Professional Documents

Culture Documents

132 KV CT

Uploaded by

Anubhav Hem Kumar JainOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

132 KV CT

Uploaded by

Anubhav Hem Kumar JainCopyright:

Available Formats

Vishal Transformers & Switchgears (P) LTD.

(Estd. 1970)

INSTRUCTIONS FOR ERECTION, OPERATION, COMMISSIONING AND MAINTENANCE

OF 132 KV, OUTDOOR, OIL IMMERSED CURRENT TRANSFORMERS

PRE-INSTALLATION CHECKS: The CT should be visually examined and following points should be

carefully observed and implementation of the same be ensured.

a) Check the CT for oil leakage if any.

b) Check that the Porcelain Bushing is intact and has not got damaged during transit.

c) Check the oil level, viewing through the oil level indicator. The level of oil should not be below the

marking on the indicator.

d) Clean external surface of the CT including the Porcelain Bushings with a clean dry cloth to remove the

dust particles and moisture contents if any.

e) The LT gland (if not fitted) kept in the secondary terminal box be fitted.

COMMISSIONING:

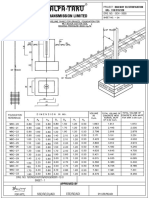

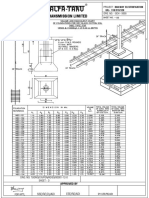

a) Ensure that the mounting surface of the CT is horizontal and the CT is installed at 90 deg. to the

mounting platform and is not inclined.

b) Ensure that the connections to the Primary and Secondary windings are made as shown in the

connection diagram plate fixed on each CT. In case of tapping on secondary side there will be three

terminals marked S1, S2 & S3. Keep S3 open, if using S1 & S2 and keep S2 open, if using S1 & S3.

c) Ensure that the CT body is solidly grounded through the earthing terminals provided.

d) Kindly ensure that the CT is handled carefully, ensuring that the CT is not subjected to any kind of jerks.

e) Insulation Resistance between primary & secondary winding to be measured with 2500 V Meggar & that

between secondary winding & earth shall be measured with 500 V Meggar

f) If development of electrostatic field is experienced between the secondary terminals of CT's and

earth, any one terminal of each CT may please be earthed.

g) 2 Nos. MS supporting strips duly marked with a sticker REMOVE BEFORE

COMMISSIONING provided to protect the CT Bushing during transit should be removed.

h) Ensure that all the connections made to Primary as well as secondary terminals are fully tight so

as to avoid development of any excessive heat.

MAINTENANCE:

a) The CT in general does not require any periodical maintenance except for cleaning of surface of

Porcelain Bushing once in six months with a clean dry cloth. In case the CT is installed in heavily

polluted area, possibility of deposit of dust particles are more hence in such case the cleaning of

Bushing be carried out frequently.

b) The oil level of the CT be checked periodically. In case the oil has gone below the oil level mark

which could be due to some minor leakage, the same be detected and adequate steps to stop the

leakage be taken, also fresh centrifuged oil in CT should be poured upto the oil level mark on the

indicator.

REGD. OFF. & WORKS: RITHANI, DELHI ROAD, MEERUT – 250103 (U.P.) INDIA. PH.: +91 -121-2441073/74

PDF createdE-with

MAIL : INFO@ VISHALTRANSFORMERS. IN WEBSITE : WWW.VISHALTRANSFORMERS.IN

pdfFactory trial version www.pdffactory.com

You might also like

- 16th Edition IEE Wiring Regulations: Design and Verification of Electrical InstallationsFrom Everand16th Edition IEE Wiring Regulations: Design and Verification of Electrical InstallationsRating: 4 out of 5 stars4/5 (1)

- Prestressing Methodology Girder Casting MethodologyDocument7 pagesPrestressing Methodology Girder Casting MethodologyAkhilesh DwivediNo ratings yet

- 11kV CT & PTDocument6 pages11kV CT & PTSanjeev RajputNo ratings yet

- 70.00.00 Standard Practices - InspectionDocument2 pages70.00.00 Standard Practices - InspectionTimoteo Molina RomeroNo ratings yet

- Temp 1Document1 pageTemp 1Donald SimsNo ratings yet

- ML C 650 c65mm213Document6 pagesML C 650 c65mm213operacionesNo ratings yet

- API 510 QUIZ No.3Document6 pagesAPI 510 QUIZ No.3Hatem Ragab0% (1)

- Specification of 11KV MUDocument16 pagesSpecification of 11KV MUPaatala Raagamlo Jeevitha SaagaramNo ratings yet

- 33kv Capacitor Bank SpecsDocument13 pages33kv Capacitor Bank SpecssanresNo ratings yet

- CL-NG-6460-002-027 Checklist For GIS Rev01Document6 pagesCL-NG-6460-002-027 Checklist For GIS Rev01WajahatNo ratings yet

- Tech Spec - 6.3&10MVA With OLTC &SCADA-compatible-RTCCDocument34 pagesTech Spec - 6.3&10MVA With OLTC &SCADA-compatible-RTCCkushal BNo ratings yet

- ASME B31.3: Code For Process PipingDocument53 pagesASME B31.3: Code For Process Pipingdipesh6030100% (2)

- A) Positive Allowance + Negative AllowanceDocument5 pagesA) Positive Allowance + Negative AllowancerashmiameNo ratings yet

- CT, CVT, La IiDocument73 pagesCT, CVT, La IiSayender Yadav E100% (1)

- DM Specs For Surge Vessel PDFDocument6 pagesDM Specs For Surge Vessel PDFatadanleventNo ratings yet

- 500 TF ManualDocument13 pages500 TF ManualJawad AmjadNo ratings yet

- Current Transformer: Engineering DepartmentDocument8 pagesCurrent Transformer: Engineering DepartmentbinodeNo ratings yet

- TS - 25 KV Current TransformerDocument9 pagesTS - 25 KV Current TransformerbinodeNo ratings yet

- Method StaementDocument4 pagesMethod StaementNickNo ratings yet

- Summer and Pre MonsoonDocument3 pagesSummer and Pre MonsoonSiva PrasadNo ratings yet

- Power Energy - Tender SpecsDocument6 pagesPower Energy - Tender SpecsAbdul-Madid Ciudad GuimbaNo ratings yet

- HV Porcelain Bushing: IS2099 Galvanization: IS2633 Primary Terminals: IS 10601Document9 pagesHV Porcelain Bushing: IS2099 Galvanization: IS2633 Primary Terminals: IS 10601AnilNo ratings yet

- FFD - 4 - Maintenance Manual PDFDocument15 pagesFFD - 4 - Maintenance Manual PDFKaleb Z king webNo ratings yet

- Cga TB 2.1980Document6 pagesCga TB 2.1980gabriela troncosoNo ratings yet

- 33 KV Outdoor Type Current Transformer TSDocument6 pages33 KV Outdoor Type Current Transformer TSSandip AhireNo ratings yet

- Thuyền phao EAM (CMM 25-60-24)Document4 pagesThuyền phao EAM (CMM 25-60-24)Duy Khanh NguyễnNo ratings yet

- Technical Specification TRDocument14 pagesTechnical Specification TR武文凯No ratings yet

- Tender - II-100Document113 pagesTender - II-100krcdewanewNo ratings yet

- API 510 Question Bank Set JDocument7 pagesAPI 510 Question Bank Set JNayeem UllahNo ratings yet

- Oil Tender Part 3Document40 pagesOil Tender Part 3Dhrubajyoti SonowalNo ratings yet

- Enclosure To DYT/DDHP/15-16/106 (A) /PL-INCOD/IN SHIPS-ST3 STD/165 Dated 19 May 2016Document11 pagesEnclosure To DYT/DDHP/15-16/106 (A) /PL-INCOD/IN SHIPS-ST3 STD/165 Dated 19 May 2016Rajesh BNo ratings yet

- 4 Test CommissioningDocument50 pages4 Test CommissioningAdjieNo ratings yet

- Api 510 Preparatory ExamDocument13 pagesApi 510 Preparatory Exameldobie3100% (1)

- SWGR & MCC, 9611Document5 pagesSWGR & MCC, 9611Ma.socorro SaballaNo ratings yet

- CT Manual-Final Version (With Composite Insulator)Document21 pagesCT Manual-Final Version (With Composite Insulator)Ganesh DeyNo ratings yet

- CL NG 6460 0002 018 Checklist For Oil Immersed Transformer Rev00Document9 pagesCL NG 6460 0002 018 Checklist For Oil Immersed Transformer Rev00MohamedElmahdyNo ratings yet

- Current Transformers For Out D 040126Document4 pagesCurrent Transformers For Out D 040126eccos3No ratings yet

- AuthorisationDocument3 pagesAuthorisationRamojiNaikNo ratings yet

- CL-NG-6460-002-018 Checklist For Oil-Immersed Transformer Rev02Document8 pagesCL-NG-6460-002-018 Checklist For Oil-Immersed Transformer Rev02WajahatNo ratings yet

- AVR SpecificationDocument18 pagesAVR Specificationmanu892007No ratings yet

- Checklist For Shunt Reactor Rev01Document4 pagesChecklist For Shunt Reactor Rev01Santhosh Kumar VinayagamNo ratings yet

- 2-Stroke Engines Cylinder ConditionDocument9 pages2-Stroke Engines Cylinder ConditionKaushalNo ratings yet

- Current Transformer of Different RatioDocument12 pagesCurrent Transformer of Different RatioPawan Kumar SahaNo ratings yet

- Priming MethodologyDocument5 pagesPriming MethodologyPanashe ChikomweNo ratings yet

- ASME A112 14 3 Rev 5 18 2018 ED 1 18 2020Document9 pagesASME A112 14 3 Rev 5 18 2018 ED 1 18 2020alexitazarumaNo ratings yet

- CL-NG-6460-002-023 Checklist For CT Rev02Document6 pagesCL-NG-6460-002-023 Checklist For CT Rev02محمد عادلNo ratings yet

- Combined CT PT SpecificationDocument7 pagesCombined CT PT SpecificationShajahan ShariefNo ratings yet

- EI Laying OFC 310107Document21 pagesEI Laying OFC 310107agmtechnical100% (1)

- Technical Specification For 11 KV Combined Current & Potential Transformer Suitable For Three Element MeterDocument8 pagesTechnical Specification For 11 KV Combined Current & Potential Transformer Suitable For Three Element MeterAnilNo ratings yet

- 70.00.00 Standard Practices - RepairDocument8 pages70.00.00 Standard Practices - RepairTimoteo Molina RomeroNo ratings yet

- CVT O & M ManualDocument12 pagesCVT O & M ManualAgaram VenkateshNo ratings yet

- CT SizingDocument10 pagesCT SizingAmit NagNo ratings yet

- API 653 PC 26feb05 Exam Final ClosedDocument8 pagesAPI 653 PC 26feb05 Exam Final ClosedNuwan Ranaweera100% (1)

- Maintenance Procedure For Switchyard Equipment Volume-II (EHV CBS, CTs Etc) PDFDocument39 pagesMaintenance Procedure For Switchyard Equipment Volume-II (EHV CBS, CTs Etc) PDFRAJESH PARIKSYANo ratings yet

- H6 Compressor Revs Sensor TSBDocument3 pagesH6 Compressor Revs Sensor TSBSolomanTrismosinNo ratings yet

- Padding&erection Procedure MRUDocument4 pagesPadding&erection Procedure MRUคุณพ่อน้อง บิ๊กบอสNo ratings yet

- CMCP 1100 InstructionsDocument1 pageCMCP 1100 InstructionsVicente GarciaNo ratings yet

- 72 50 02Document6 pages72 50 02alvaro lemosNo ratings yet

- Installation and Operation Instructions For Custom Mark III CP Series Oil Fired UnitFrom EverandInstallation and Operation Instructions For Custom Mark III CP Series Oil Fired UnitNo ratings yet

- 126 PDFDocument62 pages126 PDFAnubhav Hem Kumar JainNo ratings yet

- 13 RDSOSpec8 - 9Document46 pages13 RDSOSpec8 - 9Anubhav Hem Kumar JainNo ratings yet

- 11 RDSOSpec3 - 4 - 5 - 6Document80 pages11 RDSOSpec3 - 4 - 5 - 6Anubhav Hem Kumar JainNo ratings yet

- TSS 24.07.2018-9 PDFDocument1 pageTSS 24.07.2018-9 PDFAnubhav Hem Kumar JainNo ratings yet

- 8 RDSOLayoutplan8Document4 pages8 RDSOLayoutplan8Anubhav Hem Kumar JainNo ratings yet

- Technical Specification For Earthing of Power Supply Installations of 25kV & 2X25kV, AC 50Hz, Traction SystemDocument37 pagesTechnical Specification For Earthing of Power Supply Installations of 25kV & 2X25kV, AC 50Hz, Traction SystemAnubhav Hem Kumar JainNo ratings yet

- 20 Marriage Biodata Format WordDocument1 page20 Marriage Biodata Format WordAnubhav Hem Kumar Jain50% (2)

- 19 PDFDocument70 pages19 PDFAnubhav Hem Kumar JainNo ratings yet

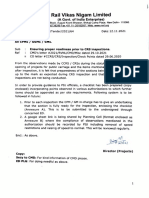

- Government of India Ministry of RailwayDocument23 pagesGovernment of India Ministry of RailwayAnubhav Hem Kumar JainNo ratings yet

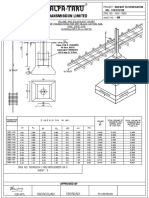

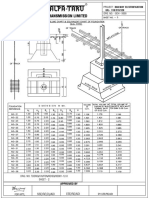

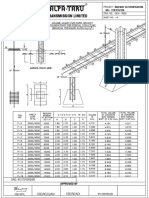

- Power Transmission Limited: Project: Railway Electrification GR:-318/319/320Document1 pagePower Transmission Limited: Project: Railway Electrification GR:-318/319/320Anubhav Hem Kumar JainNo ratings yet

- EMC For European Railways: Reference: 67575 - ERA - EMC - Final - Report Issue: 05Document134 pagesEMC For European Railways: Reference: 67575 - ERA - EMC - Final - Report Issue: 05Anubhav Hem Kumar JainNo ratings yet

- TSS Building MethodDocument7 pagesTSS Building MethodAnubhav Hem Kumar JainNo ratings yet

- 98 PDFDocument1 page98 PDFAnubhav Hem Kumar JainNo ratings yet

- 09 PDFDocument1 page09 PDFAnubhav Hem Kumar JainNo ratings yet

- Power Transmission Limited: Project: Railway Electrification GR:-318/319/320Document1 pagePower Transmission Limited: Project: Railway Electrification GR:-318/319/320Anubhav Hem Kumar JainNo ratings yet

- 76Document1 page76Anubhav Hem Kumar JainNo ratings yet

- Power Transmission Limited: Project: Railway Electrification GR:-318/319/320Document1 pagePower Transmission Limited: Project: Railway Electrification GR:-318/319/320Anubhav Hem Kumar JainNo ratings yet

- Jeffrey Russell - DR Stephen Goh - Aurecon Paper PDFDocument14 pagesJeffrey Russell - DR Stephen Goh - Aurecon Paper PDFAnubhav Hem Kumar JainNo ratings yet

- 21 PDFDocument1 page21 PDFAnubhav Hem Kumar JainNo ratings yet

- 08 PDFDocument1 page08 PDFAnubhav Hem Kumar JainNo ratings yet

- 15.05.2021 Kasganj-Mailani ProgressDocument4 pages15.05.2021 Kasganj-Mailani ProgressAnubhav Hem Kumar JainNo ratings yet

- 21 11 12 Check List For CRS InspectionDocument12 pages21 11 12 Check List For CRS InspectionAnubhav Hem Kumar Jain100% (2)

- 9th EPC World Awards - Brochure 0122 PDFDocument4 pages9th EPC World Awards - Brochure 0122 PDFAnubhav Hem Kumar JainNo ratings yet

- Cimechel-Kptl (JV) : SHEET No: 23Document1 pageCimechel-Kptl (JV) : SHEET No: 23Anubhav Hem Kumar JainNo ratings yet

- Cousre Material For App Technicians OHEDocument94 pagesCousre Material For App Technicians OHEAnubhav Hem Kumar JainNo ratings yet

- GNG-JNH Pkg-2 RE Project Review DocumentDocument12 pagesGNG-JNH Pkg-2 RE Project Review DocumentAnubhav Hem Kumar JainNo ratings yet

- Clearance Study For Tunnel (Udhampur - Katra Section)Document7 pagesClearance Study For Tunnel (Udhampur - Katra Section)Anubhav Hem Kumar JainNo ratings yet

- Design of Ohe Structures and FoundationDocument34 pagesDesign of Ohe Structures and FoundationAnubhav Hem Kumar JainNo ratings yet

- IR Vs DMRCDocument28 pagesIR Vs DMRCAnubhav Hem Kumar JainNo ratings yet

- Re Works in Railway ProjectsDocument172 pagesRe Works in Railway ProjectsAnubhav Hem Kumar JainNo ratings yet

- Electrolux Clarus Error CodesDocument42 pagesElectrolux Clarus Error CodesRudy prastamaNo ratings yet

- Cummins OTPC Series Service ManualDocument157 pagesCummins OTPC Series Service ManualHugo PaulinNo ratings yet

- Data Sheet 3VM1225-4EE32-0AA0: ModelDocument7 pagesData Sheet 3VM1225-4EE32-0AA0: ModelChristian A LCNo ratings yet

- IECEx BAS 10.0099X 009Document6 pagesIECEx BAS 10.0099X 009ESTEBAN DUARTE VIDESNo ratings yet

- MTELecoGO Pro-Eco H enDocument9 pagesMTELecoGO Pro-Eco H enRaja DuraiNo ratings yet

- Unit-1 Sensors Part-2Document39 pagesUnit-1 Sensors Part-217 CSE Lokesh VNo ratings yet

- E3.0 Sup Tras 24VDocument3 pagesE3.0 Sup Tras 24VAdrian Romero RomeroNo ratings yet

- TR231 or TR241 - E4 - 8112W00078 PDFDocument1 pageTR231 or TR241 - E4 - 8112W00078 PDFDave ChaudhuryNo ratings yet

- BSB Solar SeriesDocument2 pagesBSB Solar SeriesAdji PrasetyaNo ratings yet

- Contender Series Manual Motor Starters and Contactors: Explosionproof, Dust-IgnitionproofDocument2 pagesContender Series Manual Motor Starters and Contactors: Explosionproof, Dust-Ignitionproofpr_oilNo ratings yet

- Philippine Electrical CodeDocument6 pagesPhilippine Electrical CodeDia Necson Nicole SapongNo ratings yet

- Catalog en SEUEN01A-H015H026 RUDocument13 pagesCatalog en SEUEN01A-H015H026 RUalexNo ratings yet

- Hence To Keep The CT Burden Lower, CT With 1A Secondary Is PreferableDocument1 pageHence To Keep The CT Burden Lower, CT With 1A Secondary Is PreferableAjay PatilNo ratings yet

- Biodynamisation of WaterDocument8 pagesBiodynamisation of Waterpetri_jvNo ratings yet

- Electric Field and CapacitorsDocument18 pagesElectric Field and CapacitorsTharushiNethmiNo ratings yet

- Pole Slip Protection Out of Step Protection 78PS Working Principle - Electrical4uDocument2 pagesPole Slip Protection Out of Step Protection 78PS Working Principle - Electrical4uTLD 4 PSNo ratings yet

- Physics 12th Important Graphs: 1. Field Lines Due To Some Simple Charge ConfigurationsDocument19 pagesPhysics 12th Important Graphs: 1. Field Lines Due To Some Simple Charge ConfigurationsArjun PasrichaNo ratings yet

- MQ 216Document2 pagesMQ 216Farshad yazdiNo ratings yet

- This Design May Enable Cars To Run On WaterDocument4 pagesThis Design May Enable Cars To Run On WaterRossen PetrovNo ratings yet

- Lab Session: 2 Experiment No:1 1.1 Title: Figure 1 EDM Die SinkingDocument3 pagesLab Session: 2 Experiment No:1 1.1 Title: Figure 1 EDM Die SinkingSyed Shahzaib AliNo ratings yet

- Trans 1Document3 pagesTrans 1sanjeevmeilNo ratings yet

- W 48 × H 48 MM Power ON Delay Analog Timers: ATE8 SeriesDocument3 pagesW 48 × H 48 MM Power ON Delay Analog Timers: ATE8 Seriesyanier martinezNo ratings yet

- Max Series Caapbb Rohs Compliant NewDocument2 pagesMax Series Caapbb Rohs Compliant NewkhemrajmahadewNo ratings yet

- SSM501 ManualDocument25 pagesSSM501 ManualPrakash VerekarNo ratings yet

- Amb4520R2V06 2Mxx-690-960/1710-2200-65/33-16I/19.5I-M/M-R Easyret Hybrid Triple-Beam Antenna With 3 Integrated Rcus - 2.0MDocument3 pagesAmb4520R2V06 2Mxx-690-960/1710-2200-65/33-16I/19.5I-M/M-R Easyret Hybrid Triple-Beam Antenna With 3 Integrated Rcus - 2.0MRobertNo ratings yet

- E7 2users Manual CDocument291 pagesE7 2users Manual CAleksandar StankovićNo ratings yet

- Users Manual 3437176minisoDocument4 pagesUsers Manual 3437176minisoluis mdoNo ratings yet

- Logic Design - EEE205: Dr. Hassan SharabatyDocument30 pagesLogic Design - EEE205: Dr. Hassan SharabatysaraabdfffNo ratings yet