100% found this document useful (1 vote)

305 views2 pagesRCA Sample

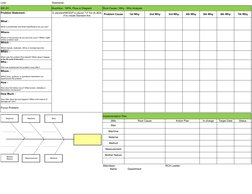

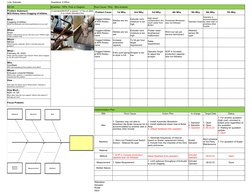

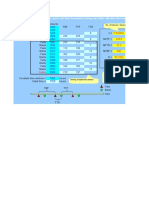

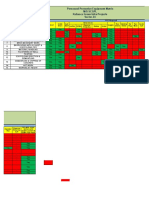

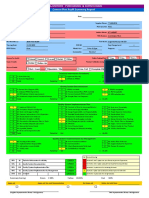

Operator was not able to blowdown the Boiler because he is accommodated by other tasks or priorities. This led to high steam condensation and moisture in the extruder output. The root causes were identified as lack of proper scheduling of blowdown, high steam condensation due to too much water from the boiler, and the operator forgetting to prioritize this task.

The implementation plan involves installing an automatic blowdown system for the boiler and additional steam traps to control condensation, as well as ensuring operators properly prioritize scheduled maintenance. Salvador is assigned to oversee the implementation with a target completion date of February 25, 2023.

Uploaded by

edward tagarinoCopyright

© © All Rights Reserved

We take content rights seriously. If you suspect this is your content, claim it here.

Available Formats

Download as XLSX, PDF, TXT or read online on Scribd

100% found this document useful (1 vote)

305 views2 pagesRCA Sample

Operator was not able to blowdown the Boiler because he is accommodated by other tasks or priorities. This led to high steam condensation and moisture in the extruder output. The root causes were identified as lack of proper scheduling of blowdown, high steam condensation due to too much water from the boiler, and the operator forgetting to prioritize this task.

The implementation plan involves installing an automatic blowdown system for the boiler and additional steam traps to control condensation, as well as ensuring operators properly prioritize scheduled maintenance. Salvador is assigned to oversee the implementation with a target completion date of February 25, 2023.

Uploaded by

edward tagarinoCopyright

© © All Rights Reserved

We take content rights seriously. If you suspect this is your content, claim it here.

Available Formats

Download as XLSX, PDF, TXT or read online on Scribd

- Problem Solving Template

- Example Problem Analysis