Professional Documents

Culture Documents

Irbp L

Uploaded by

ANDREOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Irbp L

Uploaded by

ANDRECopyright:

Available Formats

Robotics

IRBP L

Positioner

The ABB positioners are optimized

to be used for manipulating of

work pieces in arc welding, ther-

mal cutting and other applications.

All axes can be fully coordinated

with the robot when programming

as well as during operation.

IRBP L

This positioner is suitable for applications requiring one or two ABB’s positioners are designed to be highly functional yet

stations and for workpieces requiring rotation around one axis to compact to make maximum use of available floor space.

access optimal process position. The IRBP L is of modular design Standardised dimensions for all rotating plates greatly simplify

with four main components – rotary unit, stand for rotary unit, the exchange of fixtures.

tailstock and support beam.

Dynamic modelling allows rapid acceleration, fast movements

The positioner IRBP L, which comes in five versions, is designed and re-orientation so that cycle times are kept to a minimum.

to handle workpieces including fixture of a weight up to 5000 kg The dynamic model automatically compensates for the effects

of gravity, inertia and friction to provide fast movements

The modular design, few and heavy-duty moving parts as well (QuickMove™) and accurate following of the programmed path

as minimal maintenance demands make the positioner service (TrueMove™).

friendly.

The Load ID-function is used to calculate the centre of gravity and

Dynamically adaptive software plus high speed drives result in fast the inertia of the workpiece and of the fixture.

changeovers and high productivity.

To meet requirements from our users the positioners can be

General positioner features supplied, or retrofitted, with a comprehensive range of pneumatic

swivels (1 and 2 channels) and slip-rings (10 power signals and

All ABB positioners offer users a complete and efficient solution. ProfiBus).

They are of a robust design to ensure excellent stability and are

well protected for operation in harsh production environments. ABB positioner systems can be supplied with all necessary safety

All positioners can be combined with any ABB six axes robots equipment.

except the small IRB 120.

The positioners are easy to use with clear, simple instructions

for programming. The control equipment is located in the robot

controller and uses the same drive system and software as the

robots.

IRBP L

Specification

Variants L-300 L-600 L-1000 L-2000 L-5000

Handling capacity kg 300 600 1000 2000 5000

Max cont. torque Nm 350 650 900 3800 9000

Max bending moment Nm 600 3300 5000 15000 60000

Repetitive accuracy (r=500) mm +/-0.05 +/-0.05 +/-0.05 +/-0.05 +/-0.05

Max rotation speed °/s 180 150 150 90 39

Copyright © ABB Robotics PR10112EN_R4 April 2010

Measurements A B C D

L-300 1250 950 750 1979

1600 950 750 2329

2000 950 750 2729

2500 950 750 3229

3150 950 750 3879

4000 950 750 4729

L-600 & L-1000 1250 950 750 2182

1600 950 750 2532

2000 950 750 2932

2500 950 750 3432

3150 950 750 4082

4000 950 750 4932

L-2000 1250 950 750 2423

1600 950 750 2773

2000 950 750 3173

2500 950 750 3673

3150 950 750 4323

4000 950 750 5173

L-5000 - 1200 1100 -

- 1200 1100 -

- 1200 1100 -

- 1200 1100 -

- 1200 1100 -

- 1200 1100 -

For complementary information , please see the product specification.

ABB reserves the rights to change specifications without notice

www.abb.com/robotics

You might also like

- IRBP-L Datasheet PR10112EN RevDDocument2 pagesIRBP-L Datasheet PR10112EN RevDkantapon sompanithanNo ratings yet

- IRBP L Positioner Range: Fast Rotating Workpiece SolutionsDocument2 pagesIRBP L Positioner Range: Fast Rotating Workpiece SolutionsMaurício Jorge CostaNo ratings yet

- Irbp R: PositionerDocument2 pagesIrbp R: PositionerIulia CostacheNo ratings yet

- Datablad Irbp A Pr10080en r3Document2 pagesDatablad Irbp A Pr10080en r3VeronicaNistorNo ratings yet

- Maini Stackers Complete Range CatalogueDocument8 pagesMaini Stackers Complete Range CataloguesaravananNo ratings yet

- Bonfiglioli Marine Drives for marine and offshore machinesDocument20 pagesBonfiglioli Marine Drives for marine and offshore machinesVlad AndronacheNo ratings yet

- Summary Machine Program Inspection Report: Model Unit C/N Engine GR256 Model S/NDocument8 pagesSummary Machine Program Inspection Report: Model Unit C/N Engine GR256 Model S/NJoko WahonoNo ratings yet

- BD 330 en Eu 050527Document2 pagesBD 330 en Eu 050527Cesar GuerraNo ratings yet

- IRB1520ID ROB0214EN Rev.IDocument2 pagesIRB1520ID ROB0214EN Rev.IAndrzej WojciechowskiNo ratings yet

- Rendering Rotary Cooker Ver. 1.3Document2 pagesRendering Rotary Cooker Ver. 1.3TG-MachinesNo ratings yet

- GB Double Scissors VDocument2 pagesGB Double Scissors VCostescuAdrianNo ratings yet

- HMB-HMC Motors PDFDocument7 pagesHMB-HMC Motors PDFCharly CharlyNo ratings yet

- Liebherr lb36 Drilling RigDocument16 pagesLiebherr lb36 Drilling RigRichard OngNo ratings yet

- Renk T Recs Leading Propulsion TechnologyDocument8 pagesRenk T Recs Leading Propulsion Technologyhumayun121No ratings yet

- Manual Book DS (HAPAM)Document3 pagesManual Book DS (HAPAM)Farchan Agus SujonoNo ratings yet

- 10 - Accesorios de Los Transformadores (Parte2)Document63 pages10 - Accesorios de Los Transformadores (Parte2)LOURDES JANNETH LIMON ROMERONo ratings yet

- Features of The Sideros RotoLiftDocument2 pagesFeatures of The Sideros RotoLiftDaniel AustinNo ratings yet

- Product-Datasheet PS2 60-kN enDocument20 pagesProduct-Datasheet PS2 60-kN enPolimatec MecânicaNo ratings yet

- 08 Steering Manouvr.Document3 pages08 Steering Manouvr.Ariel Farinon100% (1)

- Solutions For: Marine & OffshoreDocument28 pagesSolutions For: Marine & OffshoreBimo Cungkring IINo ratings yet

- Volvo Trucks VolvoDocument16 pagesVolvo Trucks VolvoSri WaluyoNo ratings yet

- Inertia Bases Model VIB: ApplicationsDocument1 pageInertia Bases Model VIB: Applicationsddaalayamoct313024No ratings yet

- Monolithic Wheels for Harsh EnvironmentsDocument1 pageMonolithic Wheels for Harsh EnvironmentsEko PrastyoNo ratings yet

- Maruti Suzuki India LimitedDocument23 pagesMaruti Suzuki India LimitedAkhilesh JainNo ratings yet

- Wide Operating Speed Range Engine RatingsDocument10 pagesWide Operating Speed Range Engine Ratingszxy320dNo ratings yet

- Up To 35kV TransformerDocument23 pagesUp To 35kV TransformerRatnagiri RamkumarNo ratings yet

- Hyundai Heavy Industries - Gas Insulated SwitchgearDocument25 pagesHyundai Heavy Industries - Gas Insulated SwitchgearbadbenzationNo ratings yet

- 682 v380 ENDocument8 pages682 v380 ENVenk KisaragiNo ratings yet

- Single Girder CranesDocument5 pagesSingle Girder CranesVignesh NadimuthuNo ratings yet

- Directional Force Geared Exciter OverviewDocument1 pageDirectional Force Geared Exciter OverviewYousef AlipourNo ratings yet

- IRB 2600ID-8 - 2.00 Product PresentationDocument17 pagesIRB 2600ID-8 - 2.00 Product Presentation)Y(arianoNo ratings yet

- RM 900ib (E) 07Document4 pagesRM 900ib (E) 07oscar AlvaradoNo ratings yet

- Capacity WestfaliaDocument1 pageCapacity WestfaliaAlexanderNo ratings yet

- Renk T2recsDocument8 pagesRenk T2recs3819706776No ratings yet

- Agitators: We Are The Expert ofDocument12 pagesAgitators: We Are The Expert ofArriandiArriandiNo ratings yet

- Liebherr Complete Brochure enDocument24 pagesLiebherr Complete Brochure enناصرقوجيلNo ratings yet

- 12 HOberDocument4 pages12 HOberAhmad YaniNo ratings yet

- Lobe Rotor Pump for Olive Mass TransferDocument2 pagesLobe Rotor Pump for Olive Mass TransferDorcioman AndreiNo ratings yet

- Hangcha Electrico, Operador SentadoDocument2 pagesHangcha Electrico, Operador SentadoFreddy AndresNo ratings yet

- Increasing The Robot's Working Area High Speed - Short Cycle Time Direct or Slewing DriveDocument2 pagesIncreasing The Robot's Working Area High Speed - Short Cycle Time Direct or Slewing DriveIulia CostacheNo ratings yet

- 65L, 95L, 120L, 160L, 250L, 320L: 6" Stainless Steel Submersible PumpsDocument9 pages65L, 95L, 120L, 160L, 250L, 320L: 6" Stainless Steel Submersible PumpsTimothy Joshua GatchalianNo ratings yet

- BondekUserGuideJune2012 PDFDocument0 pagesBondekUserGuideJune2012 PDFkh88hmiNo ratings yet

- 132KV Isolator CatalogDocument3 pages132KV Isolator CatalogTanvir Ahmed Minar0% (1)

- Liebherr LRB355 Piling and Drilling Rig Data Sheet 11890403 EnglishDocument20 pagesLiebherr LRB355 Piling and Drilling Rig Data Sheet 11890403 EnglishManuelNo ratings yet

- IRB120Document2 pagesIRB120sedat atalayNo ratings yet

- TDA-F Series: Smokespill Axial FanDocument4 pagesTDA-F Series: Smokespill Axial FanViệt Đặng XuânNo ratings yet

- FUKUSHIMA Hydraulic Deck MachineryDocument26 pagesFUKUSHIMA Hydraulic Deck MachinerypcatruongNo ratings yet

- Vibrochimica General CatalogueDocument28 pagesVibrochimica General CatalogueYatrikNo ratings yet

- Datos Técnicos Robot Industrial IRB 6600 03Document2 pagesDatos Técnicos Robot Industrial IRB 6600 03gussyNo ratings yet

- DS PantographDocument3 pagesDS PantographmazzoffaNo ratings yet

- Brosjyre GSSB PDFDocument3 pagesBrosjyre GSSB PDFVishnu ShankerNo ratings yet

- Lexe0170 00Document2 pagesLexe0170 00Victor PoquizNo ratings yet

- Work Boats Waflaf 2346 - 7760Document8 pagesWork Boats Waflaf 2346 - 7760Adhietama SumarsonoNo ratings yet

- Financial Services Co BudgetsDocument21 pagesFinancial Services Co BudgetsAlexandru VasilescuNo ratings yet

- High-Pressure Fans, typeXP - BrochureDocument4 pagesHigh-Pressure Fans, typeXP - BrochureAnonymous Cxriyx9HIXNo ratings yet

- M 6ib FootprintDocument4 pagesM 6ib Footprintto0984903132No ratings yet

- Hiab 800: Technical DataDocument52 pagesHiab 800: Technical DataGerald Leon FloresNo ratings yet

- Allison Transmissions: How to Rebuild & Modify: How to Rebuild & ModifyFrom EverandAllison Transmissions: How to Rebuild & Modify: How to Rebuild & ModifyRating: 5 out of 5 stars5/5 (1)

- High-Performance GM LS-Series Cylinder Head GuideFrom EverandHigh-Performance GM LS-Series Cylinder Head GuideRating: 4.5 out of 5 stars4.5/5 (2)

- IRBP R PositionerDocument2 pagesIRBP R PositionerMario DuranNo ratings yet

- Irbp CDocument2 pagesIrbp CANDRENo ratings yet

- Irb 660Document2 pagesIrb 660ANDRENo ratings yet

- IRBP R PositionerDocument2 pagesIRBP R PositionerMario DuranNo ratings yet

- Irb 460Document2 pagesIrb 460ANDRENo ratings yet

- ROB0207EN - A - IRB 760 Data SheetDocument2 pagesROB0207EN - A - IRB 760 Data SheetDraghescu DanielNo ratings yet

- Irb 260Document2 pagesIrb 260ANDRENo ratings yet

- Industrial Robot: Main Application Arc WeldingDocument2 pagesIndustrial Robot: Main Application Arc WeldingANDRENo ratings yet

- Toyota 8FBN PDFDocument7 pagesToyota 8FBN PDFweda utama100% (1)

- 6600 AbbDocument80 pages6600 AbbANDRENo ratings yet

- MSeries RevB2Document7 pagesMSeries RevB2Guillermo MartínezNo ratings yet

- Toyota 8FBN PDFDocument7 pagesToyota 8FBN PDFweda utama100% (1)

- Irb 4400 Pr10035en r8 PDFDocument2 pagesIrb 4400 Pr10035en r8 PDFBien LeNo ratings yet

- FGMNXFMDocument1 pageFGMNXFMplayboi501No ratings yet

- HiDocument1 pageHiANDRENo ratings yet

- Overdue invoices notice from MyCompanyNameDocument1 pageOverdue invoices notice from MyCompanyNameplayboi501No ratings yet

- Formal CollectionDocument1 pageFormal CollectionrgmilleriiiNo ratings yet

- 3 Motion and I/O Programming: 3.1 Coordinate SystemsDocument6 pages3 Motion and I/O Programming: 3.1 Coordinate SystemsANDRENo ratings yet

- Speed Control Methods of 3-Phase Induction MotorsDocument3 pagesSpeed Control Methods of 3-Phase Induction MotorsBenzene diazonium saltNo ratings yet

- Mobilization and Participation: Social-Psychological Expansisons of Resource Mobilization TheoryDocument19 pagesMobilization and Participation: Social-Psychological Expansisons of Resource Mobilization TheoryJoaquim OliveiraNo ratings yet

- User Manual: Smart Alarm System & AppDocument41 pagesUser Manual: Smart Alarm System & AppEduardo Jose Fernandez PedrozaNo ratings yet

- Akhtamov A.A. - Destination C1-C2, Test CollectionDocument37 pagesAkhtamov A.A. - Destination C1-C2, Test CollectionNguyen NhiNo ratings yet

- G8 - Light& Heat and TemperatureDocument49 pagesG8 - Light& Heat and TemperatureJhen BonNo ratings yet

- Brochure PILA Lamps and LuminairesDocument42 pagesBrochure PILA Lamps and Luminairesaldtol21No ratings yet

- Electroencephalography (EEG) : Dr. Altaf Qadir KhanDocument65 pagesElectroencephalography (EEG) : Dr. Altaf Qadir KhanAalia RanaNo ratings yet

- Hve r13Document1 pageHve r13aleem_201sNo ratings yet

- Vastu House PlanDocument187 pagesVastu House Planshilpa shahNo ratings yet

- Captiva 2013 Systema Electric 3.0Document13 pagesCaptiva 2013 Systema Electric 3.0carlos martinez50% (2)

- BOYSEN® Marmorino™ Italian Marble Finish: Liters UseDocument1 pageBOYSEN® Marmorino™ Italian Marble Finish: Liters UseJohn Ray Esmama CalasicasNo ratings yet

- Lesson 4 - Nature of The Speech Communication ProcessDocument4 pagesLesson 4 - Nature of The Speech Communication ProcessDon Miguel SpokesNo ratings yet

- E - Program Files (x86) - Schneider - sft2841 - sft2841 Serie 80 - Notice - en - Manual - Sepam - Series80 - Operation - ENDocument180 pagesE - Program Files (x86) - Schneider - sft2841 - sft2841 Serie 80 - Notice - en - Manual - Sepam - Series80 - Operation - ENJuan Cristóbal Rivera PuellesNo ratings yet

- DL1 - Epicyclic Gear Train & Holding Torque ManualDocument4 pagesDL1 - Epicyclic Gear Train & Holding Torque Manualer_arun76100% (1)

- SC Project Closeout Report v6Document27 pagesSC Project Closeout Report v6SateeshIngoleNo ratings yet

- Simpack Off-Line and Real Time SimulationDocument23 pagesSimpack Off-Line and Real Time SimulationAnderson ZambrzyckiNo ratings yet

- Achmad Nurdianto, S.PD: About MeDocument2 pagesAchmad Nurdianto, S.PD: About Medidon knowrezNo ratings yet

- Memo-on-Orientation and Submission of PNPKIDocument5 pagesMemo-on-Orientation and Submission of PNPKICoronia Mermaly LamsenNo ratings yet

- The Practice of Medicinal Chemistry, 4th EditionDocument2 pagesThe Practice of Medicinal Chemistry, 4th Editionlibrary25400% (1)

- Java Pattern Programming AssignmentsDocument9 pagesJava Pattern Programming Assignmentstamj tamjNo ratings yet

- Advanced Long Range Proximity Reader PDFDocument1 pageAdvanced Long Range Proximity Reader PDFPhangkie RecolizadoNo ratings yet

- MCC-2 (Intermediate & Finishing Mill)Document17 pagesMCC-2 (Intermediate & Finishing Mill)Himanshu RaiNo ratings yet

- Mitspeck 2014 e VersionDocument130 pagesMitspeck 2014 e VersionVedantDomkondekarNo ratings yet

- Modified o and G Slides 2Document21 pagesModified o and G Slides 2Salam FaithNo ratings yet

- Analyzing an Anti-Smoking Poster Using a Formalist ApproachDocument20 pagesAnalyzing an Anti-Smoking Poster Using a Formalist ApproachAlphred Jann NaparanNo ratings yet

- BITS Vulnerability Management Maturity ModelDocument19 pagesBITS Vulnerability Management Maturity ModelJack JacksonNo ratings yet

- Chapter 5Document31 pagesChapter 5Marvin VinasNo ratings yet

- CatalogDocument12 pagesCatalogjonz afashNo ratings yet

- Develop, Implement and Maintain WHS Management System Task 2Document4 pagesDevelop, Implement and Maintain WHS Management System Task 2Harry Poon100% (1)

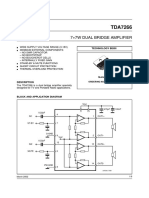

- Tda7266 PDFDocument9 pagesTda7266 PDFRenato HernandezNo ratings yet