Professional Documents

Culture Documents

Risk-Fall of Person and Object From Height (Work at Height)

Uploaded by

Susil Kumar SahooOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Risk-Fall of Person and Object From Height (Work at Height)

Uploaded by

Susil Kumar SahooCopyright:

Available Formats

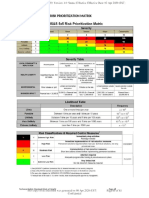

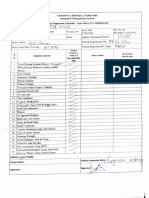

Critical Control Verification Checklist

Fall of Person Object from Height

Risk- Fall of Person and Object from Height (Work at Height)

Date 17-Apr-23

Fall from height onto a lower level & Strike by objects Area SS8E

falling from height Owner ISGEC

Verifier Name

Critical controls

1- Fixed structure and fall prevention installations meet design specifications & standards

Objective : To ensure that fixed work platforms and fixed ladders are suitable for the task and prevents falls from height

1.1 Fixed walkways and ladders on structures and mobile plants are constructed to meet industry/site

engineering specifications for fall protection and load bearing Yes No ✘ N/A

1.2 Fixed walkways and ladders on structures and mobile plant are inspected and maintained to site engineering

standards Yes No ✘ N/A

1.3 Fixed ladders should be provided with a ladder cage. Alternatively, fall arrest equipment should be used at all

times. Yes No ✘ N/A

1.4 Anchor points are rated for load bearing capacity and certified Yes No ✘ N/A

1.5 Roof construction meets the site engineering standards, including access to roof structures, and are assessed

by a competent person. Yes No ✘ N/A

1.6 Platforms and mezzanines meets site engineering standards and certified by a competent person. Yes No ✘ N/A

Suggested Action (mandatory for all "No") :

2

3

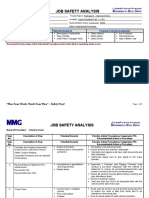

2- Mobile platforms and equipment meets design specifications & standards

Objective : To ensure that mobile work platforms, ladders and scaffolding are suitable for the task and prevents falls from height

2.1 Portable ladders must meet the minimum design requirements ✘ Yes No N/A

2.2 Elevated Work Platforms (EWP) selection should be appropriate for the task (e.g. scissor lift, self-propelled

boom, truck-mounted boom) and should meet the requirement as per engineering/ OEM standards Yes No ✘ N/A

2.3 Erected scaffolding in the field meets the design criteria and sign-off has been confirmed Yes ✘ No N/A

2.4 The field verification activities for mobile platforms & scaffolding are being completed on a routine basis and

that deficiencies found during field verification are immediately addressed. ✘ Yes No N/A

Suggested Action (mandatory for all "No") :

1. Scaffolding design shall be submitted for approval.

2

3

3- Equipment is maintained, inspected, established and used by competent and trained people

Objective : To ensure that mobile and temporary work platforms are safe for use and that all people working at height are trained and

competent in order to prevent falls from height

3.1 People erecting/ dismantling/ inspecting scaffolds are certified & competent. Verify documentation to

confirm training & competence certification. ✘ Yes No N/A

3.2 Daily inspection checklist is completed and the current scaffolding tag is available before use. Yes ✘ No N/A

3.3 Scaffolding is inspected on daily basis and declared safe for use (daily inspection checklist is completed &

current tag is available) ✘ Yes No N/A

3.4 Inspection & tag-out process for portable ladders is in place to ensure that the ladders are safe for use.

Yes No N/A

Inspection checklist are completed and available. Tags are available for damaged/unsafe ladders ✘

3.5 Elevated work platform are operated in line with procedure by competent & certified operators. Training &

competency records for EWP operators are available and are certified Yes No ✘ N/A

3.6 Rope access and abseiling is managed through a permitting process and performed by certified operators.

Records are available for training for operators & inspection & maintenance of rope access equipment. Yes No ✘ N/A

3.7 The field verification activities are being completed on a routine basis and that deficiencies found during field

verification are immediately addressed. ✘ Yes No N/A

Suggested Action (mandatory for all "No") :

1. Daily checklist of scaffolding should be maintained and recorded.

_x000D_ Sensitivity: Public (C4)

#

Critical Control Verification Checklist

Fall ofCritical

Person controls

Object from Height

3

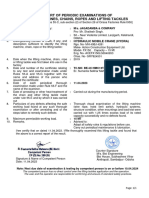

4- Correct fall prevention/ protection equipment is used or installed

Objective : To ensure fall protection is installed near open edges and voids in order to prevent falls from height

4.1 Railing/edge protection/anchor points are installed around work areas on roof ✘ Yes No N/A

4.2 Railing/edge protection/anchor points installed around work area on mezzanine, edge area and all access

stairs Yes ✘ No N/A

4.3 Railing/edge protection/anchor points installed around voids and openings. ✘ Yes No N/A

4.4 Fall arrest/ restraint equipment is used where fall prevention is not provided including full body harness

attached to a an anchor point ✘ Yes No N/A

4.5 Work at height equipment is inspected prior to use including dual lanyard, shock absorber, trauma straps ✘ Yes No N/A

4.6 Employees are prohibited from working alone (with-out a stand by person) while using the fall arrest harness.

A rescue plan is in place and all team members are familiar with the plan ✘ Yes No N/A

4.7 All employees working in elevated platform or suspend basket are wearing fall restraint equipment anchored

Yes No ✘ N/A

in the basket

Suggested Action (mandatory for all "No") :

1. Handrails installed in SS8E found haphazard condition. Midrails and toprails are observed 50 mm away from edge of the staircase.

2

3

5- Access control to restricted areas (hard barricading)

Objective : To ensure access is controlled to restricted or unsafe areas in order to prevent falls from height

5.1 Access to scaffolding is controlled through gating, permitting and signage. Confirm the process to obtain

permission for unauthorized persons/ visitors to access the work area near the scaffolds. Yes No ✘ N/A

5.2 Confirm access to roof areas is locked out including gates and ladders that provide access to the roof.

Confirm the process used to authorize access. Yes No ✘ N/A

5.3 Access is controlled to restricted areas on fixed walkways and ladders on structures using gates and locks Yes No ✘ N/A

5.4 Access is controlled to restricted areas on fixed walkways and ladders on mobile plant using gates and locks Yes No ✘ N/A

5.5 All voids and openings are hard barricaded or access controlled ✘ Yes No N/A

Suggested Action (mandatory for all "No") :

2

3

6- Dropped object management (exclusion zones, lanyards, tool inspection)

Objective : To ensure that preventative measures are in place to avoid objects falling from height

6.1 All hand tools are tethered (secured from falling using appropriate devices). Netting is provided where ever

required ✘ Yes No N/A

6.2 Exclusion zones are deployed when working at height takes place and barricaded to prevent access Yes ✘ No N/A

6.3 All platforms are fitted with kickboards ✘ Yes No N/A

6.4 Simultaneous or concurrent activities are planned so that no work is taking place in the drop zone (exclusion

zone)

✘ Yes No N/A

Suggested Action (mandatory for all "No") :

1. Exclusion zone shall be barricaded to prevent unauthorized entry.

2

3

_x000D_ Sensitivity: Public (C4)

#

Critical Control Verification Checklist

Fall ofCritical

Person controls

Object from Height

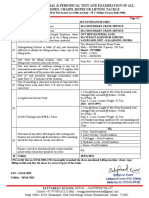

Verification Result Summary:

CC No No of Checks No of "GO" No of "NO GO" % Compliance No of Improvement actions

CC-1 6 0 0 #DIV/0!

CC-2 4 2 1 67%

CC-3 7 4 1 80%

CC-4 7 5 1 83%

CC-5 5 1 0 100%

CC-6 4 3 1 75%

_x000D_ Sensitivity: Public (C4)

#

You might also like

- Small Unit Leaders Operational Planning GuideFrom EverandSmall Unit Leaders Operational Planning GuideRating: 5 out of 5 stars5/5 (1)

- Mobile Scaffold Inspection Checklist: Scaffold Location / Number: Complies? Y Yes N No N/A Not ApplicableDocument1 pageMobile Scaffold Inspection Checklist: Scaffold Location / Number: Complies? Y Yes N No N/A Not ApplicableMyolwinooNo ratings yet

- Mobile Scaffold Inspection ChecklistDocument2 pagesMobile Scaffold Inspection ChecklistjohainaNo ratings yet

- Mobile Scaffold Inspection Checklist: Scaffold Location / Number: Complies? Y Yes N No N/A Not ApplicableDocument2 pagesMobile Scaffold Inspection Checklist: Scaffold Location / Number: Complies? Y Yes N No N/A Not ApplicableMarulitua100% (1)

- Mobile Scaffold Inspection ChecklistDocument1 pageMobile Scaffold Inspection Checklistmarulipakpahan001No ratings yet

- Risk-Vehicle Pedestrian Interaction: Critical Control Verification ChecklistDocument2 pagesRisk-Vehicle Pedestrian Interaction: Critical Control Verification ChecklistSusil Kumar SahooNo ratings yet

- Fall PreventionsDocument16 pagesFall PreventionsRajesh gp100% (1)

- Subject Area: Lifting Safety: Management SystemDocument5 pagesSubject Area: Lifting Safety: Management Systemvrlbhavanisankaram3786No ratings yet

- Checklist - Planning The Safe Set-Up and Operation of Tower CranesDocument10 pagesChecklist - Planning The Safe Set-Up and Operation of Tower CranesSagar BhavsarNo ratings yet

- Flare PSSR Checklist - ProcessDocument18 pagesFlare PSSR Checklist - Processrajneesh agnihotri100% (1)

- Suspended Personnel Platform Check List PDFDocument1 pageSuspended Personnel Platform Check List PDFmark lester caluzaNo ratings yet

- Lifting Plan AgcDocument8 pagesLifting Plan Agcragesh p rNo ratings yet

- Working at Height Risk Assessment Mar 21Document2 pagesWorking at Height Risk Assessment Mar 21tariq1987No ratings yet

- Checklist - Planning The Safe Use, Erection and Dismantling of Prefabricated or Modular ScaffoldingDocument13 pagesChecklist - Planning The Safe Use, Erection and Dismantling of Prefabricated or Modular ScaffoldingNoor Aimi Ayunie Mohd AzmiNo ratings yet

- 4.assembly & Erection of StructureDocument3 pages4.assembly & Erection of StructureFrancis Vinoj100% (2)

- Checklist - Planning The Safe Set-Up and Operation of Personnel and Materials HoistsDocument8 pagesChecklist - Planning The Safe Set-Up and Operation of Personnel and Materials HoistsSajeewa LakmalNo ratings yet

- Lifting Operation Rev2Document29 pagesLifting Operation Rev2Chong Yun QingNo ratings yet

- JSA For Scaffolding.Document16 pagesJSA For Scaffolding.jeswinimanualNo ratings yet

- INFINITY LIFT PlanDocument1 pageINFINITY LIFT PlanWeru MorrisNo ratings yet

- 1 Scaffolding Work PDFDocument16 pages1 Scaffolding Work PDFfadliNo ratings yet

- PREVENTING LIFTING POINT FAILURES IN CONSTRUCTIONv2Document3 pagesPREVENTING LIFTING POINT FAILURES IN CONSTRUCTIONv2Sandra FildesNo ratings yet

- WSWP For Hamisa Installation of Lift FramesDocument6 pagesWSWP For Hamisa Installation of Lift FramesVictor Thembinkosi MakhubeleNo ratings yet

- Tower Crane ChecklistDocument10 pagesTower Crane ChecklistalizafareeerNo ratings yet

- Lifting PlanDocument23 pagesLifting PlanSameer KmNo ratings yet

- Preventing Lifting Point Failures in ConstructionDocument3 pagesPreventing Lifting Point Failures in ConstructionSandra FildesNo ratings yet

- Machine Guarding ChecklistDocument4 pagesMachine Guarding Checklistadam rizkiNo ratings yet

- SWP 02 - Use of Mobile ScaffoldDocument4 pagesSWP 02 - Use of Mobile ScaffoldGerald Wong NttNo ratings yet

- Mobile Crane Checklist FinalDocument9 pagesMobile Crane Checklist FinalRony XavierNo ratings yet

- 05 - Weekly Safety Audit and Inspection ReportDocument4 pages05 - Weekly Safety Audit and Inspection ReportGyanendra Narayan NayakNo ratings yet

- Checklist - Planning The Safe Use, Erection and Dismantling of Prefabricated or Modular ScaffoldingDocument11 pagesChecklist - Planning The Safe Use, Erection and Dismantling of Prefabricated or Modular ScaffoldingChâu TúNo ratings yet

- SA 04 EN Inspector Falls From ScaffoldingDocument1 pageSA 04 EN Inspector Falls From ScaffoldingMogodan GabrielNo ratings yet

- Ehv SWP Form Lifting Lowering Operation PDF NewDocument3 pagesEhv SWP Form Lifting Lowering Operation PDF NewSn AhsanNo ratings yet

- Brookfield Properties - Rope Access (Abseiling) Permit - 20Document6 pagesBrookfield Properties - Rope Access (Abseiling) Permit - 20mugenthararaoNo ratings yet

- Scaffolding Erection &dismanlting JSADocument7 pagesScaffolding Erection &dismanlting JSAShahid Bhatti100% (1)

- Hot Work and Modification PDFDocument19 pagesHot Work and Modification PDFmyo lwinNo ratings yet

- HSE RiskChecklistExample 05may2017Document4 pagesHSE RiskChecklistExample 05may2017Hass MamacheNo ratings yet

- Crane Operator EvaluationDocument1 pageCrane Operator EvaluationHelp Tubestar CrewNo ratings yet

- SOP 01 Precast Concrete ElementsDocument5 pagesSOP 01 Precast Concrete ElementsrenjithrithvikNo ratings yet

- PRO-00861 Corporate Safety - Cranes and Lifting Equipment Safety ProcedureDocument30 pagesPRO-00861 Corporate Safety - Cranes and Lifting Equipment Safety ProcedureGustavo Alonso BerettaNo ratings yet

- FRM-00414 Corporate Safety - Work at Height Permit FormDocument1 pageFRM-00414 Corporate Safety - Work at Height Permit FormAdarsh sNo ratings yet

- Hydro Jetting and Sludge RemovalDocument18 pagesHydro Jetting and Sludge Removalmarvin100% (1)

- Travelling of CraneDocument3 pagesTravelling of CraneDelta akathehuskyNo ratings yet

- Jsa For Chemical Ware HouseDocument4 pagesJsa For Chemical Ware Housesalauddin0mohammedNo ratings yet

- Sample Swms Heights Mobile ScaffoldDocument7 pagesSample Swms Heights Mobile ScaffoldAnonymous BzGb2fnfENo ratings yet

- Procedure - ScaffoldDocument7 pagesProcedure - ScaffoldYani EsbeNo ratings yet

- Lifting PlanDocument35 pagesLifting PlanAva GhaziNo ratings yet

- Health Safety Compliance Evaluation Checklist.Document19 pagesHealth Safety Compliance Evaluation Checklist.SAKTHIVEL NATARAJANNo ratings yet

- Information:: YellowDocument4 pagesInformation:: YellowLi QiNo ratings yet

- JSA SK Erection DismantlingDocument1 pageJSA SK Erection DismantlingSamuel Hugos100% (4)

- Sample Swms Heights Mobile ScaffoldDocument7 pagesSample Swms Heights Mobile Scaffoldmani narayananNo ratings yet

- SWMS (Cable Glanding and Termination )Document6 pagesSWMS (Cable Glanding and Termination )PRIYESH . K. PRIYANNo ratings yet

- PWA-RPD-HSS-ALRT-067 Mobile Scaffolding SafetyDocument2 pagesPWA-RPD-HSS-ALRT-067 Mobile Scaffolding SafetySonesh SethumadhavanNo ratings yet

- Suspended Personnel Platform Check List PDFDocument1 pageSuspended Personnel Platform Check List PDFDenease CrummieNo ratings yet

- EPM EHS SP F 016 Scaffold ChecklistDocument2 pagesEPM EHS SP F 016 Scaffold ChecklistTamoor Mirza100% (2)

- Crane Competency Test Checklist - SafetyCultureDocument8 pagesCrane Competency Test Checklist - SafetyCulturearslanahmedkhawajaNo ratings yet

- FPE - 1 - Working at Heights PDFDocument7 pagesFPE - 1 - Working at Heights PDFKaruppuswamy PalanisamyNo ratings yet

- Lifting PlanDocument23 pagesLifting PlanAbdul GhaffarNo ratings yet

- Sop 001 Fibre CT Site Set UpDocument8 pagesSop 001 Fibre CT Site Set UpjoseltnNo ratings yet

- vYMeuoP5WRyc8NIv - Jltnw0O1UgbBz9sp-OSHA 10 Construction - Module 11 - Study GuideDocument7 pagesvYMeuoP5WRyc8NIv - Jltnw0O1UgbBz9sp-OSHA 10 Construction - Module 11 - Study GuideBelkacem BouazzaNo ratings yet

- My Resume LatestDocument1 pageMy Resume LatestSusil Kumar SahooNo ratings yet

- Yahoo Mail - Re - Permission Request For Extended Hour Working at BHS Area-6Document2 pagesYahoo Mail - Re - Permission Request For Extended Hour Working at BHS Area-6Susil Kumar SahooNo ratings yet

- Testi: OrationDocument1 pageTesti: OrationSusil Kumar SahooNo ratings yet

- Sonepar - Year End Evaluation Form-2023 - Deepak MohantyDocument7 pagesSonepar - Year End Evaluation Form-2023 - Deepak MohantySusil Kumar SahooNo ratings yet

- NDT - PBLDocument1 pageNDT - PBLSusil Kumar SahooNo ratings yet

- Saren Crane 130T TPIDocument1 pageSaren Crane 130T TPISusil Kumar SahooNo ratings yet

- 14.03.2024 MM Handler F-15Document1 page14.03.2024 MM Handler F-15Susil Kumar SahooNo ratings yet

- Ms PBL Transport Corporation PVT - Ltd. C/o - M/s. Monomak Engineering India PVT - LTDDocument1 pageMs PBL Transport Corporation PVT - Ltd. C/o - M/s. Monomak Engineering India PVT - LTDSusil Kumar SahooNo ratings yet

- Hydra TpiDocument2 pagesHydra TpiSusil Kumar SahooNo ratings yet

- Load Capacity Certificate ZTC800R542 - ZTC6H5D3ANA002846 - Choudhary Crane ServiceDocument1 pageLoad Capacity Certificate ZTC800R542 - ZTC6H5D3ANA002846 - Choudhary Crane ServiceSusil Kumar SahooNo ratings yet

- Susil Mob Bill Aug-OctDocument2 pagesSusil Mob Bill Aug-OctSusil Kumar SahooNo ratings yet

- PBL SliDocument1 pagePBL SliSusil Kumar SahooNo ratings yet

- Zoomlion 80 Ton - 011Document2 pagesZoomlion 80 Ton - 011Susil Kumar SahooNo ratings yet

- Mess - MARCH 2023Document1 pageMess - MARCH 2023Susil Kumar SahooNo ratings yet

- Adobe Scan Aug 27, 2022Document1 pageAdobe Scan Aug 27, 2022Susil Kumar SahooNo ratings yet

- 29 Method Statement BRICK WORKDocument6 pages29 Method Statement BRICK WORKSusil Kumar SahooNo ratings yet

- Method Statement For RCC R0 09.03.2017Document6 pagesMethod Statement For RCC R0 09.03.2017Susil Kumar SahooNo ratings yet

- Invoice 20262009610Document2 pagesInvoice 20262009610Susil Kumar SahooNo ratings yet

- DVC HywaDocument1 pageDVC HywaSusil Kumar SahooNo ratings yet

- Invoice 19820361670Document2 pagesInvoice 19820361670Susil Kumar SahooNo ratings yet

- DVC Excavator ChainDocument1 pageDVC Excavator ChainSusil Kumar SahooNo ratings yet

- Kauchansn: Date 7 - 2Document1 pageKauchansn: Date 7 - 2Susil Kumar SahooNo ratings yet

- DVC CBT & Truck TankerDocument1 pageDVC CBT & Truck TankerSusil Kumar SahooNo ratings yet

- PollutionDocument1 pagePollutionSusil Kumar SahooNo ratings yet

- Driving: LicencetDocument2 pagesDriving: LicencetSusil Kumar SahooNo ratings yet

- ENE - JIA C - TO.: - Cle.SDocument1 pageENE - JIA C - TO.: - Cle.SSusil Kumar SahooNo ratings yet

- PermitDocument1 pagePermitSusil Kumar SahooNo ratings yet

- Isgeo: Isgec Heavy Engineering LTDDocument1 pageIsgeo: Isgec Heavy Engineering LTDSusil Kumar SahooNo ratings yet

- Regi F L: LLL L L L LLL L LLLDocument1 pageRegi F L: LLL L L L LLL L LLLSusil Kumar SahooNo ratings yet

- Elliott Athletics Is Trying To Determine Its Optimal Capital Structure Which NowDocument1 pageElliott Athletics Is Trying To Determine Its Optimal Capital Structure Which NowAmit PandeyNo ratings yet

- Fake or Credible Antecedents and Consequences of Perce - 2023 - Journal of BusiDocument15 pagesFake or Credible Antecedents and Consequences of Perce - 2023 - Journal of BusiTariqNo ratings yet

- Hotel Beverage Manager J.D.Document2 pagesHotel Beverage Manager J.D.Luca PezzollaNo ratings yet

- Yannick Obara ResumeDocument1 pageYannick Obara Resumeapi-315619034No ratings yet

- Humanmade vs. SFMade California LawsuitDocument72 pagesHumanmade vs. SFMade California LawsuitMissionLocalNo ratings yet

- Fentahun's Research 111Document37 pagesFentahun's Research 111AytenewNo ratings yet

- MS 109 Water Cooling SystemDocument3 pagesMS 109 Water Cooling SystemAmila Priyadarshana DissanayakeNo ratings yet

- All Grown Up - BareDocument9 pagesAll Grown Up - BareNiamh HawkesNo ratings yet

- Zalora Lite 2Document1 pageZalora Lite 2Rowena HipolitoNo ratings yet

- Resume - Huzaifa Khan BDM23Document2 pagesResume - Huzaifa Khan BDM23Huzaifa KhanNo ratings yet

- Advantages of Kaizen CostingDocument14 pagesAdvantages of Kaizen CostingNoor HaNa HakMa100% (1)

- Your Residential Electricity Bill: Total To PayDocument2 pagesYour Residential Electricity Bill: Total To PayJaram JohnsonNo ratings yet

- Online - Q1 Week - 1 - 2 - Module 1 Product and Service Design Specification Based On The Market FeedbackDocument17 pagesOnline - Q1 Week - 1 - 2 - Module 1 Product and Service Design Specification Based On The Market FeedbackIseiah MiraflorNo ratings yet

- DLL - Epp 6 - Q1 - W4Document4 pagesDLL - Epp 6 - Q1 - W4jairose detablanNo ratings yet

- B-BTAX313 Module 4 (Expenditure Cycle) - Part 1Document15 pagesB-BTAX313 Module 4 (Expenditure Cycle) - Part 1will passNo ratings yet

- Korean DramaDocument2 pagesKorean DramalofsNo ratings yet

- CH 05Document4 pagesCH 05Von Andrei Medina100% (1)

- Micro Economics - PGDMDocument3 pagesMicro Economics - PGDMSAI CHARAN REDDY GALVANo ratings yet

- Ura - DT 1017Document4 pagesUra - DT 1017Allan HenryNo ratings yet

- BCML Risk Management Polcy and FrameworkDocument13 pagesBCML Risk Management Polcy and FrameworkCS Trainee OOLNo ratings yet

- Wilkins 2003Document21 pagesWilkins 2003Amelia afidaNo ratings yet

- Completing The TCEQ Core Data FormDocument7 pagesCompleting The TCEQ Core Data FormRachaelNo ratings yet

- Equivalent Units and Cost Per Equivalent UnitDocument14 pagesEquivalent Units and Cost Per Equivalent UnitIqra AbbasNo ratings yet

- Tiny Tweaks James WedmoreDocument31 pagesTiny Tweaks James WedmoreErise Global100% (1)

- Value, Case #KEL688Document10 pagesValue, Case #KEL688tushar2308No ratings yet

- ECO & BCK - Additional MCQs - ICAIDocument42 pagesECO & BCK - Additional MCQs - ICAI3257 Vibhuti WadekarNo ratings yet

- Hotel Budget Excel TemplateDocument36 pagesHotel Budget Excel TemplateGhaouti ZidaniNo ratings yet

- Risk Ranking and Filtering: Annex I.8Document14 pagesRisk Ranking and Filtering: Annex I.8louish9175841No ratings yet

- New York State Senate Committee Report On Utility Pricing PracticesDocument119 pagesNew York State Senate Committee Report On Utility Pricing PracticesDaily FreemanNo ratings yet

- OD223485816626172000Document1 pageOD223485816626172000Mahipal SinghNo ratings yet