Professional Documents

Culture Documents

Liquefaction - Resistance - of - Soils - Summary 4

Uploaded by

Chaudary Azhar Saleem0 ratings0% found this document useful (0 votes)

3 views1 pageOriginal Title

LIQUEFACTION_RESISTANCE_OF_SOILS_SUMMARY 4

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

3 views1 pageLiquefaction - Resistance - of - Soils - Summary 4

Uploaded by

Chaudary Azhar SaleemCopyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You are on page 1of 1

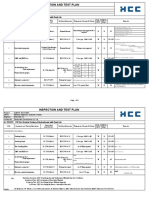

tory of the clean-sand base curve at low (N1)60 to a projected TABLE 2.

Corrections to SPT (Modified from Skempton 1986) as

intercept of about 0.05 (Fig. 2). This adjustment reshapes the Listed by Robertson and Wride (1998)

clean-sand base curve to achieve greater consistency with CRR Factor Equipment variable Term Correction

curves developed for the CPT and shear-wave velocity pro-

Overburden pressure — CN (Pa / ⬘vo)0.5

cedures. Seed and Idriss (1982) projected the original curve Overburden pressure — CN CN ⱕ 1.7

through the origin, but there were few data to constrain the Energy ratio Donut hammer CE 0.5–1.0

curve in the lower part of the plot. A better fit to the present Energy ratio Safety hammer CE 0.7–1.2

empirical data is to bow the lower end of the base curve as Energy ratio Automatic-trip Donut- CE 0.8–1.3

indicated in Fig. 2. type hammer

Borehole diameter 65–115 mm CB 1.0

At the University of Texas, A. F. Rauch (personal commu-

Borehole diameter 150 mm CB 1.05

nication, 1998), approximated the clean-sand base curve plot- Borehole diameter 200 mm CB 1.15

ted in Fig. 2 by the following equation: Rod length <3 m CR 0.75

Downloaded from ascelibrary.org by Indian Institute of Tech Gandhinagar on 11/29/12. Copyright ASCE. For personal use only; all rights reserved.

Rod length 3–4 m CR 0.8

1 (N1)60 50 1 Rod length 4–6 m CR 0.85

CRR7.5 = ⫹ ⫹ 2 ⫺ (4)

34 ⫺ (N1)60 135 [10 ⭈ (N1)60 ⫹ 45] 200 Rod length 6–10 m CR 0.95

Rod length 10–30 m CR 1.0

This equation is valid for (N1)60 < 30. For (N1)60 ⱖ 30, clean Sampling method Standard sampler CS 1.0

granular soils are too dense to liquefy and are classed as non- Sampling method Sampler without liners CS 1.1–1.3

liquefiable. This equation may be used in spreadsheets and

other analytical techniques to approximate the clean-sand base

curve for routine engineering calculations. (N1)60 = NmCNCECBCRCS (8)

Influence of Fines Content where Nm = measured standard penetration resistance; CN =

factor to normalize Nm to a common reference effective over-

In the original development, Seed et al. (1985) noted an burden stress; CE = correction for hammer energy ratio (ER);

apparent increase of CRR with increased fines content. CB = correction factor for borehole diameter; CR = correction

Whether this increase is caused by an increase of liquefaction factor for rod length; and CS = correction for samplers with or

resistance or a decrease of penetration resistance is not clear. without liners.

Based on the empirical data available, Seed et al. developed Because SPT N-values increase with increasing effective

CRR curves for various fines contents reproduced in Fig. 2. A overburden stress, an overburden stress correction factor is ap-

revised correction for fines content was developed by work- plied (Seed and Idriss 1982). This factor is commonly calcu-

shop attendees to better fit the empirical database and to better lated from the following equation (Liao and Whitman 1986a):

support computations with spreadsheets and other electronic

computational aids. CN = (Pa / ⬘v o)0.5 (9)

The workshop participants recommend (5) and (6) as ap-

proximate corrections for the influence of fines content (FC) where CN normalizes Nm to an effective overburden pressure

on CRR. Other grain characteristics, such as soil plasticity, v⬘o of approximately 100 kPa (1 atm) Pa. CN should not ex-

may affect liquefaction resistance as well as fines content, but ceed a value of 1.7 [A maximum value of 2.0 was published

widely accepted corrections for these factors have not been in the National Center for Earthquake Engineering Research

developed. Hence corrections based solely on fines content (NCEER) workshop proceedings (Youd and Idriss 1997), but

should be used with engineering judgment and caution. The later was reduced to 1.7 by consensus of the workshop partic-

following equations were developed by I. M. Idriss with the ipants] Kayen et al. (1992) suggested the following equation,

assistance of R. B. Seed for correction of (N1)60 to an equiv- which limits the maximum CN value to 1.7, and in these writ-

alent clean sand value, (N1)60cs: ers’ opinion, provides a better fit to the original curve specified

by Seed and Idriss (1982):

(N1)60cs = ␣ ⫹ (N1)60 (5)

CN = 2.2/(1.2 ⫹ ⬘v o /Pa) (10)

where ␣ and  = coefficients determined from the following

relationships: Either equation may be used for routine engineering applica-

␣=0 for FC ⱕ 5% (6a)

tions.

The effective overburden pressure ⬘v o applied in (9) and

␣ = exp[1.76 ⫺ (190/FC )] 2

for 5% < FC < 35% (6b) (10) should be the overburden pressure at the time of drilling

and testing. Although a higher ground-water level might be

␣ = 5.0 for FC ⱖ 35% (6c) used for conservatism in the liquefaction resistance calcula-

= 1.0 for FC ⱕ 5% (7a) tions, the CN factor must be based on the stresses present at

the time of the testing.

= [0.99 ⫹ (FC /1,000)]

1.5

for 5% < FC < 35% (7b) The CN correction factor was derived from SPT performed

in test bins with large sand specimens subjected to various

= 1.2 for FC ⱖ 35% (7c) confining pressures (Gibbs and Holtz 1957; Marcuson and

These equations may be used for routine liquefaction resis- Bieganousky 1997a,b). The results of several of these tests are

tance calculations. A back-calculated curve for a fines content reproduced in Fig. 3 in the form of CN curves versus effective

of 35% is essentially congruent with the 35% curve plotted in overburden stress (Castro 1995). These curves indicate con-

Fig. 2. The back-calculated curve for a fines contents of 15% siderable scatter of results with no apparent correlation of CN

plots to the right of the original 15% curve. with soil type or gradation. The curves from looser sands,

however, lie in the lower part of the CN range and are reason-

Other Corrections ably approximated by (9) and (10) for low effective overbur-

den pressures [200 kPa (<2 tsf )]. The workshop participants

Several factors in addition to fines content and grain char- endorsed the use of (9) for calculation of CN, but acknowl-

acteristics influence SPT results, as noted in Table 2. Eq. (8) edged that for overburden pressures >200 kPa (2 tsf) the re-

incorporates these corrections sults are uncertain. Eq. (10) provides a better fit for overburden

820 / JOURNAL OF GEOTECHNICAL AND GEOENVIRONMENTAL ENGINEERING / OCTOBER 2001

J. Geotech. Geoenviron. Eng. 2001.127:817-833.

You might also like

- Stone Column With OverloadingDocument1 pageStone Column With Overloadingavijitdey1975No ratings yet

- CT200 LittlefuseDocument2 pagesCT200 LittlefuseHugo Dennis Mattos EspinozaNo ratings yet

- TCE E Consul Lting Eng Gineers L Limited: Design Nofstr AS Ructural Per Is: 8 L Steel E 00-2007 Element TSDocument1 pageTCE E Consul Lting Eng Gineers L Limited: Design Nofstr AS Ructural Per Is: 8 L Steel E 00-2007 Element TSNeeraj DubeyNo ratings yet

- Assembly Data Symbol Units Value: Lo-Cog DC GearmotorDocument2 pagesAssembly Data Symbol Units Value: Lo-Cog DC GearmotornickNo ratings yet

- Reinforcement Pad CalculationDocument5 pagesReinforcement Pad Calculationsada siva100% (1)

- A. Check For Compression: DESIGN USING ASME BTH1-2005 - Code For LiftingDocument6 pagesA. Check For Compression: DESIGN USING ASME BTH1-2005 - Code For LiftingShabirNo ratings yet

- SPT Liquefaction PezeshkDocument8 pagesSPT Liquefaction PezeshkZhenhe SongNo ratings yet

- A. Check For Compression: DESIGN USING ASME BTH1-2005 - Code For LiftingDocument5 pagesA. Check For Compression: DESIGN USING ASME BTH1-2005 - Code For LiftingDhanraj VasanthNo ratings yet

- Bending Stress CalculationsDocument4 pagesBending Stress Calculationsschaali100% (5)

- Compound Wall SinghaniaDocument1 pageCompound Wall SinghaniaAHSANNo ratings yet

- Aisc 14 Edition (Asd) : 0 1 18/jan/16 13/jun/16 SN SN AN ANDocument5 pagesAisc 14 Edition (Asd) : 0 1 18/jan/16 13/jun/16 SN SN AN ANGousePeerzadeNo ratings yet

- KP201-CC - CV Mode Charger Design Spreadsheet 24V 1.5aDocument8 pagesKP201-CC - CV Mode Charger Design Spreadsheet 24V 1.5aVishal dtuNo ratings yet

- SS Stub End Thickness CalculationDocument1 pageSS Stub End Thickness CalculationSrinivas KadivetiNo ratings yet

- (Check Scantlings of Crankshaft) PDFDocument11 pages(Check Scantlings of Crankshaft) PDFHari RamNo ratings yet

- Assembly Data Symbol Units Value: Lo-Cog DC Servo GearmotorDocument2 pagesAssembly Data Symbol Units Value: Lo-Cog DC Servo GearmotorJuan De los PalotesNo ratings yet

- Specific Energy As A Criterion For Drill Performance PredictionDocument4 pagesSpecific Energy As A Criterion For Drill Performance PredictionSantiagoCadenaNo ratings yet

- E.1.1) Nozzle Neck Thickness For Cyl. Shell Nozzles As Per UG-45Document2 pagesE.1.1) Nozzle Neck Thickness For Cyl. Shell Nozzles As Per UG-45Rajesh KumarNo ratings yet

- En 1982 Copper and Copper Alloy Ingots and Castings - Compositions, Uses and Typical Properties-Table8Document1 pageEn 1982 Copper and Copper Alloy Ingots and Castings - Compositions, Uses and Typical Properties-Table8yw_oulalaNo ratings yet

- Design of 150kl CWRDocument16 pagesDesign of 150kl CWRMUKESH RAJENDRANo ratings yet

- Bracing - Angles - Single RowDocument2 pagesBracing - Angles - Single RowSakthivel VNo ratings yet

- FoundationEngineeringbyMd ManzurRahmanDocument38 pagesFoundationEngineeringbyMd ManzurRahmanSerafinaNo ratings yet

- CT Saturation Tolerance For 87L ApplicationsDocument26 pagesCT Saturation Tolerance For 87L ApplicationsBolivar Martinez100% (1)

- SIGUIL-VETM-F-TEC-AWWA0-001-R1 11/19/2019 - 3:27 PM Page 1 of 1 Form: FRP-AWWA-M45-R3Document1 pageSIGUIL-VETM-F-TEC-AWWA0-001-R1 11/19/2019 - 3:27 PM Page 1 of 1 Form: FRP-AWWA-M45-R3gojiNo ratings yet

- Bus-bar-Sizing-Calculation For 5000 ADocument12 pagesBus-bar-Sizing-Calculation For 5000 Aanandpurushothaman100% (1)

- Inspection and Test Plan: ACTIVITY: ITP For Material Testing of Embankment With Pond AshDocument2 pagesInspection and Test Plan: ACTIVITY: ITP For Material Testing of Embankment With Pond AshjitendraNo ratings yet

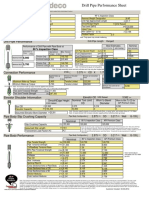

- For Additional Detail, Specifications and Charts See:: FeaturesDocument1 pageFor Additional Detail, Specifications and Charts See:: FeaturesFerhat YavasNo ratings yet

- BR305 BR310: FeaturesDocument3 pagesBR305 BR310: FeaturesnorbertoNo ratings yet

- Piping Letrolet AssessmentDocument17 pagesPiping Letrolet AssessmentmanuelNo ratings yet

- CN 05Document3 pagesCN 05GousePeerzadeNo ratings yet

- Prestressed RectDocument1 pagePrestressed Rectmahmoud IbrahemNo ratings yet

- Datasheet Diode FST RecoveryDocument9 pagesDatasheet Diode FST RecoverybkcapayaniNo ratings yet

- Connection Design As Per Bs en 1993-1-8:2005Document2 pagesConnection Design As Per Bs en 1993-1-8:2005waquarstrNo ratings yet

- Bending in Beam 2: Reinforced Concrete Design IDocument53 pagesBending in Beam 2: Reinforced Concrete Design IMongkol JirawacharadetNo ratings yet

- 3RD Floor TransDocument26 pages3RD Floor TransengineersparkconstructioncleanNo ratings yet

- Installation Information Emg Model: 707-TwDocument4 pagesInstallation Information Emg Model: 707-TwAgus MulyaNo ratings yet

- Moment ConnectionsDocument16 pagesMoment Connectionsankit kadam0% (1)

- CBR CorrelationsDocument2 pagesCBR CorrelationsStuart PenningtonNo ratings yet

- MMPDS-11 1 July 2016: Previous PageDocument18 pagesMMPDS-11 1 July 2016: Previous Pageanon_558118723No ratings yet

- SA5.0 SA180CA: FeaturesDocument5 pagesSA5.0 SA180CA: FeaturesThaynar BarbosaNo ratings yet

- Aisc 14 Edition (Asd) : 14/jan/16 SN SN 0 1Document2 pagesAisc 14 Edition (Asd) : 14/jan/16 SN SN 0 1GousePeerzadeNo ratings yet

- Drill Pipe Configuration: 80 % Inspection ClassDocument3 pagesDrill Pipe Configuration: 80 % Inspection ClassLuis Manuel García GuillénNo ratings yet

- One Way Slab - ACIDocument1 pageOne Way Slab - ACIsharanekkmNo ratings yet

- Foundation Engineering1Document7 pagesFoundation Engineering1mahmoud alawnehNo ratings yet

- Place Photo Here: Product DescriptionDocument1 pagePlace Photo Here: Product DescriptionRintheGreatNo ratings yet

- Mega Paint PDFDocument1 pageMega Paint PDFJysar ReubalNo ratings yet

- C Ring 40kL 20m 50w 10t Ohsr On PlainDocument20 pagesC Ring 40kL 20m 50w 10t Ohsr On PlainVineel Kumar BapatlaNo ratings yet

- Direct Strut and Tie Model For Single Span and Continuous Deep BeamDocument15 pagesDirect Strut and Tie Model For Single Span and Continuous Deep BeamTùng HìNo ratings yet

- Thickness CalcuationDocument6 pagesThickness CalcuationRanjan KumarNo ratings yet

- EGEN 488 FE Review MechMatls Brahma 2016Document19 pagesEGEN 488 FE Review MechMatls Brahma 2016Amarjot SinghNo ratings yet

- 13-Wire MeshDocument2 pages13-Wire MeshthowchinNo ratings yet

- Module 03 Part 1 Reinforced Concrete Design For Beams USD FlexureDocument44 pagesModule 03 Part 1 Reinforced Concrete Design For Beams USD FlexureSteph BruanNo ratings yet

- C 0 - 85 F ' C B A T A F: Reference: ACI 318-05 Reinforced Concrete Beam Design DefinitionsDocument116 pagesC 0 - 85 F ' C B A T A F: Reference: ACI 318-05 Reinforced Concrete Beam Design DefinitionsIbrahim El SharNo ratings yet

- Relay Setting Calculation For 11 KV Panel-Ecr-2 Setting Co-Ordination Chart & Graph Variables-OC Settings - 11 KV SWGR-ECR-2Document7 pagesRelay Setting Calculation For 11 KV Panel-Ecr-2 Setting Co-Ordination Chart & Graph Variables-OC Settings - 11 KV SWGR-ECR-2susovan bIswasNo ratings yet

- Artificial Mastoid - Type 4930Document6 pagesArtificial Mastoid - Type 4930kazej61No ratings yet

- Assignment CSTT 1Document21 pagesAssignment CSTT 1KHÁNH VÕ ĐĂNGNo ratings yet

- Emg - HZDocument4 pagesEmg - HZestenioNo ratings yet

- SF1/2EU-A3 RP No: D05.051: 0100101130 2,8 Male TerminalDocument1 pageSF1/2EU-A3 RP No: D05.051: 0100101130 2,8 Male TerminalEhsan PoravarNo ratings yet

- Theoretical T-Z Curves For Axially Loaded PilesDocument20 pagesTheoretical T-Z Curves For Axially Loaded PilesChaudary Azhar SaleemNo ratings yet

- Ascegm 1943-5622 0002422Document20 pagesAscegm 1943-5622 0002422Chaudary Azhar SaleemNo ratings yet

- LOM MahtabDocument2 pagesLOM MahtabChaudary Azhar SaleemNo ratings yet

- LOM OTH AmbergDocument2 pagesLOM OTH AmbergChaudary Azhar SaleemNo ratings yet

- Aja10212019 19246Document23 pagesAja10212019 19246Chaudary Azhar SaleemNo ratings yet

- Lithofacies and Petrography of Miocene Murree Formation, Peshawar Basin, NW Pakistan: Implications For Provenance and PaleoclimateDocument14 pagesLithofacies and Petrography of Miocene Murree Formation, Peshawar Basin, NW Pakistan: Implications For Provenance and PaleoclimateChaudary Azhar SaleemNo ratings yet

- Mahtab Ul HassanDocument1 pageMahtab Ul HassanChaudary Azhar SaleemNo ratings yet

- Electrical Engineering Fall-2012Document18 pagesElectrical Engineering Fall-2012Chaudary Azhar SaleemNo ratings yet

- S 2400 Hot Mix Asphalt ConcreteDocument8 pagesS 2400 Hot Mix Asphalt ConcreteChaudary Azhar SaleemNo ratings yet

- CE102-Bituminious Materials ZMDocument41 pagesCE102-Bituminious Materials ZMChaudary Azhar SaleemNo ratings yet

- Keefer 2002, Landslides Caused by Earthquakes A Historical ReviewDocument38 pagesKeefer 2002, Landslides Caused by Earthquakes A Historical ReviewJosé Quiroz OlmosNo ratings yet

- KP 130Document5 pagesKP 130Agus WahyudiNo ratings yet

- Prediction of Pore Water Pressure Generation Leading To LiquefactionDocument13 pagesPrediction of Pore Water Pressure Generation Leading To LiquefactiontasaddaqYounasNo ratings yet

- Demir 2020Document15 pagesDemir 2020ardabili100% (1)

- Camisea Opt 2005 25-02-05Document4 pagesCamisea Opt 2005 25-02-05davidmars100% (1)

- Shear Strength Degradation of Vibrated Dry SandsDocument10 pagesShear Strength Degradation of Vibrated Dry SandsSelda DurmazNo ratings yet

- The Design of Foundations For High Rise Buildings Harry Poulos PDFDocument6 pagesThe Design of Foundations For High Rise Buildings Harry Poulos PDFudadaripaddang100% (1)

- 05Document84 pages05hammouche_soufianeNo ratings yet

- An Innovative Foundation Technique For Residential Building - Case StudiesDocument6 pagesAn Innovative Foundation Technique For Residential Building - Case StudiesguruNo ratings yet

- 2008 Bray, J. D., and Sancio, R. B. Closure To - Assessment of The Liquefaction Susceptibility of Fine-Grained SoilsDocument10 pages2008 Bray, J. D., and Sancio, R. B. Closure To - Assessment of The Liquefaction Susceptibility of Fine-Grained Soilsgushiken SantosNo ratings yet

- SHA and Retrofit SlidesDocument144 pagesSHA and Retrofit SlidesJeewanNo ratings yet

- 00 Proceeding 16th ARC-2019 Content Page PDFDocument35 pages00 Proceeding 16th ARC-2019 Content Page PDFPavan HarishNo ratings yet

- Failure of Foundation Due To EarthquakeDocument20 pagesFailure of Foundation Due To EarthquakeKuldeep Kumar83% (6)

- Ap 2a-0 Report-2-1Document16 pagesAp 2a-0 Report-2-1sgecs.chennaiNo ratings yet

- Liquefation of Cohesive SoilsDocument19 pagesLiquefation of Cohesive SoilsHeberson DiasNo ratings yet

- DRR Report GasanDocument15 pagesDRR Report GasanTeddyNo ratings yet

- Liquefaction and Settlement Analysis 1Document54 pagesLiquefaction and Settlement Analysis 1Sheril Chandrabose50% (2)

- A Preliminary Report On The February 6Document28 pagesA Preliminary Report On The February 6Ouchen IbrahimNo ratings yet

- 08+Updates+to+the+Seismic+Provisions+in+ASCE+7 16+Document20 pages08+Updates+to+the+Seismic+Provisions+in+ASCE+7 16+Humberto EstevezNo ratings yet

- Effects of Soils On Ground Motion Liquefaction Group 7 SexyDocument27 pagesEffects of Soils On Ground Motion Liquefaction Group 7 Sexyduaneadriancatedrillatabor100% (1)

- Canterbury Technical Guidance IntroductionDocument15 pagesCanterbury Technical Guidance IntroductionRan WangNo ratings yet

- Balakrishnan1999 PDFDocument11 pagesBalakrishnan1999 PDFATISH KUMAR DASNo ratings yet

- Critical State Line and State Parameter of Sand-Fines MixturesDocument8 pagesCritical State Line and State Parameter of Sand-Fines MixturesJacky_LEOLEONo ratings yet

- Module 3 - Geotechengg PDFDocument22 pagesModule 3 - Geotechengg PDFDio LazatinNo ratings yet

- Seismic RisksDocument34 pagesSeismic RisksFlorentina SuduNo ratings yet

- Peck 1969 Observational Method Advantages and LimitationsDocument17 pagesPeck 1969 Observational Method Advantages and LimitationsIyata Rogers100% (1)

- Active Fault Mapping and Modeling in Bangladesh - 2009Document72 pagesActive Fault Mapping and Modeling in Bangladesh - 2009CDMP Bangladesh100% (1)

- Hazard Risk Vulnerability and Risk AssessmentDocument22 pagesHazard Risk Vulnerability and Risk AssessmentAnanya SinghNo ratings yet

- Gorkha EarthquakeDocument18 pagesGorkha EarthquakeSandip BudhathokiNo ratings yet

- Arthur CasagrandeDocument8 pagesArthur CasagrandeSean James Celeste CaangayNo ratings yet