Professional Documents

Culture Documents

Spray Nozzle

Uploaded by

Ninad AcharyaOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Spray Nozzle

Uploaded by

Ninad AcharyaCopyright:

Available Formats

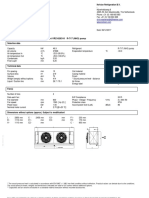

MEDIUM VELOCITY

WATER SPRAY NOZZLE

TECHNICAL DATA :

MODEL A & B

MAXIMUM WORKING 12.3 Kg./Sq.Cm. (175 psi)

PRESSURE

MINIMUM EFFECTIVE 7 Kg./Sq.Cm. (100 psi)

WORKING PRESSURE maximum

1.4 Kg./Sq.Cm. (20 psi)

minimum

END CONNECTION ½" BSPT (½" NPT OPTIONAL)

MATERIAL Model A - Brass

Model B - Stainless Steel

INCLUDED WATER 140°, 120°, 110°, 100°, 90°,

SPRAY ANGLE FOR 80° & 65°

EACH K-FACTOR

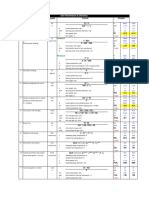

ORIFICE SIZE AND (MM) (INCH) METRIC (US)

K-FACTOR 6.0(0.236) - K22(1.54)

7.0(0.275) - K30(2.10)

7.5(0.295) - K35(2.45)

8.0(0.314) - K41(2.87) considerable change in spray angle. The spray pattern

9.0(0.354) - K51(3.57) shown is with indoor application. System designer must

10.0(0.393) - K64(4.48) consider wind velocity while designing the system for

11.0(0.433) - K79(5.53) outdoor application. Field obstruction if any affecting

12.0(0.472) - K91(6.37) the spray pattern of the nozzle must also be considered.

12.5(0.492) - K102(7.14) The nozzle may be oriented to any position as deemed

necessary to cover the hazard.

WEIGHT 0.115 Kg. (approximately)

MAINTENANCE

FINISH Brass or Nickel Chrome The spray nozzle must be handled with due care. For

plated for Model A best results , the storage as well as any further

Natural finish for Model B shipment be made in original packing only.

APPROVALS UL Listed for Model A Nozzle which is visibly damaged should not be installed.

ORDERING Specify K-Factor, spray angle Use Teflon tape or soft thread sealant on male thread

INFORMATION and finish. of the nozzle. The nozzles must be hand tightened into

the fitting. HD make wrench must be used to tighten

the nozzle unit into the fitting. Excessive tightening

APPLICATION torque may result into serious damage to nozzle arms

Medium velocity water spray nozzle has an external and the deflector which may affect spray pattern of

deflector, which discharges water in a directional cone the nozzle and it's performance.

shaped pattern of small droplet size. The water is

uniformly distributed over the surface to be protected. It is recommended that water spray system be

inspected regularly by authorised technical personnel.

The nozzle is used in deluge water spray system for The nozzle must be checked for corrosion, external and

special hazard fire protection application. internal obstruction, blockage if any. The nozzle should

be cleaned or replaced if required. The system must be

As the design and intent of specific water spray system operated with optimum water flow at least twice in a

may vary considerably, a MV nozzle is made available in year or as per the provisions of NFPA/TAC or local

several combination of orifice sizes and spray angles. authority having jurisdiction.

The minimum desirable pressure to achieve a reasonable The owner is solely responsible for maintaining the water

spray pattern is 1.4 Kg./Sq.cm. The water distribution spray system and the components therein so that it

pattern as shown in the graph in following pages is at performs properly when required.

an average pressure of 2.0 Kg/Sq.cm. The change in

pressure between 1.4 to 3.5 Kg./sq.cm. does not affect

JANUARY, 2006 PAGE 1 OF 6 HD108

PART LIST

COMPONENT MODEL-A MODEL-B

HOUSING FORGED BRASS SS 316

IS:291, GR.-I

(EQUIVALET TO ASTM B21)

DEFLECTOR PIN BRASS IS:291, GR.-I SS 316

(EQUIVALET TO ASTM B21)

DEFLECTOR BRASS IS:2768 SS 316

(EQUIVALET TO ASTM B36)

DISCHARGE CHARACTERISTICS

JANUARY, 2006 PAGE 2 OF 6 HD108

SPRAY PATTERN

ALL DIMENSIONS ARE IN METERS

JANUARY, 2006 PAGE 3 OF 6 HD108

ALL DIMENSIONS ARE IN METERS

JANUARY, 2006 PAGE 4 OF 6 HD108

ALL DIMENSIONS ARE IN METERS

JANUARY, 2006 PAGE 5 OF 6 HD108

ALL DIMENSIONS ARE IN METERS

LIMITED WARRANTY

Products manufactured by HD FIRE PROTECT PVT.LTD.. are warranted against defects in material and workmanship for a period of Two (2) years from the date of

shipment.

HD's obligation under this warranty is limited to replace or repair the products or its parts, which are shown to HD's examination to be in a defective condition

attributable to HD. No warranty is given for products or components which have been subject, to misuse, improper installation, corrosion, wear and tear, improper

storage, modification or repaired. If the defect attributable to HD cannot be rectified by repair or replacement, then HD may elect to refund the purchase price of

the equipment in complete discharge of its obligation under this Limited Warranty.

IN NO EVENT SHALL HD FIRE PROTECT PVT. LTD. BE LIABLE IN CONTRACT, STRICT LIABILITY OR ANY OTHER LEGAL THEORY, FOR INCIDENTAL, IN-DIRECT, SPECIAL OR

CONSEQUENTIAL DAMAGES, INCLUDING DAMAGES. FOR INJURY TO PERSON OR DEATH OR DAMAGE TO PROPERTY AND OR PENALTIES RESULTING FROM ANY PRODUCTS

OR COMPONENT MANUFACTURED OR ASSEMBLED BY HD. THIS IS LIMITED WARRANTY ONLY. HD DISCLAIMS WITH RESPECT TO THE PRODUCTS ALL IMPLIED WARRANTIES

OF MERCHANTABILITY AND ALL IMPLIED WARRANTIES OF FITNESS FOR A PARTICULAR PURPOSE. THERE IS NO WARRANTY OF ANY NATURE MADE BY HD BEYOND AS

STATED ABOVE.

NOTICE :

The equipment presented in this bulletin is to be installed in accordance with the latest publication standards of NFPA or other similar organisations and also

with the provision of government codes or ordinances wherever applicable.

The information provided by us are to the best of our knowledge and belief, and are general guidelines only. Site handling and installation control is beyond our reach.

Hence we give no guarantee for result and take no liability for damages, loss or penalties whatsoever, resulting from our suggestion, information, recommendation

or damages due to our product.

Product development is a continuous programme of HD FIRE PROTECT PVT. LTD. and hence the right to modify any specification without prior notice is reserved with

the company.

C-3/6, THE NANDANVAN IND. ESTATE, L.B.S. MARG, THANE 400 604., INDIA.

PHONES : +(91) 22 2583 5434 2582 6958 2582 6793

FAX : +(91) 22 2581 2524 5596 9049

EMAIL : info@hdfire.com WEBSITE : www.hdfire.com

JANUARY, 2006 PAGE 6 OF 6 HD108

You might also like

- Journal of The Folk Song Society No.8Document82 pagesJournal of The Folk Song Society No.8jackmcfrenzieNo ratings yet

- Jacobi Progressive Speed Agility Training For High School Middle School AthletesDocument39 pagesJacobi Progressive Speed Agility Training For High School Middle School AthletesAnthony Mckay100% (1)

- API Calcs Rev1 (Version 2)Document112 pagesAPI Calcs Rev1 (Version 2)Jake Sparrow100% (1)

- To Begin: MantraDocument9 pagesTo Begin: MantraashissahooNo ratings yet

- BARACARBDocument2 pagesBARACARBYudha Satria50% (2)

- Bulk Density PDFDocument15 pagesBulk Density PDFrudi rockerNo ratings yet

- 1.4878 Eng PDFDocument3 pages1.4878 Eng PDFRoberto_PrrNo ratings yet

- Oxygen TransferDocument37 pagesOxygen TransferKaycee ChirendaNo ratings yet

- Vacuum Leaf FilterDocument2 pagesVacuum Leaf FilterGangadharan NagappanNo ratings yet

- The Influence of Air-Fuel Ratio On Engine Performance and Pollutant Emission of An SI Engine Using Ethanol-Gasoline-Blended FuelsDocument8 pagesThe Influence of Air-Fuel Ratio On Engine Performance and Pollutant Emission of An SI Engine Using Ethanol-Gasoline-Blended FuelsISLAM I. Fekry100% (1)

- Optimizing Raw Mills PerformanceDocument14 pagesOptimizing Raw Mills PerformanceLe HoangNo ratings yet

- Comparing Gypsum Dewatering TechnologiesDocument9 pagesComparing Gypsum Dewatering TechnologiesthayaNo ratings yet

- Analog Layout Design (Industrial Training)Document10 pagesAnalog Layout Design (Industrial Training)Shivaksh SharmaNo ratings yet

- 1995 FS CycloneDocument8 pages1995 FS CycloneCharitha CherryNo ratings yet

- Equipment DesignDocument7 pagesEquipment DesignGodstandAimiuwuNo ratings yet

- Solvent Extraction: Please Submit Question 4 For MarkingDocument3 pagesSolvent Extraction: Please Submit Question 4 For MarkingThembi Matebula100% (1)

- Aspects of Process Measurement in The Natural Gas IndustryDocument22 pagesAspects of Process Measurement in The Natural Gas IndustrySalimullah100% (1)

- P Psa S G E P: Olybed Ystems FOR AS Xtraction and UrificationDocument2 pagesP Psa S G E P: Olybed Ystems FOR AS Xtraction and UrificationVivi OktaviantiNo ratings yet

- Hopper Heating Design GuideDocument4 pagesHopper Heating Design GuideBadukwangNo ratings yet

- Better Burner Specifications PDFDocument4 pagesBetter Burner Specifications PDFAbdul HayyeNo ratings yet

- Portland CementDocument58 pagesPortland CementNani DeskaaNo ratings yet

- Design and Analysis of Fluidized Bed GasifierDocument6 pagesDesign and Analysis of Fluidized Bed GasifierNguyen Mau Phung0% (1)

- 09.work Instruction For Operation of Additive Ball MillDocument9 pages09.work Instruction For Operation of Additive Ball MillRahul VermaNo ratings yet

- Effect of GA On Model Parameters of A Cement Ball Mill and An Air ClassifierDocument51 pagesEffect of GA On Model Parameters of A Cement Ball Mill and An Air ClassifierNam HuynhNo ratings yet

- Filter media selection for cement production processesDocument4 pagesFilter media selection for cement production processesm_verma21No ratings yet

- Ball Mill Volume LoadingDocument2 pagesBall Mill Volume LoadingThaigroup CementNo ratings yet

- Executive Summary: Delhi Pollution Control CommitteeDocument26 pagesExecutive Summary: Delhi Pollution Control CommitteeparthNo ratings yet

- Empowerment Technologies: Quarter 3 - 8: Imaging and Design Fo R The Online Environment IDocument14 pagesEmpowerment Technologies: Quarter 3 - 8: Imaging and Design Fo R The Online Environment IShaira Jane Estrella UcolNo ratings yet

- Waste CFB CombustionDocument15 pagesWaste CFB CombustionmihugirNo ratings yet

- Lime - Reactivity - WC2014 - 01 PDFDocument7 pagesLime - Reactivity - WC2014 - 01 PDFAlbertNo ratings yet

- A Critical Review of SAG Mill Design ProceduresDocument3 pagesA Critical Review of SAG Mill Design ProceduresAbhay BodhmageNo ratings yet

- Mechanical OperationDocument116 pagesMechanical OperationNomee PatelNo ratings yet

- Thermos Design of Rotary Kiln For Reduction of Radiation Losses-10Document17 pagesThermos Design of Rotary Kiln For Reduction of Radiation Losses-10Madhav Krishna MNo ratings yet

- Manufacture of Portland Cement: Inorganic Chemistry Paper Iv: Applied Chemistry (Unit I)Document4 pagesManufacture of Portland Cement: Inorganic Chemistry Paper Iv: Applied Chemistry (Unit I)Gautam RanaNo ratings yet

- PHD Thesis of Y K MohantyDocument256 pagesPHD Thesis of Y K MohantyAnonymous P7J7V4No ratings yet

- NoxDocument10 pagesNoxRahulSinghNo ratings yet

- Fluid Bed Drying PDFDocument83 pagesFluid Bed Drying PDFsouhir gritliNo ratings yet

- BR-1833 - B&W - A Comparison of Fluid-Bed Technologies For Renewable Energy Applications PDFDocument7 pagesBR-1833 - B&W - A Comparison of Fluid-Bed Technologies For Renewable Energy Applications PDFEduardo DreifusNo ratings yet

- Properties MaterialDocument9 pagesProperties MaterialKurniawan JekiNo ratings yet

- Energy Recovery - TspaceDocument26 pagesEnergy Recovery - TspaceAlfonso Blanco100% (1)

- Ercom Brief ProfileDocument57 pagesErcom Brief ProfileKarthik DhayalanNo ratings yet

- Recent Catalyst Technology Development in Residue Catalytic Cracking Unit: A Mini ReviewDocument8 pagesRecent Catalyst Technology Development in Residue Catalytic Cracking Unit: A Mini ReviewDika CodNo ratings yet

- Combustion Processes Part 3Document175 pagesCombustion Processes Part 3debjani kunduNo ratings yet

- Cyclone SeparatorDocument1 pageCyclone SeparatorsriramNo ratings yet

- Comparison of Different Methods For Enhancing Reactivity of Pozzolans PDFDocument6 pagesComparison of Different Methods For Enhancing Reactivity of Pozzolans PDFArtemia Loayza ArguellesNo ratings yet

- Slides of Prilling TowerDocument12 pagesSlides of Prilling TowerCHUCHUNo ratings yet

- Counter Rotating FanDocument10 pagesCounter Rotating Fanapoorvs75No ratings yet

- V Sepa PresentationDocument13 pagesV Sepa Presentationzementhead0% (1)

- Bubble Column ReactorDocument2 pagesBubble Column Reactormamcii100% (1)

- CogenerationDocument3 pagesCogenerationPower PowerNo ratings yet

- Energy Changes When Kaolin Minerals Are HeatedDocument10 pagesEnergy Changes When Kaolin Minerals Are HeatedtaghdirimNo ratings yet

- Delta AluminaDocument8 pagesDelta AluminaFahim Bin Abdur RahmanNo ratings yet

- Estimation of Urea in Silo: AuthorDocument8 pagesEstimation of Urea in Silo: AuthorNeyda Flores VasquezNo ratings yet

- Organic - New - 2019 Product ProfileDocument15 pagesOrganic - New - 2019 Product Profilevaibhav khodakeNo ratings yet

- StanexDocument2 pagesStanexSamehibrahemNo ratings yet

- Kreber - Datasheet Prilling ProcessDocument9 pagesKreber - Datasheet Prilling ProcessLim CSNo ratings yet

- Fineness of Hydraulic Cement by Air-Permeability Apparatus: Standard Test Methods ForDocument9 pagesFineness of Hydraulic Cement by Air-Permeability Apparatus: Standard Test Methods ForKalindaMadusankaDasanayakaNo ratings yet

- Hydrodynamic Simulation of Cyclone SeparatorsDocument25 pagesHydrodynamic Simulation of Cyclone SeparatorsgamadaNo ratings yet

- Biogas PurificationDocument5 pagesBiogas PurificationHarsh GutgutiaNo ratings yet

- Fundamental analysis of ACC Ltd and India's cement industryDocument5 pagesFundamental analysis of ACC Ltd and India's cement industryDevika SuvarnaNo ratings yet

- LSF CaculationDocument5 pagesLSF CaculationhamedNo ratings yet

- Prilling & GranulationDocument50 pagesPrilling & GranulationselviraNo ratings yet

- WFI0004 Low Nox ConversionDocument2 pagesWFI0004 Low Nox ConversionAlexis CordovaNo ratings yet

- Thesis Final About Lime KilnsDocument144 pagesThesis Final About Lime KilnspwmvsiNo ratings yet

- Stack HT FGDDocument8 pagesStack HT FGDKiranNo ratings yet

- Comparison of Several Packings For CO2 Chemical Absorption in A Packed ColumnDocument7 pagesComparison of Several Packings For CO2 Chemical Absorption in A Packed ColumnianphilanderNo ratings yet

- Medium Velocity NozzleDocument6 pagesMedium Velocity Nozzledarsh2001patelNo ratings yet

- Maersk QuestionnaireDocument43 pagesMaersk QuestionnaireSahil SharmaNo ratings yet

- EVS Complete Notes PDFDocument148 pagesEVS Complete Notes PDFrevantrajkpdh2002No ratings yet

- Engineering Statics FundamentalsDocument28 pagesEngineering Statics FundamentalsurwaNo ratings yet

- Pres. Quirino Treasured Child School, Inc.: Grade 8-St. Joseph & ST MatthewDocument2 pagesPres. Quirino Treasured Child School, Inc.: Grade 8-St. Joseph & ST MatthewChristian jade QuijanoNo ratings yet

- Regulation 1 Regulation 2 Regulation 3 Regulation 4 Regulation 5 Regulation 6 Regulation 7 Regulation 8 Regulation 9 AppendixDocument10 pagesRegulation 1 Regulation 2 Regulation 3 Regulation 4 Regulation 5 Regulation 6 Regulation 7 Regulation 8 Regulation 9 AppendixAnonymous 7gJ9alpNo ratings yet

- MUSCULAR SYSTEM WORKSHEET Slides 1 To 4Document4 pagesMUSCULAR SYSTEM WORKSHEET Slides 1 To 4kwaiyuen ohnNo ratings yet

- Entry-Exit Arrangement With Service RoadDocument1 pageEntry-Exit Arrangement With Service RoadRamBhuvan SonkarNo ratings yet

- Slovakia C1 TestDocument7 pagesSlovakia C1 TestĐăng LêNo ratings yet

- Rainas, Lamjung: Office of Rainas MunicipalityDocument5 pagesRainas, Lamjung: Office of Rainas MunicipalityLakshman KhanalNo ratings yet

- Essay Writing-PTEDocument13 pagesEssay Writing-PTEAnita GajjarNo ratings yet

- Alaina W - Food Project ReflectionDocument1 pageAlaina W - Food Project Reflectionapi-438601399No ratings yet

- SE 276B Syllabus Winter 2018Document2 pagesSE 276B Syllabus Winter 2018Manu VegaNo ratings yet

- GSL DIP Phase - 1 Cooler 45kWDocument1 pageGSL DIP Phase - 1 Cooler 45kWMuhasin PallikkalNo ratings yet

- Problem Set 3_Cross-Text ConnectionDocument31 pagesProblem Set 3_Cross-Text Connectiontrinhdat11012010No ratings yet

- Systems Design: Job-Order Costing and Process Costing: MANAGEMENT ACCOUNTING - Solutions ManualDocument16 pagesSystems Design: Job-Order Costing and Process Costing: MANAGEMENT ACCOUNTING - Solutions ManualBianca LizardoNo ratings yet

- (New) Adjustable Voltage Power Supply 55 V - 20A High Power and Current - Automatic Fan On - OffDocument1 page(New) Adjustable Voltage Power Supply 55 V - 20A High Power and Current - Automatic Fan On - OffSek PyroNo ratings yet

- Lab ReportDocument9 pagesLab ReportQi Yi TanNo ratings yet

- Maximizing Area and Minimizing Costs with CalculusDocument18 pagesMaximizing Area and Minimizing Costs with Calculusanon_218576188No ratings yet

- Israel Is The MessIahDocument288 pagesIsrael Is The MessIahTeerayoot NoidaNo ratings yet

- PDM TempDocument2 pagesPDM Tempamit rajputNo ratings yet

- SampleDocument8 pagesSampleAntônioNo ratings yet

- M/S Majumder Construction: Valuation Statement of PropertyDocument3 pagesM/S Majumder Construction: Valuation Statement of PropertyManoj MajumderNo ratings yet