhaNo ratings yet

- Tairilac PS 树 脂: Formosa Chemicals Industries (Ningbo)Document1 pageTairilac PS 树 脂: Formosa Chemicals Industries (Ningbo)Phuoc Thinh TruongNo ratings yet

- 1021 Cement Floor Finish (Moratal, Axel)Document4 pages1021 Cement Floor Finish (Moratal, Axel)Axel Naome Zyrah MoratalNo ratings yet

- Steel PropertiesDocument2 pagesSteel PropertiesTillNo ratings yet

- 0.6-1kV HFCO 4C (23.08.18) - N.C - CAT ADocument6 pages0.6-1kV HFCO 4C (23.08.18) - N.C - CAT AQuang LuongNo ratings yet

- Journal of Molecular Liquids: Mohammad Hatami Maryam Hasanpour, Dengwei JingDocument22 pagesJournal of Molecular Liquids: Mohammad Hatami Maryam Hasanpour, Dengwei JingSugam KarkiNo ratings yet

- 7 Interlining, FusingDocument54 pages7 Interlining, FusingARYAN RATHORENo ratings yet

- PBL MTCP LabDocument7 pagesPBL MTCP LabAdarsh SinghNo ratings yet

- Applied Surface Science: D.C.D. Nath, S. Bandyopadhyay, S. Gupta, A. Yu, D. Blackburn, C. WhiteDocument5 pagesApplied Surface Science: D.C.D. Nath, S. Bandyopadhyay, S. Gupta, A. Yu, D. Blackburn, C. WhitesrinilsukumarkhdNo ratings yet