Professional Documents

Culture Documents

Supplement To Chapter 7 Repair Work On Senderreceiver Unit"

Uploaded by

eka pramudia santoso0 ratings0% found this document useful (0 votes)

5 views4 pagesOriginal Title

Supplement to Chapter 7 Repair work on senderreceiver unit“

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

5 views4 pagesSupplement To Chapter 7 Repair Work On Senderreceiver Unit"

Uploaded by

eka pramudia santosoCopyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You are on page 1of 4

FLOWSIC100 Flare

Supplement for Service Manual 2.1

1 FL100 Flare/Process · Su p p lemen t to Serv ice Ma n u a l · /V 1-0/2017-08 · © SICK Engineering GmbH

1. 1 About this document

This document is a supplement to the current valid Service Manual FLOWSIC100

Flare/Process V2.1 and may only be used together with the manual.

Special attention has to be paid to the general and specific safety instructions,

warnings and rules for repair and service work (chapter 1 and 7 of Service Manual).

1. 2 Supplement to Chapter 7 "Repair work on sender/receiver unit“

The following notes and information refer to certain components of the FLOWSIC100

Flare, which are an integral part of the following device variants:

1. Exchange Flange EX-S

7.7.2 Replacement of sensor assembly FLOWSIC100 EX-S - retractable types

7.7.3 Replacement of sealing set at probe retraction mechanism

2. Exchange Noozle EX-RE/EX-S

7.8.3 Replacement of sealing set at probe retraction mechanism

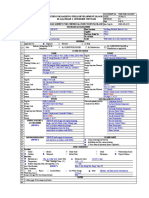

Device variants EX-S and EX-RE

In order to replace either the sealing set at probe retraction mechanism or

replacement of the sensor itself the screws of the cover plate as shown in Figure 1

are fixed with Loctite glue.

Figure 1: Removing cover plate

2 FL100 Flare/Process · Su p p lemen t to Serv ice Ma n u a l · /V 1-0/2017-08 · © SICK Engineering GmbH

Attention:

To make it easier to loosen the screws, they should be preheated with a hot air dryer.

It is imperative that a screwdriver is selected which corresponds to the size of the screw

head. As it is to be expected that the screws are difficult to loosen despite preheating, there

is the danger that the screw heads can be destroyed.

The following sizes must be used for the corresponding device variant:

EX-S standard version: PZ2

EX-S High or low temperature version, EXRE: PH2

After the service work on the exchange flange have been finished according to the

respective named chapters, the screws must be fixed with a Logtite.

Care must be taken to ensure a high strength as well as a sufficient temperature

specification of the screw securing position.

It is necessary to use a screw safety lacquer which meets the following technical

characteristics:

Suitable for: threads up to M36

Temperature resistance: -55 ° C - 150 ° C

Strength: medium

Safety information GHS / Hazard description: GHS07: Caution

3 FL100 Flare/Process · Su p p lemen t to Serv ice Ma n u a l · /V 1-0/2017-08 · © SICK Engineering GmbH

4 FL100 Flare/Process · Su p p lemen t to Serv ice Ma n u a l · /V 1-0/2017-08 · © SICK Engineering GmbH

You might also like

- 16th Edition IEE Wiring Regulations: Design and Verification of Electrical InstallationsFrom Everand16th Edition IEE Wiring Regulations: Design and Verification of Electrical InstallationsRating: 4 out of 5 stars4/5 (1)

- The IEE Wiring Regulations Explained and IllustratedFrom EverandThe IEE Wiring Regulations Explained and IllustratedRating: 4 out of 5 stars4/5 (14)

- Denon Avr-1707 1507 687 587 487 Service enDocument131 pagesDenon Avr-1707 1507 687 587 487 Service enNathan Pullen100% (1)

- Dokumen - Pub A Textbook of Production Engineering 11nbsped 9788121901116Document993 pagesDokumen - Pub A Textbook of Production Engineering 11nbsped 9788121901116RahulNo ratings yet

- ABB High Voltage Fuses CatalogueDocument64 pagesABB High Voltage Fuses CataloguerocketvtNo ratings yet

- DH01 M E 0007 - Mechanical Datashet For TankDocument4 pagesDH01 M E 0007 - Mechanical Datashet For TankDuy NamNo ratings yet

- Computer NetworkDocument22 pagesComputer NetworkNilesh Chaudhari0% (1)

- Alle K-Infos EnglischDocument134 pagesAlle K-Infos EnglischasalinaspadillaNo ratings yet

- Glovia Lean ManufacturingDocument16 pagesGlovia Lean ManufacturingALEJANDRANo ratings yet

- PR-1000 - Operations Handover ProcedureDocument19 pagesPR-1000 - Operations Handover ProcedureParmit Choudhury100% (1)

- IT Database DGDFGDocument16 pagesIT Database DGDFGshriya shettiwarNo ratings yet

- Main GeofabricsDocument16 pagesMain GeofabricsThota RevanthNo ratings yet

- Product Overview: Valves Actuators Automation TechnologyDocument36 pagesProduct Overview: Valves Actuators Automation TechnologyBrion Bara IndonesiaNo ratings yet

- Heat Transfer: Non-Stationary Heat Transfer Through Walls, Measurement of Thermal Conductivity, Heat Transfer with Two Phase RefrigerantsFrom EverandHeat Transfer: Non-Stationary Heat Transfer Through Walls, Measurement of Thermal Conductivity, Heat Transfer with Two Phase RefrigerantsRating: 5 out of 5 stars5/5 (1)

- Commissioning ProcedureDocument7 pagesCommissioning ProcedureAndreas Schlager100% (5)

- Siprotec (7SJ80) SiemensDocument40 pagesSiprotec (7SJ80) SiemensMuhammad KuntoroNo ratings yet

- Pointek CLS 300 - Standar - SiemensDocument180 pagesPointek CLS 300 - Standar - SiemensRodrigo CiezaNo ratings yet

- Air Dryer Instruction ManualDocument32 pagesAir Dryer Instruction ManualZoran MRSICNo ratings yet

- KLINGER Ballostar KHA 3 Pieces Ball Valve DN 10 - 150: Edition 2011Document36 pagesKLINGER Ballostar KHA 3 Pieces Ball Valve DN 10 - 150: Edition 2011Andy LuthorNo ratings yet

- Fisher POSI SEAL A11 High Performance Butterfly ValveDocument20 pagesFisher POSI SEAL A11 High Performance Butterfly ValveJan Richardo GultomNo ratings yet

- Mi-706en - Id162 Valvula BolaDocument40 pagesMi-706en - Id162 Valvula BolacarlosyanezlagosNo ratings yet

- Tech Manual: Tech-5.12 10K Eh Triple W/ LRG S/SDocument33 pagesTech Manual: Tech-5.12 10K Eh Triple W/ LRG S/SRiski KurniawanNo ratings yet

- LG Rht397h Rht398hDocument137 pagesLG Rht397h Rht398hvideoson100% (1)

- Apv Delta Sv1Document20 pagesApv Delta Sv1VLASTARNo ratings yet

- E 65 32 27 PDFDocument4 pagesE 65 32 27 PDFDhuvi LuvioNo ratings yet

- Valvula Guilhotina D2GDocument4 pagesValvula Guilhotina D2Gkrlos_SW2009No ratings yet

- 2020 Vexve Long Stem Ball Valves Manual enDocument36 pages2020 Vexve Long Stem Ball Valves Manual env.cheliuh22No ratings yet

- SITOR - Engineering - (E20001 A700 P302 X 7600) PDFDocument128 pagesSITOR - Engineering - (E20001 A700 P302 X 7600) PDFFarhan ShahNo ratings yet

- Denon-S32!52!52DAB Wireless Music SysDocument102 pagesDenon-S32!52!52DAB Wireless Music SyscesarlcaNo ratings yet

- Supplement SM FLOWSIC100 Flare V2-1 en 2014-05Document5 pagesSupplement SM FLOWSIC100 Flare V2-1 en 2014-05eka pramudia santosoNo ratings yet

- LG DR175, DR165, DR676XDocument108 pagesLG DR175, DR165, DR676XRICARDO ConteNo ratings yet

- LR200Document21 pagesLR200atheb12345100% (1)

- E.1.09.01 Stop Maintenance ValvesDocument2 pagesE.1.09.01 Stop Maintenance ValvesEdgardo EscribanoNo ratings yet

- KAT-B 2452 EROXplus Edition1 07-02-2014 EN PDFDocument11 pagesKAT-B 2452 EROXplus Edition1 07-02-2014 EN PDFphamvantranllmNo ratings yet

- TD-esc-02-De-En-16-011 Rev000 Change Back To Original Maintenance Cycle BSO Safety Catch For Work PlatformDocument3 pagesTD-esc-02-De-En-16-011 Rev000 Change Back To Original Maintenance Cycle BSO Safety Catch For Work PlatformFelipe SilvaNo ratings yet

- IN2065-07-01 MPreC enDocument6 pagesIN2065-07-01 MPreC enknsbNo ratings yet

- Neojv 0040 enDocument0 pagesNeojv 0040 enLuis GuevaraNo ratings yet

- Product Bulletin Fisher 8532 High Performance Butterfly Valve en 123262Document16 pagesProduct Bulletin Fisher 8532 High Performance Butterfly Valve en 123262Jan Richardo GultomNo ratings yet

- D 500203 X 012Document20 pagesD 500203 X 012Aarthi PadmanabhanNo ratings yet

- M60eh54 Z549xy Man 001Document22 pagesM60eh54 Z549xy Man 001Riski KurniawanNo ratings yet

- N-Eupex y N-Eupex Ds - CatalogoDocument25 pagesN-Eupex y N-Eupex Ds - CatalogoJohn Salazar0% (1)

- A31A Butterfly Valve BulletinDocument12 pagesA31A Butterfly Valve BulletinRizalfariz HasbiNo ratings yet

- Worcester Large 3-Piece Cryogenic Valves: Installation, Operating & Maintenance InstructionsDocument14 pagesWorcester Large 3-Piece Cryogenic Valves: Installation, Operating & Maintenance Instructionsافضح الكوارثNo ratings yet

- 7Sx80xx Oper Inst A6 V040501 en de PDFDocument80 pages7Sx80xx Oper Inst A6 V040501 en de PDFGuiProdocioNo ratings yet

- Flender N EupexDocument26 pagesFlender N EupexbbulutmmNo ratings yet

- ASCO Solenoid ValvesDocument2 pagesASCO Solenoid ValvesStelian StefanovNo ratings yet

- BRAHMA Gas Sol Valve EG12....Document5 pagesBRAHMA Gas Sol Valve EG12....Efril DIlen FranciscoNo ratings yet

- Revco CXF ULT User Manual EN - Rev12Document135 pagesRevco CXF ULT User Manual EN - Rev12Krzysiek PrądzińskiNo ratings yet

- Mini Hermet Pressure SwitchesDocument24 pagesMini Hermet Pressure SwitchesMilosglNo ratings yet

- Delta Controls Pressure SwitchesDocument2 pagesDelta Controls Pressure SwitchesMargaret DaughertyNo ratings yet

- LST-3410A Service ManualDocument135 pagesLST-3410A Service ManualzlrigNo ratings yet

- Infineon-MOSFET CoolMOS 600V S7T With Integrated Temparature sensor-ApplicationNotes-v01 00-ENDocument22 pagesInfineon-MOSFET CoolMOS 600V S7T With Integrated Temparature sensor-ApplicationNotes-v01 00-ENDante AlighieriNo ratings yet

- Ferrites and Accessories: Data Sheet Data SheetDocument4 pagesFerrites and Accessories: Data Sheet Data SheetGabo GrassiNo ratings yet

- DPSPDFDocument6 pagesDPSPDFNavneet SinghNo ratings yet

- LG LHB645Document113 pagesLG LHB645boroda2410100% (1)

- EagleBurgmann TS4000 enDocument3 pagesEagleBurgmann TS4000 enkeyur1109No ratings yet

- Type 8532 High-Performance Butterfly Valve: Bulletin 51.6:8532Document12 pagesType 8532 High-Performance Butterfly Valve: Bulletin 51.6:8532Datt NguyenNo ratings yet

- Document No. KE-2022-03: Operation ManualDocument36 pagesDocument No. KE-2022-03: Operation ManualGia Minh Tieu TuNo ratings yet

- 06.08.02.S4 A320DL SLIDE RAFT-SpecificationDocument10 pages06.08.02.S4 A320DL SLIDE RAFT-SpecificationFly WingsNo ratings yet

- SPE 77-201 (2005) Valves For Vacuum ServiceDocument2 pagesSPE 77-201 (2005) Valves For Vacuum Service김창배No ratings yet

- Globe Shut-Off or Control V Alve: Series HV, HVRDocument16 pagesGlobe Shut-Off or Control V Alve: Series HV, HVRSenthilNo ratings yet

- Fire and Smoke Spring Return Actuators FSLF230 (-S) US, FSLF24 (-S) USDocument2 pagesFire and Smoke Spring Return Actuators FSLF230 (-S) US, FSLF24 (-S) USSrikanth TagoreNo ratings yet

- Fisherr Posi-Sealt A31A High-Performance Butterfly ValveDocument12 pagesFisherr Posi-Sealt A31A High-Performance Butterfly ValveThanapaet RittirutNo ratings yet

- Inpro 6050 Series O Sensors Instruction Manual Bedienungsanleitung Instructions D'UtilisationDocument40 pagesInpro 6050 Series O Sensors Instruction Manual Bedienungsanleitung Instructions D'UtilisationJuan Manuel GiraldoNo ratings yet

- Manual Actuator: Code: FR2:LB700050008 Reference: CM16Document2 pagesManual Actuator: Code: FR2:LB700050008 Reference: CM16rafa100% (1)

- (GSA-OA) 1ZSE 2750-111 en Rev 8Document16 pages(GSA-OA) 1ZSE 2750-111 en Rev 8ThiagoPinheiroNo ratings yet

- HSCB SecheronDocument80 pagesHSCB SecheronTaufiq HidayatNo ratings yet

- 1 - Product DescriptionDocument39 pages1 - Product Descriptioneka pramudia santosoNo ratings yet

- SM FLOWSIC100 Flare en V2-1 2016-06Document298 pagesSM FLOWSIC100 Flare en V2-1 2016-06eka pramudia santosoNo ratings yet

- Supplement SM FLOWSIC100 Flare V2-1 en 2014-05Document5 pagesSupplement SM FLOWSIC100 Flare V2-1 en 2014-05eka pramudia santosoNo ratings yet

- TD OPTIMASS2000 en 101122 4000228104 R04Document28 pagesTD OPTIMASS2000 en 101122 4000228104 R04eka pramudia santosoNo ratings yet

- E 49990 CMI FLOWSIC100 Flare enDocument9 pagesE 49990 CMI FLOWSIC100 Flare eneka pramudia santosoNo ratings yet

- 2012 17 Different Requirements and Methods For Calibrating Gas and Liquid Ultrasonic Flow Custody Transfer Meters Kegel CEESIDocument13 pages2012 17 Different Requirements and Methods For Calibrating Gas and Liquid Ultrasonic Flow Custody Transfer Meters Kegel CEESIeka pramudia santosoNo ratings yet

- DS BiRotor Plus Single Case R13Document4 pagesDS BiRotor Plus Single Case R13eka pramudia santosoNo ratings yet

- Case Study BR 8 Inch R03 1Document4 pagesCase Study BR 8 Inch R03 1eka pramudia santosoNo ratings yet

- ER100 Flow Monitor Certificates BinderDocument20 pagesER100 Flow Monitor Certificates Bindereka pramudia santosoNo ratings yet

- Brochure BiRotor Plus For Crude Oil R03Document4 pagesBrochure BiRotor Plus For Crude Oil R03eka pramudia santosoNo ratings yet

- Brodie Meters Chew Thru Paraffin: Case Study: Measurement of Crude Oil Containing ParaffinDocument2 pagesBrodie Meters Chew Thru Paraffin: Case Study: Measurement of Crude Oil Containing Paraffineka pramudia santosoNo ratings yet

- Non-Ferrous Birotor Plus (Models Ab270, Ab280, Ab290) : Technical DataDocument4 pagesNon-Ferrous Birotor Plus (Models Ab270, Ab280, Ab290) : Technical Dataeka pramudia santosoNo ratings yet

- PD Meter BiRotor Plus Datasheet Low TempDocument6 pagesPD Meter BiRotor Plus Datasheet Low Tempeka pramudia santosoNo ratings yet

- PTZ FCDV3 CommunicationDocument9 pagesPTZ FCDV3 Communicationeka pramudia santosoNo ratings yet

- DS AddPak Injection Block R08Document4 pagesDS AddPak Injection Block R08eka pramudia santosoNo ratings yet

- DS AddPak Chemical Transfer Systems R02Document4 pagesDS AddPak Chemical Transfer Systems R02eka pramudia santosoNo ratings yet

- PTZ-BOX FCD Download ModbusmapDocument8 pagesPTZ-BOX FCD Download Modbusmapeka pramudia santosoNo ratings yet

- RBR Ball ValveDocument16 pagesRBR Ball Valveeka pramudia santosoNo ratings yet

- 1.1 Overview of The Modbus ProtocolDocument9 pages1.1 Overview of The Modbus Protocoleka pramudia santoso100% (1)

- Technical Information On IP, NEMA and ATEX RatingsDocument4 pagesTechnical Information On IP, NEMA and ATEX Ratingseka pramudia santosoNo ratings yet

- Wonderware System Platform 2017 1 Day Workshop: Presented by GigihDocument46 pagesWonderware System Platform 2017 1 Day Workshop: Presented by Gigiheka pramudia santosoNo ratings yet

- Continental Data GuideDocument48 pagesContinental Data GuideJose FontenlaNo ratings yet

- Sunil ResumeDocument3 pagesSunil ResumeKetanNo ratings yet

- Geometry Creation PDFDocument222 pagesGeometry Creation PDFJoseGutierrezNo ratings yet

- Tuvsud Dust Hazard AnalysisDocument13 pagesTuvsud Dust Hazard AnalysisKarunakarNo ratings yet

- Trinidad and Tobaggo Corruption Ballah ReportDocument132 pagesTrinidad and Tobaggo Corruption Ballah Reportsylodhi100% (1)

- Plate CompactorDocument1 pagePlate CompactormullapudimNo ratings yet

- Connecting DAS To CRANDocument3 pagesConnecting DAS To CRANfarrukhmohammedNo ratings yet

- AMD FirePro PTC DataSheetDocument2 pagesAMD FirePro PTC DataSheetsebi270No ratings yet

- 2011123Document1 page2011123jeffinNo ratings yet

- Gigih Avenue Welders Company ProfileDocument17 pagesGigih Avenue Welders Company ProfileKaidobar AlexusNo ratings yet

- Computer Integrated Manufacturing: "Coming Together Is A Beginning .Document18 pagesComputer Integrated Manufacturing: "Coming Together Is A Beginning .Anonymous 7ZYHilDNo ratings yet

- 06 Srinivas NarayanaDocument5 pages06 Srinivas NarayanaSrinivas N GowdaNo ratings yet

- Quotation: Spray Extraction Carpet Cleaner Model No: PUZZI 8/1 Technical DataDocument8 pagesQuotation: Spray Extraction Carpet Cleaner Model No: PUZZI 8/1 Technical DataMalahayati ZamzamNo ratings yet

- Bom For Residential BuildingsDocument3 pagesBom For Residential BuildingsAaron Casey LorectoNo ratings yet

- WEBINAR2012 03 Optimizing MySQL ConfigurationDocument43 pagesWEBINAR2012 03 Optimizing MySQL ConfigurationLinder AyalaNo ratings yet

- Bridgestone Data 2019Document20 pagesBridgestone Data 2019Amine AminouNo ratings yet

- Interview QuestionsDocument16 pagesInterview QuestionsAyathullah KhanNo ratings yet

- Humanities Revolution EssayDocument4 pagesHumanities Revolution EssayPearl SriorathaikulNo ratings yet

- Installation and Maintenance Instructions Reflector CondorledDocument2 pagesInstallation and Maintenance Instructions Reflector CondorledDiseño Lexu LightNo ratings yet

- LG Catalog107Document40 pagesLG Catalog107mehdi abdianNo ratings yet

- ABB - WikipediaDocument16 pagesABB - WikipediaSumith VkNo ratings yet

- Brochure 2023 - ECAM Cambodia - WebDocument4 pagesBrochure 2023 - ECAM Cambodia - WebOun VikrethNo ratings yet