Professional Documents

Culture Documents

Process Sequence of Garments Finishing Section

Uploaded by

Zahid zami0 ratings0% found this document useful (0 votes)

12 views2 pagesThe garments finishing section is the last stage of garments manufacturing. It involves an initial quality check of received sewn garments, spot removal, ironing or pressing, inspection, hangtag attachment, folding, polybagging, metal detection, and final packaging or cartoning before shipment. The goal is to finish garments and prepare them for safe delivery to buyers.

Original Description:

Original Title

Process Sequence of Garments Finishing Section.docx

Copyright

© © All Rights Reserved

Available Formats

DOCX, PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentThe garments finishing section is the last stage of garments manufacturing. It involves an initial quality check of received sewn garments, spot removal, ironing or pressing, inspection, hangtag attachment, folding, polybagging, metal detection, and final packaging or cartoning before shipment. The goal is to finish garments and prepare them for safe delivery to buyers.

Copyright:

© All Rights Reserved

Available Formats

Download as DOCX, PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

12 views2 pagesProcess Sequence of Garments Finishing Section

Uploaded by

Zahid zamiThe garments finishing section is the last stage of garments manufacturing. It involves an initial quality check of received sewn garments, spot removal, ironing or pressing, inspection, hangtag attachment, folding, polybagging, metal detection, and final packaging or cartoning before shipment. The goal is to finish garments and prepare them for safe delivery to buyers.

Copyright:

© All Rights Reserved

Available Formats

Download as DOCX, PDF, TXT or read online from Scribd

You are on page 1of 2

Process Sequence of Garments Finishing Section:

Garments finishing is an important section in the readymade garments sector. It’s the last

section of the garments manufacturing department. As with all the other sections of

garments manufacturing, the garments finishing section has also followed a process flow

chart, which has explained in this article.

Process Flow Chart of Garments Finishing:

Sewn garments received in finishing section

↓

Initial quality check

↓

Spot removing if there’s any spot

↓

Ironing or pressing

↓

Inspection

↓

Hangtag attaching

↓

Folding

↓

Polybag

↓

Metal check

↓

Packaging or cartoning

All the processes have discussed in the below table:

S/L No. Process Procedure

Here, sewn garments are received for finishing the

01 Sewn garments received in finishing section garments.

Sewn garments are checked here by the quality

controller. If found major sewing problems then

garments sent again to the sewing section for

02 Initial quality check rectification.

Sometimes garments contain various types of spots

03 Spot removing if there’s any spot which are removed here carefully.

It’s one of the important processes in garment

finishing. Here garments are ironed by following the

04 Ironing or pressing measurement chart of those garments.

After completing ironing or finishing, garments are

inspected again here by the quality controller to

05 Inspection confirm the correct measurement of the apparel.

In this section, the hangtag has to attach to the

06 Hangtag attaching garments.

After completing all the above processes, garments

07 Folding are folded here.

Garments are poly-bagged here to keep the garments

dust, dirt, and other impurities free. send the

08 Polybag garments safely to the buyer.

In this section, garments should be passed through a

metal detector machine to identify metal lies in the

09 Metal check garments.

Finally, all the garments should pack to send the

10 Packaging or cartooning garments safely to the buyer.

You might also like

- 3 6-FinishingDocument10 pages3 6-FinishingShahriarNo ratings yet

- Denim Washing ProcessDocument14 pagesDenim Washing ProcessShilpa LimjeNo ratings yet

- Quality Control SopDocument7 pagesQuality Control SopKumera HaileyesusNo ratings yet

- Study On CCI Sizing MachineDocument5 pagesStudy On CCI Sizing MachineNaimul HasanNo ratings yet

- Garment Industry DepartmentDocument4 pagesGarment Industry DepartmentNidhi GargNo ratings yet

- Washing Flow ChartDocument4 pagesWashing Flow ChartShahadat Hossain BayzidNo ratings yet

- Post Production Process: Thread Trimming Washing & Drying Pressing Initial CheckingDocument4 pagesPost Production Process: Thread Trimming Washing & Drying Pressing Initial CheckingSakshiNo ratings yet

- Flow Chart of Garments Manufacturing ProcessDocument17 pagesFlow Chart of Garments Manufacturing ProcessMandal SouvikNo ratings yet

- Flow Chart of Garments Manufacturing Process / Technology:: Pattern MakingDocument3 pagesFlow Chart of Garments Manufacturing Process / Technology:: Pattern MakingMohammed ĹukmanNo ratings yet

- Garments Inspection SystemDocument16 pagesGarments Inspection SystemZahid Hasan0% (1)

- 3 5-SewingDocument4 pages3 5-SewingShahriarNo ratings yet

- Apparel Quality ManagementDocument32 pagesApparel Quality Managementshawar6967% (3)

- DocumentasDocument5 pagesDocumentasRAZOR GAMINGNo ratings yet

- Unit 1Document17 pagesUnit 1Senthil DuraiNo ratings yet

- Fabrics SopDocument4 pagesFabrics SopLizon music choiceNo ratings yet

- Quality & Quality InspectionDocument5 pagesQuality & Quality InspectionRAZOR GAMINGNo ratings yet

- Daffodil International University AssignDocument13 pagesDaffodil International University AssignXoven SaikatNo ratings yet

- Process of Fully Fashioned Knitwear ManufacturingDocument5 pagesProcess of Fully Fashioned Knitwear ManufacturingDr. RajibNo ratings yet

- PID 990KR2 - Target Store Quality IssueDocument9 pagesPID 990KR2 - Target Store Quality IssueAll In OneNo ratings yet

- Fabrics Warehouse Procedure in Garments IndustryDocument3 pagesFabrics Warehouse Procedure in Garments Industrysok daraNo ratings yet

- Quality Check Points in Garment ProductionDocument5 pagesQuality Check Points in Garment ProductionumairvmdNo ratings yet

- WH7560J3DE7060G1 User ManualDocument52 pagesWH7560J3DE7060G1 User ManualLtc ChromeNo ratings yet

- Denim Fabrics:: JeansDocument2 pagesDenim Fabrics:: Jeansdyuti singhNo ratings yet

- Total Quality Management: SIPOC Diagram For Irfan TextilesDocument9 pagesTotal Quality Management: SIPOC Diagram For Irfan TextileszainNo ratings yet

- Powercube1000 Power System Routine Maintenance and TroubleshootingDocument54 pagesPowercube1000 Power System Routine Maintenance and TroubleshootingHoda GaziaNo ratings yet

- Garment InspectionDocument12 pagesGarment Inspectionmohan smrNo ratings yet

- Garment Factory Production ProcessDocument2 pagesGarment Factory Production ProcessSadakchar PeriyiahNo ratings yet

- Garments Finishing and QCDocument27 pagesGarments Finishing and QCHadiuzzaman LeonNo ratings yet

- KOMATSU Hydraulic Breaker JMHB09H-1 SEN06664-01 Shop ManualDocument60 pagesKOMATSU Hydraulic Breaker JMHB09H-1 SEN06664-01 Shop ManualchinhNo ratings yet

- Dumptruck Operator ManualDocument26 pagesDumptruck Operator Manual董磊100% (1)

- Operating Instructions Washing MachineDocument24 pagesOperating Instructions Washing Machineغزوان عماد الدين الحسينيNo ratings yet

- Analysis of Sewing Defects and Control IJPTE-V7I2P10420200710-95083-1vdx52v-with-cover-page-v2Document8 pagesAnalysis of Sewing Defects and Control IJPTE-V7I2P10420200710-95083-1vdx52v-with-cover-page-v2Abdul Mateen TahirNo ratings yet

- Apparel ProductionDocument27 pagesApparel ProductionISHITANo ratings yet

- Garment Quality ConceptDocument119 pagesGarment Quality ConceptMila IcuzNo ratings yet

- Last Mile Base - Development 14.08Document9 pagesLast Mile Base - Development 14.08Fernando LimaNo ratings yet

- Finishing Section SOPDocument3 pagesFinishing Section SOPAbdul AzizNo ratings yet

- Process Flow Chart of Garments ManufacturingDocument3 pagesProcess Flow Chart of Garments ManufacturingdhanafdNo ratings yet

- Garment Manufacturing Process Flow From Buyer To ShipmentDocument27 pagesGarment Manufacturing Process Flow From Buyer To Shipmenttallraj50% (2)

- Garments Manufacturing SequenceDocument32 pagesGarments Manufacturing SequenceRudi PurnamaNo ratings yet

- Quality Control in Joggers Knit TrouserproductionDocument12 pagesQuality Control in Joggers Knit TrouserproductionSazzadul AhsanNo ratings yet

- Ra - MC8 Drier CabinsDocument3 pagesRa - MC8 Drier CabinsalbinkhanNo ratings yet

- Safety Checks For Escalators Ramps and Autowalks - May 2020 - tcm46-91316Document17 pagesSafety Checks For Escalators Ramps and Autowalks - May 2020 - tcm46-91316vikrant987No ratings yet

- Washer GTWN3000MWS ManualDocument24 pagesWasher GTWN3000MWS ManualTravisNo ratings yet

- Fabric Inspection ProcedureDocument20 pagesFabric Inspection ProcedureGarmentLearnerNo ratings yet

- Presentation Denim ProjectDocument27 pagesPresentation Denim ProjectAnshuman SinghNo ratings yet

- 430218B Front-Loader Washer user-install-guide-FL600-NZAUSGDocument64 pages430218B Front-Loader Washer user-install-guide-FL600-NZAUSGabdulsmithNo ratings yet

- Sequence of Operaion of SpinningDocument68 pagesSequence of Operaion of SpinningShivam AgnihotriNo ratings yet

- Quality Section GarmentsDocument11 pagesQuality Section GarmentsSM.SOBUZ HOSENNo ratings yet

- Safety InstructionsDocument12 pagesSafety InstructionsNaythan CasasnovasNo ratings yet

- Garment InspectionDocument9 pagesGarment InspectionJames_45No ratings yet

- Amaan Work. 01Document21 pagesAmaan Work. 01Izhan ANo ratings yet

- WLW 3600 BDocument24 pagesWLW 3600 BJesus Rafael Mendoza BrachoNo ratings yet

- WB156PS 5Document556 pagesWB156PS 5PooNo ratings yet

- Yeasin Arafat Omi WETDocument14 pagesYeasin Arafat Omi WETjack omeNo ratings yet

- Statistical Approach To Quality ManagementDocument46 pagesStatistical Approach To Quality Managementmsj fall2021No ratings yet

- General Steucture of Denim Garment UnitDocument17 pagesGeneral Steucture of Denim Garment UnitumairvmdNo ratings yet

- Lifting Plan (25T XCMG)Document2 pagesLifting Plan (25T XCMG)Armando AballeNo ratings yet

- Ironing Process Procedure - Foldmaker 35Document4 pagesIroning Process Procedure - Foldmaker 35haizad_hamzah100% (1)

- Sewing ThreadDocument10 pagesSewing ThreadZahid zamiNo ratings yet

- PrintingDocument9 pagesPrintingZahid zami100% (1)

- TextileDocument13 pagesTextileZahid zamiNo ratings yet

- Sewing Thread Consumption For Some ApparelDocument3 pagesSewing Thread Consumption For Some ApparelZahid zamiNo ratings yet

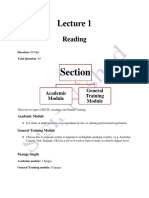

- M.Lecture 1 (Reading) PDFDocument2 pagesM.Lecture 1 (Reading) PDFZahid zamiNo ratings yet