Professional Documents

Culture Documents

1979 - Ashe - A Cane Core Sampling

Uploaded by

dariusiasdasdOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

1979 - Ashe - A Cane Core Sampling

Uploaded by

dariusiasdasdCopyright:

Available Formats

Proceedings of The South African Sugar Technologists' Association - June 1979

A CANE CORE SAMPLING INSTALLATION AT UMFOLOZI

By G. G. ASHE

Umfolozi Co-operative Sugar Planters Limited

Abstract Basket Sampler

Core sampling equipment for tramway and railway wagons Approximately 400 basket type trucks-with cane from the

is described. Both whole stick and chopped cane are sampled chopper harvesters are brought in each day and these are also

in the tramway system. sampled just after the weighbridge. A clam type hydraulic

grab is used to take a sample out of the basket. The first

grab is placed on top of the truck which has been sampled

and the second grab is then emptied into the pre-breaker

where it is handled in the same way as the core sample.

At Ilmfolozi factory all cane is delivered to the mill either

in SAR wagons or the company's own cane trucks or baskets The excess cane from the pre-breaker falls into a hopper

(chopped cane). No cane is stockpiled on the ground. Um- beside the clam grab where it is picked up by the clam grab

folozi has a conventional mill and a diffuser and it was not and placed on top of a cane truck after sampling. This is

difficult to keep individual consignments separate when being then transport~edto the mill on the cane truck.

crushed. It was decided to increase the throughput of cane

to the mill to 300 tons per hour but in order tb achieve this

it was necessary to mix SAR's and company smalls and this

made it impossible to use the hatch sampler. Cane core

sampling installations in other countries. were inspected and

it was decided that a similar system - would be the only

feasiblle method of sampling cane at Umfolozi.

Compizny Smalls Sampler

Approximately two thirds of the cane arrives in company

cane trucks, averaging about three and a half tons per truck,

and arnounts to approximately 1300 trucks in 24 hours. The

remainder is brought in on SAR wagons of approximately

30 tons each. Immediately after the Smalls weighbridge two

corers of 200 mm diameter are mounted horizontally and at an

angle of 45' to the tramline and approximately 2 m apart.

By lhaving two corers mounted on the one carriage, two

cane tirucks can be sampled simultaneously. Each corer can

be raised or lowered independently in order to vary the posi-

tion w'here the sample is taken. The entire corer is hydrauli-

cally c~perated.

Theire is only one operator who starts the sampling cycle FIGURE I corer entering cane bundle.

by pressing a button. When the button is pressed a clamp,

in beti~eenthe rails on which the trucks run, is raised and

when a truck comes from the weighbridge it is caught by the

clamp. When this happens the corers start to rotate and at

the same time the whole carriage moves in towards the two

trucks held by the clamp.

When the corers have travelled just over halfway through

the a n e bundles on the trucks the carriage stops and com-

mences its return; at the same time the corers stop rotating.

When the carriage has returned to rest, a plunger inside each

corer is actuated and this ejects the sample which has been

~0llectld.

At the same time a slat conveyor under the end of the

corers is started and this conveys the samples of cane from

the co:rers to the pre-breaker. The chopped cane from the

pie-brmker is then sub-sampled and placed in the small

shredder and from there it is placed in a sample bucket

marked with the farmer's code number and conveyed to the

1aboral:ory. Two men are required for the whole operation.

A pneumatic conveyor system from the sample station to the

laboratory is being investigated and this will get the sample

to the laboratory in fifteen seconds and also eliminate the

need for one man. FIGURE 3 Inclined corer to sample railway wagons.

Proceedings of The South African Sugar Technologists' Association - June 1979 77

FIGURE 2 General view of the installation. Corers on carriage (left), conveyor toprebreaker(centre) and clamshell grab for chopper harvested cane (right).

Figure 1 shows the corer entering the side of a cane truck When the operator presses the start button the corer starts

and Figure 2 shows the corers on the carriage on the left and to rotate and at the same time it is lowered into the top of

the slat conveyor feeding the pre-breaker on the right. The the cane truck on the inclined slide. When the camer has

grab sampler is shown on the extreme right. travelled 2 m into the cane the corer stops rotating and with-

draws from the cane. When the carriage has returned to rest

SAR Core Sampler the corer lifts one end to come to rest over the hopper on the

The carrier is mounted vertically and at an angle of 45O pre-breaker (see Figure 4).

to the horizontal, with its motor mounted in a slide (Figure The cane sample is ejected by a piston within the carrier

3). At one end of the platform a pre-breaker is mounted. barrel into the pre-breaker. The, sample is collected in a tray

under the pre-breaker and the excess falls back into the SAR

truck. The sample is then sub-divided and placed in a bucket

marked 'with the farmer's code number and is lowered on a

wire slide to the shredder and from there to the laboratory.

Conclusions .

This system has enabled Umfolozi to crush cane on the

mill at the higher rate without having to worry about samples

being mixed in the carriers.

Another advantage is that the cane is sampled immediately

after it has been weighed, and as each truck can be sampled

individually there is little chance of the wrong cane being

sampled or of a sample being mixed. Also, cane can be

cleaned if necessary after this point or rejected if of too low

a purity whilst it is still being unloaded.

Analytical data using this system has been taken over a

long period by the Sugar Industry Central Board, Cane

Testing Division, and the results are being analysed for com-

parison with both a hatch and grab sampler. At the time of

writing these results are not known.

Pol and brix factors, during the period the mill was on

FIGURE 4 Corer raised t o eject sample. core sampling only, were within 050% of the mill balance.

You might also like

- 1983 Mhlume Rota Tipper Cane Offloading System PDFDocument4 pages1983 Mhlume Rota Tipper Cane Offloading System PDFbonginkosi mathunjwaNo ratings yet

- Automatic Reeling Machine: by Sadao OkiDocument4 pagesAutomatic Reeling Machine: by Sadao Okiaj iseNo ratings yet

- WarpingDocument10 pagesWarpingKalyan Ray GuptaNo ratings yet

- Comber Part 1Document31 pagesComber Part 1TuhinNo ratings yet

- Chapter Three: Rapier LoomsDocument27 pagesChapter Three: Rapier LoomsGadisa Abrahim100% (1)

- Stacker ReclaimerDocument23 pagesStacker Reclaimertan_dat2003No ratings yet

- Stacker Cum Reclaimer - Operation & MaintenanceDocument7 pagesStacker Cum Reclaimer - Operation & MaintenanceDurjoy Chakraborty75% (4)

- Working Principle of BCM, DTS, UNIMATDocument97 pagesWorking Principle of BCM, DTS, UNIMATshuja2008No ratings yet

- Study On Take Up Mechanism: (Cotton Weaving)Document4 pagesStudy On Take Up Mechanism: (Cotton Weaving)Bhaskar MitraNo ratings yet

- SeriesIII EnglishDocument15 pagesSeriesIII EnglishF.Brit0 FelixNo ratings yet

- CentrifugationDocument20 pagesCentrifugationGun SmithNo ratings yet

- Unit-2: WarpingDocument53 pagesUnit-2: WarpingMUHAMMADATHER UDDINNo ratings yet

- Sugar Manufacturing Process PDFDocument55 pagesSugar Manufacturing Process PDFShivkumar SK67% (3)

- How Far Automatic?: Mechanized SpreadingDocument4 pagesHow Far Automatic?: Mechanized SpreadingPrabhuti ChauhanNo ratings yet

- Assignment On Under Picking MechanismDocument3 pagesAssignment On Under Picking MechanismZAyedNo ratings yet

- Shoa Internship Report: Chapter OneDocument53 pagesShoa Internship Report: Chapter OneSegni KitilaNo ratings yet

- TGD No.5 - Static Grain Sampling - May2018Document18 pagesTGD No.5 - Static Grain Sampling - May2018fachrizal cesarNo ratings yet

- A Method For Determining The Effects of Various Gin Treatments On The Spinnability of CottonDocument4 pagesA Method For Determining The Effects of Various Gin Treatments On The Spinnability of Cottoncan ergenekonNo ratings yet

- Lab Paracticle: National Textile UniversityDocument10 pagesLab Paracticle: National Textile UniversityShahan AkhtarNo ratings yet

- Cross Belt Sampling SystemsDocument17 pagesCross Belt Sampling Systemsmahesa34No ratings yet

- Auto Coal SamplerDocument20 pagesAuto Coal Sampleryousufali56No ratings yet

- BWSR Safety Features PDFDocument3 pagesBWSR Safety Features PDFVijayakumarVageesanNo ratings yet

- Handling Systems: SimulationDocument14 pagesHandling Systems: SimulationWilliam ZazaNo ratings yet

- Study On Rapier Weaving Mechanism.Document11 pagesStudy On Rapier Weaving Mechanism.Naimul HasanNo ratings yet

- Centrifuge and Rotor SOP: Types of CentrifugesDocument5 pagesCentrifuge and Rotor SOP: Types of CentrifugesSajanan TrimedNo ratings yet

- Presentación de Actividades Realizadas Durante Prácticas Pre ProfesionalesDocument28 pagesPresentación de Actividades Realizadas Durante Prácticas Pre ProfesionalesCésar EstrellaNo ratings yet

- Sugar MillDocument99 pagesSugar MillSunny Kataria67% (6)

- Con WindingDocument3 pagesCon WindingyousuftexduetNo ratings yet

- Textile Technology Internship ReportDocument24 pagesTextile Technology Internship Reportgunashekarkalluri100% (1)

- Weft InsertionDocument6 pagesWeft InsertionVishal ChavanNo ratings yet

- Box Transfer Mechanism PDFDocument31 pagesBox Transfer Mechanism PDFVaibhav50% (2)

- Cane, Hareve, Weighing&handlling Plant (1)Document55 pagesCane, Hareve, Weighing&handlling Plant (1)Gebeyehu GetachewNo ratings yet

- Operation Manual &: Motorized TrolleyDocument44 pagesOperation Manual &: Motorized TrolleymigueljesusmNo ratings yet

- Drawwork Control: Cormorant Alpha Drilling Operations GuideDocument7 pagesDrawwork Control: Cormorant Alpha Drilling Operations GuidealiNo ratings yet

- Name Numan Sharif Reg. # 19-NTU-TE-0117 Lab Report 01 TitleDocument10 pagesName Numan Sharif Reg. # 19-NTU-TE-0117 Lab Report 01 TitleAhmad ButtNo ratings yet

- Cane Unloading and Transport (Preparation)Document49 pagesCane Unloading and Transport (Preparation)valerie annNo ratings yet

- G-PM Lab 4Document5 pagesG-PM Lab 4Sohail AhmedNo ratings yet

- Safety Precautions: Technological Institute of The PhilippinesDocument5 pagesSafety Precautions: Technological Institute of The PhilippinesMichelle MendozaNo ratings yet

- Meadows 98 Mud RecycleDocument6 pagesMeadows 98 Mud RecyclesusuetawapasuruanNo ratings yet

- Weaving Technology 3rd Sem Unit - II DHTTDocument59 pagesWeaving Technology 3rd Sem Unit - II DHTTSANJIT JANANo ratings yet

- McCLOSKEY ST80-MANUAL-KUBOTADocument29 pagesMcCLOSKEY ST80-MANUAL-KUBOTAPitupy100% (1)

- Complete LabDocument54 pagesComplete LabMujahid MehdiNo ratings yet

- G-PM Lab 5Document6 pagesG-PM Lab 5Sohail AhmedNo ratings yet

- Bettlenut Procesing ReportDocument4 pagesBettlenut Procesing ReportBg gleeNo ratings yet

- PE PandGJ AMPL PDFDocument4 pagesPE PandGJ AMPL PDFTinuoye Folusho OmotayoNo ratings yet

- Service Manual Winch Models Pa55 & Pa56: SENR5358-04Document62 pagesService Manual Winch Models Pa55 & Pa56: SENR5358-04Gabriel Paredes E.No ratings yet

- GUL AHMED TEXTILES No.8 Internship Report (Sfdac)Document25 pagesGUL AHMED TEXTILES No.8 Internship Report (Sfdac)raoshahbazkhan50% (6)

- Lap FormerDocument2 pagesLap FormerRatul Hasan100% (1)

- Nkosi Jig & Float ReportDocument14 pagesNkosi Jig & Float ReportTeererai Kagura100% (1)

- Fabric Manufacturing ProcessDocument13 pagesFabric Manufacturing ProcessChristian AsareNo ratings yet

- Lab Manual For Trommel CitDocument2 pagesLab Manual For Trommel CitRyle ArbonNo ratings yet

- Lap Former The Objective of Lap FormerDocument40 pagesLap Former The Objective of Lap FormerAhmed Ifsan NayeemNo ratings yet

- Application OF Horizontal Vacuum: THE A Belt Filter TO Smuts Dewatering and Cane Mud FiltrationDocument5 pagesApplication OF Horizontal Vacuum: THE A Belt Filter TO Smuts Dewatering and Cane Mud FiltrationMichel M.No ratings yet

- Drafting Waves of SliversDocument4 pagesDrafting Waves of Sliversnalaka.sampathNo ratings yet

- Cpms College of Nursing: Assignment ON Setting, Use and Maintainance of Centrifuge MachineDocument6 pagesCpms College of Nursing: Assignment ON Setting, Use and Maintainance of Centrifuge MachineAmy Lalringhluani ChhakchhuakNo ratings yet

- Welcome To Our PresentationDocument40 pagesWelcome To Our PresentationAbdul AzizNo ratings yet

- Can Robots Milk Cows?: Questions and Answers About Farm MachinesFrom EverandCan Robots Milk Cows?: Questions and Answers About Farm MachinesNo ratings yet

- Pneumatic and Hydrautic Conveying of Both Fly Ash and Bottom AshFrom EverandPneumatic and Hydrautic Conveying of Both Fly Ash and Bottom AshNo ratings yet

- 5 Roll Idler Geometry CEMA June 2015Document10 pages5 Roll Idler Geometry CEMA June 2015dariusiasdasdNo ratings yet

- TrajectoryDocument1 pageTrajectorydariusiasdasdNo ratings yet

- Chains and Buckets Etc.Document6 pagesChains and Buckets Etc.dariusiasdasdNo ratings yet

- A Company Continually Evolving.: Introduzione Inglese 14-01-2003 11:04 Pagina 3Document115 pagesA Company Continually Evolving.: Introduzione Inglese 14-01-2003 11:04 Pagina 3maiquelernNo ratings yet

- Creo Parametric Qick Reference CardsDocument14 pagesCreo Parametric Qick Reference CardsdariusiasdasdNo ratings yet

- Creo Parametric Qick Reference CardsDocument14 pagesCreo Parametric Qick Reference CardsdariusiasdasdNo ratings yet

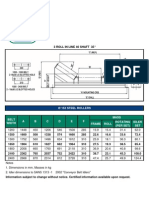

- 3 Roll in Line 40 Shaft 35degDocument1 page3 Roll in Line 40 Shaft 35degdariusiasdasdNo ratings yet

- Genie Model TML-4000 / TML-4000N, Parts ManualDocument107 pagesGenie Model TML-4000 / TML-4000N, Parts ManualPrejit Radhakrishna0% (1)

- Price ListDocument14 pagesPrice ListRavi MakhijaNo ratings yet

- ContainerDocument12 pagesContainerlakkekepsuNo ratings yet

- Railway Electrification (Pink Book 2019-2020)Document9 pagesRailway Electrification (Pink Book 2019-2020)Muhammad Meraj AlamNo ratings yet

- Dry Bulk Cargo Handling in Perlis PortDocument5 pagesDry Bulk Cargo Handling in Perlis PortShahrul ShafiqNo ratings yet

- Lifesport's Free Bike Repair GuideDocument7 pagesLifesport's Free Bike Repair GuideLifesport ShopsNo ratings yet

- Your Boarding Pass To Jakarta - ETIHAD AIRWAYSDocument2 pagesYour Boarding Pass To Jakarta - ETIHAD AIRWAYSKrishna Kalyan dakiNo ratings yet

- Colregs (Rule 17-41)Document29 pagesColregs (Rule 17-41)Lexter Mapalad100% (1)

- Parent-Taught Driver Education in Texas: Traffic Safety FactsDocument2 pagesParent-Taught Driver Education in Texas: Traffic Safety FactskeyawallaceNo ratings yet

- Iot Based Smart Car Monitoring System: Amruta Rajendra Chougule Dr. K. SuganthiDocument5 pagesIot Based Smart Car Monitoring System: Amruta Rajendra Chougule Dr. K. SuganthiRajesh SahaNo ratings yet

- Hydrarchy - GasworksDocument2 pagesHydrarchy - GasworksnicolaceliawrightNo ratings yet

- Aventador Oil ChangeDocument4 pagesAventador Oil Changeharmeet kaur100% (2)

- C10 Builder Guide - December 2017 PDFDocument132 pagesC10 Builder Guide - December 2017 PDFJuan Ignacio GeminianiNo ratings yet

- Swami Vivekananda Road NGEF Road Krishnayan Palya Road Railway Parallel RoadDocument10 pagesSwami Vivekananda Road NGEF Road Krishnayan Palya Road Railway Parallel RoadNethraa SkNo ratings yet

- Pavement MarkingDocument3 pagesPavement Markingsethu1091No ratings yet

- Automotive AerodynamicsDocument3 pagesAutomotive AerodynamicsManoj PradhanNo ratings yet

- Geotechnical Engineering Progress With The Incheon Bridge ProjectDocument12 pagesGeotechnical Engineering Progress With The Incheon Bridge ProjectSuzon IkramNo ratings yet

- Brochure Range Rover 2010Document44 pagesBrochure Range Rover 2010Beepin JeNo ratings yet

- Community ChecklistDocument3 pagesCommunity Checklistasdf521No ratings yet

- Significance of Lipids in Biological Membranes and Transport MechanismsDocument9 pagesSignificance of Lipids in Biological Membranes and Transport Mechanismsroshan khan100% (2)

- Proof of DeliveryDocument2 pagesProof of DeliveryAnonymous ANFsBkNo ratings yet

- ISYS2110 - Case 8.1 - G6 - Team 1Document6 pagesISYS2110 - Case 8.1 - G6 - Team 1Moonie090% (1)

- Berhanu's Final Internship Report AastuDocument50 pagesBerhanu's Final Internship Report AastuphilipostamruNo ratings yet

- LNG Shipping OverviewDocument29 pagesLNG Shipping OverviewpadangiringNo ratings yet

- Final Thesis - Chapter 1-WPS OfficeDocument36 pagesFinal Thesis - Chapter 1-WPS OfficeBai-Sandra Tabua Macarimbang100% (1)

- Question Bank C To BDocument211 pagesQuestion Bank C To Bsushiljp1984No ratings yet

- ICBC - Proving Your Driving Experience PDFDocument1 pageICBC - Proving Your Driving Experience PDFbianca7sallesNo ratings yet

- Erste Bank Research Euro 2012Document10 pagesErste Bank Research Euro 2012Wito NadaszkiewiczNo ratings yet

- OP Lifting Equipment 1006Document1 pageOP Lifting Equipment 1006Sinead1990No ratings yet

- 005 - OBA-QAC-MST-DIS-REV - R00 - Dismantling WorksDocument11 pages005 - OBA-QAC-MST-DIS-REV - R00 - Dismantling WorksDritan PeshtaniNo ratings yet