Professional Documents

Culture Documents

MCTD 1

Uploaded by

Clash GodOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

MCTD 1

Uploaded by

Clash GodCopyright:

Available Formats

(

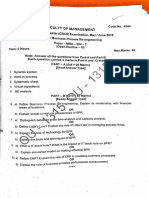

Totalt-.. ofPage 02 Roll No .......

FOUR:1'H SEMESTER B.Tecb. (PE)

SUPPLEMENTARY EXAMINATION August-2018

PE-208 Metal Cutting & Tool Design

Time: 3:00 Hours Max. Marks: 40

Note:Answer any Five questions.

Assume suitable rnissin data, if an .

la Draw Merchant's circle diagram, explaining all the notations used. State 5

the assumptions made in the development of such a diagram

b How do you differentiate between orthogonal cutting and·oblique cutting? 3

2a Prove that 5

'Tfl2

State the assumptions made.

b What does the term size effect mean in metal cutting? 3

3a Explain the various methods of measuring the chip tool interface 5

temperature in metal _cutting.

b What are the benefits and harmful effects of cutting fluids? 3

--------- ---4a-Discuss the different mechanisms of tool wear.--- - - - - _ _ ___, _____ _

b Describe the criteria's which influence_machinability. 3

Sa Derive an expressio~ for optimum cutting speed for minimum cost in 5 .

turning. .

b A carbide . cutting tool lasted. for 2 hours while machining mild steel 3

workpiece at 45m/min. Compute the tool life if a similar tool is used for

machining mild steel at 20% higher sp~ Also what will be the value of

cutting speed if the tool is required to machine for 3 hours without

failing. Assume Taylor's exponent n = 02.7.

6What is the m~asure of performance of a grinding wheel? Define the 8

equivalent diameter of a grinding wheel and derive an expression in terms

of wheel diameter dt and workpiece diameter dw in internal and external

---cylindrical grinding;-··--,- -c·- -~ =-==== - --- -- - - ______ ___ __ ___ ____ _ ____ _

P.T.O

,r: ·

·-l .

7a How broaches are classified? Explain with the help of a figure the 5

different portions ofa pull type broach?

b What are the steps that have to be considered when cutting tools have to 3

be designed?

-END-

- . - . --. . ' . . - ..

·····- ·- •·- - ----------··- --- -----· -- ----------- ·-·-· · · -· --··· --

...·--· ··

You might also like

- Production Engineering: Jig and Tool DesignFrom EverandProduction Engineering: Jig and Tool DesignRating: 4 out of 5 stars4/5 (9)

- 01 - Dispersion of A Free Non-Buoyant Fluid JetDocument5 pages01 - Dispersion of A Free Non-Buoyant Fluid JetJoren HuernoNo ratings yet

- 53112-MT - Theory of Metal Cutting & Tool DesignDocument2 pages53112-MT - Theory of Metal Cutting & Tool Designhari0118No ratings yet

- P 7.8a, 7.8B 7.8CDocument23 pagesP 7.8a, 7.8B 7.8Csyahmi samirNo ratings yet

- 2021 22jun 2022IVRegularAR20MECH20ME403MetalCutting&MachineToolsDocument2 pages2021 22jun 2022IVRegularAR20MECH20ME403MetalCutting&MachineToolsJury.rahulNo ratings yet

- Homework 3Document2 pagesHomework 3Kirandeep GandhamNo ratings yet

- Rotaz No. of 1 : PE 208 M - Time 3 HoursDocument1 pageRotaz No. of 1 : PE 208 M - Time 3 HoursClash GodNo ratings yet

- WT2 (4th) May2022Document1 pageWT2 (4th) May2022adhish071No ratings yet

- Cambridge IGCSE: MATHEMATICS 0580/22Document12 pagesCambridge IGCSE: MATHEMATICS 0580/22alyazia6163No ratings yet

- 03 0580 22 2024 3rp Afp m24 12022024Document12 pages03 0580 22 2024 3rp Afp m24 12022024nflbubba468100% (1)

- Faculty of Manag EmentDocument12 pagesFaculty of Manag EmentSriharsha SKNo ratings yet

- 112 - Dwi Rizky Rosilila - UNIT3 - EssayDocument11 pages112 - Dwi Rizky Rosilila - UNIT3 - EssayDwi Rizky RosililaNo ratings yet

- Jntuworld: R09 Set No. 2Document6 pagesJntuworld: R09 Set No. 2Dr-Asit Kumar ParidaNo ratings yet

- MCMT Mid-1 P-QusDocument5 pagesMCMT Mid-1 P-QusN Dhanunjaya Rao BorraNo ratings yet

- Me 5 PT 2021Document3 pagesMe 5 PT 2021SameerNo ratings yet

- Circle MADocument32 pagesCircle MAzozelkady18No ratings yet

- SL 317 - Manufacturing Engineering - Sem V - May 2017 PDFDocument3 pagesSL 317 - Manufacturing Engineering - Sem V - May 2017 PDFAnantkumar GujarNo ratings yet

- Die Casting Design PDFDocument38 pagesDie Casting Design PDFPrabagarane Ramachandran100% (2)

- Internal Assessment Test 2Document15 pagesInternal Assessment Test 2Don bhauNo ratings yet

- Internal Assessment Test 2Document15 pagesInternal Assessment Test 2Don bhauNo ratings yet

- Ain Shams Untversity (' / ') (' (''') / ',L'',-) ' L Faculty of EngineeringDocument2 pagesAin Shams Untversity (' / ') (' (''') / ',L'',-) ' L Faculty of EngineeringMostafaNo ratings yet

- P.E.S. College of Engineering, Mandya - 571 401Document2 pagesP.E.S. College of Engineering, Mandya - 571 401coolmagaNo ratings yet

- W 2019 A - Merged - WatermarkDocument18 pagesW 2019 A - Merged - WatermarkDivya ChandewarNo ratings yet

- Key 4Document14 pagesKey 4Jury.rahulNo ratings yet

- 3-1 MT (Nov 2009 Regular)Document5 pages3-1 MT (Nov 2009 Regular)micmechNo ratings yet

- Experiment 3Document12 pagesExperiment 3ambryx2001No ratings yet

- MT-II LM-319F VSemDocument18 pagesMT-II LM-319F VSemHarkulvinder SinghNo ratings yet

- Ffiuk: Ain Shams University I - :) Faculty of EngineerngDocument2 pagesFfiuk: Ain Shams University I - :) Faculty of EngineerngMostafaNo ratings yet

- Design and Fabrication of Metal Spinning ComponentsDocument6 pagesDesign and Fabrication of Metal Spinning ComponentsAnonymous VRspXsmNo ratings yet

- Die Casting Die DesignDocument38 pagesDie Casting Die DesignSuneth TharakaNo ratings yet

- Me G532 262 CDocument2 pagesMe G532 262 Croy 123No ratings yet

- Cambridge IGCSEDocument16 pagesCambridge IGCSEgrengtaNo ratings yet

- Questions Paper of 2021Document10 pagesQuestions Paper of 2021Momin Ameen khanNo ratings yet

- Workshop Technology-Ii 4 Exam/Mech./RAC/Prod/Auto/Marine/5310/9410/Nov'18 Duration: 3Hrs. M.Marks:75 Section-A Q1. Do As Directed. 15x1 15Document1 pageWorkshop Technology-Ii 4 Exam/Mech./RAC/Prod/Auto/Marine/5310/9410/Nov'18 Duration: 3Hrs. M.Marks:75 Section-A Q1. Do As Directed. 15x1 15Sourav yadavNo ratings yet

- Ie&ec - 2022 C20Document4 pagesIe&ec - 2022 C20CALVARY NIBANDHANANo ratings yet

- Part B SheetsDocument33 pagesPart B SheetsShaikh IrfanNo ratings yet

- Machine Tool Tech.Document7 pagesMachine Tool Tech.Shashi Bhushan PatelNo ratings yet

- Memb 333 - Final Exam - Sem II-207-208Document4 pagesMemb 333 - Final Exam - Sem II-207-208jihardistNo ratings yet

- EASA Mod 7A BK 7 RivetsDocument65 pagesEASA Mod 7A BK 7 RivetsVasco M C Santos100% (1)

- MED Lab Manual PDFDocument44 pagesMED Lab Manual PDFharshNo ratings yet

- End Sem PyqDocument5 pagesEnd Sem PyqJaspreet veeraNo ratings yet

- WWW - Manaresults.co - In: Design of Machine Members - IiDocument2 pagesWWW - Manaresults.co - In: Design of Machine Members - IiXyz AbcNo ratings yet

- Qustion Bank AMP 1Document24 pagesQustion Bank AMP 1Pramod DhaigudeNo ratings yet

- D-Bot Build GuideDocument78 pagesD-Bot Build GuidemailNo ratings yet

- NoteDocument2 pagesNoteClash GodNo ratings yet

- D-Bot - Build - Guide Rev2Document77 pagesD-Bot - Build - Guide Rev2pieter.gabriel005No ratings yet

- Shipbulding Technology 5th Semester SyllabusDocument33 pagesShipbulding Technology 5th Semester SyllabusDiploma in Engineering Shipbuilding Technology100% (1)

- IPE 203 Fall 2020 Mist (Sec A)Document2 pagesIPE 203 Fall 2020 Mist (Sec A)Ayesha MalihaNo ratings yet

- Cambridge IGCSEDocument8 pagesCambridge IGCSErayirthr2010No ratings yet

- Experiment 1: Aim: Study and Practice of Orthogonal & Oblique Cutting On A Lathe. Apparatus: Lathe Machine TheoryDocument20 pagesExperiment 1: Aim: Study and Practice of Orthogonal & Oblique Cutting On A Lathe. Apparatus: Lathe Machine TheoryMuhammad ShahryabNo ratings yet

- D-Bot Build GuideDocument77 pagesD-Bot Build GuideSpencer ColeNo ratings yet

- Question Bank For Machining and MetrologyDocument7 pagesQuestion Bank For Machining and MetrologyAbhisheak DineshNo ratings yet

- Keywords: Twist Drills, Geometric Modeling, Solidmodeling TechniquesDocument4 pagesKeywords: Twist Drills, Geometric Modeling, Solidmodeling TechniqueserkmorenoNo ratings yet

- Tool Model Building and Research On Cutting Simulation Experiment of Ti6Al4VDocument21 pagesTool Model Building and Research On Cutting Simulation Experiment of Ti6Al4VhaceneNo ratings yet

- Set 18 3Document19 pagesSet 18 3Caro Kan LopezNo ratings yet

- Mid 2 &mid 3Document10 pagesMid 2 &mid 30 0No ratings yet

- Prompting Science and Engineering Students in Practical TrigonometryFrom EverandPrompting Science and Engineering Students in Practical TrigonometryNo ratings yet

- Screwcutting in the Lathe for Home Machinists: Reference Handbook for Both Imperial and Metric ProjectsFrom EverandScrewcutting in the Lathe for Home Machinists: Reference Handbook for Both Imperial and Metric ProjectsNo ratings yet

- Total No. of Pages 02 Roi/No ......... .. Machine Design ME-262 Fourth SEM., B.Tech. (PE)Document2 pagesTotal No. of Pages 02 Roi/No ......... .. Machine Design ME-262 Fourth SEM., B.Tech. (PE)Clash GodNo ratings yet

- Semesrer Examination Pe-202: Thermal Engineering-Ii: !?our - Ta SemesterDocument2 pagesSemesrer Examination Pe-202: Thermal Engineering-Ii: !?our - Ta SemesterClash GodNo ratings yet

- Semester: I.T1cb. lPEIDocument2 pagesSemester: I.T1cb. lPEIClash GodNo ratings yet

- End Semester Examinatlbn Pe-215 Thermal System-Ii: Time:3:00 HourDocument2 pagesEnd Semester Examinatlbn Pe-215 Thermal System-Ii: Time:3:00 HourClash GodNo ratings yet

- Thermal 5Document2 pagesThermal 5Clash GodNo ratings yet

- NoteDocument2 pagesNoteClash GodNo ratings yet

- Ieor 3Document2 pagesIeor 3Clash GodNo ratings yet

- Thermal 6Document1 pageThermal 6Clash GodNo ratings yet

- Time 3 Hours Max. Marks: 100 : Roll No.Document2 pagesTime 3 Hours Max. Marks: 100 : Roll No.Clash GodNo ratings yet

- Thermal 7Document2 pagesThermal 7Clash GodNo ratings yet

- Thermal 8Document1 pageThermal 8Clash GodNo ratings yet

- FMM 3Document1 pageFMM 3Clash GodNo ratings yet

- Trigonometry Level 1 Test: Committed To Excellence in EducationDocument2 pagesTrigonometry Level 1 Test: Committed To Excellence in EducationShreyas BansalNo ratings yet

- Mathematical StudiesDocument3 pagesMathematical StudiesEddy R. VélezNo ratings yet

- An Introduction To Matched FilterDocument19 pagesAn Introduction To Matched FilterMuhammad Abdul HadiNo ratings yet

- 0.6 Out of 0.6 Points: Distribution As 68% Is Typically Used For Normal DistributionDocument5 pages0.6 Out of 0.6 Points: Distribution As 68% Is Typically Used For Normal Distribution高晴汝No ratings yet

- Site Surveying and Levelling John ClansyDocument36 pagesSite Surveying and Levelling John ClansyJohn William TolentinoNo ratings yet

- Lesson 1.3: General Properties of Indefinite IntegralsDocument6 pagesLesson 1.3: General Properties of Indefinite IntegralsMarkNo ratings yet

- Precalculus ch6 ReviewDocument2 pagesPrecalculus ch6 Reviewapi-213604106No ratings yet

- Mathematics 3Document142 pagesMathematics 3fafaNo ratings yet

- SAP 2000 Tutorial Session Notes: 1.051 Structural Engineering Design Prof. Oral Buyukozturk Fall 2003Document9 pagesSAP 2000 Tutorial Session Notes: 1.051 Structural Engineering Design Prof. Oral Buyukozturk Fall 2003Daniel HaileNo ratings yet

- STPM Maths T Assignment Introduction ExampleDocument2 pagesSTPM Maths T Assignment Introduction ExampleLing YiNo ratings yet

- H. R. Post Auth., Steven French, Harmke Kamminga Eds. Correspondence, Invariance and Heuristics Essays in Honour of Heinz Post PDFDocument375 pagesH. R. Post Auth., Steven French, Harmke Kamminga Eds. Correspondence, Invariance and Heuristics Essays in Honour of Heinz Post PDFAnonymous Ut5fBmdVENo ratings yet

- Transport Phenomena Fluid Mechanics Problem Solution BSL - Parabolic Mirror Fabrication From Free Surface Shape of Rotating LiquidDocument5 pagesTransport Phenomena Fluid Mechanics Problem Solution BSL - Parabolic Mirror Fabrication From Free Surface Shape of Rotating LiquidyudhaputraNo ratings yet

- Math - Module 1Document7 pagesMath - Module 1Carlos PadillaNo ratings yet

- Chhattisgarh Public Service Commission: Telegram - Vasu Study IQDocument15 pagesChhattisgarh Public Service Commission: Telegram - Vasu Study IQjerseyNo ratings yet

- Finite Element AnalysisDocument160 pagesFinite Element AnalysisRichie Richard0% (1)

- Jackson 1.4 Homework Problem SolutionDocument4 pagesJackson 1.4 Homework Problem SolutionJhonNo ratings yet

- Brownian Motion: Langevin EquationDocument14 pagesBrownian Motion: Langevin Equationctasaltin100% (2)

- When Does Investor Sentiment Predict Stock Returns?: San-Lin Chung, Chi-Hsiou Hung, and Chung-Ying YehDocument40 pagesWhen Does Investor Sentiment Predict Stock Returns?: San-Lin Chung, Chi-Hsiou Hung, and Chung-Ying YehddkillerNo ratings yet

- 2020 MMP-AI Assignment 01 PDFDocument2 pages2020 MMP-AI Assignment 01 PDFpalakNo ratings yet

- Marine Engineering Mtech AssignmentDocument3 pagesMarine Engineering Mtech AssignmentDaniel Inemugha100% (1)

- ADDDocument162 pagesADDrahimNo ratings yet

- Cobol Interview QuestionsDocument4 pagesCobol Interview QuestionshudarulNo ratings yet

- KrolresumeDocument3 pagesKrolresumeapi-282046209No ratings yet

- 1.4: Quadratic Equations: Section OutlineDocument4 pages1.4: Quadratic Equations: Section OutlineAHMED ALSHAMMARINo ratings yet

- R7211003 Electromagnetic Waves and Transmission LinesDocument1 pageR7211003 Electromagnetic Waves and Transmission LinessivabharathamurthyNo ratings yet

- Decimals: From White Rose Maths Schemes For Year 6 Spring TermDocument8 pagesDecimals: From White Rose Maths Schemes For Year 6 Spring TermShabana MullaNo ratings yet

- I 1691Document32 pagesI 1691Juan Carlos Montes CastillaNo ratings yet

- Mixing-A Detailed Look at The Factors That Influence Mix UniformityDocument19 pagesMixing-A Detailed Look at The Factors That Influence Mix UniformityreyesdavidNo ratings yet

- Unil Ecch 26 MagnetismDocument72 pagesUnil Ecch 26 Magnetismeviegonzalez211No ratings yet