Professional Documents

Culture Documents

Acs Spring 2020 Expo 3312605

Uploaded by

Amm ÃrOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Acs Spring 2020 Expo 3312605

Uploaded by

Amm ÃrCopyright:

Available Formats

Nanoscale Degradation Mechanism of Mixed Cation Perovskite

under Humidity and Light Revealed by Peak Force Infrared Microscopy

Kevin Ho, and Gilbert C. Walker*

Department of Chemistry, University of Toronto, Toronto, Ontario M5S 3H6, Canada

After 17 - 20 hrs, the

ABSTRACT Degradation pathways

This degradation pathway summarizes the findings from the degradation by

morphology and

X-ray diffraction (XRD)

Light and water are well known factors that can cause degradation to organic PFIR intensity does α α-CsFAPbI3 δ δ-FAPbI3

light and high humidity. δ0-CsPbI3 Time

lead halide perovskites, which hinders their commercial applications. Here, we not change. O

* PbI2

studied the degradation mechanism of FA0.85Cs0.15PbI3 using peak force infrared δ-FAPbI3 δ 34 hr After 32 hrs, δ-FAPbI is

microscopy, which enables subdiffractional spatial identification of the

At 0 hr, the surface is FAI When exposed to light

δ αδα α

3

still present in the XRD,

homogenous from FAI or high humidity alone,

CsFAPbI3

O O

formamidinium (FA) cation and allows us to probe the degradation mechanism

of individual grains. We found that upon exposure to light or water alone, no

both the atomic force I2 no degradation occured δ

but from PFIR, the the

26 hr large grains shrank. This

microscopy (AFM) and PbI2 PbI2 during this time. *O δ

significant change in the spatial distribution of FA and no pure inorganic α δ α α α difference arised because

decomposition product was observed. However, upon exposure to both light

PFIR. Pb O

XRD samples a very large

and high humidity, we found that FA0.85Cs0.15PbI3 degrades through a multistep δ0-CsPbI3 12 δ *O area (mm2) but PFIR

pathway. First, α-FA0.85Cs0.15PbI3 decays to δo-CsPbI3, δ-FAPbI3, and PbI2 and the CsI V

O α α δα α images only the central

distribution of the FA cation became increasingly inhomogeneous. Second, the Exposure to spot in the wafer (μm2).

δ

A

organic cations are lost and PbI2 further photodecomposes. 17 hr

Intensity (a.u.)

low humidity *α

PFIR

1 δα α

and light Large grains formed rapidly 400 O α

from 8 - 13 hrs. The large nm δ O

grains show a large increase *α δ α α 13 hr

INTRODUCTION in the PFIR signal. O α

AFM

0 hr 17 hr -400 δ 9 hr

Perovskites are a promising materials for solar cell applications, but suffer

rapid degradation due to various factors such as heat, light, and humidity. XRD shows the formation of 12 O

*α α δ α α

8 hr

δ-FAPbI3 during this time. V After 6 hrs, δ-FAPbI3, and

α 6 hr

The degradation pathways of mixed cation perovskites have been less well Exposure to δ *α PbI2 began to form.

understood. Futhermore, the degradation have not been well studied at the B high humidity

The large grains correspond O αδ α

PFIR

length scale of the individual grains. to the formation of δ-FAPbI3. 1 α α

in the dark 400

nm α α The characterisitc peaks

0 hr for a perovskite are

In this experiment, we studied the degradation of a mixed cation perovskite,

shown at 0 hr.

focusing on the chemical and structural change to the individual grains as 5 10 15 20 25 30 35

-400

AFM

the degradation occured. 0 hr 20 hr 2θ (deg.)

To achieve this, we used peak force infrared microscopy. 12

V

The large grains shrank

and the PFIR intensity

decreased as the volatile

PFIR

organic component in

C δ-FAPbI3 evaportaed. 1

400

nm

Exposure to

high humidity

and light

AFM

0 hr 5 hr 8 hr 9 hr 13 hr 17 hr 28 hr -400 Time

α-CsFAPbI3

CsPbI3 CsPbI3

PbI2 PbI2

δ-FAPbI3 δ-FAPbI3 CONCLUSION

o PFIR was used as a novel technique to study the degradation of

At 0 hr, the sample is perovskites at the nanoscale.

homogenous in both Time-of-flight secondary o When exposed to high humidity or light alone, degradation of FA0.85Cs0.15PbI3

MATERIALS and METHODS The needles do not show

Cs

240

I

AFM and PFIR. ion mass spectrometry was not observed under 20 hr. With simultaneous exposure to light and high

any PFIR absorption at

humdity, the degradation occurred in a two step process.

a. u.

(TOF-SIMS) shows a 1712 cm-1.

The mixed cation perovksite, FA0.85Cs0.15PbI3 was used in the degradation studies. o First, FA0.85Cs0.15PbI3 phase separated into CsPbI3 needles and FAPbI3 as large

400 9 hr After 5 hrs of simultaneous strong signal in the Cs 400

0

12 nm

nm V

and I channel on the

-400 grains.

exposure to light and high 12 V

needles. 0 o PbI2 was formed as depressions, as volatile FAI evaporated.

humidity, needles and 9 hr 13 hr

1 o Second, large grains disappeared, and PbI2 was converted to Pb and I2.

-400 depressions were formed.

*data from another sample

N2

PbI2, CsI, FAI

in DMF/DMSO

Static spin coat

onto a ITO/

Thermal anneal:

150 C, 10 min Peak Force Infrared Microscopy (PFIR) The needles are ACKNOWLEDGEMENTS

Pb solution glass substrate The depression does not identified as CsPbI3.

under N2 have PFIR absorption at 1 2 3

I lase

r

Cs 1712 cm-1, therefore, it does

formamidinium (FA) not contain the FA cation.

H Photodegradation

Imaged in the dark, low humidity: light source

<20% R.H., 22 C. 20% R.H.

The depressions are PbI2. Laser is focused onto The sample thermal expands The deflection can be

Intensity: the tip and the sample. after absorbing the light. measured as a function of

+

H2N NH2 Peak Force tapping mode high humidity: 10 mW/cm2

with Bruker InspireTM The tip is deflected from the the wavenumber or

85% R.H. wavelength range: thermal expansion. spatial position.

500 - 1200 nm

You might also like

- PicarroDocument1 pagePicarroDidi AdisaputroNo ratings yet

- Poster Científico Ej. 2Document1 pagePoster Científico Ej. 2Andres Felipe MNo ratings yet

- Massve Fermion-Pk ApriDocument17 pagesMassve Fermion-Pk ApriKhanin LaylasNo ratings yet

- Radio Frequency (RF) Is A Rate of Oscillation in The Range of About 30Document8 pagesRadio Frequency (RF) Is A Rate of Oscillation in The Range of About 30Rakesh KumarNo ratings yet

- Potenliometrit TitrationsDocument4 pagesPotenliometrit TitrationsJuan Camilo Aguilar MayaNo ratings yet

- Accurate Determination of Catalyst Loading On Glassy Carbon Disk and Its Impact On Thin Film Rotating Disk Electrode For Oxygen Reduction Reaction.Document1 pageAccurate Determination of Catalyst Loading On Glassy Carbon Disk and Its Impact On Thin Film Rotating Disk Electrode For Oxygen Reduction Reaction.Muralidhar ChourashiyaNo ratings yet

- Tang Et Al-2003-Polymers For Advanced TechnologiesDocument5 pagesTang Et Al-2003-Polymers For Advanced TechnologiesMario Dzul CervantesNo ratings yet

- Section Thru B-B: Pre-Departure Departure Drop-Off Area Drop-Off AreaDocument1 pageSection Thru B-B: Pre-Departure Departure Drop-Off Area Drop-Off Areaalezandro del rossiNo ratings yet

- JDSU Fibercharacterization Poster October2005Document1 pageJDSU Fibercharacterization Poster October2005Gaurav SainiNo ratings yet

- Editorial Forum: Page 1 of 7Document7 pagesEditorial Forum: Page 1 of 7afrianiNo ratings yet

- Cartography of Anthropogenic Materials, Sierra de Cartagena-La Unión, SpainDocument2 pagesCartography of Anthropogenic Materials, Sierra de Cartagena-La Unión, SpainManuel AzancotNo ratings yet

- RF PropogationDocument3 pagesRF PropogationShubham RastogiNo ratings yet

- SMAM-in-Epithermal-Porphyry-Systems Poster PDFDocument1 pageSMAM-in-Epithermal-Porphyry-Systems Poster PDFJulian I SwandiNo ratings yet

- Cell Membrane PPDocument43 pagesCell Membrane PPJjrlNo ratings yet

- CCCC Water Transportation Consultants Co - LTD: Designer: Project: Drawing Title: Scale: Client: NotesDocument1 pageCCCC Water Transportation Consultants Co - LTD: Designer: Project: Drawing Title: Scale: Client: NotesJoel MontoyaNo ratings yet

- Aronés-Ayón - EBUS 2022 - 06-P4Document1 pageAronés-Ayón - EBUS 2022 - 06-P4KatiaNo ratings yet

- Ces Drg. No. - Br/Rvnl-241/2022: Junction Arrangement at 'A'Document1 pageCes Drg. No. - Br/Rvnl-241/2022: Junction Arrangement at 'A'satishkumaar053No ratings yet

- Wall Chart NFMT eDocument1 pageWall Chart NFMT eArchana PathakNo ratings yet

- Idaho Dark Sky 2Document1 pageIdaho Dark Sky 2babyyoda5No ratings yet

- Approved For Construction: AusencoDocument1 pageApproved For Construction: AusencoamirNo ratings yet

- Survey Map: in Order To Preserve The Scale, The Map Should Be Printed in Colour Onto A3 PaperDocument2 pagesSurvey Map: in Order To Preserve The Scale, The Map Should Be Printed in Colour Onto A3 PapertawandaNo ratings yet

- Transformer Testing Diagnostics ToolDocument1 pageTransformer Testing Diagnostics ToolOsi MalickNo ratings yet

- Crystals FinalReportDocument12 pagesCrystals FinalReportUkash sukarmanNo ratings yet

- Municipal Drawings of A Residential Unit in BandraDocument5 pagesMunicipal Drawings of A Residential Unit in Bandra1819Janhavi DeshpandeNo ratings yet

- Werkstatt 01 SchematicsDocument9 pagesWerkstatt 01 Schematicsfelas37616No ratings yet

- Light WavesDocument43 pagesLight WavesRizwan AhmedNo ratings yet

- Western Galaxy-Yadagiri BrochureDocument4 pagesWestern Galaxy-Yadagiri BrochureRishi KhuranaNo ratings yet

- Cahaba River 2010-2011Document2 pagesCahaba River 2010-2011spcsysNo ratings yet

- Nice Epmb Eplb Photocells ManualDocument2 pagesNice Epmb Eplb Photocells ManualMFANo ratings yet

- Handbook of XPS PDFDocument193 pagesHandbook of XPS PDFBernay CifuentesNo ratings yet

- Downloaded From: Bajado De/ De/ DeDocument3 pagesDownloaded From: Bajado De/ De/ DeHomero Ruiz HernandezNo ratings yet

- Direct Ammonia Fuel CellDocument1 pageDirect Ammonia Fuel CellParijat MishraNo ratings yet

- RF and EMC Formulas and Charts: Conversions for 50Ω Environment Antenna Equations www.arworld.usDocument1 pageRF and EMC Formulas and Charts: Conversions for 50Ω Environment Antenna Equations www.arworld.usamirNo ratings yet

- Peta GeologiDocument1 pagePeta GeologiOkto FerdinanNo ratings yet

- P&ID For Air CoolersDocument9 pagesP&ID For Air CoolersAvinash ShuklaNo ratings yet

- Project No.3 (Plumbing) CAD File (JLCAE) - TRACING 01Document1 pageProject No.3 (Plumbing) CAD File (JLCAE) - TRACING 01Kurt Laurhon CabahugNo ratings yet

- Steam Network OPTOPN - 2ADocument1 pageSteam Network OPTOPN - 2AbikasheilNo ratings yet

- Ejemplo PosterDocument5 pagesEjemplo PosterJose GNo ratings yet

- Bernard R. Matis ACS Nano 6 17Document6 pagesBernard R. Matis ACS Nano 6 17Tania ChatterjeeNo ratings yet

- PracDocument1 pagePracmccoytingosiaNo ratings yet

- GeohydrologicColumns AGWSE2003Document1 pageGeohydrologicColumns AGWSE2003cptnastroNo ratings yet

- 3.1.1 Periodicity QPDocument19 pages3.1.1 Periodicity QPSarahNo ratings yet

- DDG2007Document2 pagesDDG2007Mohamed AbbasNo ratings yet

- 1.3 Extragalactic EmpiricismDocument4 pages1.3 Extragalactic EmpiricismSHAM painNo ratings yet

- 11 Network - Poster - Pbde CabelloDocument1 page11 Network - Poster - Pbde CabelloSabrina MammanaNo ratings yet

- Plumbing Notes:: Isometric DiagramDocument1 pagePlumbing Notes:: Isometric DiagramAshley VelascoNo ratings yet

- ASTM D5373-13 - CHN in Coal and Coke-3Document11 pagesASTM D5373-13 - CHN in Coal and Coke-3Luis M Molina100% (1)

- HEY There Is HistoryDocument1 pageHEY There Is HistoryAntonio SgròNo ratings yet

- A036513001 PDFDocument1 pageA036513001 PDFanon_929347044100% (2)

- Elec 3Document1 pageElec 3Shiela Tala-oc Sapois-AndoNo ratings yet

- Atlas Towers - KIKKE0068 KerwaDocument7 pagesAtlas Towers - KIKKE0068 KerwaPsi FactorsNo ratings yet

- Poster Ecoc Rimini 030921Document1 pagePoster Ecoc Rimini 030921Jaya Kumar KbNo ratings yet

- Presentacion Final JdepierolaDocument13 pagesPresentacion Final JdepierolaCarlosNo ratings yet

- Biochemistry 244 Practical Test NotesDocument1 pageBiochemistry 244 Practical Test NotesIlse de LangeNo ratings yet

- Redox Signaling in Widespread Health Benefits of Exercise: Forum Review ArticleDocument45 pagesRedox Signaling in Widespread Health Benefits of Exercise: Forum Review ArticleJessicaNo ratings yet

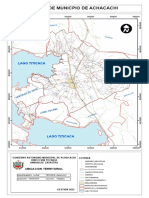

- MAPA MunicipioDocument1 pageMAPA MunicipioInez apazaNo ratings yet

- Breccia Poster Vancouver 07 V2 NHDocument1 pageBreccia Poster Vancouver 07 V2 NHZulfa SabilyNo ratings yet

- Poster Miranda PDFDocument1 pagePoster Miranda PDFxabihdez05No ratings yet

- Chap 3Document11 pagesChap 3sunsms0108No ratings yet

- Using Vibrational Spectroscopy To Assess The Influence of Defects On The Local Structures of Low Dimension Hybrid PerovskitesDocument1 pageUsing Vibrational Spectroscopy To Assess The Influence of Defects On The Local Structures of Low Dimension Hybrid PerovskitesAmm ÃrNo ratings yet

- Acs Spring 2020 Expo 3298011Document1 pageAcs Spring 2020 Expo 3298011Amm ÃrNo ratings yet

- Acs Spring 2020 Expo 3276624Document1 pageAcs Spring 2020 Expo 3276624Amm ÃrNo ratings yet

- Acs Spring 2020 Expo 3305393Document1 pageAcs Spring 2020 Expo 3305393Amm ÃrNo ratings yet

- Acs Spring 2020 Expo 3302905Document1 pageAcs Spring 2020 Expo 3302905Amm ÃrNo ratings yet

- Acs Spring 2020 Expo 3299686Document1 pageAcs Spring 2020 Expo 3299686Amm ÃrNo ratings yet

- ArticleDocument16 pagesArticleAmm ÃrNo ratings yet

- Acs Spring 2020 Expo 3295482Document1 pageAcs Spring 2020 Expo 3295482Amm ÃrNo ratings yet

- Acs Spring 2020 Expo 3284738Document1 pageAcs Spring 2020 Expo 3284738Amm ÃrNo ratings yet

- Acs Fall 2020 MTG 3426003Document1 pageAcs Fall 2020 MTG 3426003Amm ÃrNo ratings yet

- Acs Spring 2020 Expo 3275326Document19 pagesAcs Spring 2020 Expo 3275326Amm ÃrNo ratings yet

- Features of ESP: University of Batna - 2-Motefa Benboulaid Module: IlsDocument5 pagesFeatures of ESP: University of Batna - 2-Motefa Benboulaid Module: IlsAmm ÃrNo ratings yet

- Acs Spring 2020 Expo 3281335 - 2Document1 pageAcs Spring 2020 Expo 3281335 - 2Amm ÃrNo ratings yet

- HypothesesDocument2 pagesHypothesesAmm ÃrNo ratings yet

- منهجية البحث العلمي و كيفية تحرير المقالات العلمية - 220516 - 155918Document18 pagesمنهجية البحث العلمي و كيفية تحرير المقالات العلمية - 220516 - 155918Amm ÃrNo ratings yet

- Needs Analysis - A Prior Step To ESP Course DesignDocument29 pagesNeeds Analysis - A Prior Step To ESP Course DesignAmm Ãr100% (1)

- A Sample Proposal With CommentDocument3 pagesA Sample Proposal With CommentramszlaiNo ratings yet

- A Needs Analysis Approach To ESP Syllabus Design in Greek Tertiary Education: A Descriptive Account of Students' NeedsDocument6 pagesA Needs Analysis Approach To ESP Syllabus Design in Greek Tertiary Education: A Descriptive Account of Students' NeedsHazim HasbullahNo ratings yet

- The Discourse of Nurse-Patient InteractionsDocument3 pagesThe Discourse of Nurse-Patient InteractionsAmm ÃrNo ratings yet

- Development Learning Material EspDocument6 pagesDevelopment Learning Material EspAmm ÃrNo ratings yet

- Needs Assessment in ESP: A Review: Adeel KhalidDocument9 pagesNeeds Assessment in ESP: A Review: Adeel KhalidAmm ÃrNo ratings yet

- An ESP Course Design For Postgraduate Students of Engineering at Badji Mokhtar Annaba UniversityDocument10 pagesAn ESP Course Design For Postgraduate Students of Engineering at Badji Mokhtar Annaba UniversityAmm ÃrNo ratings yet

- Developing ESP Teaching Materials Based On The AnaDocument11 pagesDeveloping ESP Teaching Materials Based On The AnaAmm ÃrNo ratings yet

- Migrant Workers in Home CareDocument9 pagesMigrant Workers in Home CareAmm ÃrNo ratings yet

- The Role of Needs Analysis in English For SpecificDocument18 pagesThe Role of Needs Analysis in English For SpecificAmm ÃrNo ratings yet

- The ESP Teacher: Issues, Tasks and Challenges: English For Specific Purposes World January 2014Document34 pagesThe ESP Teacher: Issues, Tasks and Challenges: English For Specific Purposes World January 2014Ami NaNo ratings yet

- The Role of Needs Analysis in English For SpecificDocument18 pagesThe Role of Needs Analysis in English For SpecificAmm ÃrNo ratings yet

- The Neccesitty F Teaching ESP For NursingDocument12 pagesThe Neccesitty F Teaching ESP For NursingAmm ÃrNo ratings yet

- Needs Analysis: Esp Syllabus Design For Indonesian Efl Nursing StudentsDocument11 pagesNeeds Analysis: Esp Syllabus Design For Indonesian Efl Nursing StudentsFitraAshariNo ratings yet

- INGEPAC LINE PROTECTION RELAY-overviewDocument2 pagesINGEPAC LINE PROTECTION RELAY-overviewmilan9bNo ratings yet

- SV1-10-4/4M/4R: - Solenoid ValveDocument2 pagesSV1-10-4/4M/4R: - Solenoid ValveCORTOCIRCUITANTENo ratings yet

- Sprint Case - Study IICS - UpdatedDocument3 pagesSprint Case - Study IICS - UpdatedajaybhosalNo ratings yet

- Notes On Graph Algorithms Used in Optimizing Compilers: Carl D. OffnerDocument100 pagesNotes On Graph Algorithms Used in Optimizing Compilers: Carl D. Offnerref denisNo ratings yet

- 17.11.1501 - Andhy Panca SaputraDocument10 pages17.11.1501 - Andhy Panca SaputraRiyan pandusadewoNo ratings yet

- s67 Rosen Thermo - Hi.pvc Iz 2018 enDocument34 pagess67 Rosen Thermo - Hi.pvc Iz 2018 enSomea NoneaNo ratings yet

- Tutorial 6Document5 pagesTutorial 6Nixon GamingNo ratings yet

- PetDocument15 pagesPetAhmed RhifNo ratings yet

- Sunshape Thesis - Wilbert - DLRDocument177 pagesSunshape Thesis - Wilbert - DLRAhmed AlshehrriNo ratings yet

- Excel CheatsheetDocument1 pageExcel CheatsheetBoring BlandNo ratings yet

- DS PGM Using CPPDocument18 pagesDS PGM Using CPPanand5703No ratings yet

- Keyop Functions 9F3715Document114 pagesKeyop Functions 9F3715Art MessickNo ratings yet

- 11.4.2.5 Packet Tracer - Backing Up Configuration FDocument2 pages11.4.2.5 Packet Tracer - Backing Up Configuration FRichardWhitley100% (1)

- CSS - 05-Module 5.2 - Network Devices1Document6 pagesCSS - 05-Module 5.2 - Network Devices1Elixa HernandezNo ratings yet

- Parker Comoso P16 Series Aluminium Bushing Gear Pump.55b98395d96e7Document4 pagesParker Comoso P16 Series Aluminium Bushing Gear Pump.55b98395d96e7Jas SumNo ratings yet

- SI CI (1) Simple Interest, Compound InterstDocument3 pagesSI CI (1) Simple Interest, Compound Interstdiksahu wfeeNo ratings yet

- FlowLine Level Transmitter Ultrasonic EchoSpan LU80 LU81 LU83 LU84 Data SheetDocument2 pagesFlowLine Level Transmitter Ultrasonic EchoSpan LU80 LU81 LU83 LU84 Data SheetPromagEnviro.comNo ratings yet

- Liquidity Commonality in The Cryptocurrency MarketDocument16 pagesLiquidity Commonality in The Cryptocurrency MarketabhinavatripathiNo ratings yet

- Singapore DTL Signalling by Joana Lee (Siemens Pte LTD) 18th Nov 2016Document23 pagesSingapore DTL Signalling by Joana Lee (Siemens Pte LTD) 18th Nov 2016Rizky Harry SungguhNo ratings yet

- Advanced Manufacturing Processes (ALL SLIDES Gaurav Arora)Document259 pagesAdvanced Manufacturing Processes (ALL SLIDES Gaurav Arora)faizNo ratings yet

- Introduction To DSADocument11 pagesIntroduction To DSAdhiraj1223353No ratings yet

- RFID VasuDocument22 pagesRFID Vasuapi-19984981No ratings yet

- Curl and DivDocument3 pagesCurl and DivgjdapromiseNo ratings yet

- Planets, Luminaries, Asteroids, and Points in AstrologyDocument3 pagesPlanets, Luminaries, Asteroids, and Points in AstrologySushant ChhotrayNo ratings yet

- Door SheetDocument9 pagesDoor SheetAnilkumarNo ratings yet

- Bazaar Tent StructureDocument5 pagesBazaar Tent StructurephilipyapNo ratings yet

- Design Characteristics and Development of A Nozzle For Coaxial Laser CladdingDocument10 pagesDesign Characteristics and Development of A Nozzle For Coaxial Laser CladdingEduardo MendezNo ratings yet

- Remy Hvh250 Application Manual: Preliminary Draft Hvh250 Motormanual20110407.Doc Page 1 of 31Document31 pagesRemy Hvh250 Application Manual: Preliminary Draft Hvh250 Motormanual20110407.Doc Page 1 of 31David WalshNo ratings yet

- Log TMBAG6NEXD0028904 210446km 130765miDocument6 pagesLog TMBAG6NEXD0028904 210446km 130765miSasa MitrovicNo ratings yet

- Applsci 1985066 Peer Review v1Document19 pagesApplsci 1985066 Peer Review v1mlupoae2003No ratings yet