Professional Documents

Culture Documents

Recommended Maintenance Works

Uploaded by

Alejo Arboleda DuqueOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

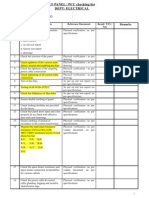

Recommended Maintenance Works

Uploaded by

Alejo Arboleda DuqueCopyright:

Available Formats

Recommended Maintenance Works

Main controller (PC):

Check hardware and general function of the computer

Check free space of hard disk

Check defragment

Check windows version

Check communication between computer and PTS devices (test via Control Program)

Check whether Control Program shows fault messages in the main window

Check free run (test via Control Program)

Check times in the timetable

Check program versions

Check database jobs

Check delete log

Check service card

Set date of maintenance

Make backup of database UTF

Station:

Mechanical:

Clean all surfaces inside the station

Apply silicone spray to surface of plastic plates in the bottom and top part inside the station

Check ball-slide-bearings in the rear part inside the station

Check function of the carrier dispatcher plate (including restoring spring) in carrier buffer on top of

the station

Check driving pin (cam) for carrier dispatcher

Check sealing rings on both sides of the send/receive magazine

check air tightness in send and receive position of the magazine

Check fixing of station and of tube connections

Check tooth clearance on gear wheel and gear rack

Electrical:

Check tight connection of all plugs

Carry out service functions (that are available)

Check the LCD

Check single keys on the keyboard

Check function of the LED

Check buzzer

Check proper function of proximity switches (observe alignment marks)

Measure operating voltage

Check reading function (distance)

Check sensors

Check remote arrival indicators (if there are any)

Diverter

Mechanical:

Clean all surfaces inside the station

Apply silicone spray to surface of plastic plate for the out ports inside the station

Check ball-bearing

Check sealing rings on both sides of the S-tube

Check fixing of diverter and of tube connections

Check tooth clearance on gear wheel and gear rack

Electrical:

Check tight connection of all plugs

Check proper function of proximity switches (observe alignment marks)

Measure operating voltage

Check function of carrier sensor (tube switch)

Blower unit:

Check function and settings of blower/motor

Check airtight connection of fittings/tube

Check function of air diverter (see “Diverter”)

Check function of motor contactor

Check correct setting (amperage) of the thermal overload relay

Check proper connection of wiring

Check carrier damper (if any) and clean if required

Check valves/stoppers inside carrier damper and clean if required

Power pack:

Measure voltage

Check tight connection of all plugs and terminals

Tubing:

Check for any damage

Check for any leaks

Check fixing and joints

Check travelling times of carriers

Check fixing and routing of cables

Carriers:

Check carrier lids

Check wear bands for wear & tear

Check carrier body for any damage

For maintenance works on additional components not listed (e.g. special units), please refer to

Swisslog Rohrpostsysteme

You might also like

- Practical Guides to Testing and Commissioning of Mechanical, Electrical and Plumbing (Mep) InstallationsFrom EverandPractical Guides to Testing and Commissioning of Mechanical, Electrical and Plumbing (Mep) InstallationsRating: 3.5 out of 5 stars3.5/5 (3)

- PM Checklist BNMDocument3 pagesPM Checklist BNMmuhammad afendyNo ratings yet

- PNEUMATICS AND AIR CIRCUITS UNDERSTANDING THE CASCADE VALVE AND PLC UNDERSTANDINGFrom EverandPNEUMATICS AND AIR CIRCUITS UNDERSTANDING THE CASCADE VALVE AND PLC UNDERSTANDINGNo ratings yet

- BF Scope of SupplyDocument1 pageBF Scope of SupplyRishi RajNo ratings yet

- Helicopter Maneuvers Manual: A step-by-step illustrated guide to performing all helicopter flight operationsFrom EverandHelicopter Maneuvers Manual: A step-by-step illustrated guide to performing all helicopter flight operationsRating: 5 out of 5 stars5/5 (1)

- PLC Panel Check ListDocument6 pagesPLC Panel Check ListPATEL AKASHNo ratings yet

- Visual and Technical Checking of Instrumentation and Control SystemDocument13 pagesVisual and Technical Checking of Instrumentation and Control SystemzhangyiliNo ratings yet

- Medical Imaging Equipment Maintenance Checklist CompressDocument6 pagesMedical Imaging Equipment Maintenance Checklist CompressHamed64No ratings yet

- Check List of Furnace Wash MachineDocument15 pagesCheck List of Furnace Wash Machinesuhasphatak007No ratings yet

- Instrumentation Check Sheet 1Document3 pagesInstrumentation Check Sheet 1renjithv_4100% (1)

- Land Rig Acceptance MasterDocument17 pagesLand Rig Acceptance Masterislam atif100% (1)

- Pump Station Inspection CheckListDocument4 pagesPump Station Inspection CheckListsa he0% (1)

- Maint IPENDocument13 pagesMaint IPENosmaidaNo ratings yet

- JKR Acmv Ahu PDFDocument4 pagesJKR Acmv Ahu PDFHafiz Abdullah50% (2)

- Centrifugal Compresssor Pre-Commissioning ChecklistDocument3 pagesCentrifugal Compresssor Pre-Commissioning ChecklistNikhil JadhavNo ratings yet

- Training P&IDDocument45 pagesTraining P&IDM R Patraputra100% (3)

- What Is Instrument Hook Up Diagram ? Instrument Hook Up Diagram Is Also Called Installation Drawing, Specifies The ScopeDocument31 pagesWhat Is Instrument Hook Up Diagram ? Instrument Hook Up Diagram Is Also Called Installation Drawing, Specifies The ScopevrajakisoriDasiNo ratings yet

- Generator Set Pre-Start-Up ChecklistDocument2 pagesGenerator Set Pre-Start-Up Checklist4685752No ratings yet

- P&ID ChecklistDocument4 pagesP&ID ChecklistShyBokxNo ratings yet

- Sample Preventative Maintenance Inspection Sheet: Fixed Route Vehicle InspectionDocument4 pagesSample Preventative Maintenance Inspection Sheet: Fixed Route Vehicle InspectionVin BdsNo ratings yet

- Machine / Plant Checklist Technology Studies: Term 1Document6 pagesMachine / Plant Checklist Technology Studies: Term 1spkumarthNo ratings yet

- Service Manual - Sorvall - Heraeus - Thermo Scientific - Megafuge 8 SL8 ST8 - V180113Document62 pagesService Manual - Sorvall - Heraeus - Thermo Scientific - Megafuge 8 SL8 ST8 - V180113Carlos Roldan100% (3)

- PM Check ListDocument10 pagesPM Check Listsachinsharma31No ratings yet

- Engineering ChecklistDocument4 pagesEngineering ChecklistShyBokxNo ratings yet

- P & ID PresentationDocument104 pagesP & ID PresentationShaheer Shabbir100% (17)

- Electrical Maintenance Check List Jan 19Document37 pagesElectrical Maintenance Check List Jan 19Ashish Mishra100% (1)

- Precommissioning, Commissioning and Start Up ExplainationDocument12 pagesPrecommissioning, Commissioning and Start Up ExplainationKevin Muhammad100% (1)

- Manlift ChecklistDocument1 pageManlift ChecklistFarid Brango0% (1)

- PFG PDI FormDocument3 pagesPFG PDI FormRichard LairdNo ratings yet

- SS04 CH01 - 48V BDT Transducer SAT FormatDocument74 pagesSS04 CH01 - 48V BDT Transducer SAT FormatshameemindiaNo ratings yet

- Flow 7 DiagramsDocument12 pagesFlow 7 DiagramsIne Florez PalaciozNo ratings yet

- P&ID SeminarDocument66 pagesP&ID Seminar蔡蕲82% (11)

- 1-INTRO2 Basics PnID PDFDocument29 pages1-INTRO2 Basics PnID PDFMuhd FahmiNo ratings yet

- Preventive Maintenance ChecklistDocument5 pagesPreventive Maintenance ChecklistshabkhaizNo ratings yet

- Conduct Loop TestDocument19 pagesConduct Loop TestkoangyakNo ratings yet

- Accuspin 1R 120V 230VDocument70 pagesAccuspin 1R 120V 230VAndrew Holmes100% (1)

- Flow Diagrams and InstrumentationDocument5 pagesFlow Diagrams and InstrumentationLordsennyshantia P. JamesNo ratings yet

- Caterpillar 311b 330b Excavators Engine and Pump Electronic Control SystemDocument10 pagesCaterpillar 311b 330b Excavators Engine and Pump Electronic Control Systemjohn100% (50)

- A Simple Single-Input-Single-Output (SISO) Feedback Control Loop Consists of FollowingDocument3 pagesA Simple Single-Input-Single-Output (SISO) Feedback Control Loop Consists of FollowingMicahNo ratings yet

- Checklist For PMIDocument28 pagesChecklist For PMIpitambervermaNo ratings yet

- Machine / Plant Checklist Technology Studies: Term 1Document6 pagesMachine / Plant Checklist Technology Studies: Term 1gaanneshNo ratings yet

- Loop Check PresentationDocument39 pagesLoop Check Presentationsaqib javaid100% (5)

- Plant Testing Acceptance and Commissioning InstructionsDocument1 pagePlant Testing Acceptance and Commissioning InstructionssivavalaiNo ratings yet

- Commn. Check ListDocument8 pagesCommn. Check ListsbpathiNo ratings yet

- LT PANEL / PCC Checking List Dept: Electrical: Equipment Tag No: Incoming PCC Feeder No.: DateDocument3 pagesLT PANEL / PCC Checking List Dept: Electrical: Equipment Tag No: Incoming PCC Feeder No.: DateVelmurugan Chakkravarthy100% (4)

- Preventive Maintenance Checklist 2019Document4 pagesPreventive Maintenance Checklist 2019Ricardo Chegwin HillembrandNo ratings yet

- Daily Checklist For Electric Overhead Travelling CranesDocument3 pagesDaily Checklist For Electric Overhead Travelling CranestatonyNo ratings yet

- AtlasDocument5 pagesAtlasSunil KumarNo ratings yet

- Air Handling Unit Construction ChecklistDocument7 pagesAir Handling Unit Construction Checklistameeri143No ratings yet

- CXA ExpectationDocument4 pagesCXA Expectationdiki anggriawanNo ratings yet

- TICI Report1Document8 pagesTICI Report1razu1234No ratings yet

- Conduct Loop CheckDocument22 pagesConduct Loop CheckkoangyakNo ratings yet

- TBMC12Document10 pagesTBMC12Joel E ValenciaNo ratings yet

- Prefunctional ChecklistsDocument37 pagesPrefunctional Checklistsrenjithv_4100% (1)

- Domestic Water Booster Test ProcedureDocument6 pagesDomestic Water Booster Test ProcedureEduardo ChvaNo ratings yet

- Study of Instrumentation Symbols As Per ISA StandardsDocument54 pagesStudy of Instrumentation Symbols As Per ISA Standardspra578100% (1)

- 2.6.1.1 AHU - Construction.checklistDocument5 pages2.6.1.1 AHU - Construction.checklistHiếu Nguyễn100% (1)

- Checklist of DU250 & DU400Document9 pagesChecklist of DU250 & DU400MadanBhadoriyaNo ratings yet

- Auto TransmissionDocument61 pagesAuto Transmissionlamping_apNo ratings yet

- Pressure Control TrinerDocument35 pagesPressure Control TrinerSourav Sarkar50% (2)

- AJava GTU Study Material Presentations Unit-4 24052021042157AMDocument101 pagesAJava GTU Study Material Presentations Unit-4 24052021042157AMMR.CHITTY PATELNo ratings yet

- JavaScript - If... Else StatementDocument4 pagesJavaScript - If... Else StatementsurvivalofthepolyNo ratings yet

- Cloud Vs On Premise SoftwareDocument9 pagesCloud Vs On Premise SoftwareQuang LiemNo ratings yet

- Design and Application of SCADA Based Control System For Filling Process (Interfacing and Monitoring)Document14 pagesDesign and Application of SCADA Based Control System For Filling Process (Interfacing and Monitoring)oscarNo ratings yet

- 9691 - May June 2011 All Question Papers PDFDocument80 pages9691 - May June 2011 All Question Papers PDFTrynosNo ratings yet

- Cisco Nexus 3232C - 215-15147 - A0Document9 pagesCisco Nexus 3232C - 215-15147 - A0nixdorfNo ratings yet

- DigitDocument108 pagesDigitProdipto MajumdarNo ratings yet

- Radare2 TutorialDocument375 pagesRadare2 TutorialSonu SangwanNo ratings yet

- Instructions: Csce 212: Final Exam Spring 2009Document5 pagesInstructions: Csce 212: Final Exam Spring 2009NapsterNo ratings yet

- TEMS Discovery HASP Licensing - Guide LineDocument15 pagesTEMS Discovery HASP Licensing - Guide LineMichal BarcikowskiNo ratings yet

- Design Pattern MCQS 11 - 20Document5 pagesDesign Pattern MCQS 11 - 20Genghis Khan 69No ratings yet

- Information Technology British English Teacher Ver2 BWDocument4 pagesInformation Technology British English Teacher Ver2 BWBUJOR MIHAI-SEBASTIANNo ratings yet

- Unit 4 - Data Types and KeywordsDocument9 pagesUnit 4 - Data Types and KeywordsbarnabasNo ratings yet

- Solution Manual For Introduction To Javascript Programming With XML and PHP 0133068307Document4 pagesSolution Manual For Introduction To Javascript Programming With XML and PHP 0133068307Daryl TrahanNo ratings yet

- COS30008 Programming Project 1 - 2020S1Document4 pagesCOS30008 Programming Project 1 - 2020S1Fizz ZaroNo ratings yet

- MSDN - Debugging GuideDocument4,176 pagesMSDN - Debugging GuideAjit Kumar SinghNo ratings yet

- Oracle Engineered Systems Price ListDocument12 pagesOracle Engineered Systems Price Listsda123qweNo ratings yet

- General MODBUS TCP Master DriverDocument28 pagesGeneral MODBUS TCP Master DrivercutoNo ratings yet

- Service Broker PCRFDocument140 pagesService Broker PCRFAshish ShuklaNo ratings yet

- CS Midterm2 2020 - Qs OnlyDocument6 pagesCS Midterm2 2020 - Qs OnlyShady MagedNo ratings yet

- V1 - Oferta Scanner Intra-Oral MEDIT I500Document2 pagesV1 - Oferta Scanner Intra-Oral MEDIT I500CristianMarandiucNo ratings yet

- Employee Attendance Management SystemDocument72 pagesEmployee Attendance Management SystemMangesh Amant Aure55% (20)

- SIPLACE Explorer Eng 10-2012Document18 pagesSIPLACE Explorer Eng 10-2012High Tech Katlane100% (1)

- Scad500l ManualDocument35 pagesScad500l ManualcsmanienNo ratings yet

- Aict004!3!2 Os Group Assignment Ucd2f1204dit (Se) Ucd2f1204ditDocument4 pagesAict004!3!2 Os Group Assignment Ucd2f1204dit (Se) Ucd2f1204ditSathya SeelanNo ratings yet

- Intelivision 5Document43 pagesIntelivision 5contactNo ratings yet

- Difference of Straight Through and Crossover CableDocument4 pagesDifference of Straight Through and Crossover CableRez HabloNo ratings yet

- 12-SOC and Embedded SystemDocument45 pages12-SOC and Embedded SystemNitesh JoshiNo ratings yet

- AWS Vs Azure Vs GCPDocument5 pagesAWS Vs Azure Vs GCPZaid_SultanNo ratings yet

- Consuming Messages With Kafka Consumers and Consumer Groups: Ryan PlantDocument38 pagesConsuming Messages With Kafka Consumers and Consumer Groups: Ryan PlantancgateNo ratings yet

- iPhone Unlocked for the Non-Tech Savvy: Color Images & Illustrated Instructions to Simplify the Smartphone Use for Beginners & Seniors [COLOR EDITION]From EverandiPhone Unlocked for the Non-Tech Savvy: Color Images & Illustrated Instructions to Simplify the Smartphone Use for Beginners & Seniors [COLOR EDITION]Rating: 5 out of 5 stars5/5 (6)

- iPhone 14 Guide for Seniors: Unlocking Seamless Simplicity for the Golden Generation with Step-by-Step ScreenshotsFrom EverandiPhone 14 Guide for Seniors: Unlocking Seamless Simplicity for the Golden Generation with Step-by-Step ScreenshotsRating: 5 out of 5 stars5/5 (8)

- Chip War: The Fight for the World's Most Critical TechnologyFrom EverandChip War: The Fight for the World's Most Critical TechnologyRating: 4.5 out of 5 stars4.5/5 (84)

- Digital Transformation: An Executive Guide to Survive and Thrive in the New EconomyFrom EverandDigital Transformation: An Executive Guide to Survive and Thrive in the New EconomyRating: 5 out of 5 stars5/5 (1)

- CompTIA Security+ All-in-One Exam Guide, Sixth Edition (Exam SY0-601)From EverandCompTIA Security+ All-in-One Exam Guide, Sixth Edition (Exam SY0-601)Rating: 5 out of 5 stars5/5 (1)

- Arduino: A Beginner's Guide to Arduino ProgrammingFrom EverandArduino: A Beginner's Guide to Arduino ProgrammingRating: 3 out of 5 stars3/5 (1)

- Chip War: The Quest to Dominate the World's Most Critical TechnologyFrom EverandChip War: The Quest to Dominate the World's Most Critical TechnologyRating: 4.5 out of 5 stars4.5/5 (231)

- Computer Science: A Concise IntroductionFrom EverandComputer Science: A Concise IntroductionRating: 4.5 out of 5 stars4.5/5 (14)

- CompTIA A+ Complete Review Guide: Core 1 Exam 220-1101 and Core 2 Exam 220-1102From EverandCompTIA A+ Complete Review Guide: Core 1 Exam 220-1101 and Core 2 Exam 220-1102Rating: 5 out of 5 stars5/5 (2)

- CompTIA A+ Complete Review Guide: Exam Core 1 220-1001 and Exam Core 2 220-1002From EverandCompTIA A+ Complete Review Guide: Exam Core 1 220-1001 and Exam Core 2 220-1002Rating: 5 out of 5 stars5/5 (1)

- Methods to Increase the Internal Storage Space of Android DevicesFrom EverandMethods to Increase the Internal Storage Space of Android DevicesNo ratings yet

- Jensen Huang's Nvidia: Processing the Mind of Artificial IntelligenceFrom EverandJensen Huang's Nvidia: Processing the Mind of Artificial IntelligenceNo ratings yet

- INSTANT PLC Programming with RSLogix 5000From EverandINSTANT PLC Programming with RSLogix 5000Rating: 4.5 out of 5 stars4.5/5 (10)

- Amazon Web Services (AWS) Interview Questions and AnswersFrom EverandAmazon Web Services (AWS) Interview Questions and AnswersRating: 4.5 out of 5 stars4.5/5 (3)

- How to Jailbreak Roku: Unlock Roku, Roku Stick, Roku Ultra, Roku Express, Roku TV with Kodi Step by Step GuideFrom EverandHow to Jailbreak Roku: Unlock Roku, Roku Stick, Roku Ultra, Roku Express, Roku TV with Kodi Step by Step GuideRating: 1 out of 5 stars1/5 (1)

- Design Recipes for FPGAs: Using Verilog and VHDLFrom EverandDesign Recipes for FPGAs: Using Verilog and VHDLRating: 2 out of 5 stars2/5 (1)

- Open System LANs and Their Global Interconnection: Electronics and Communications Reference SeriesFrom EverandOpen System LANs and Their Global Interconnection: Electronics and Communications Reference SeriesRating: 5 out of 5 stars5/5 (1)

- ARDUINO PROGRAMMING FOR BEGINNERS: A Comprehensive Beginner's Guide, Tips and Tricks, Simple and Effective methods and Advanced methods to learn and understand Arduino Hardware and SoftwareFrom EverandARDUINO PROGRAMMING FOR BEGINNERS: A Comprehensive Beginner's Guide, Tips and Tricks, Simple and Effective methods and Advanced methods to learn and understand Arduino Hardware and SoftwareNo ratings yet

- CompTIA A+ Certification All-in-One Exam Guide, Eleventh Edition (Exams 220-1101 & 220-1102)From EverandCompTIA A+ Certification All-in-One Exam Guide, Eleventh Edition (Exams 220-1101 & 220-1102)Rating: 5 out of 5 stars5/5 (2)

- Beginning Robotics with Raspberry Pi and Arduino: Using Python and OpenCVFrom EverandBeginning Robotics with Raspberry Pi and Arduino: Using Python and OpenCVNo ratings yet

![iPhone Unlocked for the Non-Tech Savvy: Color Images & Illustrated Instructions to Simplify the Smartphone Use for Beginners & Seniors [COLOR EDITION]](https://imgv2-1-f.scribdassets.com/img/audiobook_square_badge/728318688/198x198/f3385cbfef/1715990620?v=1)