Professional Documents

Culture Documents

Ra Lifting

Uploaded by

AssoOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Ra Lifting

Uploaded by

AssoCopyright:

Available Formats

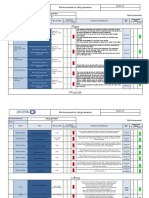

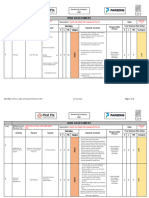

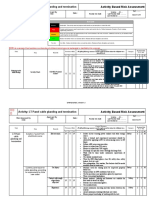

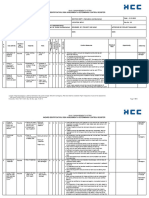

Form-

Risk Assessment Form

Rev. :

Risk Assessment Title: Lifting Operations

Risk Assessment

Revision: 01

Residual Risk

Risk Rating Action

Item Hazard Risk Who is at Risk Necessary Control Measures Rating

By

S F Rating S L Rating

Plant

1 Only trained and authorised persons are permitted to operate the plant

Personal risk of injury and / or ill health Supervisor – Prior to setting up the operator and the designated banks man will assess

Operator –Labour- the ground conditions for stability to prevent subsidence.

Risk of Injury to the public Public The crane will be set up as close to the lift area as possible to avoid over

Overturning,

reaching.

Risk of damage to property and Supervis

The crane operator will not attempt to lift outside the specified crane

equipment

2 3

6 capacity

The load should always be Kept close to the ground

or –

Operator

3 1

3

The crane operator should maintain a steady speed during the operation s

Ground conditions : The crane company you have elected to use can give

you suitable words to the effect that the ground on which the cranes will

operate from are capable of supporting the weight of the cranes and load.

Crane outriggers will use ground mats and supporting grillages to provide

additional support.

Where possible an exclusion zone should be erected to segregate the

2 Collision with Personal risk of injury and / or ill health Supervisor – work area from other plant.

Structures or mobile Operator –Labour Setting up will be under the control of the banksman. The banksman Supervis

Risk of Injury to the public

Plant

Risk of damage to property and

- Public 3 2

6 should ensure there is adequate space between the crane and any

structures and take into account the swing radius.

or –

Operator

3 1

3

Before starting the crane operator shouldS carry out a trial run to ensure s

equipment

there is adequate room.

Lack of

3 communication Personal risk of injury and / or ill health Supervisor –

Operator -Labour Supervis

Risk of Injury to the public

Risk of damage to property and

3 2

6 All instructions to the excavator operator will be given by the banks man

or –

Operator

3 1

3

s

equipment (where possible this will be with the use of 2 way radios)

4 Unauthorized Access Personal risk of injury and / or ill health Supervisor –

Operator –Labour Supervis

The crane operator will ensure that the plant is never left running or a load

Risk of Injury to the public

Risk of damage to property and

-Public 3 2

6 suspended when he is not in attendance.

The operator will ensure the keys are removed and the cab doors locked

or –

Operator

3 1

3

s

equipment when he is on a break or at the end of his shift

Lifting near open Ensure suitable barriers are erected around the lift.

5 Trenching Personal risk of injury and / or ill health Supervisor – Ensure suitable warning signs are attached around the lift area.

Operator –Labour Ensure a permit to lift is obtained. Ensure the load is fully braced before Supervis

Risk of Injury to the public

Risk of damage to property and

-Public 3 2

6 lifting.

Ensure all plant equipment remains at least 1 meter form the edge of the

or –

Operator

3 1

3

open trenches. s

equipment

HSE-001 Risk Assessment

1

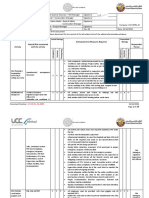

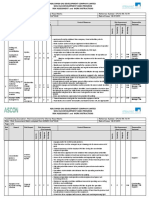

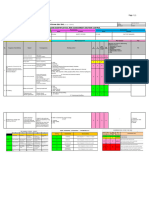

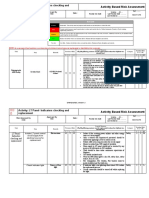

Form-

Risk Assessment Form

Rev. :

Risk Assessment Title: Lifting Operations

Risk Assessment

Revision: 01

Residual Risk

Risk Rating Action

Item Hazard Risk Who is at Risk Necessary Control Measures Rating

By

S F Rating S L Rating

Physical

Ensure there is adequate information, instruction, training and supervision. Where Supervis

1 Manual Handling

Muscular / Skeletal Disorders

Labour 3 2

6 ever-possible use mechanical aids to reduce manual handling. or &

Individual

1 1

1

s

Ensure each lift is planned and assessed, avoid double handling of materials.

Supervis

2 Manual Handling

Slips, Trips and Falls

Public, Staff,

Labour

3 3

9 Ensure the route to be travelled is free from obstacles or hazards and has

adequate lighting.

or &

3 1

Individual

s 3

Look at the individual and their capabilities (ensure they are capable of lifting or

Supervis

3 Manual Handling

Crushing or Trapping

Labour 3 2

6 moving the load). Assess the load for size, shape, weight, and stability before it is

moved. Never try to lift above your own capabilities.

or &

Individual 3 1

s

3

When lifting the load carry out a test lift to ensure the load can be moved Supervis

4 Manual Handling

Stresses and Strains

Labour 3 2

6 comfortably, check for sharp edges (if required wear gloves to protect the hands). or &

3 1

Individual

s 3

When lifting the load carry out a test lift to ensure the load can be moved Supervis

5 Manual Handling

Cuts and Abrasions

Labour 2 2

4 comfortably, check for sharp edges (if required wear gloves to protect the hands). or &

2 1

Individual

s 2

If moving heavy or obscure loads use more than 1 person (one person should

Supervis

6 Manual Handling Personal Injury Labour 3 2

6 give the lifting instruction). Ensure that the correct handling techniques are used

such as – keeping the load close to the body, keep feet shoulder width apart, and

avoid twisting or stooping.

or &

Individual 3 1

s

3

Supervis

7 Manual Handling

Over exertion

Labour 3 2

6 Avoid carrying heavy or obscure loads up or down stairs. Never carry heavy loads

up or down ladders.

or &

Individual 3 1

s 3

HSE-001 Risk Assessment

2

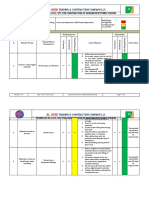

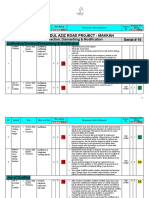

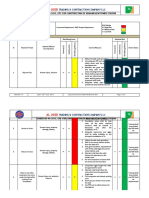

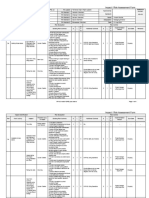

Form-

Risk Assessment Form

Rev. :

Risk Assessment Title: Lifting Operations

Risk Assessment

Revision: 01

Residual Risk

Risk Rating Action

Item Hazard Risk Who is at Risk Necessary Control Measures Rating

By

S F Rating S L Rating

Lifting

Ensure the correct type of lifting equipment is selected for the lift.

Ensure the load does not exceed the SWL of the equipment.

Do not lift outside of the cranes safe working radius

Failure of lifting equipment

1 Lifting

Labour, Staff,

Public, Operators

3 3

9 Ensure that all equipment certification is in date.

Inspect equipment before use to ensure it is free from damage.

Do not use makeshift or untested equipment.

Rigger

Charge-

1 3

Report any damage to your supervisor and take it out of use. hand

Only allow competent operatives to carry out lifting activities.

3

Ensure all equipment is stored correctly when not in use.

2

Lifting

Damage to lifting equipment

Labour, Operators 3 3

9 Only use lifting equipment for what it is designed.

Do not leave nylon sling exposed to heat or sunlight.

Do not tie nylon or wire lifting equipment together to extend it.

Rigger

Charge- 3 1

hand

3

Ensure only competent persons are permitted to carry out the lifting operations.

3 Lifting

Loss of load

Public, Operators,

Labour

3 3

9 Ensure tag lines are used to control the load.

Place packing around sharp edges or corners to prevent damage.

Do not use hooks that are stretched or damaged.

Rigger

Charge- 3 1

hand

3

Traffic Management

Ensure that an adequate barriers or hoardings are erected around the site to CM,Supe

prevent access. rvisor

1

Traffic

Public Access

Public, Staff,

Labour

2 3

6 Ensure that appropriate warning signs are on display (multi language if required)

warning of the dangers.

Restrict the access to construction traffic only.

and

Operativ

es

2 1

2

Provide security to prevent unauthorised access.

CM,Supe

rvisor

Where appropriate implement a one way system to control vehicle movement,

2

Traffic

Plant & Vehicle Movement

Public, Staff,

Labour

2 3

6 where possible segregate walkways form vehicle movement.

Install designated parking areas.

and

Operativ

es

2 1

2

HSE-001 Risk Assessment

3

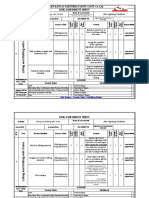

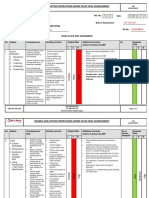

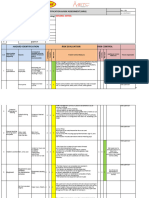

Form

Risk Assessment Form

Rev. :

Risk Assessment Title: Lifting Operations

Risk Assessment

Revision: 01

Residual Risk

Risk Rating Action

Item Hazard Risk Who is at Risk Necessary Control Measures Rating

By

S F Rating S L Rating

Ensure that only trained and authorised persons are permitted to operate plant CM,Supe

and equipment. rvisor

3

Traffic

Trapping / Crushing

Public, Staff,

Labour

2 3

6 Ensure that reversing vehicles are fitted with audible warning systems, where this

is not possible provide a banksman to direct the operator.

Provide High Viz Vests to the workforce so they are more visible to the operators

and

Operativ

es

2 1

2

of plant.

Ensure all reversing vehicles are controlled by a trained and competent banks

man. Logistics

4

Traffic

Collision while reversing

Public, Staff,

Labour

3 3

9 Ensure routes are checked before reversing.

All mobile plant should be fitted with an audible reverse alarm.

Where practicable safety cones and plastic chain should be erected around the

Manager

Banksma

n 3 1

reversing area. Driver

3

Logistics

Manager

Ensure adequate access lighting is installed and maintained on main road ways.

/

5

Traffic

Collision at night

Public, Staff,

Labour

3 3

9 Ensure all vehicle and plant lights are in good working order and used at night.

Restrict vehicle movement at night

Unloading should be carried out in well lit and restricted areas.

Supervis

or

3 1

Banksma

n 3

Ensure vehicles stay on the designated access roads and do not take shortcuts Supervis

6

Traffic

Overturning

Public, Staff,

Labour

2 2

4 over the sandy areas.

If unloading materials using a forklift ensure the ground is level.

Ensure roads are maintained and free from potholes.

or

Banksma

n

2

1

2

Logistics

Ensure adequate pedestrian accesses are installed that give pedestrian right of

Manager

way. Where possible post a flagman to control vehicle and pedestrian movement.

/

Construct speed humps in areas where pedestrians need to cross.

7

Traffic

Contact with people or pedestrians

Public, Staff,

Labour

3 3

9 Implement designated pedestrian routes with barriers to segregate the

pedestrians from vehicle movement.

Supervis

or

Banksma

3

1

3

Ensure operatives are equipped with High Visibility Vests so they can be easily

n

seen by the drivers.

HSE-001 Risk Assessment

4

Form

Risk Assessment Form

Rev. :

Risk Assessment Title: Lifting Operations

Risk Assessment

Revision: 01

Residual Risk

Risk Rating Action

Item Hazard Risk Who is at Risk Necessary Control Measures Rating

By

S F Rating S L Rating

Welfare

Site welfare facilities shall be established in line with the requirements set out in

General site Site Establishment. Sufficient toilets, washing facilities, drying facilities and

Lack of welfare and

1 medical facilities

Food / drinking water contamination workers

General site staff

Site visitors

3 3

9 mess facilities shall be installed in line with manpower levels. As manpower

levels change, welfare facilities shall be reviewed and altered accordingly. Mess

and welfare facilities shall be installed in a safe area where there is no risk from

CM 3 1

3

moving vehicles or other site hazards

General site Temporary chemical toilets may be utilized in the early stages of a project,

Lack of welfare and Human waste contamination of

2 medical facilities temporary facilities and site

workers

General site staff

Site visitors

3 3

9 however, these shall not be permitted in the long term. Full flushing WC’s shall

be installed

CM 3 1

3

General site Medical facilities shall be established in line with the requirements set out in

Lack of welfare and

3 medical facilities

Disease and ill health due to lack of

washing facilities

workers

General site staff

Site visitors

3 3

9 Site establishment. Sufficient first aiders and / or a site nurse shall be

appointed for the project

CM

Nurse

3 1

3

General site

Lack of welfare and Escalation of minor injuries due to

4 medical facilities lack of treatment – infection risk

workers

General site staff

Site visitors

3 3

9 Vehicle to be on site to transport any medical emergency to the nearest hospital

for further checks and treatment

CM 3 1

3

General site

Lack of welfare and Ill health due to lack of recognition of

5 medical facilities medical conditions

workers

General site staff

Site visitors

3 3

9 All prolonged medical illnesses reported must be sent to the nearest hospital for

further checks and treatment.

CM

Nurse

3 1

3

General site

Lack of welfare and

6 medical facilities

Preventable fatalities due to lack of

first aid skills and equipment

workers

General site staff

Site visitors

3 3

9 Where local regulations require a different standard to that set out in site

establishment, the higher standard shall be implemented

PM 3 1

3

Prepared By: Severity (S) Frequency (F) Risk Rating (RR) Very High High Medium Low

A - Architect R=SxF 15-25 8-12 4-6 1-3

PM – Project Manager 1 Minor Injury 1 Improbable

CM – Construction Manager 2 Major Single Injury 2 Possible Unacceptability Limits S 5 4 3 2 1 F

LM – Logistics Manager 3 Major Multiple Injuries 3 Occasional More than 5 is unacceptable re-assess task 5 25 20 15 10 5

PLM – Plant Manager 4 Single Death 4 Frequent and preventative actions. 4 20 16 12 8 4

HSEM – HSE Manager 5 Multiple Deaths 5 Regular 3 15 12 9 6 3

PS – Project Supervisor S = 0 is deemed to be the limit of practicability 2 10 8 6 4 2

SC – Subcontractor of control measures. 1 5 4 3 2 1

Project:

Assessment Carried out by:

Assessment Date:

Risk Assessment Number:

HSE-001 Risk Assessment

You might also like

- Risk Assessment Lifting OperationsDocument5 pagesRisk Assessment Lifting OperationsHưng Hoàng Duy100% (1)

- Lifting Risk AssessmentDocument5 pagesLifting Risk AssessmentimranNo ratings yet

- Lifting Operations Risk AssessmentDocument4 pagesLifting Operations Risk AssessmentIdris AdeniranNo ratings yet

- Risk Assessment-Lifting OperationsDocument5 pagesRisk Assessment-Lifting OperationsMuhammad Shahid IqbalNo ratings yet

- Risk Assessment Lifting Operations PDFDocument6 pagesRisk Assessment Lifting Operations PDFkim alfonsoNo ratings yet

- ABRA for CGA COMMISSIONING_04-12-2023_DanishDocument7 pagesABRA for CGA COMMISSIONING_04-12-2023_DanishichharajratanNo ratings yet

- RA For Asphalt WorksDocument19 pagesRA For Asphalt WorksBleep News100% (6)

- Road Asphalt Works-Epc10-Ra-74-R0Document5 pagesRoad Asphalt Works-Epc10-Ra-74-R0tariq1987100% (1)

- Ra09 Lifting ActivitiesDocument4 pagesRa09 Lifting Activitiesluatdolphin100% (1)

- 003 Material HandlingpdfDocument4 pages003 Material Handlingpdfghada gattouchNo ratings yet

- Risk assessment for sewerage installation projectDocument2 pagesRisk assessment for sewerage installation projectmd_rehan_20% (1)

- Z - MP-EHS-01 IRA - 02 Supp & Installn of Pontoon & Gangway (1aug2023)Document3 pagesZ - MP-EHS-01 IRA - 02 Supp & Installn of Pontoon & Gangway (1aug2023)Din JalilNo ratings yet

- Risk Assessment: Date: Activity Hazard Impact Hazards Controls Responsible Person S L RR CategoryDocument18 pagesRisk Assessment: Date: Activity Hazard Impact Hazards Controls Responsible Person S L RR CategoryFawad KhanNo ratings yet

- RA-70 Risk Assessment For Internal Road Works-R1Document6 pagesRA-70 Risk Assessment For Internal Road Works-R1tariq1987No ratings yet

- Hira Register: Grasim Industries Limited, Vilayat Bharuch (Gujarat)Document3 pagesHira Register: Grasim Industries Limited, Vilayat Bharuch (Gujarat)Mithlesh Singh75% (4)

- 5-Pole Erection & Stringing PDFDocument2 pages5-Pole Erection & Stringing PDFAhmed Zai50% (4)

- 10 RA Scaffolding Erection Dismantling Modification & UseDocument3 pages10 RA Scaffolding Erection Dismantling Modification & UseravindraNo ratings yet

- RA Cable PullingDocument3 pagesRA Cable PullingRandy Adisyah0% (1)

- RA for Container OffloadingDocument3 pagesRA for Container OffloadingMladen2303No ratings yet

- Baseline Risk Assessment 2014 Construction Regulations (Rev 2)Document26 pagesBaseline Risk Assessment 2014 Construction Regulations (Rev 2)preciousphooko50No ratings yet

- HIRA of Tower CraneDocument3 pagesHIRA of Tower Craneshahhussain1031No ratings yet

- KCC Lifting and Shifting With CraneDocument7 pagesKCC Lifting and Shifting With CraneDelta akathehuskyNo ratings yet

- Hazard Identification & Risk Assessment for Painting WorkDocument4 pagesHazard Identification & Risk Assessment for Painting WorkRawoofuddin ChandNo ratings yet

- Sec Ehvpd Risk Assessment: Hazard Identification Control Risk Reduction Action PlanDocument1 pageSec Ehvpd Risk Assessment: Hazard Identification Control Risk Reduction Action PlanSn AhsanNo ratings yet

- + 009 Site & General Activities (v4.0 May 20)Document12 pages+ 009 Site & General Activities (v4.0 May 20)Grace DoucetteNo ratings yet

- Mobilization Tanajib Cogeneration and Desalination Plant HIRADocument4 pagesMobilization Tanajib Cogeneration and Desalination Plant HIRAZishan AliNo ratings yet

- ISS-ABRA-TECH-21 R1 - LT Panel Cable Glanding and TerminationDocument7 pagesISS-ABRA-TECH-21 R1 - LT Panel Cable Glanding and TerminationVarun GuptaNo ratings yet

- Cutting Rig Bracing Risk AssessmentDocument9 pagesCutting Rig Bracing Risk AssessmentHafeez AliNo ratings yet

- 04 HIRA For Reinforcement WorkDocument7 pages04 HIRA For Reinforcement WorkMithlesh Singh100% (1)

- Acondicionamiento de Lamina Mineral de RocaDocument7 pagesAcondicionamiento de Lamina Mineral de Rocamichael carpinteroNo ratings yet

- HIRA-Metalic Pipe ErectionDocument13 pagesHIRA-Metalic Pipe ErectionShams Tabrez100% (2)

- Instalación Rieles de Soporte CeldasDocument9 pagesInstalación Rieles de Soporte Celdasmichael carpinteroNo ratings yet

- 7-Asphalt Road Cutting PDFDocument3 pages7-Asphalt Road Cutting PDFAhmed ZaiNo ratings yet

- HIRARC Project Ignite - Id.enDocument17 pagesHIRARC Project Ignite - Id.enSyahrial AgusandiNo ratings yet

- Risk Assessment: CCTV Inspection - Al MerifDocument9 pagesRisk Assessment: CCTV Inspection - Al MerifSaim AliNo ratings yet

- Bidaa Tower Risk Assessment From CALISTO UpdatedDocument5 pagesBidaa Tower Risk Assessment From CALISTO Updatedirshad gNo ratings yet

- ISS-ABRA-TECH-04 R1 - DG - Preventive Maintenance (Monthly)Document7 pagesISS-ABRA-TECH-04 R1 - DG - Preventive Maintenance (Monthly)Varun GuptaNo ratings yet

- Risk Assessment For Installation and Testing of CCTVDocument11 pagesRisk Assessment For Installation and Testing of CCTVAnandu Ashokan100% (4)

- Lone Working Risk AssessmentDocument3 pagesLone Working Risk AssessmentMuhammed yahiyaNo ratings yet

- Risk AssessmentDocument14 pagesRisk AssessmentApm FoumilNo ratings yet

- Drum CrushingDocument3 pagesDrum CrushingShannon MooreNo ratings yet

- Laboratory Hirarc KGM SHF 002 01Document85 pagesLaboratory Hirarc KGM SHF 002 01tk69rajNo ratings yet

- AL JOOD TRADING & CONTRACTION COMPANY LLC TENDER NO 96-2013, EPC FOR CONSTRUCTION OF KHASAB NEW POWER STATIONDocument3 pagesAL JOOD TRADING & CONTRACTION COMPANY LLC TENDER NO 96-2013, EPC FOR CONSTRUCTION OF KHASAB NEW POWER STATIONghada gattouchNo ratings yet

- Risk Assessment For Crane Operations (Oml-Hse-Ra-3003) - Atlas Engom Civil Camp MoveDocument3 pagesRisk Assessment For Crane Operations (Oml-Hse-Ra-3003) - Atlas Engom Civil Camp MoveNorman Ainomugisha67% (15)

- Hira - Insulation & Cladding WorkDocument9 pagesHira - Insulation & Cladding WorkAbzad HussainNo ratings yet

- HIRA - Stressing Platform at Pylon and Working-Hcc F 001 15 001-r9Document4 pagesHIRA - Stressing Platform at Pylon and Working-Hcc F 001 15 001-r9Pinaki BhattacharjeeNo ratings yet

- Contractor Health and Safety Risk AssessmentDocument70 pagesContractor Health and Safety Risk AssessmentmakeencvNo ratings yet

- RISK ASSESSMENT FIBRECO PROJECTDocument22 pagesRISK ASSESSMENT FIBRECO PROJECTThandabantu MagengeleleNo ratings yet

- HARC Mast Rais & LowerDocument2 pagesHARC Mast Rais & LowerBarkat UllahNo ratings yet

- ISS-ABRA-TECH-16 R1 - LT Panel - Indicators Checking and ReplacementDocument6 pagesISS-ABRA-TECH-16 R1 - LT Panel - Indicators Checking and ReplacementVarun GuptaNo ratings yet

- Risk Assessment For Installation of Light FittingsDocument11 pagesRisk Assessment For Installation of Light FittingsHerdhiska Pradhiarta AjiprayogaNo ratings yet

- Z - MP-EHS-01 IRA - 03 Install HDPE Pipe Sleeve (1aug2023)Document3 pagesZ - MP-EHS-01 IRA - 03 Install HDPE Pipe Sleeve (1aug2023)Din JalilNo ratings yet

- Risk Assessment - Sheet Piling DraftDocument8 pagesRisk Assessment - Sheet Piling DraftSinaNo ratings yet

- Decking Risk AssessmentDocument4 pagesDecking Risk AssessmentReagan MukeboNo ratings yet

- 101 Deck Watch KeepingDocument1 page101 Deck Watch KeepingMr-SmithNo ratings yet

- AVN-MAR-PIP-RA-003 - R0 - Installation of Drain Line Below HelipadDocument3 pagesAVN-MAR-PIP-RA-003 - R0 - Installation of Drain Line Below HelipadtaufikNo ratings yet

- 7C. RA - 001 - Forklift and Overhead Crane OperationsDocument5 pages7C. RA - 001 - Forklift and Overhead Crane Operationssiva rajuNo ratings yet

- Electrical Safety ProcedureDocument25 pagesElectrical Safety ProcedureAssoNo ratings yet

- HSE Excavation ProcedureDocument12 pagesHSE Excavation ProcedureAssoNo ratings yet

- Lifting & RiggingDocument35 pagesLifting & RiggingAssoNo ratings yet

- Expert Trainers Academy Checklist For Equipment Inspection: Project Name: Project CodeDocument43 pagesExpert Trainers Academy Checklist For Equipment Inspection: Project Name: Project CodeLoreley NguemNo ratings yet

- Guidelines On First-AidDocument22 pagesGuidelines On First-AidAssoNo ratings yet

- A Straightforward Guide To ERC20 Tokens - EthHubDocument9 pagesA Straightforward Guide To ERC20 Tokens - EthHubAsad HayatNo ratings yet

- SJ Salomon International - Lagarde Predicts Recovery For Europe Late 2021Document2 pagesSJ Salomon International - Lagarde Predicts Recovery For Europe Late 2021PR.comNo ratings yet

- SAIL Expansion Plan and Review Q3-FY-22Document52 pagesSAIL Expansion Plan and Review Q3-FY-22kanwarkahlonNo ratings yet

- Enterprenurship Lecture # 1Document25 pagesEnterprenurship Lecture # 1Ab CNo ratings yet

- Detailstatement - 27 9 2021@14 15 21Document18 pagesDetailstatement - 27 9 2021@14 15 21Kshitija BirjeNo ratings yet

- Eco RevampDocument21 pagesEco RevampCriese lavileNo ratings yet

- KTN 55 Communication MatrixDocument18 pagesKTN 55 Communication MatrixHugo PimentaNo ratings yet

- Contract To Sell LansanganDocument2 pagesContract To Sell LansanganTet BuanNo ratings yet

- CashManagement 2019 2029Document13 pagesCashManagement 2019 2029Betre HurtoNo ratings yet

- Overview of The Money Supply Process: Changes in The Required Reserve Ratio, RRDocument10 pagesOverview of The Money Supply Process: Changes in The Required Reserve Ratio, RRmaria ritaNo ratings yet

- Performance Review of JeeraDocument13 pagesPerformance Review of JeeraMargita InfraNo ratings yet

- CV Nata TERBARUDocument6 pagesCV Nata TERBARUArif L Khafidhi100% (1)

- S&P GlobalDocument3 pagesS&P Globalriyec98621No ratings yet

- Ddi-2704-R0-Pky-Rc - Details of 28M Span (6 Lane) - Wing (DS)Document1 pageDdi-2704-R0-Pky-Rc - Details of 28M Span (6 Lane) - Wing (DS)rohitNo ratings yet

- A Short Story of Philippine EconomyDocument28 pagesA Short Story of Philippine EconomyCandie TancianoNo ratings yet

- Variant Perception Understanding-VolatilityDocument20 pagesVariant Perception Understanding-VolatilityLinda FreemanNo ratings yet

- FerraroDocument38 pagesFerrarodaniela soto gNo ratings yet

- MCQ Problems On Marginal Costing: Q.1 (D) (V) AnsDocument1 pageMCQ Problems On Marginal Costing: Q.1 (D) (V) AnsHasim SaiyedNo ratings yet

- MM Bread Bakery Enterprise: Business PlanDocument11 pagesMM Bread Bakery Enterprise: Business PlanAbel Zegeye100% (7)

- List of Participating Organization For Campus Sept-Oct, 2021Document5 pagesList of Participating Organization For Campus Sept-Oct, 2021Siva KrishnaNo ratings yet

- Rivera, Karen Diane C. - GS REPORTDocument18 pagesRivera, Karen Diane C. - GS REPORTKaren Diane Chua RiveraNo ratings yet

- Site Report Check ListDocument4 pagesSite Report Check ListShureendran Muniandy RajanNo ratings yet

- FM Jack Tar Case StudyDocument2 pagesFM Jack Tar Case StudyjanelleNo ratings yet

- Art of Being MinimalistDocument70 pagesArt of Being MinimalistbluexizorNo ratings yet

- Cheiron PricelistDocument4 pagesCheiron Pricelistimcoolmailme2No ratings yet

- Chapter 1 Current Multinational Challenges and The Global Economy Multiple Choice and True/ False Questions 1.1 The Global Financial MarketplaceDocument10 pagesChapter 1 Current Multinational Challenges and The Global Economy Multiple Choice and True/ False Questions 1.1 The Global Financial Marketplacequeen hassaneenNo ratings yet

- Indian Economy-Pre Independace Perion (Sandeep Garg)Document13 pagesIndian Economy-Pre Independace Perion (Sandeep Garg)parthNo ratings yet

- Creative Use of Stops: Jason Alan JankovskyDocument22 pagesCreative Use of Stops: Jason Alan Jankovskypderby1100% (1)

- Eco 101 ElasticityDocument26 pagesEco 101 ElasticityMovie SeriesNo ratings yet

- Chap23 Measuring The Cost of LivingDocument85 pagesChap23 Measuring The Cost of LivingThanh Thư100% (1)