Professional Documents

Culture Documents

Practical No 10 Satyam Yadav

Uploaded by

Brijesh Ukey0 ratings0% found this document useful (0 votes)

4 views3 pagesOriginal Title

practical no 10 satyam yadav

Copyright

© © All Rights Reserved

Available Formats

DOCX, PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as DOCX, PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

4 views3 pagesPractical No 10 Satyam Yadav

Uploaded by

Brijesh UkeyCopyright:

© All Rights Reserved

Available Formats

Download as DOCX, PDF, TXT or read online from Scribd

You are on page 1of 3

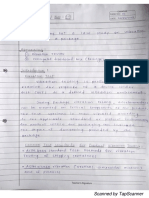

Practical No: - 10

Aim: - Conduct folding endurance of paper.

Apparatus:-Folding endurance tester.

Folding endurance of paper: Folding endurance of paper is defined log10 the

number of double folds required. To break paper sample under standardized

condition of load applied. F= 10910 N

Where F is the folding endurance and N the number of double folds folding

endurance is especially applicable. For papers used for maps, bank notes, archival

document etc.

Affecting factors: - (1) the direction of the fibers in relation to the folding. (2) The

type of fibers used (length, diameter) (3) the filler percentage. (4) The thickness the

paper. Degree of refining of fibers used in pulp slurry for paper making.

Significance:- The folding endurance test measure a combination of tensile

Strength Stretch and torque properties this test is also useful four measure the

duration of paper upon again as it is Sensitive to changes. Before there is which a

change prow & up with long before there is change tensile burst Resistance =

slight measure in relative humidity Cause a marked measure in the folding

endurance this copied with the extremely small area faced result m wide variation

for individual sample measure of this variability, folding endurance is not often

used as a specification unless a tolerance of at least 20% is allowed for high grade

paper and 30% of extraordinary paper.

Test Specimens: - Specimen to be tacked shall be cut accident. In each principal

direction of a paper with a width of 10cm (4in) and at least 10cm length long they

shall be initially free from folds wrinkle or blemished not inherent m the paper, and

the area where the takes place shall not contain. Any portion of a watermark the

edges of the Specimen must be lean at a parallel the Specimen shall be so selected

from the sample Standard by the sampling method as to be representative of the

Sample lest to specimens cut form each principal direction of the paper.

Conditioning:-Condition and test the paper in an atmosphere in accordance with

TAPPI T 402 "Standard Conditioning and Testing Atmospheres for Paper, Board,

Pulp Hand sheets and Related Products"

Procedure: -

1. Test sample strips of size 1.5cm width and 20 cm (enough to be clamped in

upper and. lower jaw) length should be taken

2. First press the upper clamp to compress the spring with the help of load as

we have to apply tension 1kgf or 9.8 n sample strips.

3. The fix the sample strip in both upper and lower jaws so that it should be

fight without any slackness and distortion.

4. Now, release the load applied and supplies the on top of upper jaw on camp

so the spring will expand and apply the tension of 9.8 № in paper sample

strip.

5. We can fix two samples, one in loft side Assembly of clamps and one

Assembly of clamps.

6. The samples of paper are taken from MD and Co direction of paper, so first

cut sample trip length wise and then width wise of paper sample given

7. 7. Fix both the samples in left and right set Assembly of clamps.

8. Fix the reading at o at start of folding operation.

9. Now start motor by switching on both simultaneously.

10.The counter will start counting the double. Fold in left and right display

white.

11. AL the break point counter will stop. So note down the readings of both

side.

12.. This will give number of double folds. And using the calculation in given

above formula. Find the values of folding endurance.

13. Three reading should be taken fall every samples and average should be

calculated.

Calculation: -

Observations: - Folding endurance to machine direction or grain direction is

greater than the cross direction of paper.

Result: - we have studied about folding endurance test of paper and paper board

and calculate and folding endurance to machine and cross direction of paper.

You might also like

- Scope: Provisional Method - 1994 © 1984 TAPPIDocument3 pagesScope: Provisional Method - 1994 © 1984 TAPPIМаркус СилваNo ratings yet

- Tearing Resistance of PaperDocument13 pagesTearing Resistance of PaperkakakhmmNo ratings yet

- Exercrse: Triaxia1 Shear ofDocument7 pagesExercrse: Triaxia1 Shear ofTantanNo ratings yet

- Determination of Elmendorf Tearing Resistance: Product Testing Apparatus Product Testing ApparatusDocument3 pagesDetermination of Elmendorf Tearing Resistance: Product Testing Apparatus Product Testing Apparatusjrlr65No ratings yet

- T220 Testing HandsheetsDocument6 pagesT220 Testing HandsheetsMark VicsonNo ratings yet

- Tensile Strength, Breaking Length, Tensile Index, Stretch, Tensile Energy Absorption, and Tensile StiffnessDocument24 pagesTensile Strength, Breaking Length, Tensile Index, Stretch, Tensile Energy Absorption, and Tensile StiffnessWudassie AyeleNo ratings yet

- Tensile Strength, Breaking Length, Tensile Index, Stretch, Tensile Energy Absorption, and Tensile StiffnessDocument22 pagesTensile Strength, Breaking Length, Tensile Index, Stretch, Tensile Energy Absorption, and Tensile StiffnessSujanto WidjajaNo ratings yet

- Elongation TestDocument14 pagesElongation TestAinil Hawa MusaNo ratings yet

- TTM SolvedDocument3 pagesTTM SolvedJoy GoswamiNo ratings yet

- Test 09Document6 pagesTest 09Ateafac Anastasia NjuafacNo ratings yet

- Testing of BOPET, BOPP, Metallized Jumbo SamplesDocument11 pagesTesting of BOPET, BOPP, Metallized Jumbo SamplesNaman JainNo ratings yet

- Triaxial Test: Xzdetermination of Shear Parameters by Triaxail TestDocument8 pagesTriaxial Test: Xzdetermination of Shear Parameters by Triaxail TestTenzinKesangNo ratings yet

- Testing Pet Jumbo Film SampleDocument3 pagesTesting Pet Jumbo Film SampleNaman Jain100% (1)

- Splitting Tensile Strength of Cylindrical Concrete Specimens DetailedDocument4 pagesSplitting Tensile Strength of Cylindrical Concrete Specimens DetailedYasirNo ratings yet

- Triaxial TestDocument4 pagesTriaxial TestLaxmikant KadamNo ratings yet

- Strength of Materia Lab Manual UET, LahoreDocument14 pagesStrength of Materia Lab Manual UET, LahoreRizwan Khurram100% (3)

- Lab ManualDocument24 pagesLab Manualzenjoy57No ratings yet

- Unconfined Compression TestDocument2 pagesUnconfined Compression TestMohamed FarahNo ratings yet

- Concrete TestingDocument1 pageConcrete TestingNadia IzzatiNo ratings yet

- Tri Axial TestDocument10 pagesTri Axial TestAskart Nano Crime-artNo ratings yet

- Test Method of Multipack: 1. ConditioningDocument9 pagesTest Method of Multipack: 1. ConditioningHoai thu NguyenNo ratings yet

- Folding Endurance of Paper by The Schopper Tester: Standard Test Method ForDocument6 pagesFolding Endurance of Paper by The Schopper Tester: Standard Test Method Forjamaljamal20No ratings yet

- Fabric Stiffness Testing Determination of Fabric Stiffness by Shirley Stiffness TesterDocument4 pagesFabric Stiffness Testing Determination of Fabric Stiffness by Shirley Stiffness TesterRajesh DwivediNo ratings yet

- KD - KC 2022 - G6 Criteria B and C Lab Report TemplateDocument9 pagesKD - KC 2022 - G6 Criteria B and C Lab Report Templateyouyoonseo04880No ratings yet

- Field Work 2Document12 pagesField Work 2Paulo Remulla50% (2)

- 3 (D) Workability of Concrete - Flow Table TestDocument11 pages3 (D) Workability of Concrete - Flow Table TestFrank JohnNo ratings yet

- Outline: Mechanical Properties of Textile FibersDocument13 pagesOutline: Mechanical Properties of Textile FibersTamanna TasnimNo ratings yet

- Thickness (Caliper) of Towel, Tissue, Napkin and Facial Products (Proposed New Provisional Method)Document0 pagesThickness (Caliper) of Towel, Tissue, Napkin and Facial Products (Proposed New Provisional Method)andy981No ratings yet

- Product Analysis & Development: Final Submission Sleeveless Shirt With CapDocument31 pagesProduct Analysis & Development: Final Submission Sleeveless Shirt With CapRAVIKANT DEONo ratings yet

- Unconfined Compression TestDocument4 pagesUnconfined Compression TestRajat KotwalNo ratings yet

- F 119 - 82 R98 - Rjexos04mli5oaDocument3 pagesF 119 - 82 R98 - Rjexos04mli5oajamaljamal20No ratings yet

- Testing PaperDocument5 pagesTesting PaperSariyyaHeydarovaNo ratings yet

- Bending Stiffness of FiberboardDocument6 pagesBending Stiffness of FiberboardBobKatNo ratings yet

- School Base Assessment-1Document48 pagesSchool Base Assessment-1Marissa FreemanNo ratings yet

- T404Document5 pagesT404yavkoyNo ratings yet

- SM Lab ManualsDocument27 pagesSM Lab ManualspraveenampilliNo ratings yet

- 5.tension Test FinalDocument7 pages5.tension Test FinalFausto Da GamaNo ratings yet

- Correct Sampling Methods and Regular SamplingDocument18 pagesCorrect Sampling Methods and Regular Samplingfanelenzima03No ratings yet

- WPR NipandcrownDocument18 pagesWPR NipandcrownronaldsacsNo ratings yet

- Experiment5 8Document5 pagesExperiment5 8Aneesha PandaNo ratings yet

- Abrasion, Pilling, PH, Tear, Tensile, Crease Recovery: M.Muslim Umair BS (H) App - Chemistry 8 Semester (Evening)Document5 pagesAbrasion, Pilling, PH, Tear, Tensile, Crease Recovery: M.Muslim Umair BS (H) App - Chemistry 8 Semester (Evening)Muslim Umair ButtNo ratings yet

- Ap Physics Lab 3 2Document4 pagesAp Physics Lab 3 2api-305227476No ratings yet

- IPC-TM-650 Test Methods ManualDocument3 pagesIPC-TM-650 Test Methods ManualRoman MiahNo ratings yet

- Fabric Stiffness TestingDocument13 pagesFabric Stiffness TestingFahima RashidNo ratings yet

- Laboratory Test and Preparation of Report Use of EquipmentDocument16 pagesLaboratory Test and Preparation of Report Use of Equipmentlsatchithananthan100% (1)

- Testing For Knitted FabricDocument11 pagesTesting For Knitted FabricRAVIKANT DEONo ratings yet

- Som ExperimentsDocument17 pagesSom ExperimentsAnudeex ShettyNo ratings yet

- Direct Shear TestDocument11 pagesDirect Shear Testshahrolhazrien91% (34)

- Tahapan Peel TestDocument6 pagesTahapan Peel TestricardoNo ratings yet

- Bending StiffnessDocument6 pagesBending StiffnessMark Samsel RohanNo ratings yet

- 54 Bending StiffnessDocument17 pages54 Bending StiffnessRavi KhandelwalNo ratings yet

- Tuft Height of Pile Floor Coverings: Standard Test Method ForDocument5 pagesTuft Height of Pile Floor Coverings: Standard Test Method ForJuanNo ratings yet

- Direct Shear TestDocument4 pagesDirect Shear TestBuğra -No ratings yet

- Unconfined Compression TestDocument8 pagesUnconfined Compression TestMohdIkrami100% (1)

- Tensile Test of SteelDocument7 pagesTensile Test of Steelcristina23No ratings yet

- SamplingDocument16 pagesSamplingbradburywillsNo ratings yet

- Machine Direction of Paper and Paperboard: Standard Test Method ForDocument2 pagesMachine Direction of Paper and Paperboard: Standard Test Method ForALFONSO_08No ratings yet

- ObjectiveDocument3 pagesObjectiveEmdadul Hoque PollobNo ratings yet

- Building Material Estimates and Rates Build Up: Second EditionFrom EverandBuilding Material Estimates and Rates Build Up: Second EditionNo ratings yet

- Theory of Silk Weaving A Treatise on the Construction and Application of Weaves, and the Decomposition and Calculation of Broad and Narrow, Plain, Novelty and Jacquard Silk FabricsFrom EverandTheory of Silk Weaving A Treatise on the Construction and Application of Weaves, and the Decomposition and Calculation of Broad and Narrow, Plain, Novelty and Jacquard Silk FabricsRating: 5 out of 5 stars5/5 (1)

- Satyam Gopichand YadavDocument3 pagesSatyam Gopichand YadavBrijesh UkeyNo ratings yet

- PR 06 (PK407E)Document11 pagesPR 06 (PK407E)Brijesh UkeyNo ratings yet

- Practical No 10 Satyam YadavDocument3 pagesPractical No 10 Satyam YadavBrijesh UkeyNo ratings yet

- PR 01 (PK407E)Document12 pagesPR 01 (PK407E)Brijesh UkeyNo ratings yet

- PR 08 (PK407E)Document7 pagesPR 08 (PK407E)Brijesh UkeyNo ratings yet

- PR 02 (PK407E)Document5 pagesPR 02 (PK407E)Brijesh UkeyNo ratings yet

- PR 04 (PK407E)Document6 pagesPR 04 (PK407E)Brijesh UkeyNo ratings yet

- PR 07 (PK407E)Document5 pagesPR 07 (PK407E)Brijesh UkeyNo ratings yet

- Progressive Test PaperDocument2 pagesProgressive Test PaperBrijesh UkeyNo ratings yet

- Divya ReportDocument3 pagesDivya ReportBrijesh UkeyNo ratings yet

- PR 05 (PK407E)Document5 pagesPR 05 (PK407E)Brijesh UkeyNo ratings yet

- Pk404e Iaks (Syed Sir) - Packaging in PharmaceuticalsDocument11 pagesPk404e Iaks (Syed Sir) - Packaging in PharmaceuticalsBrijesh UkeyNo ratings yet

- Mn101e App (Anup Pardey Sir) - Industrial Managemnet (TH) .Document9 pagesMn101e App (Anup Pardey Sir) - Industrial Managemnet (TH) .Brijesh UkeyNo ratings yet

- Pk411e Za (Zeeshan Ali Sir) - Packaging Process (PR) .Document8 pagesPk411e Za (Zeeshan Ali Sir) - Packaging Process (PR) .Brijesh UkeyNo ratings yet

- Pk504e App (Anup Pardey Sir) - Packaging of Engineering Goods (TH PR) .Document12 pagesPk504e App (Anup Pardey Sir) - Packaging of Engineering Goods (TH PR) .Brijesh UkeyNo ratings yet

- Pk505e MSD (Despande Sir) - Production Management (TH PR) .Document9 pagesPk505e MSD (Despande Sir) - Production Management (TH PR) .Brijesh UkeyNo ratings yet

- Se401e - Seminar B1 (Msd-Despande Sir) + B2 (Iaks-Syed Sir) + B3 (App-Pardey Sir) (PR) .Document5 pagesSe401e - Seminar B1 (Msd-Despande Sir) + B2 (Iaks-Syed Sir) + B3 (App-Pardey Sir) (PR) .Brijesh UkeyNo ratings yet

- Time Table (8 August) GP PK VsemDocument1 pageTime Table (8 August) GP PK VsemBrijesh UkeyNo ratings yet

- Curriculum 2016Document594 pagesCurriculum 2016Brijesh UkeyNo ratings yet

- Speech For FMCGDocument2 pagesSpeech For FMCGNitin DhantoleNo ratings yet

- Jurnal Pembuatan Kertas Dengan Bagas SorgumDocument4 pagesJurnal Pembuatan Kertas Dengan Bagas SorgumAnonymous Lh8BPiLoNo ratings yet

- CAPSTONEDocument8 pagesCAPSTONE12 BoyleArienne PelaezNo ratings yet

- Chemical Process TechnologyDocument9 pagesChemical Process TechnologyRITZCOOL FOR YOUNo ratings yet

- Tamil Nadu Newsprint and Papers LimitedDocument10 pagesTamil Nadu Newsprint and Papers LimitedNanda KumarNo ratings yet

- Al326 MP Plus Silver FSC s2045n-Bg40br Imp - enDocument2 pagesAl326 MP Plus Silver FSC s2045n-Bg40br Imp - enIván CsörgőNo ratings yet

- STEM Curriculum - Lesson Plans and DescriptionsDocument50 pagesSTEM Curriculum - Lesson Plans and DescriptionsiceeycoNo ratings yet

- Out SmokinDocument10 pagesOut SmokinKarl VNo ratings yet

- The Role of Food Packaging: February 2019Document11 pagesThe Role of Food Packaging: February 2019Agrian HuntsmanNo ratings yet

- Scibk 1Document375 pagesScibk 1Bea NufuarNo ratings yet

- Aluminum Plate LithoDocument3 pagesAluminum Plate Lithotony_baker_31No ratings yet

- QD 89Document12 pagesQD 89Jefferson OrgaNo ratings yet

- Industries at GhaziabadDocument15 pagesIndustries at GhaziabadShashikant Jaisingha100% (1)

- Chemical Engineering Research PapersDocument8 pagesChemical Engineering Research Paperstgyuhdvkg100% (1)

- Automatic Electromagnetic Punching Machine: Mr.M.S.Wani, Shubham Jagtap, Saurabh KothawadeDocument6 pagesAutomatic Electromagnetic Punching Machine: Mr.M.S.Wani, Shubham Jagtap, Saurabh KothawademanimaranNo ratings yet

- 35 Drying of Pulp and PaperDocument29 pages35 Drying of Pulp and PaperEsmar Cantu NetoNo ratings yet

- Gurugram: Jawahar Navodaya Vidyalaya BargarhDocument14 pagesGurugram: Jawahar Navodaya Vidyalaya BargarhndjdhNo ratings yet

- नेपाल गुणस्तरको सूची PDFDocument22 pagesनेपाल गुणस्तरको सूची PDFUmesh Poudel JoJoNo ratings yet

- 4 R Waste Management in TextileDocument7 pages4 R Waste Management in TextileAmir ShahzadNo ratings yet

- Downloads Papers N59e995a0ab8c2 PDFDocument6 pagesDownloads Papers N59e995a0ab8c2 PDFRudresh RakeshNo ratings yet

- Dry ConstructionDocument114 pagesDry Constructionanbertjonathan100% (2)

- Research Paper On SLU Fountain Water CleanlinessDocument23 pagesResearch Paper On SLU Fountain Water CleanlinessNathaniel CorderoNo ratings yet

- Folding OrigamiDocument36 pagesFolding Origamihmurcia100% (2)

- Printlac High Gloss TDSDocument2 pagesPrintlac High Gloss TDSDewaayu Tetha E SNo ratings yet

- AquaFit4Use - Water Quality Demands in Paper-Chemical-Food-Textile IndustryDocument125 pagesAquaFit4Use - Water Quality Demands in Paper-Chemical-Food-Textile IndustryNho Ta0% (1)

- CANON - MP510 Service ManualDocument55 pagesCANON - MP510 Service ManualDuplessisNo ratings yet

- Glossary Bookbinding TermsDocument6 pagesGlossary Bookbinding TermsJustAScribdUserNo ratings yet

- Soal Ujian Semstr Ganjil 2017-2018Document19 pagesSoal Ujian Semstr Ganjil 2017-2018Afriadi A. PalasongNo ratings yet

- Cow Manure As An Alternative To CharcoalDocument6 pagesCow Manure As An Alternative To CharcoalAlexander100% (1)

- Ppt. BTDocument23 pagesPpt. BTDaryl Gomez Timatim100% (1)