Professional Documents

Culture Documents

SP YY MRK 016 R2 InstGuide F2

Uploaded by

Jorge RamosOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

SP YY MRK 016 R2 InstGuide F2

Uploaded by

Jorge RamosCopyright:

Available Formats

I N S TA L L AT I O N & O P E R AT I O N G U I D E

Before installation please ensure you have read the Safe Swivel™

joint orientation and Operation and safety information.

This guide should be followed to ensure the Swivelpole™ is assembled

and installed safely and correctly.

Copies of general assembly drawings are available online

www.swivelpole.com

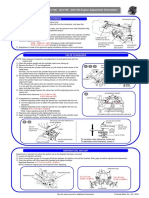

Installation of Swivelpole™ F2

1. Feed the electrical cable 12. Apply enough tension to allow

through the base section of the controlled raising of the pole top.

Swivelpole™. 13. At this point, the Swivelpole™ will

2. Position the base section over the be self supporting.

installed cage bolts (optional) or 14. To raise, push the pole top, guiding

as specified (see Safe Swivel™ joint it as it swivels to the upright

orientation). position.

3. Align the base section so it is 15. Insert the safety pin.

vertical.

16. With the pole top in the upright

4. Tighten base plate bolts. position, mark the pole in the

5. Feed the electrical cable through direction the luminaire is to face,

the pole top prior to bolting to the and lower it again to fit luminaire

base swivel plate. mount. Pole top

6. Apply multi-purpose grease to 17. To lower, retract the safety pin

swivel plate surfaces and bolts. and swivel the pole top down to a

7. Slide the clamp plate onto the pole safe working height and insert the

top. safety pin.

8. With one person holding the pole 18. Fit the luminaire mount as per

top horizontally, the second person marked position on the pole top.

can position the round swivel plate 19. When using non threaded poles

locator into the hole of the base and Swivelpole™ luminaire mount,

section swivel plate. tighten the set screws to a torque

9. Bolt the clamp plate to the base setting of 12 lb/ft to 15 lb/ft.

section swivel plate, using the 20. Complete installation and

½”UNC x 2”HT galvanized hex head termination of the luminaire.

bolts with spring and flat washers. 21. Raise the Swivelpole™ and insert

10. The safety pin wire loop should be the safety pin.

fitted between the plates using the 22. Tighten the bolts evenly to a

bottom left-hand bolt. torque setting of between 30 lb/ft Base

11. Tighten the bolts evenly. and 60 lb/ft. section

Round

swivel plate Pole top

Clamp plate

Bolt

Spring washer

Base section

Flat washer

SP-NEC-Installation Guide F2-20140725

I N S TA L L AT I O N & O P E R AT I O N G U I D E

The patented Swivelpole™ allows controlled lowering of the pole into a safe

and comfortable working position. This guide should be followed to ensure

the Swivelpole™ is assembled and installed safely and correctly so it works

to its optimum performance.

Copies of general assembly drawings are available online

www.swivelpole.com

Safe Swivel™ joint orientation

Important: Safe Swivel™ joint allows clockwise or anti-clockwise orientation at any degree from the guardrail, with lowering operation to either side to avoid any clash to either side.

0° Safe Swivel™ joint orientation 30° Safe Swivel™ joint

Orientation avoiding clash behind the

MOTION

PATH

orientation MOTION

PATH

guardrail and to the right side. 0°

Anti-clockwise orientation avoiding

clash to the left side.

30 Anti-Clockwise

ORIENTATION

MOTION PATH 0 ORIENTATION

Stanchion mounted 0°

orientation

45°

MOTION

PATH

Stanchion mounted 45°

anti-clockwise orientation

75° Safe Swivel™ joint orientation 90° Safe Swivel™ joint orientation

MOTION

Clockwise orientation avoiding PATH 90°

Anti-clockwise orientation avoiding MOTION

clash behind the guardrail and clash behind the guardrail and PATH

to either side. to the right side.

75 Clockwise

ORIENTATION

90 Anti-Clockwise

ORIENTATION

Structure mounted 90°

anti-clockwise orientation

°09

Column mounted 90°

MOTION clockwise orientation MOTION

PATH PATH

Operation and safety information

Tool and material requirements

These guides are to be followed in conjunction with your worksite

procedures, safety rules and regulations. Swivelpole™ assembly

To lower Swivelpole™: To raise Swivelpole™: • A torque wrench.

1. Ensure safety pin is inserted. 1. Retract the safety pin. • Allen keys to suit: 5/16” set screws - use for

2. Loosen - but do not remove - bolts so 2. Push the pole top, guiding it as it light mounts. ⅜” or ½” set screws - use for

the top section lowers with swivels to the upright position. Retrofit locking collars.

some resistance on the clamping 3. Insert the safety pin. • Multi-purpose grease for Safe Swivel™ joint.

plate. This allows safe and 4. Tighten the bolts evenly to a

Maintenance and inspection

controlled lowering action for torque setting of between

one-person operation. 30 lb/ft and 60 lb/ft. • Ensure the product operation label remains

3. Whilst holding the pole top with one visible and legible.

hand, retract the safety pin and lower • Visually check the Swivelpole™ for any signs

it to a comfortable working position. of damage and report findings.

4. Insert the safety pin.

Customer Service Product warranty. All equipment and goods are warranted by the seller to be free from defects in

material and workmanship for five (5) years from the date of shipment. This warranty does not apply

to equipment or goods which are misused, or abused, or damaged from installation, or not used in

Swivelpole™ accordance with seller’s instructions. Normal wear of equipment or goods is not included in this

warranty. No responsibility will be taken for any modifications, alterations or additions to the

Email: sales@swivelpole.com standard product design. This includes exceeding recommended maximum weights for any fittings

or exceeding the installed height.

swivelpole.com Patented. Swivelpole™ products are manufactured under licence.

Patents include US patent No. 6957832 and Australian patent No. 767949

You might also like

- Methods Statement-Rev A1Document61 pagesMethods Statement-Rev A1bolinag86% (7)

- De Walt 1450 - 1250 Radial Arm Saw Use and Care BookDocument12 pagesDe Walt 1450 - 1250 Radial Arm Saw Use and Care Bookloach7133% (3)

- Vemco 612 User's ManualDocument25 pagesVemco 612 User's ManualRobert Cannavino100% (1)

- ST16 ST17Document2 pagesST16 ST17miniras843No ratings yet

- Arrihead ManualDocument24 pagesArrihead ManualFede GiardinaNo ratings yet

- Use and Care of The Level and Transit-LevelDocument27 pagesUse and Care of The Level and Transit-LevelprotobooksNo ratings yet

- The Losmandy G-11 Equatorial Mount User's ManualDocument12 pagesThe Losmandy G-11 Equatorial Mount User's ManualjohnpellejeroNo ratings yet

- Technical Guide Archery Sights Bow Sights ANTSDocument8 pagesTechnical Guide Archery Sights Bow Sights ANTSCarlos Fernández SNo ratings yet

- TSR-009 - EngDocument7 pagesTSR-009 - EngA2139No ratings yet

- Operation Maintenance M1 CarbineDocument2 pagesOperation Maintenance M1 CarbineAnonymous oAbjbl4HNo ratings yet

- 888 SeriesDocument4 pages888 SeriesAntonio ArellanoNo ratings yet

- Directions For The New T-REX ROTARY TABLE AND CHAINSAW GUIDEDocument1 pageDirections For The New T-REX ROTARY TABLE AND CHAINSAW GUIDEDanny DanNo ratings yet

- 7400 Cem40 QSGDocument6 pages7400 Cem40 QSGsudhangshu_ghoseNo ratings yet

- Chapter - 05 - EN - A600 - Edizione 10-2006aDocument10 pagesChapter - 05 - EN - A600 - Edizione 10-2006aRazvan CristeaNo ratings yet

- Blade PDFDocument2 pagesBlade PDFMunyaradzi MarizaniNo ratings yet

- Navod Na PouzitieDocument32 pagesNavod Na Pouzitieali222beliNo ratings yet

- Pivot Bolt Pivot Bushing Lever Stop Adjustment: Installation InstructionsDocument1 pagePivot Bolt Pivot Bushing Lever Stop Adjustment: Installation InstructionsPaulo CostaNo ratings yet

- 512 User's ManualDocument17 pages512 User's ManualSam CozaNo ratings yet

- 114EQ and 127EQ TELESCOPES: Quick Set-Up GuideDocument10 pages114EQ and 127EQ TELESCOPES: Quick Set-Up GuideDaan LacerdaaNo ratings yet

- Eyebolts & Eyenuts: How Should You Select The Right Bolt?Document4 pagesEyebolts & Eyenuts: How Should You Select The Right Bolt?Lazzarus Az GunawanNo ratings yet

- Universal Auto Feed Reel Easy String Head: WarningDocument6 pagesUniversal Auto Feed Reel Easy String Head: WarningElena CMNo ratings yet

- 4cust Serv GuideGpLmBktDocument8 pages4cust Serv GuideGpLmBktmetalmak ltdaNo ratings yet

- Cal. 9015/90S5 Assembly ManualDocument3 pagesCal. 9015/90S5 Assembly Manualmarco arduiniNo ratings yet

- Linn Ittok LVII ManualDocument4 pagesLinn Ittok LVII Manualdougal99No ratings yet

- Series 13 Dir-Act 3-Piece Ball Valve Installation, Operation, and Maintenance InstructionsDocument3 pagesSeries 13 Dir-Act 3-Piece Ball Valve Installation, Operation, and Maintenance InstructionsluchitocapoNo ratings yet

- Veritas Hand Jointer C 01 eDocument1 pageVeritas Hand Jointer C 01 eJr JcNo ratings yet

- Photo Tripod: Owner's ManualDocument6 pagesPhoto Tripod: Owner's ManualMohnishNo ratings yet

- Warp Drive Propellers 001-04-23 Setting Propeller Blade Pitch InstructionsDocument4 pagesWarp Drive Propellers 001-04-23 Setting Propeller Blade Pitch Instructionssymbiotico6462No ratings yet

- How To Install Simply Track For 10mDocument7 pagesHow To Install Simply Track For 10mDimitri KABORENo ratings yet

- Drawout CBDocument1 pageDrawout CBrabia akramNo ratings yet

- AUTOLEVELDocument49 pagesAUTOLEVELChetan ChauhanNo ratings yet

- Mini Launcher: Instruction Manual and Experiment Guide For The PASCO Scientific Model ME-6825ADocument44 pagesMini Launcher: Instruction Manual and Experiment Guide For The PASCO Scientific Model ME-6825AaldrfgNo ratings yet

- Bearing Swaging PortableDocument13 pagesBearing Swaging PortableHemant BommidalaNo ratings yet

- Woodpecker Plungelift™ Installation Instructions: Step 1Document2 pagesWoodpecker Plungelift™ Installation Instructions: Step 1MarcosPauloGrilloNo ratings yet

- How To Adjust A Irritrol Rotor HeadDocument2 pagesHow To Adjust A Irritrol Rotor HeadSasaRadovanacNo ratings yet

- Universal Sostenuto 70743 April 2013Document3 pagesUniversal Sostenuto 70743 April 2013Jennifer BurnsNo ratings yet

- 5.3.1 Rated Lifting Capacity Table and Lifting Height Curve Diagram 5.3.1.1 Rated Lifting Capacity TableDocument9 pages5.3.1 Rated Lifting Capacity Table and Lifting Height Curve Diagram 5.3.1.1 Rated Lifting Capacity TableBasem ElhosanyNo ratings yet

- Makita hr4000c Parts ManualDocument44 pagesMakita hr4000c Parts ManualJose SanchezNo ratings yet

- Bravo Shift AdjustDocument4 pagesBravo Shift AdjustLucasNo ratings yet

- ACET208 Theodolite PresentationDocument6 pagesACET208 Theodolite Presentationsilverm_4No ratings yet

- Training Materials of DFCV DANA Axle 东风德纳车桥培训材料Document108 pagesTraining Materials of DFCV DANA Axle 东风德纳车桥培训材料rizalNo ratings yet

- Tripod User Manual PDFDocument5 pagesTripod User Manual PDFSergio Ramoz,No ratings yet

- Fuel Pump Overhauling DismantlinDocument5 pagesFuel Pump Overhauling DismantlinAnoop Vijayakumar100% (1)

- Alignment Tests On Lathe MachineDocument8 pagesAlignment Tests On Lathe Machinechandrarao chNo ratings yet

- TVF Tranšėjos Apsaugų Surinkimo Instrukcija ENDocument12 pagesTVF Tranšėjos Apsaugų Surinkimo Instrukcija ENemat41No ratings yet

- DAG 2.2 InstructionsDocument6 pagesDAG 2.2 InstructionsHector LandeteNo ratings yet

- WOLF A1 Operator ManualDocument2 pagesWOLF A1 Operator Manuallivintrife2gNo ratings yet

- 5.5 Derricking Mechanism: Stop in NeutralDocument2 pages5.5 Derricking Mechanism: Stop in NeutralRwan MarymNo ratings yet

- Honda HRA214 Quick AdjustDocument1 pageHonda HRA214 Quick AdjusthicksdpNo ratings yet

- Linhof Super Technika V 4x5 Instruction Manual 1969 - English LanguageDocument11 pagesLinhof Super Technika V 4x5 Instruction Manual 1969 - English LanguageTres BolasNo ratings yet

- Type CMR, Instalacion.Document4 pagesType CMR, Instalacion.Mario MarquezNo ratings yet

- Home Built CNCDocument110 pagesHome Built CNCBobby Chipping100% (4)

- Bernina Manual 950 ENDocument22 pagesBernina Manual 950 ENmilesdzynNo ratings yet

- Hooks and Shackles: Clevis Grab Hook Clevis Slip HookDocument7 pagesHooks and Shackles: Clevis Grab Hook Clevis Slip HookWade SperryNo ratings yet

- WooleeWinder Cleaning InstructionsDocument8 pagesWooleeWinder Cleaning InstructionsargonnixNo ratings yet

- Dremel Drill Press Model 210 InstructionsDocument1 pageDremel Drill Press Model 210 Instructionsjimdigriz0% (1)

- 2012513单亮片英文说明书 -Ia User Manual for Sequin DeviceDocument5 pages2012513单亮片英文说明书 -Ia User Manual for Sequin DeviceMohamed NadirNo ratings yet

- Levelling InstrumentsDocument2 pagesLevelling InstrumentskrisleenNo ratings yet

- Unit 3 Theodolite SurveyingDocument15 pagesUnit 3 Theodolite Surveying121915501016 gitamNo ratings yet

- Pfaff 80 Sewing Machine Instruction ManualDocument44 pagesPfaff 80 Sewing Machine Instruction ManualiliiexpugnansNo ratings yet

- Hardware Auto & Machinery May22Document86 pagesHardware Auto & Machinery May22Gustavo BritoNo ratings yet

- Detailed Specification For Damp Proof CourseDocument37 pagesDetailed Specification For Damp Proof CourseMadumitha RameshNo ratings yet

- Analysis & Design of Innovative Industrial Roof: Arpita Nikam, Priyanka JoshilkarDocument9 pagesAnalysis & Design of Innovative Industrial Roof: Arpita Nikam, Priyanka Joshilkardino mohammedNo ratings yet

- Class Ifcmaterial Quantity Qty - TypeDocument3 pagesClass Ifcmaterial Quantity Qty - TypeNguyên Trịnh CaoNo ratings yet

- Kingdom of Saudi Arabia: Epc of Package Sanitary Waste Water Treatment PlantDocument26 pagesKingdom of Saudi Arabia: Epc of Package Sanitary Waste Water Treatment PlantM Daud Aslam100% (2)

- Diamond Star White TdsDocument3 pagesDiamond Star White TdsManoj DoshiNo ratings yet

- Manual Freza BoschDocument128 pagesManual Freza Boschm_c_2913No ratings yet

- Builders Top Merchandising Dagupan Tony's Lumber, IncDocument1 pageBuilders Top Merchandising Dagupan Tony's Lumber, IncQuicksilver 1975No ratings yet

- 1986 Supplement To:: American Concrete InstituteDocument16 pages1986 Supplement To:: American Concrete InstituteAzmi BazazouNo ratings yet

- Course Building Construction IIDocument3 pagesCourse Building Construction IIhafiz hilmiNo ratings yet

- Window and Facade Magazine Global (September-October 2023)Document60 pagesWindow and Facade Magazine Global (September-October 2023)Abdul NabiNo ratings yet

- Pentens T-201 Data SheetDocument6 pagesPentens T-201 Data Sheetamelinda jocelinNo ratings yet

- Mukul's Final ReportDocument75 pagesMukul's Final Reportkuldeep_chand10No ratings yet

- Kap SonsDocument24 pagesKap SonsPrasnna DhandeNo ratings yet

- Woodcarving Issue 176Document84 pagesWoodcarving Issue 176Gianna Barcelli Fantappie100% (1)

- Sl. No. Description Specification No. Corrigendu M No.: List of Indian Railway Standard SpecificationsDocument2 pagesSl. No. Description Specification No. Corrigendu M No.: List of Indian Railway Standard SpecificationsRVNLPKG6B VBL-GTLMNo ratings yet

- Cost Effective Ferrocement Small HousesDocument25 pagesCost Effective Ferrocement Small HousesPavan DevarajNo ratings yet

- 07f Manufactured BoardsDocument29 pages07f Manufactured BoardsJim Jeus dela CruzNo ratings yet

- SP-47 - 1 - Structural SteelDocument6 pagesSP-47 - 1 - Structural Steelfernanda rojasNo ratings yet

- Plumbing Fitting Joints and FixtureDocument61 pagesPlumbing Fitting Joints and FixtureManjeet Cingh100% (1)

- Tunis Village & UttarkashiDocument22 pagesTunis Village & Uttarkashiyxb6tnwgcwNo ratings yet

- Door & WindowDocument1 pageDoor & WindowAMIT KUMARNo ratings yet

- Evolution100-200 - Overviewbrochure TK Elevator BeltDocument19 pagesEvolution100-200 - Overviewbrochure TK Elevator BeltpatoNo ratings yet

- Concrete Repair and Structure StrengtheningDocument5 pagesConcrete Repair and Structure StrengtheningAidaJalaluddinNo ratings yet

- NCERT Solutions For Class 8 Maths Chapter 11 MensurationDocument25 pagesNCERT Solutions For Class 8 Maths Chapter 11 Mensurationavinashmishra13245No ratings yet

- Epoxy HistoryDocument9 pagesEpoxy HistoryJessiNo ratings yet

- CEM II/A-LL 42,5 R: Portland Cement With Limestone With High Initial StrengthDocument3 pagesCEM II/A-LL 42,5 R: Portland Cement With Limestone With High Initial Strengthcalota_loredanaNo ratings yet

- Company ProfileDocument24 pagesCompany ProfileDereje GutaNo ratings yet

- Sector 18 Rohini - Suraj Park ppt22012020Document11 pagesSector 18 Rohini - Suraj Park ppt22012020Riya BansalNo ratings yet