Professional Documents

Culture Documents

Rev004

Uploaded by

Issam LahlouOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Rev004

Uploaded by

Issam LahlouCopyright:

Available Formats

PROCTER & GAMBLE FABRIC & HOME CARE

MANUFACTURING STANDARDS

Effective Date: 04/07/2019 GCAS: 95276864 issue 4

HIGHLY RESTRICTED

Expires: Permanent TAED: RAW MATERIAL PLANT INFORMATION Supersedes: 95276864

issue 3

TAED AGGLOMERATES ALL GRADES

RAW MATERIAL HANDLING

OBJECTIVE

This standard covers the storage and handling of the materials listed above. The information here within is important

and should be followed for reasons of safety and quality. This standard applies to any P&G site using the materials

listed above.

For safety specifics and detailed chemical behaviour of the material, the appropriate supplier’s MSDS (Material Safety

Data Sheet) should be referred to.

This standard serves to form the basis for more detailed plant specific standard operating procedures and

manufacturing standards.

MATERIAL DESCRIPTION

CAS number: 10543-57-4; EINECS number: 2341238;

Industrial Hygiene Data Sheet (IHDS) Number 000051

TAED agglomerates are produced by a process that uses Schugi and/or Loedige type agglomeration equipment to

incorporate TAED in to an agglomerate form with binder materials.

TAED extrudates are produced using a twin screw extruder, again with relevant binder materials. The particles are

incorporated into detergent finished product by dry mixing.

P&G Applications

TAED is used as a bleach activator in granular detergents (this include laundry applications as well as automatic dish

washing applications).

MATERIAL CHARACTERISTICS

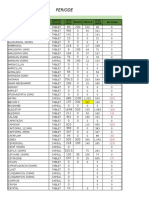

Characteristics All TAED grades used in F&HC

Form Granules

Physical state @ 20C Solid

Physical Description White or coloured free flowing powder

Chemical Formula (CH₃C(O))₂NCH₂CH₂N(C(O)CH₃)₂

Colour White or Coloured

pH Value 5 (20oC in deionised water, 1g/l)

Decomposition temperature N/A

Odour Odourless

Molecular weight 228.248

Flash Point N/A

Melting Point 149C – 154C

Explosive properties St Class 2

Dust Constant (Kst) 238 bar.m.s-1

Maximum Pressure (Pmax) 8.7 bar

Minimum ignition energy (MIE) 8 to 10 mJ

Minimum ignition temp (MIT) 470C

Incompatible Materials Acids, Alkali, Strong Oxidising Agents

Hazardous decomposition products Acetic acid and oxides of nitrogen

STORAGE & HANDLING

Unloading

TAED particles are frangible and will break up during vigorous handling. For this reason pneumatic transfer systems

are not recommended. The TAED agglomerates are prone to break-up.

Originator: Yasser Ali Function: MEA MPD Location: CTC

Last Updated: Sapnesh Jayswal Function: Global Materials Location: NIC

Business Use - P&G AUTHORIZED 95276864 Rev 004 Effective Date 2021-12-03 Printed 2023-04-19 Page 1 of 3

PROCTER & GAMBLE FABRIC & HOME CARE

MANUFACTURING STANDARDS

Effective Date: 04/07/2019 GCAS: 95276864 issue 4

HIGHLY RESTRICTED

Expires: Permanent TAED: RAW MATERIAL PLANT INFORMATION Supersedes: 95276864

issue 3

A bulk bag simulation test is recommended to assess likely caking in big bags if TAED particles are being introduced

for the first time into plants located in areas of high ambient temperature (above 30°C).

GENERAL

1. A storage time of 24 months is the recommended maximum for routine operations.

2. However, extended storage is possible if required for a specific project. Before use, re-check analysis is required for

all the quality items as specified on the TAED particles 'raw material specification' (RMS) these results must be

reviewed with the TMO.

3. Store in a cool, dry place. Maximum storage temperature is 40°C to minimise caking and lumping

4. Store in original big bags and keep sealed. Big bags must be protected from moisture ingress, otherwise lumping

and caking will occur. For plants where outside storage is used, bags must be protected (e.g. polythene shrouds).

5. Handle carefully to avoid break-up or compaction.

BULK HANDLING: Not Permitted

Bulk delivery is not used for TAED. Only Big Bags are approved for TAED shipments. Please use big bags of type B.

BULK HANDLING: SILOS and TRANSFER LINES

Particles can not be transferred using a pneumatic transfer system because of risk of particles break-up. Increase in

fines as a consequence of break-up can have an adverse effect on patchy fabric damage.

(Historical testing carried out at Clyde Engineering in September 1999 confirmed break up

when using continuous dense phase pneumatic transfer.)

Storage / Handling

1. TAED particles are to be stored in dry, clean big bags. Storage should be indoors. If outside storage is used the bag

MUST be protected from water ingress by using a polythene shroud or similar.

2. Maximum bag weight is 1.2tn.

3. Big bags of TAED particles may be double stacked

4. Each big bag of TAED particles must be labelled with the RMS number, product name TAED particles, supplier

name and address and Activity value. Additional information may be required, as per RMS guidelines.

5. Wear personal protective equipments.

6. Avoid Contamination with water / moisture, organic matter, decomposition catalyst.

7. Do not store together with acids, alkalis, reducing agents, metallic salts.

8. Do not re-use spilled or soiled product.

9. Never return spilled product into its original container for re-use (risk of decomposition).

10. Protect from sunlight, warmth and heat.

11. Keep away from flammable sources.

12. Where bags or super sacks are used these must be stored indoors protected from exposure to direct sunlight and

rain.

IN-PROCESS CONTROL AND MONITORING

1. In general, there are no specific requirements above those for normal raw material powders.

2. TAED particles must be delivered with a certificate of analysis. This confirms fitness for use as shipped from the

supplier.

3. The receiving plant may wish to re-check analysis on receipt. Critical quality items and analytical methods are

specified on the 'Raw material specification' (RMS) for the TAED particles.

Originator: Yasser Ali Function: MEA MPD Location: CTC

Last Updated: Sapnesh Jayswal Function: Global Materials Location: NIC

Business Use - P&G AUTHORIZED 95276864 Rev 004 Effective Date 2021-12-03 Printed 2023-04-19 Page 2 of 3

PROCTER & GAMBLE FABRIC & HOME CARE

MANUFACTURING STANDARDS

Effective Date: 04/07/2019 GCAS: 95276864 issue 4

HIGHLY RESTRICTED

Expires: Permanent TAED: RAW MATERIAL PLANT INFORMATION Supersedes: 95276864

issue 3

4. Transfer time, feeder addition rate, output and variability is measured by the plant as

required and in-line with standard procedures.

5. TAED is dust explosive. The hopper volume should be < 2m3 to avoid the need for explosion venting. TAED should

be delivered in type B bags due to the lower MIE (minimum ignition enrgy of 8 – 10 mJ).

Condition GCAS General USP

Controlled 96798730

Room

Temperature 15 – 30C 20 – 25C

REFERENCES FOR EMERGENCY AND DISPOSAL PROCEDURES

Refer to the Safety Data Sheet (MSDS) for the TAED agglomerate or extrudate. This data sheet contains detailed and

specific information on toxicology, hazard identification, first aid measures, exposure controls, physical and chemical

properties and disposal procedures.

SHELF-LIFE

A storage time of 24 months from production is the recommended maximum for routine operations. Re-testing is

recommended after this time. This 24 months shelf life is inline with all our TAED suppliers and backed up by stability

test results from suppliers.

Originator: Yasser Ali Function: MEA MPD Location: CTC

Last Updated: Sapnesh Jayswal Function: Global Materials Location: NIC

Business Use - P&G AUTHORIZED 95276864 Rev 004 Effective Date 2021-12-03 Printed 2023-04-19 Page 3 of 3

You might also like

- P & G F & H C R M P I R: Rocter Amble Abric OME AREDocument2 pagesP & G F & H C R M P I R: Rocter Amble Abric OME AREIssam LahlouNo ratings yet

- Flow AssuranceFrom EverandFlow AssuranceQiwei WangNo ratings yet

- Sodium Percarbonate All Grades Raw Material Handling: Procter & Gamble Manufacturing StandardsDocument5 pagesSodium Percarbonate All Grades Raw Material Handling: Procter & Gamble Manufacturing StandardsIssam LahlouNo ratings yet

- Theory and Technology of Multiscale Dispersed Particle Gel for In-Depth Profile ControlFrom EverandTheory and Technology of Multiscale Dispersed Particle Gel for In-Depth Profile ControlNo ratings yet

- P & G F & H C R M P I RESTRICTED : Rocter Amble Abric OME AREDocument2 pagesP & G F & H C R M P I RESTRICTED : Rocter Amble Abric OME AREIssam LahlouNo ratings yet

- P & G F & H C R M P I RESTRICTED : Rocter Amble Abric OME AREDocument1 pageP & G F & H C R M P I RESTRICTED : Rocter Amble Abric OME AREIssam LahlouNo ratings yet

- Rev004Document2 pagesRev004Issam LahlouNo ratings yet

- P & G F & H C R M P I R: Rocter Amble Abric OME AREDocument4 pagesP & G F & H C R M P I R: Rocter Amble Abric OME AREIssam LahlouNo ratings yet

- UntitledDocument2 pagesUntitledIssam LahlouNo ratings yet

- UntitledDocument3 pagesUntitledIssam LahlouNo ratings yet

- Restricted P & G F & H C R M P I: ChlorideDocument3 pagesRestricted P & G F & H C R M P I: ChlorideIssam LahlouNo ratings yet

- R P & G F & H C R M P I: Estricted Rocter Amble Abric OME AREDocument3 pagesR P & G F & H C R M P I: Estricted Rocter Amble Abric OME AREIssam LahlouNo ratings yet

- Araldite Ly564 Aradur 2954.PDF ResinDocument5 pagesAraldite Ly564 Aradur 2954.PDF ResinAbdul Hakim AbdullahNo ratings yet

- UntitledDocument6 pagesUntitledIssam LahlouNo ratings yet

- 8810Document2 pages8810Sikander Aleem100% (1)

- UntitledDocument2 pagesUntitledIssam LahlouNo ratings yet

- UF3323 TCR™ Resin: June 2007, Revision 9Document1 pageUF3323 TCR™ Resin: June 2007, Revision 9iluvhuggiesNo ratings yet

- Xylan 80-018-g6706 Black - BeDocument2 pagesXylan 80-018-g6706 Black - BeSYED MAZHARNo ratings yet

- Araldite 252Document4 pagesAraldite 252HectorNo ratings yet

- Formula 152 Topcoat (MILDTL-24441)Document4 pagesFormula 152 Topcoat (MILDTL-24441)Trịnh Minh KhoaNo ratings yet

- SIgmaguard 720Document7 pagesSIgmaguard 720Khan ZamanNo ratings yet

- PA66-RG301: Flame Retardant, 30% Glass Fiber Reinforced PA66Document2 pagesPA66-RG301: Flame Retardant, 30% Glass Fiber Reinforced PA66watnaNo ratings yet

- Crystic 197M (Pa) : Pre Accelerated High Performance Pipe Grade ResinDocument5 pagesCrystic 197M (Pa) : Pre Accelerated High Performance Pipe Grade ResinFrank DetchokulNo ratings yet

- Desmopan TPU ProcessingDocument48 pagesDesmopan TPU ProcessingA Mahmood100% (1)

- Araldite MY 0816 Eur eDocument3 pagesAraldite MY 0816 Eur euzzy2No ratings yet

- Tandy 4301Document2 pagesTandy 4301Kamal PriyanNo ratings yet

- Con5-25 U2-Cond736343 McaDocument3 pagesCon5-25 U2-Cond736343 McanambiarnedumchalNo ratings yet

- Bitoner Resin C5 BT-2104 TDSDocument2 pagesBitoner Resin C5 BT-2104 TDSdamiendamNo ratings yet

- G4258 Silver - Pds-EnDocument3 pagesG4258 Silver - Pds-EnuraliNo ratings yet

- Vinyl Ester-Glass Flake PaintDocument4 pagesVinyl Ester-Glass Flake PaintSimbu ArasanNo ratings yet

- Thermaline 450 PDFDocument2 pagesThermaline 450 PDFNageswara Rao BavisettyNo ratings yet

- Intan Moisture Sensitive Device GuideDocument1 pageIntan Moisture Sensitive Device GuideAdair NettoNo ratings yet

- Tds Addnox FR 950 PTDocument1 pageTds Addnox FR 950 PTRajiv DubeyNo ratings yet

- The Screw and Barrel SystemDocument31 pagesThe Screw and Barrel SystemAnonymous oyUAtpKNo ratings yet

- P & G F & H C R M P I: Carboxymethyl Cellulose Sodium Salt (CMC)Document2 pagesP & G F & H C R M P I: Carboxymethyl Cellulose Sodium Salt (CMC)Issam LahlouNo ratings yet

- TDS CapaPrimeDocument3 pagesTDS CapaPrimeMearg NgusseNo ratings yet

- Interline 1012+ds+engDocument4 pagesInterline 1012+ds+engSUBHOMOYNo ratings yet

- Interspeed 640Document4 pagesInterspeed 640Stefano CostaNo ratings yet

- Multiplant 10W30Document2 pagesMultiplant 10W30carmaNo ratings yet

- Interclene 336: TBT Free AntifoulingDocument4 pagesInterclene 336: TBT Free AntifoulingTrịnh Minh KhoaNo ratings yet

- Masterseal TC 242: Description Typical PropertiesDocument2 pagesMasterseal TC 242: Description Typical PropertiesGavriel NgNo ratings yet

- Product DataDocument2 pagesProduct DataEngTamerNo ratings yet

- مسودة مواصفة سعودية 2888-2020Document10 pagesمسودة مواصفة سعودية 2888-2020MarwaNo ratings yet

- Macropoxy 240Document2 pagesMacropoxy 240nellyNo ratings yet

- 7226 enDocument2 pages7226 enVojkan MladenovicNo ratings yet

- Hosokawa Drying Technologies A40 - EnglishDocument40 pagesHosokawa Drying Technologies A40 - EnglishAlejandro CalderónNo ratings yet

- Sigmacover 850 Sigmashield 880 HSDocument6 pagesSigmacover 850 Sigmashield 880 HSshahrimanNo ratings yet

- DYMAX Ga-103Document0 pagesDYMAX Ga-103Giosue GiacoppoNo ratings yet

- ULTRADUR Sup ® Sup +B4520+FC+AQUADocument3 pagesULTRADUR Sup ® Sup +B4520+FC+AQUACanchindoNo ratings yet

- DV462S1 5-EnDocument1 pageDV462S1 5-EnchemibermudezNo ratings yet

- Polyester Resin For Closed Mold Processing and PultrusionDocument2 pagesPolyester Resin For Closed Mold Processing and PultrusionmutazsalihNo ratings yet

- TDS - SUKANO C Me S837 - enDocument1 pageTDS - SUKANO C Me S837 - enIlham HidayatNo ratings yet

- UntitledDocument3 pagesUntitledIssam LahlouNo ratings yet

- Tds Radilon S Rv300k 333 Ner EngDocument2 pagesTds Radilon S Rv300k 333 Ner EngAshishNo ratings yet

- Energrease HTG 2 PDFDocument2 pagesEnergrease HTG 2 PDFLê Duy PhongNo ratings yet

- Technical Data SheetDocument3 pagesTechnical Data SheetAdrián SánchezNo ratings yet

- Xylan 80-510-G3196 Pfa BeDocument2 pagesXylan 80-510-G3196 Pfa BeSYED MAZHARNo ratings yet

- Xylan 4090-F2676 Clear (P92) (Be)Document3 pagesXylan 4090-F2676 Clear (P92) (Be)Abdul Rafiq SoudagarNo ratings yet

- Sigmacover™ 620: Product Data SheetDocument5 pagesSigmacover™ 620: Product Data SheetMahmoud TahaNo ratings yet

- P & G F & H C R M P I: Carboxymethyl Cellulose Sodium Salt (CMC)Document2 pagesP & G F & H C R M P I: Carboxymethyl Cellulose Sodium Salt (CMC)Issam LahlouNo ratings yet

- Restricted P & G F & H C R M P I: ChlorideDocument3 pagesRestricted P & G F & H C R M P I: ChlorideIssam LahlouNo ratings yet

- UntitledDocument3 pagesUntitledIssam LahlouNo ratings yet

- The Procter & Gamble Co.: Issue Date: See TS FormDocument7 pagesThe Procter & Gamble Co.: Issue Date: See TS FormIssam LahlouNo ratings yet

- UntitledDocument3 pagesUntitledIssam LahlouNo ratings yet

- R M P I P (90% A) : AW Aterial Lant NstructionDocument7 pagesR M P I P (90% A) : AW Aterial Lant NstructionIssam LahlouNo ratings yet

- UntitledDocument2 pagesUntitledIssam LahlouNo ratings yet

- UntitledDocument2 pagesUntitledIssam LahlouNo ratings yet

- UntitledDocument2 pagesUntitledIssam LahlouNo ratings yet

- UntitledDocument2 pagesUntitledIssam LahlouNo ratings yet

- R P & G F & H C R M P I: Estricted Rocter Amble Abric OME AREDocument3 pagesR P & G F & H C R M P I: Estricted Rocter Amble Abric OME AREIssam LahlouNo ratings yet

- P & G F & H C R M P I R: Rocter Amble Abric OME AREDocument4 pagesP & G F & H C R M P I R: Rocter Amble Abric OME AREIssam LahlouNo ratings yet

- UntitledDocument6 pagesUntitledIssam LahlouNo ratings yet

- CSEC Biology June 2012 P2Document17 pagesCSEC Biology June 2012 P2Joy BoehmerNo ratings yet

- NMI Application Form (NCLEX Scores Transfer)Document2 pagesNMI Application Form (NCLEX Scores Transfer)Ramon Carlo Almiranez100% (1)

- Design Formulation and Evaluation of Nicotine ChewDocument10 pagesDesign Formulation and Evaluation of Nicotine ChewsimaproindiaNo ratings yet

- ID Virus Avian Influenza h5n1 Biologi Molek PDFDocument13 pagesID Virus Avian Influenza h5n1 Biologi Molek PDFArsienda UlmafemaNo ratings yet

- Understanding Desistance From Crime Laub and SampsonDocument70 pagesUnderstanding Desistance From Crime Laub and Sampsonchrisgoss1No ratings yet

- Milk Supply Chain Management Upstream Downstream IssuesDocument25 pagesMilk Supply Chain Management Upstream Downstream IssuesbikramNo ratings yet

- QR CPG TobacoDisorderDocument8 pagesQR CPG TobacoDisorderiman14No ratings yet

- HârnWorld - Fyvria (CG 4505)Document36 pagesHârnWorld - Fyvria (CG 4505)Vlad T100% (1)

- Communication in Palliative CareDocument7 pagesCommunication in Palliative CareIhsan NudinNo ratings yet

- Antibiotic SolutionDocument1 pageAntibiotic SolutionBodhi DharmaNo ratings yet

- Bicol Central Academy: Mr. Geo B. AutorDocument4 pagesBicol Central Academy: Mr. Geo B. AutorGeo AutorNo ratings yet

- Sistem Pakar Diagnosis Penyakit Pada Ayam Dengan Menggunakan Metode Dempster ShaferDocument11 pagesSistem Pakar Diagnosis Penyakit Pada Ayam Dengan Menggunakan Metode Dempster ShaferYata RinNo ratings yet

- Dental Juris and Practice MGT Board 2008Document14 pagesDental Juris and Practice MGT Board 2008Anonymous FwwfR650% (2)

- 978 3 642 25446 8Document166 pages978 3 642 25446 8Gv IIITNo ratings yet

- Body GuideDocument46 pagesBody GuideBárbara Leite95% (22)

- Jurnal BM 7Document18 pagesJurnal BM 7Nitya WirasasiNo ratings yet

- 16-Week Harvey Walden MarathonTraining PlanDocument18 pages16-Week Harvey Walden MarathonTraining PlanKaren MiranoNo ratings yet

- Top 10 Regulatory Challenges in The Healthcare EnvironmentDocument3 pagesTop 10 Regulatory Challenges in The Healthcare EnvironmentNicki BombezaNo ratings yet

- CORE4 ABS Month 2 Workouts PDFDocument9 pagesCORE4 ABS Month 2 Workouts PDFkamehouse100% (1)

- Adoption LawsDocument10 pagesAdoption LawsAneesh PandeyNo ratings yet

- Building and Handling Therapeutic Closeness in The Therapist-ClientDocument9 pagesBuilding and Handling Therapeutic Closeness in The Therapist-ClientRaphaele ColferaiNo ratings yet

- Karakteristik Penderita Mioma Uteri Di Rsup Prof. Dr. R.D. Kandou ManadoDocument6 pagesKarakteristik Penderita Mioma Uteri Di Rsup Prof. Dr. R.D. Kandou ManadoIsma RotinNo ratings yet

- Professional Teacher - Secondary (Social Studies) - 03-2024Document45 pagesProfessional Teacher - Secondary (Social Studies) - 03-2024PRC BaguioNo ratings yet

- Radiation Protection Rules 1971Document10 pagesRadiation Protection Rules 1971KomalNo ratings yet

- Wa0094.Document9 pagesWa0094.lider vigilanciaNo ratings yet

- Satvik DietDocument3 pagesSatvik DietDisha TNo ratings yet

- Anoplastia Percutanea 2022Document11 pagesAnoplastia Percutanea 2022Sandra Cárdenas HilasacaNo ratings yet

- Format OpnameDocument21 pagesFormat OpnamerestutiyanaNo ratings yet

- HBN 00-09 Infection ControlDocument47 pagesHBN 00-09 Infection ControlAntenehNo ratings yet

- A Guide For The Assessment and Management of Post-Obstructive DiuresisDocument3 pagesA Guide For The Assessment and Management of Post-Obstructive DiuresisRara Aulia IINo ratings yet