Professional Documents

Culture Documents

Pipe Network Flow Analysis

Uploaded by

NaqibullahSediqi0 ratings0% found this document useful (0 votes)

6 views16 pagesThe document discusses hydraulics topics including pipe networks and the Hardy-Cross method. It provides an example application of the Hardy-Cross method to solve for flows in a pipe network. The method involves iteratively calculating flow corrections until the solution converges. Key steps are defining pipe directions, assigning initial flows, calculating flow correction terms, and iterating until corrections are negligible. The example shows tabulated results from multiple iterations as it solves for steady state flows in the given pipe network.

Original Description:

Original Title

5 Hydraulics of Eng Lecture, Fall Semester

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentThe document discusses hydraulics topics including pipe networks and the Hardy-Cross method. It provides an example application of the Hardy-Cross method to solve for flows in a pipe network. The method involves iteratively calculating flow corrections until the solution converges. Key steps are defining pipe directions, assigning initial flows, calculating flow correction terms, and iterating until corrections are negligible. The example shows tabulated results from multiple iterations as it solves for steady state flows in the given pipe network.

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

6 views16 pagesPipe Network Flow Analysis

Uploaded by

NaqibullahSediqiThe document discusses hydraulics topics including pipe networks and the Hardy-Cross method. It provides an example application of the Hardy-Cross method to solve for flows in a pipe network. The method involves iteratively calculating flow corrections until the solution converges. Key steps are defining pipe directions, assigning initial flows, calculating flow correction terms, and iterating until corrections are negligible. The example shows tabulated results from multiple iterations as it solves for steady state flows in the given pipe network.

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You are on page 1of 16

CE (353)

Hydraulics of Engineering

Fall Semester, 2022

Naqibullah Sediqi

Sediqi.naqib2020@gmail.com

11/6/2022 ENGINEERING FACULTY OF KABUL UNIVERSITY 1

CE (353)

Hydraulics of Engineering

October 2022

Chapter 4

Pipelines and Pipe Networks

Agenda/Topics:

• Four Reservoir Analysis

• Pipe Networks

- The Hardy–Cross Method

11/6/2022 ENGINEERING FACULTY OF KABUL UNIVERSITY 2

Example 4.7

A horizontal, galvanized iron pipe system consists of a 10-in-diameter, 12-ft-long main

pipe between the two junctions 1 and 2, as depicted in Figure 4.6. A gate valve is

installed at the downstream end immediately before junction 2. The branch pipe has

a 6-in. diameter and is 20ft long. It consists of two 90° elbows (R/D = 2.0) and a globe

valve. The system carries a total discharge of 10cfs of water at 40°F. Determine the

discharge in each of the pipes when the valves are both fully opened. (Note that, due

to the different local losses along the two branches, the equivalent pipe formulas

derived in Chapter 3 cannot be used in this example.)

11/6/2022 ENGINEERING FACULTY OF KABUL UNIVERSITY 3

Solution

Again find f value for new relative roughness and Reynolds number

11/6/2022 ENGINEERING FACULTY OF KABUL UNIVERSITY 4

Four Reservoir Analysis

11/6/2022 ENGINEERING FACULTY OF KABUL UNIVERSITY 5

4.4 Pipe Networks

Water-supply distribution systems in municipal districts are usually composed

of a large number of pipes interconnected to form loops and branches.

Although the calculations of flow in a pipe network involve a large number of pipes

and may become tedious, the solution scenario is based on the same principles that

govern flow in pipelines and branching pipes previously discussed.

In general, a series of simultaneous equations can be written for the network. These

equations are written to satisfy the following conditions:

11/6/2022 ENGINEERING FACULTY OF KABUL UNIVERSITY 6

4.4 Pipe Networks

1. At any junction, ΣQ = 0 based on the conservation of mass (junction equation).

2. Between any two junctions, the total head loss is independent of the path taken

based on the conservation of energy (loop equation).

As a general rule, a network with m loops and n

junctions provides a total of m + (n - 1) independent

equations.

11/6/2022 ENGINEERING FACULTY OF KABUL UNIVERSITY 7

4.4.1 The Hardy–Cross Method

• Is used for more complex water systems than the Nodal Method

• Requires an initial flow rate guess and many iterative to balance flows

and compute resulting head-losses

- By hand (very time consuming)

- By spreadsheet (takes some time to set up- but iterations are easy)

- By computer (integrated into design package: powerful, but takes

time to learn the software)

- The “Hardy Cross Method” is the basis for today’s hydraulic design

packages: it ensures energy ‘balance’ for each rout the water can take

11/6/2022 ENGINEERING FACULTY OF KABUL UNIVERSITY 8

4.4.1 The Hardy–Cross Method

• Assumes that head loss, ℎ𝐿 , in each pipe is proportional to the discharge, Q, raised to

some power n (for Darcy-Weibach, n= 2)

• You must calculate K for every pipe in the system

• Different formulas for K depending on (1) which head loss equation is used, and (2)

type of head losses

- If all head losses are due to friction (that’s what we’ll usually assume), then

K=

11/6/2022 ENGINEERING FACULTY OF KABUL UNIVERSITY 9

Calculating K: Example

400 L/s is flowing through a 750-mm concrete (e= 1.6mm) pipe segment that is 85m

long.

- Find K

K=

11/6/2022 ENGINEERING FACULTY OF KABUL UNIVERSITY 10

Hardy-Cross Procedure

1. How many loops are there?

2. What is n?

3. Define direction (Assumption clockwise is (+) and counterclockwise is (-)

4. Label pipe and loops

5. Assign “guess” flow rates

6. Find K for all pipes

7. Find KQ|Q| and nk|Q| for every pipe in a loop

8. Sum KQ|Q| and nk|Q| for each loop (sum them per loop, not all loops) 𝐾𝑄|𝑄|

∆𝑄 = −

9. Find ∆𝑄 for each loop 𝑛𝐾|𝑄|

10. Apply correction factor to each pipe in the loop

11/6/2022 ENGINEERING FACULTY OF KABUL UNIVERSITY 11

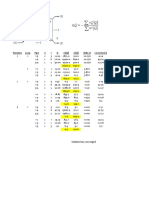

Hardy-Cross Example

Find flow in each given pipes with

known K or r values

𝐾𝑄|𝑄|

∆𝑄 = −

𝑛𝐾|𝑄|

11/6/2022 ENGINEERING FACULTY OF KABUL UNIVERSITY 12

Hardy-Cross Example

Iteration loop Pipe n r Q rQ|Q| nr|Q| Delta Q Corrected Q

1 1 1-3 2 3 25 1875 150 -20.7558 4.24

1-4 2 6 70 29400 840 -20.7558 49.24

3-4 2 5 -30 -4500 300 -20.7558 -50.76

26775 1290

2 1-2 2 1 25 625 50 3.87 28.87

2-3 2 2 -25 -1250 100 3.87 -21.13

1-3 2 3 -4.24 -54.0 25.5 3.87 -0.37

-679.0 175.5

2 1 1-3 2 3 0.37 0.4 2.2 -1.5168 -1.14

1-4 2 6 49.24 14549.9 590.9 -1.5168 47.73

3-4 2 5 -50.76 -12880.8 507.6 -1.5168 -52.27

1669.6 1100.7

2 1-2 2 1 28.87 833.5 57.7 0.37 29.24

2-3 2 2 -21.13 -893.0 84.5 0.37 -20.76

1-3 2 3 1.14 3.9 6.9 0.37 1.52

-55.6 149.1

11/6/2022 ENGINEERING FACULTY OF KABUL UNIVERSITY 13

3 1 1-3 2 3 1.52 6.9 9.1 -0.011 1.504

1-4 2 6 47.73 13667.4 572.7 -0.011 47.716

3-4 2 5 -52.27 -13662.1 522.7 -0.011 -52.284

12.2 1104.5

2 1-2 2 1 29.24 855.1 58.5 0.09 29.33

2-3 2 2 -20.76 -861.7 83.0 0.09 -20.67

1-3 2 3 -1.52 -6.9 9.1 0.09 -1.43

-13.5 150.6

4 1 1-3 2 3 -1.504 -6.8 9.0 0.012291 -1.492

1-4 2 6 47.716 13661.1 572.6 0.012291 47.729

3-4 2 5 -52.284 -13667.9 522.8 0.012291 -52.271

-13.6 1104.5

2 1-2 2 1 29.332 860.4 58.7 -0.08 29.247

2-3 2 2 -20.668 -854.3 82.7 -0.08 -20.753

1-3 2 3 1.492 6.7 9.0 -0.08 1.407

12.7 150.3

11/6/2022 ENGINEERING FACULTY OF KABUL UNIVERSITY 14

5 1 1-3 2 3 1.492 6.7 9.0 -0.012 1.480 -0.81712

1-4 2 6 47.729 13668.1 572.7 -0.012 47.717 -0.02534

3-4 2 5 -52.271 -13661.5 522.7 -0.012 -52.283 0.023127

13.4 1104.4

2 1-2 2 1 29.247 855.4 58.5 0.083 29.331 0.283281

2-3 2 2 -20.753 -861.3 83.0 0.083 -20.669 -0.40198

1-3 2 3 -1.480 -6.6 8.9 0.083 -1.397 -5.94877

-12.5 150.4

Corrected Q Percentage of correction Q

1 1-3 1.480 -0.81712

1-4 47.717 -0.02534

3-4 -52.283 0.023127

2 1-2 29.331 0.283281

2-3 -20.669 -0.40198

1-3 -1.397 -5.94877

11/6/2022 ENGINEERING FACULTY OF KABUL UNIVERSITY 15

Thanks!

11/6/2022 ENGINEERING FACULTY OF KABUL UNIVERSITY 16

You might also like

- Part A: Piping and Instrumentation DiagramDocument33 pagesPart A: Piping and Instrumentation Diagramwavhal maheshNo ratings yet

- Pipe Wall ThicknessDocument2 pagesPipe Wall ThicknessTomi Kazuo0% (1)

- PIPE SCHEDULE CHART STEEL PIPESDocument1 pagePIPE SCHEDULE CHART STEEL PIPESvijaykmj100% (1)

- Table 5 Equal Size Conductor CablesDocument1 pageTable 5 Equal Size Conductor CablesMURALINo ratings yet

- Steel Pipes - Pipe Schedule ChartDocument1 pageSteel Pipes - Pipe Schedule ChartsusantoNo ratings yet

- Steel Piping System A106Document1 pageSteel Piping System A106NoorudheenEVNo ratings yet

- PSS®E Power Flow Analysis IEEE 14-Bus Test System Dr. Frank Mercede, P.E. Mercedes Electric CompanyDocument6 pagesPSS®E Power Flow Analysis IEEE 14-Bus Test System Dr. Frank Mercede, P.E. Mercedes Electric CompanyJustin James0% (1)

- Lab Report 3Document15 pagesLab Report 3aidoo3045No ratings yet

- No Sampel Berat Wajan Agregat Kadar AspalDocument24 pagesNo Sampel Berat Wajan Agregat Kadar AspalFauziNo ratings yet

- Pipe Wall Thickness ChartDocument1 pagePipe Wall Thickness ChartVishal MistryNo ratings yet

- Bridge Plug WLTC Retrievable Bridge Plug InfoDocument1 pageBridge Plug WLTC Retrievable Bridge Plug InfoJohnNo ratings yet

- Steel Pipe Schedule Chart with OD and Wall Thickness DimensionsDocument1 pageSteel Pipe Schedule Chart with OD and Wall Thickness DimensionsJoydev GangulyNo ratings yet

- RQQ Q NRQ: 1 Loop 2Document1 pageRQQ Q NRQ: 1 Loop 2Miko AbiNo ratings yet

- D1051191072 - Wira Anggara - Tugas 1 HLDocument2 pagesD1051191072 - Wira Anggara - Tugas 1 HLGunawan DemianNo ratings yet

- Lesson Plan Calculus-ADocument3 pagesLesson Plan Calculus-AAryan aNo ratings yet

- Experiment 2: Laminar and Turbulent Flow: American University of Beirut MECH 410L-Thermal and Fluid System LabDocument9 pagesExperiment 2: Laminar and Turbulent Flow: American University of Beirut MECH 410L-Thermal and Fluid System LabAhmad El HajNo ratings yet

- Al Imam Akbar UTS at HomeDocument6 pagesAl Imam Akbar UTS at HomeDaniel Sevala 1407112344No ratings yet

- Stability Drawing - AccacochaDocument8 pagesStability Drawing - AccacochaRonald EscalanteNo ratings yet

- Blog Projectmaterials Com Pipes Pipe Size Chart Asme b36 10Document18 pagesBlog Projectmaterials Com Pipes Pipe Size Chart Asme b36 10Alberto DiazNo ratings yet

- V Notch ReportDocument8 pagesV Notch ReportMwiti TizianoNo ratings yet

- Example Problem: Unit HydrographDocument6 pagesExample Problem: Unit HydrographMen Keo RathaNo ratings yet

- Resistivity and IPDocument8 pagesResistivity and IPShoron SheikhNo ratings yet

- STEEL PIPE SCHEDULE CHARTDocument2 pagesSTEEL PIPE SCHEDULE CHARTSonaliNo ratings yet

- Tutorial Routing QnsDocument6 pagesTutorial Routing QnsAryamaan SinghNo ratings yet

- Experiment No: 1 Earthquake Analysis Date:: Structural Engineering Lab-IiDocument7 pagesExperiment No: 1 Earthquake Analysis Date:: Structural Engineering Lab-IiAswathy M NNo ratings yet

- Comsats University Islamabad Lab Report#2 Applied Physics For EngineersDocument4 pagesComsats University Islamabad Lab Report#2 Applied Physics For EngineersAli DurraniNo ratings yet

- Steel Pipes - Pipe Schedule Chart: LR Elbow 1.5 X 25.4 X Size X Tan (Angle/2) SR Elbow 25.4 X Size X Tan (Angle/2)Document1 pageSteel Pipes - Pipe Schedule Chart: LR Elbow 1.5 X 25.4 X Size X Tan (Angle/2) SR Elbow 25.4 X Size X Tan (Angle/2)mohamed salahNo ratings yet

- MTH 1001: Calculus-I Required Course TextbooksDocument2 pagesMTH 1001: Calculus-I Required Course TextbooksSunil Kumar PradhanNo ratings yet

- Final Exam: DISC 333 (Part 2Document11 pagesFinal Exam: DISC 333 (Part 2Ahsan IshtiaqNo ratings yet

- Rate Analysis For 1CUM ConcreteDocument7 pagesRate Analysis For 1CUM ConcreteHitesh JaniNo ratings yet

- Al Imam Akbar UTS at HomeDocument6 pagesAl Imam Akbar UTS at HomeDaniel Sevala 1407112344No ratings yet

- 10 Ho7v-KDocument2 pages10 Ho7v-KProEnergy solarNo ratings yet

- Batch14 Contact2 OM Assign39Document4 pagesBatch14 Contact2 OM Assign39pranjal92pandeyNo ratings yet

- Kalkulator HDD 1Document2 pagesKalkulator HDD 1Yosua BanjarnahorNo ratings yet

- Appendix A1 Data For The IEEE 10-Bus Distribution Test SystemDocument14 pagesAppendix A1 Data For The IEEE 10-Bus Distribution Test SystemSunil MåüřÿäNo ratings yet

- 3-Phase Short-Circuit Current (Isc) at Any Point Within A LV Installation - Electrical Installation GuideDocument5 pages3-Phase Short-Circuit Current (Isc) at Any Point Within A LV Installation - Electrical Installation Guidesiddiq shahNo ratings yet

- Kazakh-British Technical University Advanced Well Testing ExamDocument10 pagesKazakh-British Technical University Advanced Well Testing ExamNana TwumNo ratings yet

- Hardy Cross para Tuberia: C Hierro GalvanizadoDocument26 pagesHardy Cross para Tuberia: C Hierro Galvanizadohugo_1990No ratings yet

- FDN DesignDocument27 pagesFDN DesignZerihun IbrahimNo ratings yet

- Lab Report: Course Name: Electrical Circuit (LAB) Course Code: CSE-133Document4 pagesLab Report: Course Name: Electrical Circuit (LAB) Course Code: CSE-133Tarif Al MozahedNo ratings yet

- Electrical and Electronic Engineering Project on Solar PV System SimulationDocument18 pagesElectrical and Electronic Engineering Project on Solar PV System SimulationABU SHADAD MOHAMMAD SAYEMNo ratings yet

- Nec430 150-148Document2 pagesNec430 150-148Jonathan VillorenteNo ratings yet

- University of The East - Manila College of Engineering Civil Engineering DepartmentDocument3 pagesUniversity of The East - Manila College of Engineering Civil Engineering DepartmentRUBYJAY GALISIMNo ratings yet

- Rail stress calculation methodology document summaryDocument13 pagesRail stress calculation methodology document summaryGuha ArnabNo ratings yet

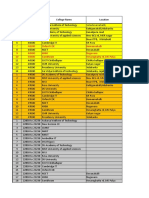

- Colleges DataDocument15 pagesColleges DataRif RizNo ratings yet

- Sharp crested weir calibrationDocument11 pagesSharp crested weir calibrationYashpal SuwansiaNo ratings yet

- Pipe Schedule DimensionsDocument1 pagePipe Schedule DimensionsSuresh SjNo ratings yet

- Optimization Potential in Indian Railways - Rajnish KumarDocument57 pagesOptimization Potential in Indian Railways - Rajnish KumarRajnish KumarNo ratings yet

- Assignment II Numerical Analysis ENEC20003 Term 1 2020: Full Name Student ID Date of Submission MarkDocument4 pagesAssignment II Numerical Analysis ENEC20003 Term 1 2020: Full Name Student ID Date of Submission MarkImranNo ratings yet

- Pipe Schedule ChartDocument1 pagePipe Schedule ChartrohimNo ratings yet

- Appendix 2010 Piping and Pipeline Calculations ManualDocument74 pagesAppendix 2010 Piping and Pipeline Calculations ManualjunhyolNo ratings yet

- 252V Specification SheetDocument1 page252V Specification SheetLin LinNo ratings yet

- Evaluation of Dislocated PileDocument17 pagesEvaluation of Dislocated PileKhandaker Khairul AlamNo ratings yet

- Compact Semi-hermetic Piston Compressor Technical SpecsDocument9 pagesCompact Semi-hermetic Piston Compressor Technical Specsroby72No ratings yet

- Experimental Analysis of Mono-stable and Astable Multivibrator CircuitsDocument8 pagesExperimental Analysis of Mono-stable and Astable Multivibrator CircuitsATHARVA BHAWSARNo ratings yet

- Products That Perform...By People Who CareDocument16 pagesProducts That Perform...By People Who CareFalak KhanNo ratings yet

- Project.1: Solved by .. Ahmed Saad Abd Elhamid Level 3Document10 pagesProject.1: Solved by .. Ahmed Saad Abd Elhamid Level 3mahmoud EissaNo ratings yet

- Exception HandlingDocument50 pagesException HandlingKshitiz ChoudharyNo ratings yet

- Continuity Notions for Multi-Valued Mappings with Disconnected ImagesDocument18 pagesContinuity Notions for Multi-Valued Mappings with Disconnected Imagesami_marNo ratings yet

- SPC 3rd Edition EnglishDocument233 pagesSPC 3rd Edition Englishdhillon63No ratings yet

- Dimensional AnalysisDocument3 pagesDimensional AnalysisDeepakrao Bornare PatilNo ratings yet

- MIMO Channel Model Matrix EquationDocument1 pageMIMO Channel Model Matrix EquationBhagya ShreeNo ratings yet

- Consistent inflow turbulence generator for LES evaluation of wind-induced responses for tall buildingsDocument19 pagesConsistent inflow turbulence generator for LES evaluation of wind-induced responses for tall buildingsHaitham AboshoshaNo ratings yet

- 7th AB Maths Question PaperDocument2 pages7th AB Maths Question PaperYrcu YvjrlyNo ratings yet

- 1201C B.P.S. XII Physics Chapterwise Advanced Study Material 2015 17 PDFDocument463 pages1201C B.P.S. XII Physics Chapterwise Advanced Study Material 2015 17 PDFRizwan SalimNo ratings yet

- Continuous Genetic Algorithm ExplainedDocument29 pagesContinuous Genetic Algorithm ExplainedChris BarreraNo ratings yet

- ALAMAR LabExercise5Document6 pagesALAMAR LabExercise5Clarissa AlfaroNo ratings yet

- Dynamics of MachineDocument24 pagesDynamics of Machinesara vanaNo ratings yet

- Fluent Chp07-Defining Physical PropertiesDocument74 pagesFluent Chp07-Defining Physical PropertiesPiyush SandujaNo ratings yet

- Drying Shrinkage of Concrete With Blended Cementitious Binders: Experimental Study and Application of ModelsDocument18 pagesDrying Shrinkage of Concrete With Blended Cementitious Binders: Experimental Study and Application of ModelsNM2104TE06 PRATHURI SUMANTHNo ratings yet

- 21 MAT41 Set 1Document8 pages21 MAT41 Set 1Sushant KNo ratings yet

- Evaluation of H ParametersDocument5 pagesEvaluation of H Parameterssarath1993No ratings yet

- Icse Class 9 Maths Sample Paper PDFDocument2 pagesIcse Class 9 Maths Sample Paper PDFKausik DewanNo ratings yet

- Asbio ManualDocument145 pagesAsbio ManualAbhijit DasNo ratings yet

- Design Aids-2015Document106 pagesDesign Aids-2015weynNo ratings yet

- 2nd Year Subjects and SyllabusDocument18 pages2nd Year Subjects and SyllabusAakash ChoudharyNo ratings yet

- Assignment 1Document7 pagesAssignment 1robert_tanNo ratings yet

- Density Practice ProblemsDocument4 pagesDensity Practice ProblemsqueenjoseNo ratings yet

- Randomized Block DesignDocument8 pagesRandomized Block DesignDhona أزلف AquilaniNo ratings yet

- Unit - 2: Code Tuning TechniquesDocument15 pagesUnit - 2: Code Tuning TechniquesRISHIRAJ CHANDANo ratings yet

- Infix To PostfixDocument27 pagesInfix To PostfixbrainyhamzaNo ratings yet

- Data CleaningDocument16 pagesData CleaningriyaNo ratings yet

- Revision WorksheetDocument5 pagesRevision Worksheethashirkk85No ratings yet

- PythonTutorial MCSC 202Document39 pagesPythonTutorial MCSC 202BinoNo ratings yet

- Caesar Cipher and Modulo Encryption ExplainedDocument21 pagesCaesar Cipher and Modulo Encryption ExplainedKhalil AhmedNo ratings yet

- Spring 2014 Geometry Review Packet QuestionsDocument13 pagesSpring 2014 Geometry Review Packet Questionsapi-195266051No ratings yet

- Twisting Momentsin Two-Way SlabsDocument6 pagesTwisting Momentsin Two-Way SlabsProfessor Dr. Nabeel Al-Bayati-Consultant Engineer100% (2)